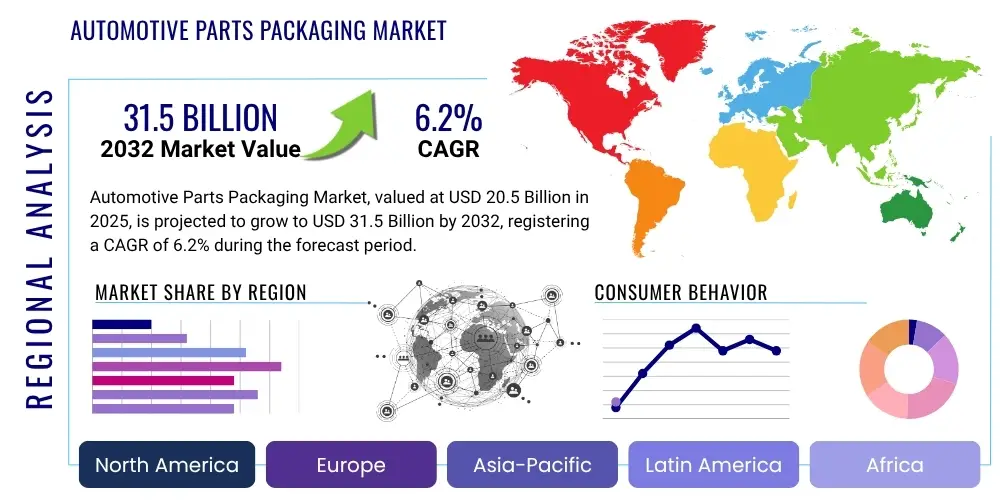

Automotive Parts Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428811 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Automotive Parts Packaging Market Size

The Automotive Parts Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at $20.5 Billion in 2025 and is projected to reach $31.5 Billion by the end of the forecast period in 2032.

Automotive Parts Packaging Market introduction

The Automotive Parts Packaging Market encompasses the design, production, and distribution of specialized packaging solutions engineered to protect and transport a wide array of automotive components. This market is critical for ensuring the safe delivery of delicate and often expensive parts, ranging from small electronic sensors to large engine blocks, across complex global supply chains. Effective packaging safeguards against damage, corrosion, and contamination, contributing significantly to logistics efficiency and overall product quality.

These packaging solutions include a diverse range of products such as collapsible containers, returnable dunnage, protective films, anti-corrosion wraps, pallets, and specialized crates, utilizing materials like plastic, wood, metal, and paperboard. Major applications span both Original Equipment Manufacturers (OEMs) and the aftermarket, facilitating the movement of components from suppliers to assembly lines and onward to distribution centers or repair shops. The primary benefits derived from advanced automotive packaging include enhanced product protection, optimized logistics, reduced transportation costs, improved supply chain visibility, and adherence to stringent industry and environmental standards.

Driving factors propelling this market include the robust growth of the global automotive industry, increasing complexity and diversification of vehicle components, the expansion of e-commerce channels for aftermarket parts, and a growing emphasis on sustainable and reusable packaging solutions. Furthermore, the globalized nature of automotive production necessitates sophisticated packaging that can withstand long transit times and varying environmental conditions, while regulatory pressures for reduced waste and improved material efficiency continue to shape innovation in the sector.

Automotive Parts Packaging Market Executive Summary

The Automotive Parts Packaging Market is experiencing dynamic shifts driven by evolving manufacturing paradigms, heightened sustainability demands, and technological advancements across global supply chains. Business trends indicate a strong move towards returnable and reusable packaging systems, designed to minimize waste and optimize operational costs for both OEMs and aftermarket players. There is also a significant push for lightweight and durable materials, alongside custom-engineered solutions that cater to the unique geometries and protective requirements of complex automotive components. The integration of smart packaging technologies, offering real-time tracking and condition monitoring, is emerging as a key differentiator, enhancing supply chain visibility and efficiency.

Regionally, Asia Pacific continues to dominate the market, propelled by its status as a major global automotive manufacturing hub and a rapidly expanding aftermarket. Countries like China, India, and Japan are investing heavily in advanced production capabilities, consequently driving demand for sophisticated packaging. Europe and North America are characterized by stringent environmental regulations and a strong emphasis on automation and sustainable packaging practices, fostering innovation in eco-friendly materials and circular economy models. Emerging markets in Latin America and the Middle East and Africa are witnessing gradual growth, supported by increasing vehicle production and infrastructure development, which in turn fuels the need for efficient parts packaging.

Segment trends reveal robust growth in plastic-based packaging due to its versatility, durability, and reusability, particularly in the form of collapsible containers and dunnage. Metal and wood packaging remain crucial for heavy and high-value components, while paper and paperboard solutions are gaining traction for smaller, lighter parts due to their recyclability. The aftermarket segment is expanding rapidly, fueled by the rising average age of vehicles and the proliferation of online parts sales, demanding flexible and cost-effective packaging solutions. Original Equipment Manufacturers (OEMs) continue to prioritize precision-engineered, protective packaging to ensure zero-defect delivery to assembly lines, maintaining high standards for component integrity.

AI Impact Analysis on Automotive Parts Packaging Market

Common user questions regarding AI's impact on the automotive parts packaging market frequently revolve around how artificial intelligence can enhance efficiency, reduce costs, improve predictive capabilities, and contribute to more sustainable operations. Users are keen to understand AI's role in optimizing packaging design, automating processes, managing complex logistics, and ensuring quality control. Concerns often include the initial investment required, data privacy, the need for skilled labor to implement and maintain AI systems, and the integration challenges with existing infrastructure. Expectations are high for AI to deliver intelligent solutions for inventory management, demand forecasting, and real-time anomaly detection, ultimately aiming for a more agile, resilient, and cost-effective packaging supply chain.

- AI-powered demand forecasting optimizes inventory levels and packaging material procurement.

- Robotics and AI in automated packaging lines enhance speed, precision, and labor efficiency.

- Predictive analytics identifies potential risks in transit, improving package integrity and preventing damage.

- Generative design tools leverage AI to create optimized packaging forms for specific automotive parts, reducing material usage.

- Computer vision systems enable automated quality control and defect detection during packaging processes.

- AI algorithms enhance route optimization and logistics planning for packaging transport, reducing fuel consumption and costs.

- Intelligent warehouse management systems, often AI-driven, streamline storage and retrieval of packaged parts.

- AI facilitates personalization and customization of packaging solutions based on component specifics and customer requirements.

DRO & Impact Forces Of Automotive Parts Packaging Market

The Automotive Parts Packaging Market is significantly shaped by a confluence of driving factors, persistent restraints, compelling opportunities, and overarching impact forces that dictate its trajectory. A primary driver is the continuous expansion of the global automotive industry, marked by increasing vehicle production and sales, particularly in emerging economies. This growth directly translates into higher demand for robust and efficient packaging solutions for a vast array of components. The rapid proliferation of e-commerce for automotive aftermarket parts is another powerful catalyst, requiring specialized packaging that can withstand individual parcel shipping demands while protecting against damage. Furthermore, the imperative for enhanced supply chain efficiency, cost reduction, and greater sustainability pushes manufacturers to adopt advanced and reusable packaging systems, favoring innovation in materials and design.

However, the market also faces notable restraints. Volatility in raw material prices, including plastics, metals, and wood, poses a significant challenge, directly impacting production costs and profit margins for packaging manufacturers. The high initial capital investment required for adopting advanced packaging technologies, such as automation systems or smart packaging solutions, can be a barrier for smaller players or those operating with tighter budgets. Moreover, the increasing complexity of regulatory frameworks concerning environmental protection, material recycling, and international shipping standards demands continuous adaptation and compliance, which can be both costly and time-consuming.

Despite these challenges, numerous opportunities exist to propel market growth. The growing emphasis on lightweight packaging solutions, driven by efforts to reduce transportation costs and environmental impact, presents a fertile ground for material innovation. The development and integration of smart packaging technologies, offering features like RFID tracking, temperature monitoring, and tamper evidence, create new value propositions for supply chain optimization. The circular economy model, promoting reuse, recycling, and repair, is fostering demand for highly durable and sustainable packaging. Furthermore, the untapped potential of emerging markets, coupled with rising disposable incomes and vehicle ownership, offers significant avenues for market expansion. The impact forces acting on this market are primarily technological advancements, driving automation and intelligent solutions; environmental regulations, pushing for eco-friendly practices; and the globalization of automotive supply chains, necessitating robust, standardized, and internationally compliant packaging.

Segmentation Analysis

The Automotive Parts Packaging Market is broadly segmented based on several key characteristics to provide a comprehensive understanding of its intricate dynamics. These segments help in analyzing market demand, identifying growth opportunities, and understanding competitive landscapes. The segmentation typically includes categories such as product type, material type, application, and end-use, each reflecting different aspects of how automotive parts are packaged and utilized across the industry value chain. This granular analysis allows stakeholders to target specific niches and develop tailored packaging solutions that meet the diverse and evolving requirements of the automotive sector.

Understanding these segments is crucial for strategic planning, product development, and market entry strategies for both packaging suppliers and automotive manufacturers. Each segment presents unique challenges and opportunities, influenced by factors like component fragility, size, weight, transportation mode, regulatory compliance, and environmental considerations. For instance, packaging for powertrain components will differ significantly from that for interior electronics, necessitating distinct material choices and design principles. The emphasis on reusability, recyclability, and cost-effectiveness also varies across segments, reflecting the diverse priorities of OEMs and the aftermarket.

- By Product Type

- Crates

- Containers (e.g., collapsible, rigid)

- Pallets (e.g., plastic, wood)

- Boxes (e.g., corrugated, plastic)

- Bags and Pouches

- Wraps and Films (e.g., anti-corrosion, stretch)

- Dunnage (e.g., foam, textile, custom inserts)

- By Material Type

- Plastic (e.g., HDPE, PP, PET)

- Metal (e.g., steel, aluminum)

- Wood (e.g., plywood, timber)

- Paper and Paperboard (e.g., corrugated fiberboard, molded pulp)

- Others (e.g., composites, biodegradable materials)

- By Application

- Powertrain Components (e.g., engines, transmissions)

- Chassis Components (e.g., axles, suspension)

- Interior & Exterior Components (e.g., dashboards, bumpers, lighting)

- Electrical & Electronic Components (e.g., sensors, control units, wiring harnesses)

- Other Components (e.g., tires, glass, fasteners)

- By End-Use

- Original Equipment Manufacturers (OEMs)

- Aftermarket (e.g., spare parts suppliers, retailers, independent workshops)

Value Chain Analysis For Automotive Parts Packaging Market

The value chain for the Automotive Parts Packaging Market is a complex network involving multiple stages, from raw material sourcing to the final delivery of packaged automotive components. The upstream segment primarily involves suppliers of raw materials such as plastic resins (HDPE, PP), metals (steel, aluminum), wood (timber, plywood), and paperboard. These raw material providers feed into the core packaging manufacturers who design and produce a wide array of specialized packaging solutions like containers, crates, pallets, films, and dunnage. This stage often involves advanced engineering and manufacturing processes to ensure packaging meets stringent automotive industry standards for protection, durability, and reusability. Innovations in sustainable materials and manufacturing techniques are particularly relevant at this upstream level.

Downstream, the manufactured packaging solutions are utilized by various entities within the automotive ecosystem. This primarily includes Original Equipment Manufacturers (OEMs), who use packaging to transport components from their Tier 1, 2, and 3 suppliers to their assembly lines. The aftermarket segment, comprising spare parts suppliers, retailers, and independent workshops, also forms a significant part of the downstream, requiring packaging for the distribution of replacement parts. Third-Party Logistics (3PL) providers often play a crucial role in managing the flow of both empty packaging for return and filled packaging for distribution, integrating packaging into broader supply chain management strategies.

The distribution channels for automotive parts packaging are multifaceted, encompassing both direct and indirect approaches. Direct channels involve packaging manufacturers selling directly to large automotive OEMs or major Tier 1 suppliers who have substantial, ongoing packaging requirements and often demand highly customized solutions. This direct relationship facilitates close collaboration on design, testing, and supply chain integration. Indirect channels involve distributors, wholesalers, and sometimes even specialized logistics companies that aggregate packaging solutions from various manufacturers and supply them to smaller aftermarket players, independent workshops, or OEMs with less frequent or smaller volume needs. These indirect channels provide broader market reach and cater to diverse customer bases, offering a range of standard and semi-customized packaging options. The efficiency of these channels is critical for ensuring timely delivery and cost-effectiveness across the entire automotive supply chain.

Automotive Parts Packaging Market Potential Customers

The potential customers and end-users of automotive parts packaging solutions span the entire automotive value chain, from initial manufacturing to aftermarket service and repair. Original Equipment Manufacturers (OEMs) represent a significant customer segment, requiring robust and precise packaging for the continuous flow of components to their assembly plants. This includes car, truck, and motorcycle manufacturers, as well as heavy machinery and specialty vehicle producers. OEMs prioritize packaging that ensures zero-defect delivery, optimizes line-side efficiency, and often aligns with their sustainability goals through reusable and returnable solutions. They demand high levels of customization and strict quality control to protect valuable components during transit and storage.

Tier 1, Tier 2, and Tier 3 suppliers are also major buyers, as they are responsible for packaging and delivering their manufactured components to OEMs or subsequent tiers. These suppliers often deal with a vast array of parts, from complex electronic modules to precision-machined metal components, each requiring specific protective packaging. The aftermarket segment, which includes distributors of spare parts, automotive retailers (both brick-and-mortar and e-commerce platforms), and independent repair workshops, constitutes another rapidly growing customer base. For the aftermarket, packaging needs often focus on durability for individual parcel shipping, brand recognition, and ease of handling for varied order sizes. Furthermore, third-party logistics (3PL) providers and specialized freight forwarders, who manage the global transportation of automotive parts, are crucial customers, integrating packaging solutions into their broader logistics services to enhance efficiency and minimize damage during complex transit routes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $20.5 Billion |

| Market Forecast in 2032 | $31.5 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | DS Smith Plc, Mondi Group, Nefab Group, R.R. Donnelley & Sons Company, Schoeller Allibert, Sonoco Products Company, Smurfit Kappa Group, Tri-Wall Limited, Orbis Corporation, Rehrig Pacific Company, CHEP (Brambles Ltd.), Menasha Corporation, Packaging Corporation of America, Sealed Air Corporation, Amcor plc, Bemis Company Inc., Mauser Packaging Solutions, RPC Group Plc, Universal Forest Products, Pregis LLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Parts Packaging Market Key Technology Landscape

The Automotive Parts Packaging Market is increasingly shaped by a dynamic technological landscape, focusing on innovations that enhance efficiency, sustainability, and protection. Automation and robotics are at the forefront, revolutionizing packaging lines with robotic arms capable of precise handling, sorting, and assembly of complex automotive components into their packaging. This not only boosts throughput and reduces labor costs but also minimizes human error and improves ergonomics. Furthermore, advancements in material science are leading to the development of lightweight yet durable plastics, composite materials, and biodegradable alternatives, addressing the industry's push for reduced carbon footprint and lower transportation costs. These materials offer superior cushioning, anti-corrosion properties, and extended reusability, aligning with circular economy principles.

Another significant technological trend is the integration of Internet of Things (IoT) sensors and smart packaging solutions. These technologies allow for real-time tracking of packages, monitoring critical conditions such as temperature, humidity, shock, and tilt during transit. Such data provides invaluable insights into supply chain performance, enables proactive intervention in case of potential damage, and ensures compliance with specific component handling requirements. This intelligent connectivity facilitates enhanced visibility, predictive maintenance of packaging assets, and improved inventory management across global supply networks. Digitalization, including the use of advanced analytics and AI-powered software, further optimizes packaging design, material usage, and logistics planning, allowing for highly customized and efficient solutions tailored to specific automotive parts and supply chain routes. Additive manufacturing (3D printing) is also emerging as a niche technology for creating highly customized dunnage and inserts, particularly for low-volume, high-value, or unusually shaped components, offering rapid prototyping and production capabilities.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to its robust automotive manufacturing base, particularly in China, Japan, India, and South Korea. The region benefits from increasing vehicle production, a burgeoning aftermarket, and significant investments in advanced manufacturing and logistics infrastructure. Demand is high for both reusable and disposable packaging solutions.

- Europe: A mature market characterized by stringent environmental regulations and a strong focus on sustainable packaging solutions. European manufacturers are leaders in developing reusable, recyclable, and lightweight packaging. Germany, France, and the UK are key contributors, driven by a strong OEM presence and a commitment to circular economy principles in packaging.

- North America: Exhibits substantial demand, fueled by a large automotive industry and a significant aftermarket sector. The region emphasizes robust and protective packaging for long-distance transport, with a growing adoption of smart packaging technologies and automation in packaging processes. The US and Canada are primary markets.

- Latin America: An emerging market with growing automotive production capacities, especially in Mexico and Brazil. The region presents opportunities for packaging manufacturers as the automotive sector expands, driving demand for cost-effective and durable solutions. Infrastructure development plays a crucial role in market growth.

- Middle East and Africa (MEA): A developing market for automotive parts packaging, driven by increasing vehicle sales and regional manufacturing initiatives. While smaller in market share, the region offers potential for growth as economic diversification and industrialization efforts continue to boost the automotive sector and associated supply chains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Parts Packaging Market.- DS Smith Plc

- Mondi Group

- Nefab Group

- R.R. Donnelley & Sons Company

- Schoeller Allibert

- Sonoco Products Company

- Smurfit Kappa Group

- Tri-Wall Limited

- Orbis Corporation

- Rehrig Pacific Company

- CHEP (Brambles Ltd.)

- Menasha Corporation

- Packaging Corporation of America

- Sealed Air Corporation

- Amcor plc

- Bemis Company Inc.

- Mauser Packaging Solutions

- RPC Group Plc

- Universal Forest Products

- Pregis LLC

Frequently Asked Questions

What are the primary drivers for the Automotive Parts Packaging Market growth?

The market is primarily driven by global automotive industry expansion, the rapid growth of e-commerce for aftermarket parts, increasing demand for supply chain efficiency, and a rising focus on sustainable and reusable packaging solutions across the sector.

How is sustainability influencing automotive parts packaging?

Sustainability is a major influence, driving innovation towards reusable packaging systems, lightweight materials, recycled content, and biodegradable options. This focus aims to reduce waste, lower carbon footprints, and meet stringent environmental regulations, promoting a circular economy approach.

What role does technology play in modern automotive parts packaging?

Technology is crucial, with advancements in automation, robotics, IoT-enabled smart packaging for real-time tracking, and AI-driven analytics optimizing design, logistics, and quality control. These innovations enhance efficiency, protect components, and improve supply chain visibility.

What are the key challenges faced by the Automotive Parts Packaging Market?

Key challenges include volatile raw material prices, high initial investment for advanced packaging technologies, complex and evolving regulatory frameworks, and the need to protect an increasingly diverse range of delicate and heavy automotive components.

Which region currently leads the Automotive Parts Packaging Market?

Asia Pacific (APAC) currently leads the Automotive Parts Packaging Market, largely due to its dominant position as a global automotive manufacturing hub and the rapid expansion of its aftermarket sector, particularly in countries like China, Japan, and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager