Automotive Roof Rail Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430854 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Automotive Roof Rail Market Size

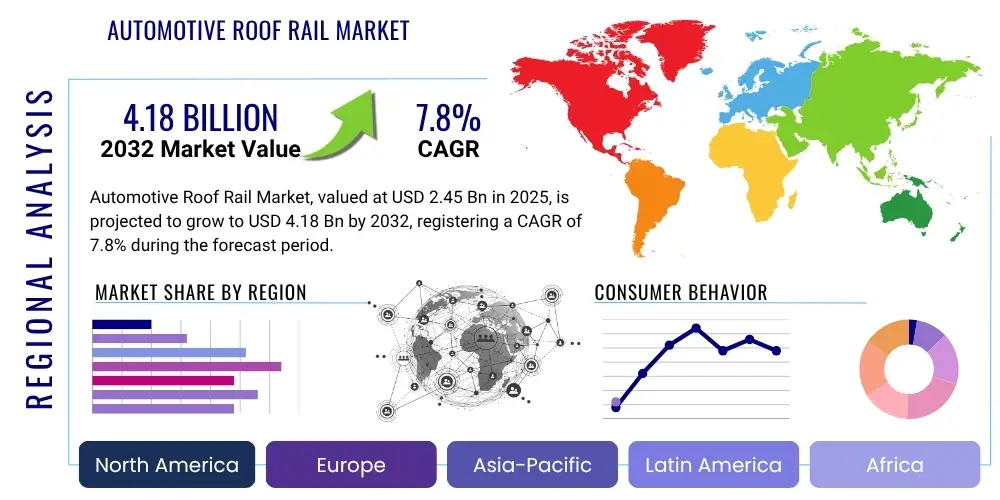

The Automotive Roof Rail Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $2.45 Billion in 2025 and is projected to reach $4.18 Billion by the end of the forecast period in 2032.

Automotive Roof Rail Market introduction

The Automotive Roof Rail Market encompasses the design, manufacturing, and distribution of rails installed on the roofs of vehicles, primarily for mounting additional cargo-carrying systems. These rails serve as a foundational component for various accessories, including luggage carriers, bike racks, ski carriers, and even rooftop tents, significantly enhancing a vehicle's utility and versatility. The increasing global demand for sport utility vehicles (SUVs) and crossover utility vehicles (CUVs), coupled with a rising consumer inclination towards outdoor recreational activities and adventure travel, are pivotal factors driving market expansion. Roof rails provide tangible benefits by offering increased storage capacity, distributing weight effectively, and maintaining interior passenger comfort.

The product, essentially a pair of elevated or flush rails running along the length of a vehicle's roof, allows for secure attachment of crossbars and subsequent cargo accessories. Major applications span from personal use for family trips and sports equipment transport to commercial uses for tradespeople requiring additional carrying capacity. Benefits include enhanced vehicle functionality, improved aerodynamics in some integrated designs, and a robust platform for modular cargo solutions. Key driving factors include the automotive industry's continuous growth, evolving consumer lifestyles prioritizing versatility and outdoor pursuits, and advancements in material science leading to lighter, stronger, and more aesthetically integrated roof rail systems.

Automotive Roof Rail Market Executive Summary

The Automotive Roof Rail Market is characterized by dynamic business trends, including a strong focus on lightweight materials such as aluminum and advanced composites to meet stringent fuel efficiency and emission standards. Innovations in aerodynamic design are also prominent, aiming to reduce drag and wind noise, thereby enhancing overall vehicle performance and passenger comfort. Manufacturers are increasingly exploring modular and integrated roof rail systems that seamlessly blend with vehicle aesthetics and offer greater customization options for end-users. Strategic partnerships between OEMs and specialized roof rail suppliers are common, ensuring optimal integration during vehicle design phases and leveraging expertise for advanced solutions.

Regionally, the market exhibits diverse growth patterns. Asia Pacific stands out as a high-growth region, propelled by rapid urbanization, increasing disposable incomes, and the burgeoning automotive manufacturing sector, especially in countries like China and India. North America and Europe represent mature markets with stable demand, driven by a strong aftermarket segment and continued preference for SUVs and outdoor activities. Latin America and the Middle East and Africa are emerging markets, showcasing steady growth as vehicle penetration increases and consumers seek greater utility from their automobiles. Each region presents unique opportunities and challenges influenced by local regulations, economic conditions, and consumer preferences.

Segment-wise, the market sees the Original Equipment Manufacturer (OEM) segment dominating revenue share, as most new SUVs and CUVs come equipped with factory-installed roof rails. However, the aftermarket segment is also experiencing substantial growth, fueled by consumers seeking to upgrade their existing vehicles or add functionality post-purchase. Material segments like aluminum are favored for their strength-to-weight ratio, while advancements in plastics and composites offer cost-effective and design-flexible alternatives. The vehicle type segment is heavily influenced by the proliferation of SUVs and crossovers, which inherently benefit most from roof rail utility, although sedans and hatchbacks also contribute to demand for more discreet or integrated solutions.

AI Impact Analysis on Automotive Roof Rail Market

The integration of Artificial Intelligence (AI) in the automotive roof rail market is a topic of increasing interest among users, with common questions revolving around how AI can enhance product design, manufacturing efficiency, material innovation, and even integrate with future autonomous vehicle systems. Users are keen to understand if AI can make roof rails lighter, stronger, more aerodynamic, and safer. Key themes emerging from these inquiries highlight expectations for AI to optimize complex design parameters, predict material performance under varying conditions, streamline production processes to reduce costs and waste, and enable personalized customization options based on user behavior and preferences. There is also significant curiosity about AI's role in developing smart roof rail systems that might communicate with vehicle sensors or adjust dynamically.

- AI in Generative Design: Optimizing roof rail shapes for superior aerodynamics and structural integrity, reducing material usage while maintaining strength.

- Predictive Maintenance in Manufacturing: AI algorithms analyzing sensor data from production lines to anticipate equipment failures, improving uptime and efficiency.

- Advanced Material Development: AI accelerating the discovery and formulation of new lightweight, high-strength composite materials for roof rail construction.

- Supply Chain Optimization: AI enhancing logistics, demand forecasting, and inventory management for raw materials and finished roof rail components.

- Quality Control: AI-powered vision systems identifying defects in manufacturing with greater accuracy and speed than human inspection.

- Personalized Customization: AI analyzing consumer data to offer highly personalized roof rail designs and functionalities, enhancing customer satisfaction.

- Integration with Vehicle Systems: Future AI integration could lead to 'smart' roof rails that sense load, alert drivers to imbalances, or dynamically adjust for optimal aerodynamics.

DRO & Impact Forces Of Automotive Roof Rail Market

The Automotive Roof Rail Market is significantly influenced by a confluence of driving factors, market restraints, emerging opportunities, and broader impact forces that shape its growth trajectory. Key drivers include the sustained global demand for SUVs, CUVs, and light trucks, vehicles that inherently benefit from and often feature roof rail systems. The growing trend of outdoor and recreational activities, such as camping, cycling, and winter sports, further propels the demand for vehicle accessories that facilitate cargo transport, positioning roof rails as essential components. Additionally, the increasing consumer desire for enhanced vehicle utility and versatility, enabling multiple functions from a single vehicle, substantially contributes to market expansion.

Despite robust growth drivers, the market faces several notable restraints. Stringent automotive safety regulations, particularly regarding crashworthiness and pedestrian safety, impose complex design and material requirements, potentially increasing manufacturing costs and design lead times. Fluctuations in raw material prices, especially for aluminum, steel, and petroleum-derived plastics, can impact production costs and profit margins for manufacturers. Furthermore, concerns regarding vehicle aerodynamics and fuel efficiency also present a restraint, as roof rails, if not optimally designed, can increase drag and slightly reduce fuel economy, pushing manufacturers to invest in more aerodynamic and integrated solutions.

Opportunities within the market are abundant, primarily driven by technological advancements. The increasing adoption of lightweight materials, such as advanced aluminum alloys and carbon fiber composites, offers manufacturers a pathway to produce more fuel-efficient and high-performance roof rails without compromising strength. The development of smart, integrated roof rail systems that feature advanced sensors, modular designs, or even dynamic adjustability presents significant innovation potential. Moreover, the robust and continuously evolving aftermarket segment offers substantial growth opportunities for customized and specialized roof rail solutions, catering to diverse consumer preferences and vehicle models. The electrification of vehicles, while posing new design challenges, also opens avenues for innovative, battery-compatible roof rail solutions.

Segmentation Analysis

The Automotive Roof Rail Market is comprehensively segmented to provide a granular understanding of its diverse components and dynamics. This segmentation facilitates targeted market strategies, product development, and competitive analysis, allowing stakeholders to identify niche opportunities and address specific customer needs. The primary segments are typically categorized by material used in construction, the design type of the roof rail, the specific vehicle types they are designed for, and the sales channel through which they are distributed to the end-consumer.

- By Material: This segment differentiates roof rails based on the primary material utilized in their manufacturing, impacting their strength, weight, cost, and aesthetic properties.

- Aluminum: Favored for its lightweight nature, corrosion resistance, and high strength-to-weight ratio.

- Steel: Known for its robustness, durability, and cost-effectiveness, though heavier than aluminum.

- Plastics: Often used for non-structural components or integrated designs due to flexibility and lower cost.

- Composites: Advanced materials offering exceptional strength, low weight, and design flexibility, albeit at a higher cost.

- By Type: This classification refers to the physical design and mounting style of the roof rails, influencing their appearance and functionality.

- Raised Roof Rails: Distinctly separated from the roof, allowing straps to pass underneath, offering high versatility.

- Flush Roof Rails: Sleek and integrated, sitting close to the vehicle roof, primarily for aesthetic appeal and reduced wind noise.

- Integrated Roof Rails: Seamlessly incorporated into the vehicle's roofline, often found on premium vehicles.

- T-track Roof Rails: Feature a T-slot channel for quick and flexible accessory attachment.

- By Vehicle Type: This segment categorizes roof rails based on the kind of automobile they are designed to fit, reflecting varying load capacities and aesthetic requirements.

- SUVs: The largest segment, driven by their utility and common inclusion of roof rails as standard.

- Sedans: A growing segment, with more discreet or detachable roof rail options for added utility.

- Hatchbacks: Similar to sedans, offering modular solutions for compact vehicles.

- Vans/MPVs: Primarily for family or commercial use, requiring robust cargo solutions.

- Pick-up Trucks: Roof rails may be less common due to bed storage, but some designs cater to cabin roof storage.

- By Sales Channel: This segmentation outlines the primary avenues through which roof rails reach the market.

- OEM (Original Equipment Manufacturer): Roof rails supplied directly to automotive manufacturers for factory installation.

- Aftermarket: Products sold separately to consumers for installation on existing vehicles, often through retailers or online platforms.

Value Chain Analysis For Automotive Roof Rail Market

The value chain for the Automotive Roof Rail Market is a complex network involving several key stages, from the sourcing of raw materials to the final distribution to consumers. This chain begins with upstream activities, focusing on the procurement and processing of fundamental resources. Suppliers of aluminum, steel, various plastics (such as ABS, polypropylene), and advanced composite materials (like carbon fiber and fiberglass) form the initial link, providing the essential inputs for roof rail manufacturing. These raw materials undergo initial processing, such as extrusion for aluminum profiles or molding for plastic components, before being supplied to component manufacturers. This upstream segment is crucial for ensuring material quality, cost-effectiveness, and sustainable sourcing.

Further along the chain, the manufacturing phase involves specialized component producers who fabricate the intricate parts of roof rail systems, including the rails themselves, mounting brackets, end caps, and associated hardware. These components are then assembled into complete roof rail units, either by the original component manufacturers or by larger automotive suppliers. The downstream analysis primarily involves two distinct distribution channels. The first is the direct supply to Original Equipment Manufacturers (OEMs), where roof rail systems are integrated into new vehicle production lines. This channel demands stringent quality control, just-in-time delivery, and close collaboration between suppliers and vehicle manufacturers to ensure seamless integration and adherence to vehicle design specifications.

The second major downstream channel is the aftermarket, catering to consumers who purchase roof rails post-vehicle acquisition for enhancement or replacement. Distribution in the aftermarket is more diversified, involving a network of wholesalers, automotive parts retailers (both brick-and-mortar and online), specialized accessory stores, and direct-to-consumer sales. Direct sales to consumers might occur through e-commerce platforms or dedicated brand outlets, while indirect channels leverage third-party retailers for wider market reach. The effectiveness of the distribution channel directly impacts market penetration and consumer accessibility. Robust logistics and efficient inventory management are critical across both OEM and aftermarket channels to meet demand and maintain competitive pricing. Installation services, often provided by dealerships or aftermarket specialists, also form an important part of the overall value proposition in the downstream segment.

Automotive Roof Rail Market Potential Customers

The Automotive Roof Rail Market serves a diverse range of potential customers, each with unique needs and purchasing motivations. Primarily, the largest segment of end-users comprises automobile manufacturers, or Original Equipment Manufacturers (OEMs). These companies integrate roof rail systems directly into their new vehicle models, particularly SUVs, CUVs, and certain sedan or hatchback lines, as a standard or optional feature. For OEMs, roof rails represent a crucial element of vehicle utility, design aesthetics, and brand positioning, necessitating reliable, high-quality, and cost-effective supply from specialized manufacturers. Their demand is driven by vehicle production volumes, evolving design trends, and consumer preferences for versatile vehicle functionality.

Beyond the OEM segment, individual vehicle owners constitute a significant portion of the aftermarket customer base. These buyers typically seek to enhance the utility of their existing vehicles, whether for recreational purposes like carrying bicycles, skis, or camping gear, or for practical needs such as transporting luggage or bulky items. Their purchasing decisions are influenced by factors such as product durability, ease of installation, compatibility with their vehicle model, brand reputation, and aesthetic appeal. This segment often values modularity and customization options, allowing them to tailor their roof rail system to specific cargo requirements. The rise of outdoor adventure and travel trends further fuels demand from this consumer group, who view roof rails as essential accessories for an active lifestyle.

Additionally, commercial fleet operators and businesses that utilize vehicles for service, delivery, or specialized tasks also represent a niche but important customer segment. These customers require robust and reliable roof rail systems for transporting tools, equipment, or commercial cargo. Durability, load capacity, and compliance with commercial vehicle standards are paramount for this group. While a smaller volume segment, their demand can be consistent and often involves bulk purchases. Overall, the market caters to a broad spectrum, from large-scale automotive production to individual consumer upgrades, reflecting the fundamental utility and growing aesthetic importance of roof rail systems in modern vehicles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.45 Billion |

| Market Forecast in 2032 | $4.18 Billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Thule Group, Yakima Products Inc., Atera GmbH, Cruzber SA, Mont Blanc Group, Rhino-Rack, Whispbar (Prorack), F. H. Brundle, Rola (Cequent Performance Products), Bosal International, Magna International, Forvia (Faurecia), Webasto Group, Inalfa Roof Systems Group, Gestamp Automocion, Benteler International AG, Plastic Omnium, Kautex Textron, Minth Group, Toyota Boshoku Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Roof Rail Market Key Technology Landscape

The Automotive Roof Rail Market is continually evolving, driven by advancements in materials science, manufacturing processes, and design methodologies aimed at enhancing product performance, aesthetics, and sustainability. A significant technological trend involves the increasing adoption of lightweight materials. Aluminum alloys remain a dominant choice due to their excellent strength-to-weight ratio and corrosion resistance, with ongoing research focused on developing even lighter and stronger variants. The use of advanced composites, such as carbon fiber reinforced polymers (CFRP) and glass fiber reinforced plastics (GFRP), is also gaining traction, particularly for premium vehicles, offering superior strength and stiffness at reduced weight, contributing to improved fuel efficiency and lower emissions.

Manufacturing technologies play a crucial role in shaping the roof rail market. Processes like advanced extrusion for aluminum profiles allow for complex cross-sections and improved structural integrity. Precision injection molding is essential for producing intricate plastic components and end caps with tight tolerances and aesthetically pleasing finishes. Robotic welding and automated assembly lines are widely utilized to ensure consistent quality and high production volumes, minimizing human error and optimizing manufacturing costs. Surface treatment technologies, including anodizing for aluminum and advanced painting or powder coating for steel and plastic parts, are critical for enhancing durability, corrosion resistance, and achieving various aesthetic finishes that integrate seamlessly with vehicle designs.

Furthermore, the design and integration of roof rail systems are benefiting from sophisticated engineering tools. Computational Fluid Dynamics (CFD) is employed to optimize aerodynamic profiles, minimizing drag and wind noise, thereby contributing to better fuel economy and a quieter ride. Finite Element Analysis (FEA) ensures structural integrity and crashworthiness, verifying that roof rails can withstand required load capacities and contribute to vehicle safety standards. The future landscape also anticipates the integration of smart technologies, such as embedded sensors for load detection, or modular designs that allow for easy customization and removal, reflecting a shift towards more intelligent and user-centric automotive accessories. These technological innovations collectively aim to deliver roof rails that are not only functional but also contribute positively to overall vehicle performance, safety, and driver experience.

Regional Highlights

- North America: This region is a mature market for automotive roof rails, characterized by a high demand for SUVs, pickup trucks, and a strong culture of outdoor recreational activities. The aftermarket segment is particularly robust, driven by consumers seeking customization and enhanced utility. Innovations often focus on heavy-duty capabilities and modular designs.

- Europe: European market emphasizes aerodynamic efficiency, sleek design integration, and premium aesthetics, aligning with the region's focus on fuel efficiency and sophisticated vehicle designs. Demand for both factory-fitted and high-quality aftermarket solutions is steady, especially for family cars and crossover vehicles.

- Asia Pacific (APAC): APAC is the fastest-growing market, propelled by escalating vehicle production, increasing disposable incomes, and the rising popularity of SUVs and CUVs in emerging economies like China and India. Cost-effectiveness and functional utility are key drivers, alongside a growing demand for stylish and integrated designs.

- Latin America: This region exhibits steady growth in the automotive sector, with an increasing demand for utility vehicles that can handle diverse road conditions. The market for roof rails is expanding, driven by urbanization and the need for enhanced cargo solutions for both personal and commercial use.

- Middle East and Africa (MEA): The MEA region is a developing market with growth influenced by expanding automotive sales and infrastructure projects. Demand for robust and durable roof rail systems is emerging, particularly for vehicles used in varied terrains and for transporting goods, though the market is still relatively nascent compared to other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Roof Rail Market.- Thule Group

- Yakima Products Inc.

- Atera GmbH

- Cruzber SA

- Mont Blanc Group

- Rhino-Rack

- Whispbar (Prorack)

- F. H. Brundle

- Rola (Cequent Performance Products)

- Bosal International

- Magna International

- Forvia (Faurecia)

- Webasto Group

- Inalfa Roof Systems Group

- Gestamp Automocion

- Benteler International AG

- Plastic Omnium

- Kautex Textron (a Textron company)

- Minth Group

- Toyota Boshoku Corporation

Frequently Asked Questions

What are the primary drivers of growth in the Automotive Roof Rail Market?

The primary growth drivers are the increasing global sales of SUVs and CUVs, the rising consumer interest in outdoor recreational activities, and the growing demand for enhanced vehicle utility and cargo capacity.

Which materials are predominantly used in manufacturing automotive roof rails?

Aluminum and steel are the most common materials due to their strength and durability. Advanced plastics and composites are also increasingly used for lightweighting and design flexibility, especially in integrated systems.

How does AI impact the future of automotive roof rails?

AI is expected to influence generative design for optimal aerodynamics, predictive maintenance in manufacturing, advanced material discovery, and potentially the development of 'smart' roof rail systems with integrated sensors for enhanced functionality and safety.

What is the difference between OEM and aftermarket roof rails?

OEM roof rails are factory-installed components on new vehicles, designed specifically for that model. Aftermarket roof rails are purchased and installed by consumers post-purchase to add or upgrade functionality on their existing vehicles, offering more customization.

Which region holds the largest market share for automotive roof rails?

North America and Europe traditionally hold significant market shares due to high vehicle penetration and strong aftermarket demand. However, Asia Pacific is rapidly emerging as the fastest-growing region driven by its burgeoning automotive industry and rising consumer base.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager