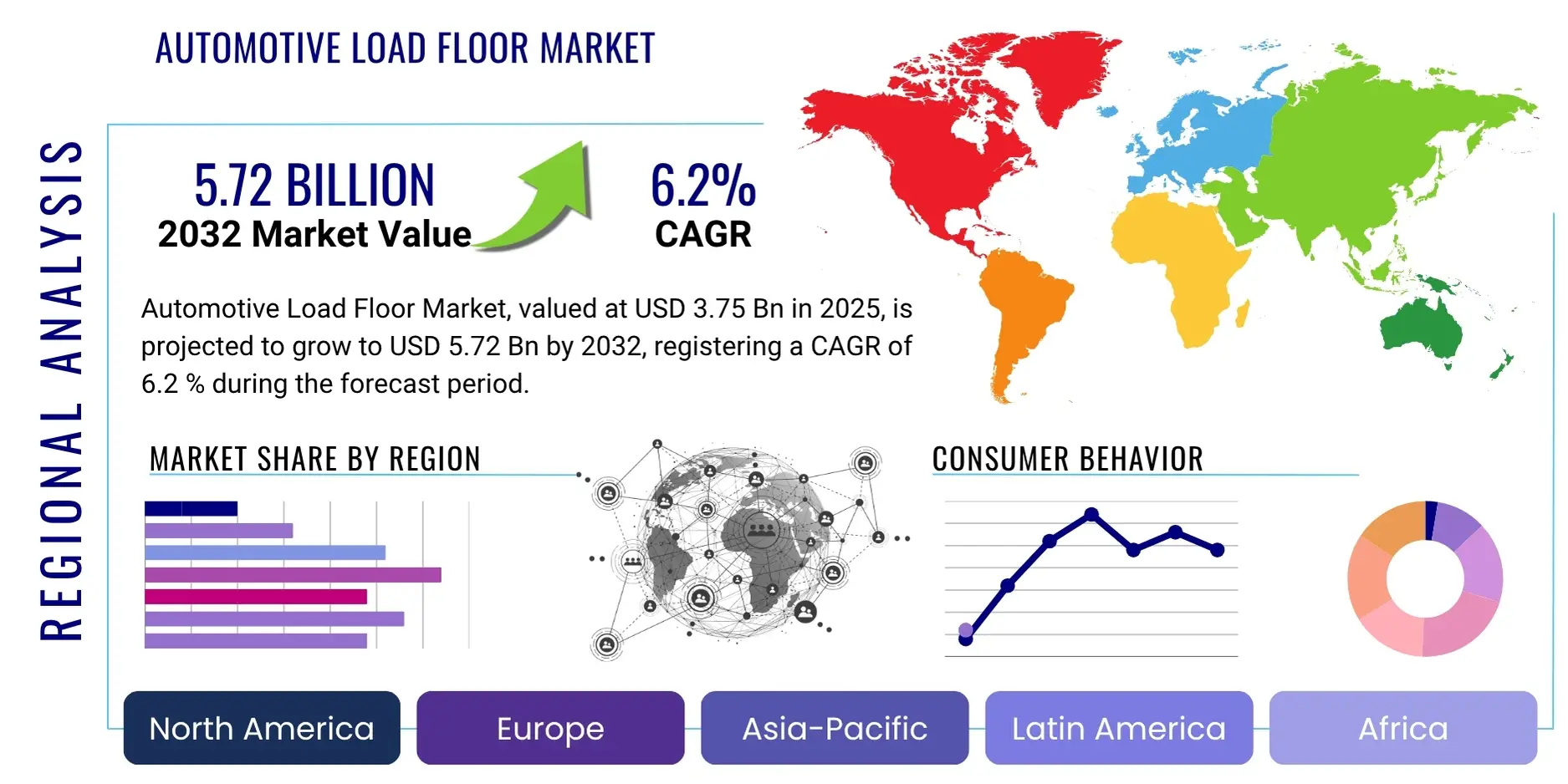

Automotive Load Floor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428234 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Automotive Load Floor Market Size

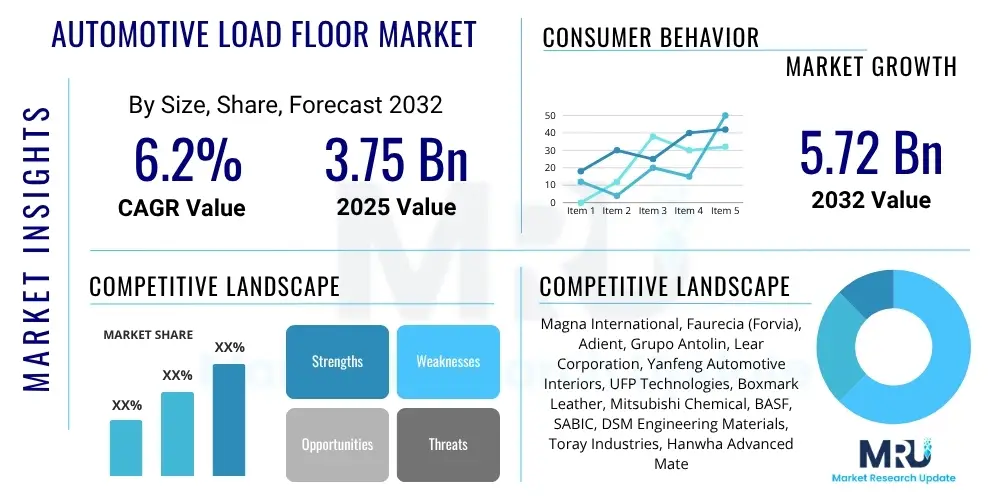

The Automotive Load Floor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 3.75 billion in 2025 and is projected to reach USD 5.72 billion by the end of the forecast period in 2032.

Automotive Load Floor Market introduction

The automotive load floor, an integral component of vehicle interior design, serves as a crucial element in optimizing cargo space, enhancing utility, and improving the overall aesthetic appeal of a vehicle's trunk or cargo area. Initially conceived as a flat, sturdy surface for transporting goods, modern load floors have evolved significantly to incorporate advanced materials, modular designs, and smart functionalities. These advancements cater to the growing consumer demand for versatile, adaptable, and convenient cargo solutions, particularly in rapidly expanding vehicle segments such as SUVs, crossovers, and electric vehicles.

Major applications of automotive load floors primarily include passenger cars, light commercial vehicles, and heavy-duty trucks, where they facilitate efficient storage, protect vehicle interiors from wear and tear, and provide a stable base for varying loads. The benefits extend beyond mere functionality, encompassing improved ergonomics for loading and unloading, enhanced safety by securing cargo, and elevated interior aesthetics. Driving factors for market growth include the rising global production of vehicles, particularly those prioritizing modularity and cargo versatility, increasing disposable incomes leading to higher vehicle ownership, and continuous technological innovations in material science and manufacturing processes.

Furthermore, the growing trend of vehicle personalization and the integration of sophisticated infotainment systems and connectivity features indirectly influence the design and material choices for load floors, pushing manufacturers to offer more premium and feature-rich solutions. The shift towards electric vehicles (EVs) also presents a significant driver, as EV platforms often allow for greater design freedom in interior configurations, including multi-level and reconfigurable load floors to maximize battery integration and passenger/cargo space optimization. This dynamic evolution ensures that automotive load floors remain a key area of innovation within the automotive interiors sector.

Automotive Load Floor Market Executive Summary

The global Automotive Load Floor Market is experiencing robust expansion, driven by a confluence of factors including the burgeoning demand for SUVs and crossovers, the pervasive trend towards lightweighting in vehicle manufacturing, and the rapid adoption of electric vehicles. Business trends indicate a strong inclination towards modularity and customization, with manufacturers increasingly offering multi-configurable load floor systems that can adapt to various cargo needs, thereby enhancing vehicle utility and consumer satisfaction. Strategic partnerships between material suppliers and automotive OEMs are becoming more prevalent, aimed at developing innovative, sustainable, and high-performance materials for future load floor applications.

Regionally, the Asia Pacific market stands out as a dominant force, propelled by high vehicle production volumes, particularly in China and India, alongside a burgeoning middle class demanding feature-rich vehicles. North America and Europe also maintain significant market shares, characterized by a strong demand for premium vehicles equipped with advanced interior features and a strong emphasis on regulatory compliance related to vehicle safety and environmental standards. Latin America and the Middle East & Africa regions are projected to exhibit steady growth, influenced by improving economic conditions and increasing urbanization.

In terms of segment trends, composite materials are gaining substantial traction due to their superior strength-to-weight ratio and design flexibility, aligning perfectly with the industry's lightweighting objectives. Foldable and multi-configurable load floors are witnessing accelerated adoption, catering to the versatile needs of modern consumers. The OEM segment continues to be the primary revenue generator, although the aftermarket is also evolving with a growing array of specialized and customizable load floor accessories, reflecting a broader market for vehicle upgrades and personalization. The integration of smart features, such as sensors for cargo management or motorized adjustments, is an emerging trend that promises to reshape future market offerings across all segments.

AI Impact Analysis on Automotive Load Floor Market

Common user questions regarding AI's impact on the Automotive Load Floor Market frequently revolve around how artificial intelligence can enhance functionality, safety, and efficiency. Users are keenly interested in whether AI can lead to "smart" load floors capable of adaptive responses, predictive maintenance, or even integrated cargo management. Concerns often touch upon the practicality of such advanced systems, their cost implications, and their reliability in diverse operating conditions. Expectations are high for AI to revolutionize the load floor's role from a static component to an intelligent, interactive system, ultimately improving the overall user experience and expanding the utility of vehicle cargo spaces. The overarching theme is the transformation of the load floor into a more dynamic and responsive element within the vehicle's ecosystem.

- AI-driven design optimization for weight reduction and structural integrity, leveraging generative design algorithms to explore novel geometries and material combinations.

- Predictive maintenance analytics for integrated sensors, enabling early detection of wear, damage, or malfunction in motorized or complex load floor mechanisms.

- Smart cargo management systems using AI vision and sensors to identify cargo, suggest optimal packing arrangements, and prevent shifting during transit.

- Personalized cargo space configuration, where AI learns user preferences and automatically adjusts load floor positions or compartments based on anticipated needs or pre-set profiles.

- Enhanced material selection and process optimization through AI, allowing for rapid evaluation of material properties and manufacturing techniques to achieve desired performance characteristics.

- Automated quality control during manufacturing, employing AI-powered inspection systems to detect defects with higher precision and speed than manual methods.

- Integration with vehicle telematics for advanced logistics, enabling intelligent routing or cargo space optimization for fleet operators based on real-time data and AI predictions.

- Development of adaptive load floors that can dynamically change their properties or shape based on sensor input, such as adjusting firmness or insulation for specific cargo types.

DRO & Impact Forces Of Automotive Load Floor Market

The Automotive Load Floor Market is significantly shaped by a distinct set of Drivers, Restraints, and Opportunities, collectively forming the Impact Forces that influence its trajectory. Key drivers include the escalating global demand for passenger vehicles, particularly SUVs, crossovers, and electric vehicles, all of which prioritize flexible and optimized cargo solutions. The increasing consumer expectation for enhanced vehicle utility, convenience, and aesthetic appeal also propels innovation in load floor design. Furthermore, the automotive industry's continuous pursuit of lightweighting to improve fuel efficiency and reduce emissions mandates the adoption of advanced, high-strength-to-weight ratio materials for load floors, further stimulating market growth.

Conversely, several restraints impede market expansion. High manufacturing costs associated with advanced materials like carbon fiber composites, coupled with the intricate design and engineering required for multi-configurable and smart load floor systems, present significant barriers. The fluctuating prices of raw materials, supply chain disruptions, and intense competition among manufacturers also contribute to market challenges. Additionally, the limited awareness and slower adoption of premium load floor solutions in developing markets can act as a restraint on overall market penetration.

Opportunities for market growth are abundant and diverse. The burgeoning electric vehicle market offers a fertile ground for innovative load floor designs that can seamlessly integrate with battery packs and electric drivetrains, creating new packaging possibilities. The growing trend of vehicle customization and personalization provides avenues for manufacturers to offer bespoke load floor solutions tailored to individual consumer preferences. Moreover, advancements in smart materials, additive manufacturing, and sensor technologies open new frontiers for developing intelligent, adaptive, and sustainable load floor systems that offer enhanced functionality, further augmenting market potential. The ongoing integration of vehicles into the Internet of Things (IoT) ecosystem also presents opportunities for connected load floor solutions.

Segmentation Analysis

The Automotive Load Floor Market is meticulously segmented to provide a granular understanding of its diverse components and the dynamics influencing each category. This segmentation allows for a comprehensive analysis of market trends, consumer preferences, and technological advancements across various product types, material compositions, vehicle applications, and sales channels. Such a structured approach is critical for stakeholders to identify lucrative opportunities, develop targeted strategies, and innovate effectively within this evolving sector, ensuring that product offerings align with specific market demands and contribute to sustainable growth.

- By Material Type:

- Composites (e.g., thermoset, thermoplastic, natural fiber composites)

- Plastics (e.g., PP, ABS, PC)

- Wood (e.g., plywood, pressed wood)

- Metal (e.g., aluminum, steel)

- Fabrics and Foams

- By Load Floor Type:

- Fixed Load Floors

- Foldable Load Floors

- Multi-Configurable Load Floors (e.g., adjustable height, modular compartments)

- Smart/Integrated Load Floors (e.g., with sensors, motorized functions)

- By Vehicle Type:

- Passenger Cars (e.g., Sedans, Hatchbacks, SUVs, Crossovers)

- Commercial Vehicles (e.g., Vans, Pickups, Light Duty Trucks)

- By Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket

- By Application Area:

- Trunk/Boot

- Rear Seat Area (e.g., under-seat storage)

- Cargo Van Interior

Value Chain Analysis For Automotive Load Floor Market

The value chain for the Automotive Load Floor Market is a complex ecosystem involving several stages, starting from raw material sourcing and extending to the end-user. Upstream analysis typically involves raw material suppliers providing essential inputs such as polymers, resins for composites, wood panels, various metals, and textile fibers. Key suppliers also include manufacturers of adhesives, fasteners, and specialized coatings that are critical for the durability and aesthetic finishing of load floor components. These raw material providers form the foundational layer, influencing cost structures, material properties, and supply chain stability for the entire market.

Midstream activities are dominated by component manufacturers and assemblers who transform raw materials into finished load floor systems. This stage involves sophisticated manufacturing processes, including injection molding for plastics, compression molding for composites, metal stamping, and various cutting and finishing techniques. These manufacturers often specialize in producing specific types of load floors, from basic fixed designs to highly intricate multi-configurable or smart systems. They are responsible for integrating various sub-components, ensuring product quality, and adhering to strict automotive industry standards and specifications.

Downstream analysis focuses on the distribution channels and end-users. The primary distribution channel is direct sales to Original Equipment Manufacturers (OEMs), where load floors are integrated into new vehicle assemblies. This segment represents the largest portion of the market. Indirect channels include the aftermarket, where independent component suppliers, distributors, and retail outlets offer replacement or upgrade load floor solutions to vehicle owners. This segment often caters to customization needs, specific utility enhancements, or repairs. The end-users, encompassing individual consumers and commercial fleet operators, ultimately drive demand through their vehicle purchasing decisions and requirements for cargo space utility and aesthetics, thereby completing the value chain loop and providing feedback for continuous product development and innovation.

Automotive Load Floor Market Potential Customers

The primary potential customers for the Automotive Load Floor Market are diverse, encompassing both segments of the automotive industry and individual consumers. Original Equipment Manufacturers (OEMs) represent the largest and most critical customer base. These include global automotive giants such as Toyota, Volkswagen, Ford, General Motors, Stellantis, Hyundai, Honda, BMW, Daimler, and Tesla, among others. OEMs procure load floor systems directly from specialized suppliers to integrate them into their vehicle production lines. Their purchasing decisions are driven by factors like material cost, performance specifications (e.g., weight, strength, noise reduction), design compatibility, supply chain reliability, and adherence to increasingly stringent safety and environmental regulations. The growing focus on electric vehicles also means new EV manufacturers are emerging as significant potential customers.

Beyond OEMs, the aftermarket constitutes another substantial segment of potential customers. This includes independent repair shops, automotive accessory retailers, and online platforms selling vehicle components. Individual vehicle owners seeking to replace damaged load floors, upgrade their existing cargo solutions for enhanced utility (e.g., adding modular dividers, waterproof surfaces), or personalize their vehicle interiors are the ultimate buyers in this segment. The aftermarket caters to a wide range of needs, from basic functionality restoration to advanced customization, making product variety and availability key factors for success.

Furthermore, commercial fleet operators and businesses utilizing light commercial vehicles (LCVs) and cargo vans also represent significant potential customers. These entities often require robust, durable, and highly functional load floor solutions designed to withstand heavy use and accommodate specific types of cargo, such as tools, equipment, or delivery packages. Their purchasing decisions are heavily influenced by durability, ease of cleaning, weight-bearing capacity, and overall cost-effectiveness over the vehicle's lifespan. The increasing demand for e-commerce and last-mile delivery services is particularly driving this commercial segment, creating a niche for specialized and heavy-duty load floor solutions that maximize cargo efficiency and vehicle longevity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.75 Billion |

| Market Forecast in 2032 | USD 5.72 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Magna International, Faurecia (Forvia), Adient, Grupo Antolin, Lear Corporation, Yanfeng Automotive Interiors, UFP Technologies, Boxmark Leather, Mitsubishi Chemical, BASF, SABIC, DSM Engineering Materials, Toray Industries, Hanwha Advanced Materials, Continental AG, Autoneum, IAC Group, Kasai Kogyo, Polytec Holding AG, Toyota Boshoku |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Load Floor Market Key Technology Landscape

The Automotive Load Floor Market is characterized by a dynamic and evolving technology landscape, primarily driven by the overarching industry trends of lightweighting, sustainability, and enhanced functionality. A significant technological focus is on advanced material science, particularly the development and application of high-performance composite materials. These include natural fiber composites, thermoset and thermoplastic composites, and glass or carbon fiber reinforced polymers. These materials offer superior strength-to-weight ratios compared to traditional steel or wood, significantly contributing to vehicle weight reduction, which in turn improves fuel efficiency in ICE vehicles and extends range in electric vehicles. Innovations in resin systems and fiber reinforcement techniques are continuously pushing the boundaries of material performance and cost-effectiveness.

Manufacturing processes are also undergoing significant technological advancements. Techniques like high-pressure resin transfer molding (HP-RTM), sheet molding compound (SMC) processing, and advanced injection molding are enabling the production of complex load floor geometries with improved dimensional stability and surface finish. The adoption of additive manufacturing (3D printing) is emerging for rapid prototyping and producing highly customized or intricate components, particularly for niche vehicle segments or specialized aftermarket solutions. Furthermore, robotic automation and advanced tooling are being implemented to enhance production efficiency, consistency, and reduce labor costs, thereby accelerating the manufacturing cycle for both OEMs and suppliers.

Beyond materials and manufacturing, the integration of smart technologies is a pivotal aspect of the evolving landscape. This includes the incorporation of sensors for various purposes, such as detecting cargo presence, weight distribution, or even impacts. Some advanced load floors feature motorized mechanisms for automatic adjustment or compartmentalization, enhancing convenience and versatility. Connectivity solutions are enabling these smart load floors to integrate with the vehicle's central electronics system, potentially allowing for remote control or diagnostic capabilities. The focus on sustainability also drives technologies for recycling and reusing load floor materials, promoting a circular economy approach throughout the product lifecycle and meeting stringent environmental regulations, influencing material selection towards bio-based and recyclable polymers and composites.

Regional Highlights

- North America: This region is a significant market for automotive load floors, driven by the strong consumer preference for SUVs, crossovers, and pickup trucks, which often feature advanced and versatile cargo management systems. High disposable income levels, coupled with the presence of major automotive OEMs and a robust aftermarket sector, contribute substantially to market growth. The increasing adoption of electric vehicles and stringent safety regulations also drive innovation in load floor design and materials.

- Europe: Characterized by a strong emphasis on automotive innovation, sustainability, and premium vehicle segments, Europe presents a mature yet growing market. Strict environmental regulations promote the use of lightweight and sustainable materials, while the demand for compact cars and luxury vehicles drives advancements in space-efficient and aesthetically pleasing load floor solutions. Germany, France, and the UK are key contributors to market revenue.

- Asia Pacific (APAC): APAC stands as the largest and fastest-growing market due to its burgeoning vehicle production, particularly in China, India, Japan, and South Korea. Rapid urbanization, increasing disposable incomes, and the rising penetration of mid-segment and premium vehicles fuel demand for diverse load floor types. The region is also a hub for material innovation and manufacturing capabilities, making it a critical player in the global market.

- Latin America: This region exhibits steady growth, influenced by improving economic conditions and increasing vehicle sales in countries like Brazil, Mexico, and Argentina. While the market may be more price-sensitive, there is a growing demand for functional and durable load floor solutions, especially in the commercial vehicle segment and compact passenger cars, reflecting urbanization and expanding logistical needs.

- Middle East and Africa (MEA): The MEA market is projected to experience moderate growth, driven by increasing infrastructure development, urbanization, and a rise in commercial vehicle sales. Countries in the GCC region, specifically Saudi Arabia and UAE, show demand for premium and robust load floor solutions in SUVs and luxury vehicles. Economic diversification efforts and increasing foreign investments in the automotive sector are also contributing factors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Load Floor Market.- Magna International

- Faurecia (Forvia)

- Adient

- Grupo Antolin

- Lear Corporation

- Yanfeng Automotive Interiors

- UFP Technologies

- Boxmark Leather

- Mitsubishi Chemical

- BASF

- SABIC

- DSM Engineering Materials

- Toray Industries

- Hanwha Advanced Materials

- Continental AG

- Autoneum

- IAC Group

- Kasai Kogyo

- Polytec Holding AG

- Toyota Boshoku

Frequently Asked Questions

What is an automotive load floor?

An automotive load floor is a crucial interior component designed to create a flat, durable, and often adjustable surface in a vehicle's trunk or cargo area. It optimizes cargo space, protects the vehicle interior, and enhances utility by allowing for organized storage and flexible loading configurations.

What are the primary types of automotive load floors available?

The primary types include fixed load floors, which offer a static cargo surface; foldable load floors, allowing partial or full folding for varied space; multi-configurable load floors, offering adjustable height or modular compartments; and smart/integrated load floors, which may include sensors or motorized functions for enhanced convenience.

How do lightweight materials impact the automotive load floor market?

Lightweight materials, such as composites and advanced plastics, significantly impact the market by reducing overall vehicle weight. This directly improves fuel efficiency in traditional internal combustion engine vehicles and extends the range for electric vehicles, aligning with industry trends for performance and sustainability.

Which regions are leading the growth in the Automotive Load Floor Market?

The Asia Pacific region, particularly countries like China and India, is currently leading the growth in the Automotive Load Floor Market due to high vehicle production volumes, increasing disposable incomes, and the surging demand for SUVs and crossovers.

What role does AI play in the future of automotive load floors?

AI is set to transform load floors by enabling features such as AI-driven design optimization for weight and strength, predictive maintenance for smart systems, and intelligent cargo management that can suggest optimal packing or adapt to user preferences, making the cargo area more dynamic and responsive.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager