Automotive Knock Sensor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429518 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Automotive Knock Sensor Market Size

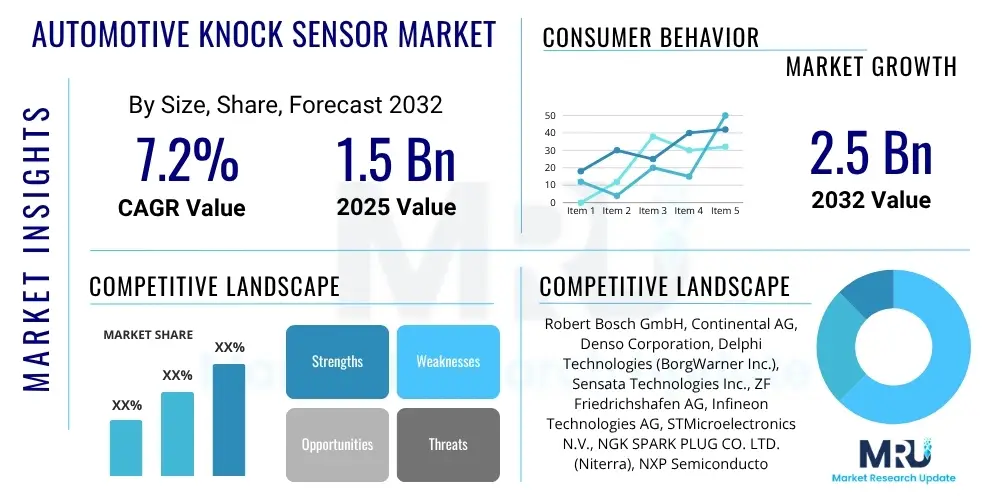

The Automotive Knock Sensor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.2% between 2025 and 2032. The market is estimated at $1.5 Billion in 2025 and is projected to reach $2.5 Billion by the end of the forecast period in 2032.

Automotive Knock Sensor Market introduction

The Automotive Knock Sensor Market encompasses the global industry dedicated to the development, manufacturing, and distribution of devices crucial for optimizing internal combustion engine performance and longevity. A knock sensor is an electronic listening device typically mounted on the engine block, designed to detect abnormal combustion events, often referred to as engine knock, pinging, or pre-ignition. These sensors utilize piezoelectric elements or other technologies to convert vibrations from the engine block into electrical signals, which are then transmitted to the engine control unit (ECU) for analysis.

The primary function of an automotive knock sensor is to enable the ECU to adjust the ignition timing in real-time. When engine knock is detected, the ECU retards the ignition timing to prevent damage to engine components such as pistons and connecting rods, and to ensure efficient combustion. This immediate adjustment not only protects the engine from excessive wear and potential failure but also significantly contributes to improved fuel economy, reduced harmful emissions, and enhanced overall engine performance. Without a functioning knock sensor, an engine could suffer severe damage and operate inefficiently, leading to higher fuel consumption and increased pollution.

Major applications for automotive knock sensors span across a wide range of vehicles, including passenger cars, light commercial vehicles, heavy-duty trucks, and off-highway equipment. The benefits derived from these sensors are multifaceted, covering aspects such as preventing catastrophic engine failure, extending engine lifespan, optimizing fuel efficiency, and ensuring compliance with increasingly stringent global emission standards. Key driving factors for market growth include the rising global production of automobiles, particularly those with advanced gasoline direct injection and turbocharged engines, alongside regulatory mandates for cleaner and more fuel-efficient vehicles worldwide. Furthermore, the integration of these sensors into sophisticated engine management systems and their role in facilitating engine downsizing trends further propel market expansion.

Automotive Knock Sensor Market Executive Summary

The Automotive Knock Sensor Market is experiencing robust growth driven by evolving automotive technologies, stringent environmental regulations, and an increasing global vehicle parc. Business trends indicate a strong focus on sensor miniaturization, enhanced durability, and the integration of advanced signal processing capabilities to improve accuracy and responsiveness. Leading manufacturers are investing heavily in research and development to create more sophisticated piezoelectric and resonant sensors that can perform optimally under diverse and challenging engine conditions, including those found in hybrid and next-generation combustion engines. This technological push is also paving the way for more integrated engine health monitoring systems.

Regionally, the Asia Pacific (APAC) market is anticipated to be the fastest-growing segment, propelled by rapid industrialization, increasing vehicle production volumes, and the gradual adoption of stricter emission standards in countries like China and India. North America and Europe continue to hold significant market shares, primarily due to the established automotive manufacturing bases and early adoption of advanced engine technologies coupled with rigorous regulatory frameworks for emissions and fuel economy. These regions are characterized by a strong demand for high-performance and environmentally compliant vehicles, necessitating sophisticated knock sensor solutions.

Segment trends highlight the dominance of piezoelectric knock sensors due to their reliability, cost-effectiveness, and established performance. The passenger vehicle segment remains the largest application area, attributed to the sheer volume of passenger car production globally and the widespread implementation of knock sensors across various vehicle models to meet fuel efficiency and emission targets. The aftermarket segment is also demonstrating steady growth, driven by the replacement demand for worn-out or damaged sensors in older vehicles, emphasizing the long-term sustainability of the market beyond initial OEM installations.

AI Impact Analysis on Automotive Knock Sensor Market

User inquiries about AI's impact on the Automotive Knock Sensor Market frequently revolve around how artificial intelligence can enhance detection accuracy, enable predictive maintenance, integrate with broader vehicle systems, and potentially revolutionize engine diagnostics. Users are keen to understand if AI can move beyond simple knock detection to provide more proactive engine health insights, identify subtle anomalies, and adapt to varying engine conditions more effectively. There is also interest in the cybersecurity implications of AI-driven sensor systems and the potential for greater data utilization for performance optimization and fault prevention.

AI is set to significantly transform the Automotive Knock Sensor Market by enabling more sophisticated data analysis and predictive capabilities. Current knock sensors provide raw vibrational data; AI algorithms can process this data in real-time, distinguishing genuine knock events from background engine noise with unprecedented accuracy. This enhanced precision allows for more optimal ignition timing adjustments, leading to superior fuel efficiency, reduced emissions, and improved engine protection. Beyond simple detection, AI can learn engine characteristics over time, anticipating potential issues before they manifest as critical knock events.

The integration of AI also facilitates predictive maintenance strategies. By continuously analyzing sensor data patterns and correlating them with other engine parameters, AI can forecast component wear or impending failures related to combustion issues, alerting drivers or service centers proactively. This shift from reactive problem-solving to preventive intervention can significantly reduce downtime, lower maintenance costs, and extend the lifespan of vehicle components. Furthermore, AI enables knock sensor data to be seamlessly integrated with other vehicle systems, such as advanced driver-assistance systems (ADAS) and broader vehicle health monitoring networks, contributing to a more holistic and intelligent vehicle ecosystem.

- Enhanced knock detection accuracy through machine learning algorithms that differentiate engine noise from combustion events.

- Predictive maintenance capabilities, allowing for early identification of potential engine issues before critical knock events occur.

- Real-time adaptive engine tuning by leveraging AI to continuously optimize ignition timing for varying fuel qualities and operating conditions.

- Integration with advanced engine control units (ECUs) and vehicle health monitoring systems for holistic diagnostics.

- Development of smart sensors with embedded AI for localized data processing and reduced latency.

- Potential for personalized engine management based on driving style and environmental factors.

- Cybersecurity considerations for protecting AI-driven sensor data from unauthorized access or manipulation.

- Data privacy concerns associated with the collection and transmission of detailed engine performance metrics.

DRO & Impact Forces Of Automotive Knock Sensor Market

The Automotive Knock Sensor Market is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, collectively shaping its trajectory and competitive landscape. A primary driver is the global escalation of stringent emission regulations, particularly Euro 6/7, CAFE standards, and similar norms in developing economies, which compel automotive manufacturers to optimize engine performance for lower emissions and improved fuel efficiency. This regulatory pressure directly fuels demand for precision sensors capable of enabling advanced engine management strategies. Concurrently, the increasing production of vehicles, especially those featuring downsized, turbocharged, and gasoline direct injection (GDI) engines that are more prone to knock, further stimulates market expansion.

Despite these significant tailwinds, the market faces several restraints. The high cost associated with research and development for more sophisticated sensor technologies, especially those incorporating advanced materials and AI capabilities, can be a deterrent for some manufacturers. Additionally, the complexity involved in seamlessly integrating these sensors into intricate modern engine control systems presents engineering challenges, demanding significant investment in validation and calibration. Furthermore, concerns regarding the durability and long-term reliability of sensors operating under extreme engine temperatures and vibrations, along with intense market competition leading to price pressures, can limit growth potential.

Nevertheless, numerous opportunities are poised to propel the market forward. The ongoing electrification of the automotive industry, encompassing hybrid electric vehicles (HEVs) and plug-in hybrid electric vehicles (PHEVs), still requires advanced combustion engine management, thus sustaining demand for knock sensors in hybrid powertrains. The emergence of autonomous driving systems and connected vehicles also presents opportunities, as these technologies necessitate highly reliable and integrated sensor data for optimal system performance and safety. Furthermore, advancements in sensor miniaturization, material science, and the incorporation of predictive analytics through AI offer pathways for developing next-generation, more robust, and intelligent knock sensors, opening new avenues for innovation and market penetration.

Segmentation Analysis

The Automotive Knock Sensor Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in analyzing market trends, identifying key growth areas, and understanding the competitive landscape across various dimensions. The market can primarily be categorized by the type of technology used in the sensors, the specific vehicle applications they serve, and the sales channels through which they reach end-users. Each segment reflects unique characteristics, growth drivers, and demand patterns within the broader automotive industry ecosystem.

Understanding these segments is crucial for strategic planning and market penetration. The choice of sensor type often depends on the specific engine design and performance requirements, while vehicle type dictates the scale of demand and regulatory compliance needs. The sales channel differentiation highlights the two distinct pathways for knock sensor distribution: initial installation during vehicle manufacturing (OEM) and subsequent replacement or upgrade in the aftermarket. These segmentations collectively offer a granular view of the market, enabling stakeholders to make informed decisions regarding product development, marketing strategies, and investment priorities to capitalize on emerging opportunities.

- By Type

- Piezoelectric Knock Sensors

- Magnetostrictive Knock Sensors

- Resonant Knock Sensors

- Non-resonant Knock Sensors

- By Vehicle Type

- Passenger Vehicles

- Commercial Vehicles

- Light Commercial Vehicles (LCVs)

- Heavy Commercial Vehicles (HCVs)

- Off-Highway Vehicles

- By Sales Channel

- Original Equipment Manufacturer (OEM)

- Aftermarket

Value Chain Analysis For Automotive Knock Sensor Market

The value chain for the Automotive Knock Sensor Market commences with upstream activities focused on the procurement and processing of specialized raw materials critical for sensor fabrication. This includes sourcing piezoelectric ceramic materials, various metals for housing and electrodes, and high-performance plastics for encapsulation and connectors. Key players in this stage are material suppliers who provide these specialized components to sensor manufacturers. Efficient and reliable supply of these materials is foundational to the quality and performance of the final knock sensor product, influencing both cost and production timelines. Innovation in material science, particularly in developing more robust and sensitive piezoelectric compounds, directly impacts the sensor's capabilities.

Midstream activities involve the design, manufacturing, and assembly of the knock sensors, primarily undertaken by Tier 1 automotive suppliers. These manufacturers combine the raw materials and components, employing advanced manufacturing processes and precision engineering to produce sensors that meet stringent automotive specifications. This stage also includes rigorous testing and calibration to ensure accuracy, durability, and reliability under harsh engine conditions. The intellectual property and technological expertise in sensor design, signal processing, and miniaturization are key competitive differentiators at this stage, enabling manufacturers to offer superior performance and integration capabilities.

Downstream, the completed knock sensors are distributed through various channels to reach the end-users. The primary distribution channel is direct sales to Original Equipment Manufacturers (OEMs), where sensors are integrated into new vehicles during the assembly process. This typically involves long-term contracts and close collaboration between sensor suppliers and vehicle manufacturers. Additionally, an extensive indirect distribution network serves the aftermarket, supplying replacement sensors to wholesale distributors, automotive parts retailers, and independent service garages. This dual distribution strategy ensures that knock sensors are available for both new vehicle production and ongoing maintenance and repair, supporting the entire lifecycle of an automobile.

Automotive Knock Sensor Market Potential Customers

The primary potential customers for automotive knock sensors are the Original Equipment Manufacturers (OEMs) within the global automotive industry. These include major car manufacturers such as Toyota, Volkswagen, General Motors, Ford, Hyundai, BMW, Mercedes-Benz, and numerous others, who integrate knock sensors directly into their new vehicle models during the manufacturing process. For OEMs, knock sensors are a critical component for engine performance optimization, achieving fuel efficiency targets, meeting emission standards, and ensuring the overall reliability and longevity of their vehicles. Their procurement decisions are heavily influenced by sensor performance, reliability, cost-effectiveness, and the supplier's ability to meet high-volume production demands and specific technical specifications.

Beyond OEMs, the aftermarket segment represents a substantial customer base. This includes a diverse array of buyers such as wholesale automotive parts distributors, large retail chains specializing in auto components, independent auto parts stores, and individual professional service garages and repair shops. These customers purchase knock sensors for replacement purposes, either to repair vehicles where the original sensor has failed or to perform routine maintenance. The aftermarket demand is driven by the aging vehicle parc, the need for repairs, and consumer willingness to maintain their vehicles for extended periods. For aftermarket customers, factors like product availability, competitive pricing, brand reputation, and ease of installation are significant purchasing considerations.

Indirectly, vehicle owners are also potential customers as they are the ultimate end-users and beneficiaries of the technology. Their demand for reliable, fuel-efficient, and low-emission vehicles implicitly drives the market for knock sensors, both at the OEM and aftermarket levels. While they do not directly purchase sensors from manufacturers, their choices influence vehicle sales and maintenance patterns, thereby dictating demand through the supply chain. Therefore, manufacturers and distributors cater to the needs and expectations of vehicle owners by ensuring high-quality, durable, and effective knock sensor solutions are available across all market segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.5 Billion |

| Market Forecast in 2032 | $2.5 Billion |

| Growth Rate | 7.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Robert Bosch GmbH, Continental AG, Denso Corporation, Delphi Technologies (BorgWarner Inc.), Sensata Technologies Inc., ZF Friedrichshafen AG, Infineon Technologies AG, STMicroelectronics N.V., NGK SPARK PLUG CO. LTD. (Niterra), NXP Semiconductors N.V., Analog Devices Inc., Aptiv PLC, Magna International Inc., Valeo S.A., Marelli Holdings Co. Ltd., Mitsubishi Electric Corporation, Siemens AG (VDO), Gentex Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Knock Sensor Market Key Technology Landscape

The Automotive Knock Sensor Market's technological landscape is characterized by continuous advancements aimed at improving sensor accuracy, durability, and integration capabilities. The predominant technology employed involves piezoelectric materials, which generate an electrical charge in response to mechanical stress, effectively converting engine vibrations into measurable electrical signals. Recent innovations in piezoelectric ceramics focus on enhancing their sensitivity, operating temperature range, and resistance to environmental factors, allowing for more precise knock detection even in high-performance or extreme engine conditions. Research is also exploring alternative materials and designs, such as magnetostrictive sensors, though piezoelectric remains the industry standard due to its proven reliability and cost-effectiveness.

Beyond the core sensing element, significant technological developments are occurring in the signal processing capabilities associated with knock sensors. Modern systems leverage sophisticated digital signal processing (DSP) algorithms and embedded microcontrollers to filter out extraneous engine noise, isolate knock frequencies, and accurately determine the intensity and duration of combustion anomalies. This allows the Engine Control Unit (ECU) to make highly precise and rapid adjustments to ignition timing, optimizing combustion for efficiency and emission reduction. The integration of these advanced algorithms directly into the sensor or its immediate control module contributes to faster response times and more reliable engine protection.

Furthermore, the trend towards greater connectivity and intelligence within vehicles is pushing the technological boundaries of knock sensors. They are increasingly designed for seamless integration with advanced engine management systems, utilizing high-speed communication protocols like CAN bus. Emerging technologies also include sensor fusion, where knock sensor data is combined with inputs from other engine sensors (e.g., pressure, temperature, oxygen) to create a more comprehensive picture of engine health. The nascent application of artificial intelligence and machine learning is paving the way for predictive diagnostics, where AI algorithms can analyze historical and real-time sensor data to anticipate potential engine issues before they become critical, thereby enhancing preventative maintenance and overall vehicle reliability.

Regional Highlights

- North America: This region maintains a significant market share, driven by stringent emission regulations and a strong emphasis on fuel efficiency. The presence of major automotive manufacturers and a high adoption rate of advanced vehicle technologies contribute to steady demand. The market here is characterized by continuous technological innovation and a robust aftermarket for replacement parts.

- Europe: Europe is a key market, propelled by pioneering emission standards (e.g., Euro 6/7) and a strong push towards engine downsizing and turbocharging, which inherently increases the need for precise knock detection. High consumer awareness regarding environmental impact and fuel economy further stimulates demand. The region also sees significant investment in R&D for advanced sensor technologies.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region in the automotive knock sensor market. Rapid urbanization, increasing disposable incomes, and the booming automotive manufacturing sector in countries like China, India, Japan, and South Korea are key drivers. Emerging emission regulations and the growing adoption of sophisticated engine technologies in these markets significantly contribute to demand.

- Latin America: This region exhibits steady growth in the automotive sector, driven by increasing vehicle production and the gradual implementation of stricter emission norms. As the automotive parc expands and modern engine technologies become more prevalent, the demand for knock sensors for both OEM and aftermarket applications is expected to rise.

- Middle East and Africa (MEA): The MEA market is gradually expanding, primarily influenced by growing vehicle sales and increasing foreign investment in automotive manufacturing and assembly plants. While emission standards may vary, there is a rising trend towards adopting modern vehicle technologies that require advanced engine management systems, including knock sensors, to ensure performance and compliance.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Knock Sensor Market.- Robert Bosch GmbH

- Continental AG

- Denso Corporation

- Delphi Technologies (BorgWarner Inc.)

- Sensata Technologies Inc.

- ZF Friedrichshafen AG

- Infineon Technologies AG

- STMicroelectronics N.V.

- NGK SPARK PLUG CO. LTD. (Niterra)

- NXP Semiconductors N.V.

- Analog Devices Inc.

- Aptiv PLC

- Magna International Inc.

- Valeo S.A.

- Marelli Holdings Co. Ltd.

- Mitsubishi Electric Corporation

- Siemens AG (VDO)

- Gentex Corporation

Frequently Asked Questions

What is an automotive knock sensor and how does it function?

An automotive knock sensor is an electronic device typically mounted on the engine block that detects abnormal combustion vibrations, known as engine knock or pinging. It uses a piezoelectric element to convert these mechanical vibrations into electrical signals, which are then sent to the Engine Control Unit (ECU). The ECU processes this data to determine if knock is occurring and, if so, adjusts the ignition timing to prevent engine damage and optimize performance. It acts as an early warning system, protecting vital engine components from harmful stresses caused by uncontrolled combustion.

Why is the automotive knock sensor market growing?

The automotive knock sensor market is growing due to several key factors, including increasingly stringent global emission regulations that mandate cleaner and more efficient engines. The rising production of vehicles, particularly those equipped with advanced engine technologies like turbocharging and gasoline direct injection, which are more susceptible to knock, also drives demand. Furthermore, the continuous focus on improving fuel economy, enhancing engine longevity, and integrating sophisticated engine management systems across all vehicle segments contributes significantly to market expansion.

What are the main types of knock sensors used in vehicles?

The main types of knock sensors utilized in vehicles primarily include piezoelectric knock sensors, which are the most common due to their reliability and cost-effectiveness. These sensors generate a voltage proportional to the vibration detected. Other types include magnetostrictive sensors, which rely on changes in magnetic properties due to mechanical stress, and resonant or non-resonant sensors, categorized by their frequency response characteristics. Piezoelectric sensors are favored for their ability to accurately identify specific knock frequencies within the engine's operational range.

How does a knock sensor contribute to improving fuel efficiency?

A knock sensor contributes to improving fuel efficiency by allowing the Engine Control Unit (ECU) to maintain optimal ignition timing. When no knock is detected, the ECU can advance the ignition timing closer to the ideal point for maximum power and efficiency. If knock is sensed, the ECU retards the timing just enough to eliminate the harmful combustion, preventing inefficiency and damage. This dynamic adjustment ensures that the engine operates at its most efficient combustion point without compromising engine health, thereby directly leading to better fuel economy.

What role does AI play in the future of knock sensor technology?

Artificial intelligence (AI) is set to revolutionize knock sensor technology by enabling more advanced data analysis and predictive capabilities. Future AI-driven systems can process sensor data in real-time with greater accuracy, distinguishing true knock from background noise more effectively. AI will facilitate predictive maintenance by identifying subtle patterns indicative of impending engine issues, allowing for proactive intervention. Furthermore, AI integration will enable adaptive engine tuning based on various environmental and fuel conditions, leading to optimized performance, enhanced efficiency, and seamless integration with broader vehicle health monitoring and autonomous driving systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager