Automotive Piezoelectric Fuel Injectors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428513 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Automotive Piezoelectric Fuel Injectors Market Size

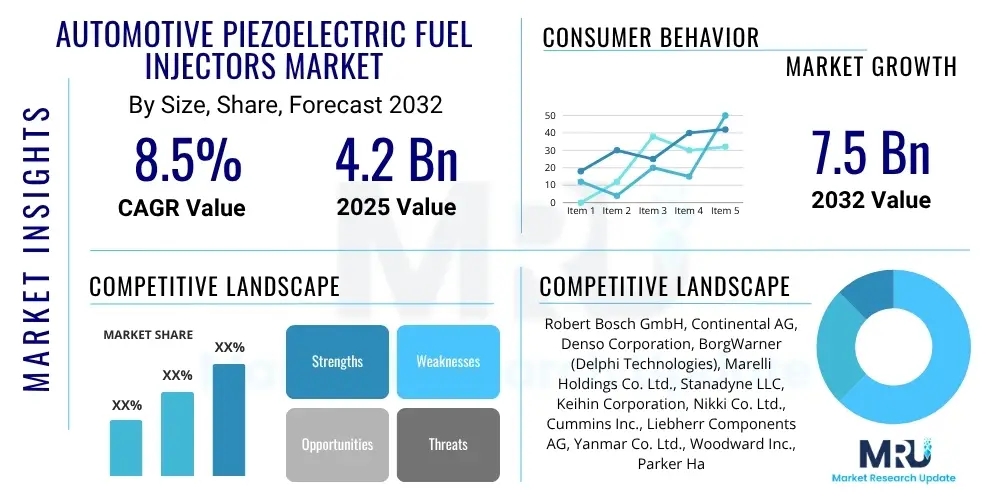

The Automotive Piezoelectric Fuel Injectors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 4.2 billion in 2025 and is projected to reach USD 7.5 billion by the end of the forecast period in 2032.

Automotive Piezoelectric Fuel Injectors Market introduction

The Automotive Piezoelectric Fuel Injectors Market encompasses the global industry involved in the design, manufacturing, and distribution of advanced fuel injection systems utilizing piezoelectric technology for internal combustion engines. Piezoelectric fuel injectors are precision components that leverage the piezoelectric effect, where certain materials produce an electric charge in response to mechanical stress or vice versa, to achieve exceptionally fast and precise fuel delivery into an engine's combustion chamber. This technology enables multiple injections per combustion cycle and extremely fine control over fuel atomization, which is critical for optimizing engine performance and emissions.

Major applications for these injectors primarily include modern common rail direct injection (CRDI) diesel engines and gasoline direct injection (GDI) engines, both prevalent in passenger cars, commercial vehicles, and off-highway machinery. The fundamental benefits derived from employing piezoelectric injectors are multifaceted, including significant improvements in fuel efficiency due to better fuel atomization and combustion, substantial reductions in harmful exhaust emissions by precisely controlling injection timing and quantity, and enhanced engine power and torque output, leading to a superior driving experience. These benefits are increasingly vital as global environmental regulations become more stringent and consumer demand for high-performance, eco-friendly vehicles grows.

Several driving factors propel the growth of this market. Foremost among these are the escalating global emission standards, such as Euro 7 and CAFE regulations, which necessitate sophisticated fuel management systems capable of achieving ultra-low emissions. The continuous demand for vehicles with superior fuel economy further stimulates adoption, as piezoelectric injectors offer a proven path to reducing fuel consumption. Moreover, the ongoing technological advancements in engine design, particularly the widespread adoption of direct injection technologies in both diesel and gasoline powertrains, provide a fertile ground for the integration of these high-precision components, making them an indispensable element in the quest for cleaner and more efficient automotive propulsion.

Automotive Piezoelectric Fuel Injectors Market Executive Summary

The Automotive Piezoelectric Fuel Injectors Market is characterized by robust growth driven by a confluence of evolving business trends, distinct regional dynamics, and segment-specific advancements. Business trends indicate a strong emphasis on research and development by key players, focusing on miniaturization, cost reduction, and enhancing durability to meet stringent automotive standards. Collaborations between Tier 1 suppliers and automotive original equipment manufacturers (OEMs) are becoming increasingly vital for co-developing customized injection solutions, while the broader shift towards electrification in the automotive sector presents both challenges and opportunities for this specialized component market, particularly in hybrid vehicle applications that still rely on efficient internal combustion engines.

Regional trends highlight Asia Pacific as a significant growth hub, propelled by rapidly expanding automotive production in countries like China and India, coupled with the gradual implementation of stricter emission norms. Europe continues to be a dominant market, largely due to its early adoption of advanced diesel technologies and ongoing commitment to reducing vehicular pollution, driving continuous innovation in piezoelectric solutions. North America is experiencing steady growth, with a focus on gasoline direct injection systems for passenger vehicles to comply with fuel economy mandates, contributing to the overall global market expansion and technology diffusion.

Segment trends reveal that while diesel engines have historically been a primary application for piezoelectric injectors, the gasoline direct injection (GDI) segment is showing accelerated growth, particularly in passenger cars, as manufacturers strive for efficiency gains from smaller, turbocharged gasoline engines. The OEM segment remains the largest revenue contributor, driven by new vehicle production, but the aftermarket segment is also steadily expanding as vehicles equipped with these advanced injectors age and require replacement parts. This segmentation underscores a diverse market landscape where technological sophistication and application-specific demands shape demand and supply dynamics across various vehicle types and fuel systems.

AI Impact Analysis on Automotive Piezoelectric Fuel Injectors Market

The integration of Artificial Intelligence (AI) is transforming various facets of the Automotive Piezoelectric Fuel Injectors Market, addressing common user questions about how technology can further enhance performance, reliability, and manufacturing efficiency. Users frequently inquire about AI's role in optimizing injector design, enabling predictive maintenance, improving production quality, and streamlining supply chains. These concerns highlight a clear expectation that AI will unlock new levels of precision and cost-effectiveness. The key themes emerging from these inquiries revolve around AI's potential to refine fuel delivery algorithms, anticipate component failures, automate quality control processes, and facilitate more responsive inventory management, ultimately leading to more robust, efficient, and intelligent fuel injection systems that contribute to cleaner and more reliable automotive powertrains.

- AI-driven optimization of fuel injection patterns for enhanced combustion efficiency and reduced emissions.

- Predictive maintenance algorithms using sensor data to forecast injector wear and prevent failures, improving vehicle uptime.

- AI-powered manufacturing and quality control systems detecting microscopic defects during production, ensuring higher reliability.

- Integration of AI into engine control units (ECUs) for real-time adaptive fuel management based on driving conditions.

- AI-enhanced supply chain management for sourcing raw materials and delivering finished products, reducing lead times and costs.

- Simulation and design optimization using AI to accelerate the development of next-generation piezoelectric materials and injector architectures.

- Facilitation of autonomous driving by ensuring precise and reliable powertrain operation under varied conditions through AI monitoring.

DRO & Impact Forces Of Automotive Piezoelectric Fuel Injectors Market

The Automotive Piezoelectric Fuel Injectors Market is shaped by a complex interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include stringent global emission regulations demanding cleaner combustion, a persistent consumer and regulatory push for improved fuel efficiency in internal combustion engines, and the widespread adoption of advanced direct injection technologies (GDI and CRDI) that benefit significantly from the precision offered by piezoelectric solutions. Continuous technological advancements in piezoelectric materials and manufacturing processes also contribute to the market's upward trajectory, making these injectors more efficient and durable. These factors collectively create a strong impetus for market expansion, particularly as traditional internal combustion engines continue to play a crucial role, even within hybrid vehicle architectures.

However, the market also faces notable restraints. The relatively higher manufacturing cost of piezoelectric injectors compared to conventional solenoid injectors poses a barrier, especially in cost-sensitive automotive segments. The inherent technical complexity of piezoelectric systems requires specialized expertise for manufacturing, installation, and maintenance, potentially limiting broader adoption. Furthermore, the accelerating global shift towards electric vehicles (EVs) presents a long-term existential challenge to the entire internal combustion engine component market, including fuel injectors, as demand for gasoline and diesel vehicles may gradually decline. Material limitations and supply chain vulnerabilities for specialized piezoelectric ceramics can also intermittently impact production and pricing.

Opportunities for growth are evident in several areas. The expanding market for hybrid electric vehicles (HEVs) offers a significant avenue, as these vehicles still rely on highly efficient internal combustion engines that benefit immensely from piezoelectric injection technology. The development and adoption of alternative fuels, such as biofuels and synthetic fuels, could also create new demand for specifically tuned piezoelectric injectors. Emerging automotive markets in Asia Pacific and Latin America, where vehicle ownership is rapidly increasing, represent fertile ground for market penetration. Additionally, advancements in onboard diagnostics and predictive maintenance systems for these injectors could enhance their perceived value and extend their lifespan, further boosting market appeal.

The broader impact forces influencing this market include the intense competitive rivalry among a few dominant Tier 1 suppliers, who continually innovate to maintain market share. The bargaining power of major automotive OEMs is high, as they procure these components in vast quantities and demand specific performance and cost parameters. The threat of substitutes, while currently limited for high-performance direct injection, comes from alternative fuel delivery methods or ultimately, complete powertrain electrification. Supplier bargaining power is moderate, influenced by the specialized nature of piezoelectric materials and manufacturing processes. The threat of new entrants is relatively low due to the significant capital investment, technological expertise, and established supply chains required to compete effectively in this niche, high-precision market.

Segmentation Analysis

The Automotive Piezoelectric Fuel Injectors Market is rigorously segmented to provide a comprehensive understanding of its diverse landscape and to identify key growth pockets and strategic opportunities. This segmentation allows for a detailed analysis of market dynamics across various categories, including vehicle type, fuel type, sales channel, and specific injection system technologies. By breaking down the market into these constituent parts, stakeholders can better identify target audiences, assess competitive positioning, and tailor their product development and market entry strategies to specific sub-markets, maximizing their commercial impact and fostering sustainable growth within the automotive industry.

- By Vehicle Type

- Passenger Cars

- Commercial Vehicles

- By Fuel Type

- Gasoline

- Diesel

- By Sales Channel

- OEM (Original Equipment Manufacturer)

- Aftermarket

- By Injection System

- Common Rail Direct Injection (CRDI)

- Gasoline Direct Injection (GDI)

- By Engine Type

- 4-Cylinder Engines

- 6-Cylinder Engines

- 8-Cylinder Engines and Above

Value Chain Analysis For Automotive Piezoelectric Fuel Injectors Market

The value chain for the Automotive Piezoelectric Fuel Injectors Market is intricate, involving multiple stages from raw material procurement to the final integration into a vehicle, ensuring precision and quality at each step. Upstream activities commence with the sourcing of highly specialized raw materials, primarily piezoelectric ceramics (like Lead Zirconate Titanate – PZT) and high-grade metals such as stainless steel and aluminum, along with sophisticated electronic components for control units. These materials are then processed by specialized manufacturers into core piezoelectric stacks, nozzles, and various mechanical and electronic sub-components. The efficiency and quality of these upstream suppliers are critical, as they directly impact the performance and reliability of the final injector unit.

Midstream, these core components converge at Tier 1 automotive suppliers who specialize in designing, assembling, and testing the complete piezoelectric fuel injector modules. This stage involves complex engineering, precision manufacturing, and rigorous quality control to meet the demanding specifications of automotive OEMs. Extensive research and development efforts are concentrated here, focusing on improving injector response times, fuel atomization, durability, and cost-effectiveness. These major suppliers often invest heavily in advanced robotics and automation to ensure consistency and scalability in production, acting as the crucial link between raw material suppliers and the end-product assemblers.

Downstream activities involve the distribution and integration of these injectors into vehicles. The primary distribution channel is direct sales from Tier 1 suppliers to automotive Original Equipment Manufacturers (OEMs), where the injectors are incorporated into new vehicles on the assembly line. This direct channel accounts for the largest share of the market. An indirect distribution channel also exists for the aftermarket, where independent distributors, wholesalers, and authorized service centers supply replacement injectors to repair shops and individual consumers. This aftermarket segment is growing as the fleet of vehicles equipped with piezoelectric injectors ages, requiring maintenance and component replacement, thereby creating a sustained demand beyond initial vehicle production.

Automotive Piezoelectric Fuel Injectors Market Potential Customers

The primary potential customers for Automotive Piezoelectric Fuel Injectors span across various segments of the automotive industry, each with distinct needs and purchasing behaviors. The largest and most influential customer group comprises automotive Original Equipment Manufacturers (OEMs) such as Volkswagen, BMW, Mercedes-Benz, Ford, General Motors, Toyota, and Hyundai-Kia. These manufacturers integrate piezoelectric fuel injectors directly into their new vehicles, demanding large volumes, competitive pricing, stringent quality standards, and close collaboration for design and development to meet their specific engine architectures and emission targets. OEMs drive the initial demand and technological specifications for these advanced components, making them the cornerstone of the market.

Another significant customer segment includes manufacturers of heavy-duty vehicles, agricultural machinery, and marine engines, where diesel direct injection systems are prevalent. Companies like Cummins, Caterpillar, and Volvo Group, which produce commercial trucks, buses, construction equipment, and industrial power units, seek piezoelectric injectors for their robust performance, fuel efficiency, and ability to meet stringent off-highway emission standards. These customers prioritize durability, reliability, and long-term operational cost savings, reflecting the demanding environments in which their vehicles operate.

Beyond new vehicle production, the aftermarket segment represents a growing base of potential customers. This includes independent automotive repair shops, authorized service centers, and individual vehicle owners who require replacement piezoelectric fuel injectors for maintenance, repair, or performance upgrades. As the global fleet of vehicles equipped with these advanced injectors expands and ages, the demand for replacement parts through aftermarket channels steadily increases. Distributors and wholesalers who serve this aftermarket ecosystem are also key customers, purchasing injectors in bulk to supply their networks and cater to the ongoing service needs of millions of vehicles globally.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 billion |

| Market Forecast in 2032 | USD 7.5 billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Robert Bosch GmbH, Continental AG, Denso Corporation, BorgWarner (Delphi Technologies), Marelli Holdings Co. Ltd., Stanadyne LLC, Keihin Corporation, Nikki Co. Ltd., Cummins Inc., Liebherr Components AG, Yanmar Co. Ltd., Woodward Inc., Parker Hannifin Corporation, Infineon Technologies AG, Vitesco Technologies GmbH, Rheinmetall Automotive AG, Hitachi Astemo Ltd., Mitsubishi Electric Corporation, Weifu High-Technology Group Co. Ltd., Eaton Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Piezoelectric Fuel Injectors Market Key Technology Landscape

The Automotive Piezoelectric Fuel Injectors Market is underpinned by a sophisticated technological landscape that drives its precision, efficiency, and environmental benefits. At its core is the utilization of advanced piezoelectric materials, predominantly Lead Zirconate Titanate (PZT) ceramics, which exhibit the unique property of deforming rapidly and predictably when an electric voltage is applied. This characteristic allows for extremely fast actuation times, often measured in microseconds, significantly surpassing the speed of conventional solenoid-based injectors. The ability to switch on and off with such high frequency enables multiple, very fine injections per combustion cycle, a technique critical for optimizing the combustion process, reducing noise, and drastically cutting down emissions.

Further technological advancements include the integration of these piezoelectric actuators into highly complex common rail direct injection (CRDI) systems for diesel engines and gasoline direct injection (GDI) systems for petrol engines. These systems operate at extremely high pressures, often exceeding 2,000 bar for diesel and 350 bar for gasoline, necessitating robust and durable injector designs. Precision manufacturing techniques, including micro-machining and laser drilling, are essential for creating the minute nozzle holes and internal passages that control fuel atomization and spray patterns with sub-millimeter accuracy. The interaction between the piezoelectric element and the hydraulic components within the injector is a marvel of miniaturized engineering, ensuring both reliability and longevity under extreme operating conditions.

Moreover, the performance of piezoelectric fuel injectors is intrinsically linked to sophisticated electronic control units (ECUs) and advanced sensor technologies. Modern ECUs utilize powerful microprocessors and complex algorithms to precisely control the timing, duration, and number of injection events, adapting in real-time to engine load, speed, and environmental conditions. This electronic precision allows for intelligent fuel management, optimizing fuel delivery for various driving scenarios, from cold starts to high-speed cruising. The ongoing development in semiconductor technology, particularly in power electronics, further enhances the efficiency and compactness of the control systems, enabling the precise voltage control required to operate piezoelectric actuators effectively and thereby continuously pushing the boundaries of engine efficiency and environmental compliance.

Regional Highlights

- Asia Pacific (APAC): Emerging as the largest and fastest-growing market due to escalating automotive production, particularly in China and India. Stringent emission regulations mirroring European standards are increasingly being adopted, propelling demand for advanced fuel injection systems in both passenger and commercial vehicles. Japan and South Korea also contribute significantly with their established automotive industries and focus on technological innovation.

- Europe: A mature yet highly innovative market, driven by some of the world's most stringent emission standards (e.g., Euro 6/7) and a strong historical emphasis on diesel technology. Countries like Germany, France, and Italy are at the forefront of adopting and developing piezoelectric fuel injectors, especially for premium and high-performance vehicles, maintaining a leading position in terms of technological advancements and R&D.

- North America: Exhibiting steady growth, primarily influenced by stringent Corporate Average Fuel Economy (CAFE) standards and an increasing preference for gasoline direct injection (GDI) engines in passenger cars and light trucks. The United States and Canada are key markets, with a focus on improving fuel efficiency and reducing emissions from their large vehicle fleets, fostering demand for advanced fuel system components.

- Latin America: An evolving market with increasing vehicle sales and production, particularly in Brazil and Mexico. While regulatory landscapes are still developing, there is a growing trend towards adopting more fuel-efficient and cleaner engine technologies, creating opportunities for piezoelectric fuel injectors in both new vehicle sales and the expanding aftermarket.

- Middle East and Africa (MEA): A nascent market with varied rates of adoption, largely dependent on economic conditions, regulatory frameworks, and vehicle import trends. Countries in the Gulf Cooperation Council (GCC) are gradually implementing higher emission standards, leading to increased demand for advanced automotive technologies, including fuel injectors, especially in the luxury and premium vehicle segments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Piezoelectric Fuel Injectors Market.- Robert Bosch GmbH

- Continental AG

- Denso Corporation

- BorgWarner (Delphi Technologies)

- Marelli Holdings Co. Ltd.

- Stanadyne LLC

- Keihin Corporation

- Nikki Co. Ltd.

- Cummins Inc.

- Liebherr Components AG

- Yanmar Co. Ltd.

- Woodward Inc.

- Parker Hannifin Corporation

- Infineon Technologies AG

- Vitesco Technologies GmbH

- Rheinmetall Automotive AG

- Hitachi Astemo Ltd.

- Mitsubishi Electric Corporation

- Weifu High-Technology Group Co. Ltd.

- Eaton Corporation

Frequently Asked Questions

Analyze common user questions about the Automotive Piezoelectric Fuel Injectors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are automotive piezoelectric fuel injectors?

Automotive piezoelectric fuel injectors are advanced components that use piezoelectric materials to precisely control fuel delivery into an engine, enabling faster and more accurate injections than traditional solenoid injectors.

What are the main advantages of piezoelectric fuel injectors?

Their primary advantages include improved fuel efficiency, significant reductions in exhaust emissions, enhanced engine performance, and greater flexibility in fuel injection strategies due to ultra-fast response times.

How do piezoelectric injectors contribute to fuel efficiency and emissions reduction?

By allowing multiple, very precise injections per combustion cycle, they optimize fuel atomization and combustion, leading to more complete fuel burn, reduced waste, and lower production of pollutants like NOx and particulate matter.

What is the market outlook for automotive piezoelectric fuel injectors?

The market is projected for steady growth, driven by increasingly stringent emission regulations, ongoing demand for fuel-efficient vehicles, and the continued adoption of direct injection technologies in both gasoline and diesel engines, particularly in hybrid applications.

Are piezoelectric fuel injectors used in electric vehicles (EVs)?

No, piezoelectric fuel injectors are components of internal combustion engines, which are not present in purely electric vehicles. However, they are highly relevant for hybrid electric vehicles (HEVs) that combine an electric motor with a highly efficient combustion engine.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager