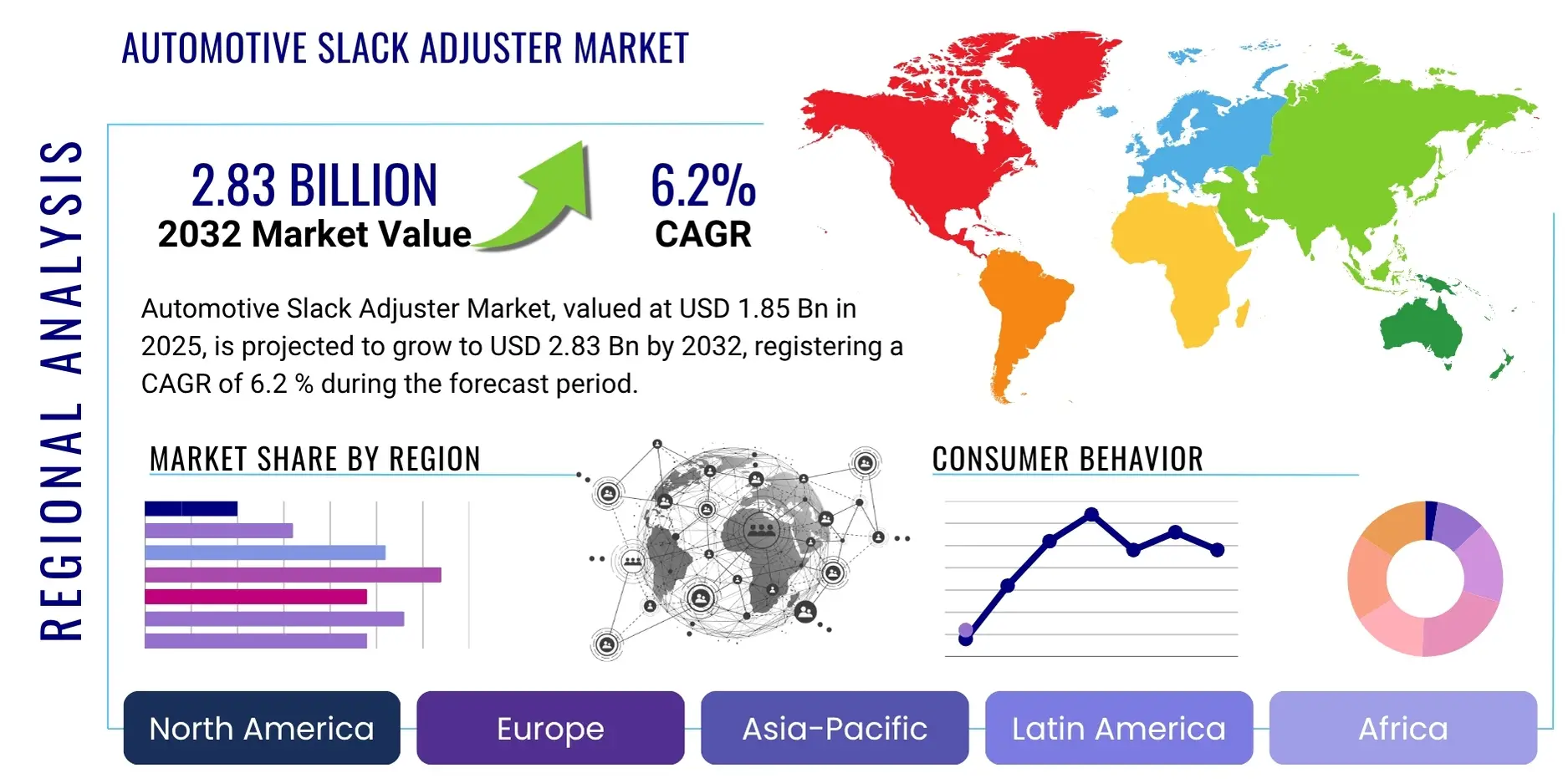

Automotive Slack Adjuster Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428338 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Automotive Slack Adjuster Market Size

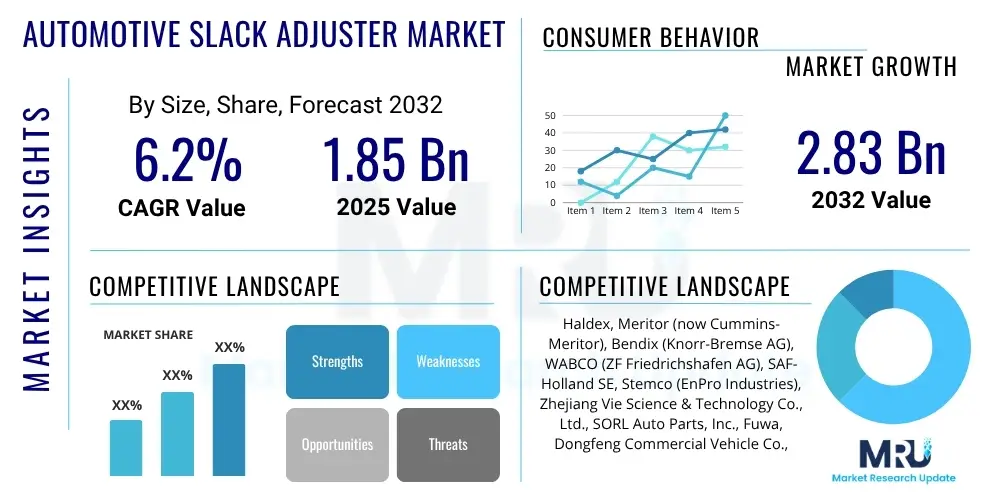

The Automotive Slack Adjuster Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 2.83 Billion by the end of the forecast period in 2032.

Automotive Slack Adjuster Market introduction

The automotive slack adjuster market represents a critical segment within the commercial vehicle braking system industry, driven by an imperative for safety, efficiency, and regulatory compliance. Slack adjusters are mechanical or automatic components in air brake systems that maintain the correct clearance between the brake shoes and the drum or disc, ensuring optimal braking performance. Historically, manual slack adjusters required periodic adjustments by mechanics, a time-consuming process prone to human error that could compromise vehicle safety. The evolution towards automatic slack adjusters has significantly enhanced operational safety and reduced maintenance demands across heavy-duty and medium-duty commercial vehicles, including trucks, buses, and trailers.

The primary function of an automotive slack adjuster is to compensate for brake lining wear, ensuring consistent brake stroke and reliable stopping power. This continuous, automatic adjustment eliminates the need for manual intervention, thereby improving fleet operational uptime and reducing labor costs associated with routine maintenance. Major applications for these devices are predominantly found in the commercial transport sector, which relies heavily on air brake systems for their robust and dependable stopping capabilities. The inherent benefits of automatic slack adjusters, such as enhanced vehicle safety, reduced operational costs, and improved brake system longevity, are key drivers propelling their adoption globally.

Key driving factors for market expansion include the stringent global safety regulations imposed on commercial vehicles, mandating the use of automatic slack adjusters to prevent brake-related accidents. Furthermore, the sustained growth in the commercial vehicle production, particularly in emerging economies, alongside an increasing emphasis on fleet efficiency and predictive maintenance, continues to bolster demand. As the transportation and logistics sectors expand, the necessity for reliable and high-performance braking systems becomes more pronounced, solidifying the slack adjuster's indispensable role in modern commercial vehicle architecture.

Automotive Slack Adjuster Market Executive Summary

The Automotive Slack Adjuster Market is undergoing a transformative period characterized by a confluence of technological advancements, evolving regulatory landscapes, and dynamic shifts in regional commercial vehicle production. Business trends indicate a pronounced shift towards automatic slack adjusters, which are becoming standard original equipment installations due to their superior safety profile and efficiency benefits over their manual counterparts. Manufacturers are increasingly focusing on developing robust, durable, and low-maintenance solutions, often incorporating advanced materials and improved sealing technologies to withstand harsh operating conditions, thereby extending product lifespan and reducing total cost of ownership for fleet operators. Furthermore, the integration potential with vehicle telematics and advanced driver-assistance systems (ADAS) is emerging as a significant area of innovation, hinting at a future where slack adjusters contribute to a more interconnected and intelligent braking ecosystem.

Regional trends reveal a diverse market landscape. Asia Pacific is poised for significant growth, driven by rapid industrialization, burgeoning logistics sectors, and increasing commercial vehicle parc in countries such as China and India. This growth is further amplified by rising safety awareness and the gradual implementation of stricter braking system regulations mirroring those in developed economies. Conversely, established markets in North America and Europe demonstrate steady demand, primarily fueled by replacement cycles, ongoing fleet modernization initiatives, and the continuous reinforcement of safety standards, particularly for heavy-duty applications. These regions also lead in the adoption of premium, technology-integrated solutions, setting benchmarks for performance and reliability that often influence global market expectations.

Segment trends underscore the dominance and accelerated growth of the automatic slack adjuster segment across all vehicle types. Within vehicle types, heavy-duty vehicles constitute the largest segment due attributing to their extensive use in long-haul logistics and construction, where braking reliability is paramount. The aftermarket segment is also substantial, driven by the need for maintenance and replacement parts for the vast existing fleet of commercial vehicles globally. As commercial vehicle fleets continue to age and operational demands intensify, the aftermarket will continue to provide lucrative opportunities for both OEM suppliers and specialized aftermarket providers. The focus across all segments remains on enhancing safety, improving operational uptime, and reducing the overall lifecycle costs associated with braking system maintenance.

AI Impact Analysis on Automotive Slack Adjuster Market

The integration of Artificial Intelligence (AI) into the automotive slack adjuster market is an area of significant user inquiry, with common questions revolving around how AI can enhance existing functionalities, improve predictive maintenance, and contribute to the broader ecosystem of smart commercial vehicles. Users are particularly keen to understand AI's role in shifting slack adjusters from purely mechanical components to intelligent, data-driven systems capable of self-diagnosis and optimized operation. Key themes and concerns include the potential for AI to prevent premature component failure, reduce unscheduled downtime, and provide real-time insights into brake system health, thereby addressing long-standing challenges related to operational efficiency and safety in commercial fleets.

The expectations surrounding AI's influence extend to its capacity for data analytics, enabling continuous monitoring of brake performance and wear patterns. This real-time data collection, when processed by AI algorithms, can predict when a slack adjuster or an associated brake component might require maintenance or replacement, moving beyond traditional mileage-based schedules to condition-based maintenance. Such a paradigm shift promises not only cost savings through optimized parts replacement but also significant improvements in vehicle uptime and overall operational safety. Furthermore, as autonomous commercial vehicles become a reality, AI-powered slack adjusters are expected to play a crucial role in ensuring precision braking and seamless integration with complex vehicle control systems, adapting dynamically to various driving conditions and payload variations.

In essence, AI is poised to revolutionize the automotive slack adjuster market by introducing an unprecedented level of intelligence and autonomy. This technological advancement addresses critical demands from fleet operators for enhanced reliability, predictive capabilities, and reduced manual intervention. The integration of AI signifies a strategic move towards creating more adaptive, resilient, and safer braking systems that are integral to the future of commercial transportation, ensuring that vehicles operate at peak performance while minimizing risks and operational expenses.

- Predictive maintenance capabilities: AI algorithms analyze real-time sensor data from slack adjusters to anticipate wear and predict potential failures, optimizing maintenance schedules and reducing unscheduled downtime for commercial vehicles.

- Real-time diagnostics and performance monitoring: AI enables continuous assessment of slack adjuster functionality, providing immediate alerts for deviations from optimal performance and assisting in rapid troubleshooting.

- Integration with Advanced Driver-Assistance Systems (ADAS) and autonomous driving: AI-enhanced slack adjusters can communicate with vehicle control systems to provide precise and adaptive braking responses crucial for autonomous operation and improved safety.

- Optimized braking performance: AI can fine-tune slack adjuster operations based on driving conditions, vehicle load, and road surface, ensuring consistent and effective braking power under diverse scenarios.

- Enhanced safety and reliability: By reducing the risk of brake-related malfunctions through proactive adjustments and diagnostics, AI contributes significantly to overall vehicle safety and operational dependability.

- Data collection and insights for product improvement: AI systems gather extensive data on slack adjuster usage and performance, offering valuable insights that can inform future product design, material selection, and manufacturing processes.

- Reduced operational costs: Through improved efficiency, reduced manual labor for inspections and adjustments, and extended component lifespan, AI integration leads to substantial savings for fleet operators.

DRO & Impact Forces Of Automotive Slack Adjuster Market

The Automotive Slack Adjuster Market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all contributing to various impact forces shaping its trajectory. A primary driver is the global enforcement of stringent vehicle safety regulations, such as FMVSS 121 in North America and ECE R13 in Europe, which mandate the inclusion of automatic slack adjusters in new commercial vehicles. This regulatory push directly addresses safety concerns related to brake system efficacy and maintenance, compelling manufacturers and fleet operators worldwide to adopt advanced solutions. Furthermore, the robust growth in commercial vehicle production and sales, particularly fueled by expanding logistics, construction, and public transportation sectors in emerging economies, consistently drives demand for both OEM installations and aftermarket replacements, thereby sustaining market momentum. The increasing emphasis on operational efficiency, fuel economy, and reduction in vehicle downtime also compels fleet managers to invest in reliable braking components that minimize manual adjustments and maintenance costs, presenting a compelling economic driver.

Despite these significant drivers, the market faces several restraining factors. The comparatively higher initial cost of automatic slack adjusters compared to their manual counterparts can deter some fleet operators, especially in price-sensitive markets or for older vehicle models where cost-benefit analysis favors lower upfront investment. This is exacerbated by the presence of a substantial aftermarket for manual slack adjusters, which, despite offering lower performance and requiring more maintenance, remains a viable option for certain segments. Economic downturns or geopolitical instabilities can directly impact commercial vehicle production and logistics activities, subsequently dampening demand for slack adjusters. Moreover, the technical complexity involved in manufacturing high-precision automatic slack adjusters, coupled with the potential for counterfeit products to infiltrate the aftermarket, poses challenges regarding product quality, market reputation, and consumer trust.

Opportunities for growth are abundant and strategically important for market players. The burgeoning electric commercial vehicle segment presents a new avenue for specialized slack adjuster designs that integrate seamlessly with evolving electric braking systems, ensuring optimal performance for vehicles with different power train dynamics. Expansion into untapped or under-regulated emerging markets offers substantial potential as these regions modernize their commercial fleets and adopt global safety standards. Collaboration with OEMs for the development of integrated, smart braking solutions incorporating sensor technology and predictive maintenance capabilities represents a high-value opportunity. The continuous push for lighter, more durable, and corrosion-resistant materials also provides avenues for innovation, enabling manufacturers to offer products with enhanced longevity and reduced environmental impact, thereby aligning with broader sustainability goals within the automotive industry. These opportunities, when strategically pursued, can effectively mitigate restraints and harness market drivers for sustained growth.

Segmentation Analysis

The Automotive Slack Adjuster Market is comprehensively segmented to provide granular insights into its diverse components, aiding in targeted market strategies and understanding specific demand dynamics. The primary segmentation criteria include the type of slack adjuster, the vehicle type it is applied to, and the sales channel through which it reaches the end-user. This structured approach helps in discerning the prevalent technologies, identifying key end-user groups, and understanding the distribution landscape, thereby offering a holistic view of the market’s operational framework. The dominance of automatic slack adjusters reflects a broader industry trend towards automation and enhanced safety standards, driven by both regulatory mandates and the desire for improved operational efficiency.

The segmentation by type clearly distinguishes between manual and automatic slack adjusters, with the latter commanding a significant and growing share due to its inherent advantages in safety, reduced maintenance, and consistent performance. Vehicle type segmentation typically covers heavy-duty, medium-duty, and light-duty commercial vehicles, each presenting unique requirements and market volumes for slack adjusters based on their braking system configurations and operational demands. Heavy-duty vehicles, due to their size and frequent use in demanding applications, represent the largest segment, consistently driving innovation and adoption of advanced slack adjuster technologies. The sales channel segmentation, encompassing Original Equipment Manufacturer (OEM) and Aftermarket, delineates the primary routes through which slack adjusters are procured and distributed, highlighting the balance between new vehicle installations and ongoing maintenance and replacement needs.

Understanding these segmentations is crucial for manufacturers to tailor their product offerings, marketing efforts, and distribution strategies effectively. The growth trajectory within each segment is influenced by varying factors, such as new vehicle sales, fleet age, regulatory updates, and economic conditions. For instance, while OEM sales are directly tied to commercial vehicle production volumes, the aftermarket flourishes with the expansion of the existing vehicle parc and the increasing focus on preventive maintenance. The continuous evolution of these segments underscores the dynamic nature of the automotive slack adjuster market, requiring constant monitoring and adaptation by market participants to capitalize on emerging trends and opportunities across the value chain.

- By Type:

- Manual Slack Adjuster

- Automatic Slack Adjuster

- By Vehicle Type:

- Heavy Duty Vehicles

- Medium Duty Vehicles

- Light Duty Vehicles

- By Sales Channel:

- Original Equipment Manufacturer (OEM)

- Aftermarket

Value Chain Analysis For Automotive Slack Adjuster Market

The value chain for the Automotive Slack Adjuster Market is characterized by a sequential flow of activities, starting from raw material sourcing and culminating in the end-use application and post-sales support. The upstream segment of the value chain involves the procurement of essential raw materials and primary components, which typically include high-grade steel, aluminum alloys, various plastics, and specialized elastomers for seals and gaskets. Key players in this stage are metallurgical companies, plastics manufacturers, and specialized component suppliers who provide precision-machined parts, springs, gears, and housing units. The quality and consistency of these raw materials are paramount, as they directly impact the durability, reliability, and performance of the final slack adjuster product, especially under the rigorous operating conditions of commercial vehicles. Relationships with these upstream suppliers are often long-term, built on trust and a shared commitment to quality control and innovation.

Moving downstream, the value chain encompasses the manufacturing, assembly, and distribution of the finished slack adjusters. Manufacturers transform raw materials and components into final products through sophisticated machining, heat treatment, and assembly processes, often employing advanced robotics and quality assurance protocols to ensure precision and compliance with stringent industry standards. Once manufactured, these products are distributed through two primary channels: directly to Original Equipment Manufacturers (OEMs) for integration into new commercial vehicles, or through an extensive aftermarket network. The direct channel to OEMs involves close collaboration with vehicle manufacturers from the design phase to production, ensuring seamless integration and optimal performance. This segment demands high volumes, consistent quality, and often custom-engineered solutions tailored to specific vehicle platforms, making long-term contracts and strategic partnerships crucial for suppliers.

The indirect channel, representing the aftermarket, is equally vital for market sustainment and growth. This channel involves a complex network of independent distributors, wholesalers, retailers, and service centers that supply slack adjusters for replacement, repair, and upgrade purposes to existing fleets, independent workshops, and individual vehicle owners. This segment is characterized by a broader product range, catering to various vehicle makes and models, and often involves competitive pricing strategies. Effective logistics and inventory management are critical for aftermarket success to ensure product availability and timely delivery across geographically dispersed markets. Post-sales services, including technical support, warranty provisions, and training for mechanics, further add value at this stage, reinforcing brand loyalty and ensuring proper installation and maintenance of the slack adjusters throughout their operational lifespan. Both direct and indirect distribution channels are essential for comprehensive market penetration and fulfilling diverse customer needs.

Automotive Slack Adjuster Market Potential Customers

The Automotive Slack Adjuster Market primarily serves a broad spectrum of commercial vehicle stakeholders who are either directly involved in the manufacturing of such vehicles or are responsible for their operation and maintenance. The largest and most influential customer segment comprises Original Equipment Manufacturers (OEMs) of heavy-duty and medium-duty commercial vehicles, including prominent truck, bus, and trailer manufacturers globally. These OEMs integrate slack adjusters as essential components into their braking systems during vehicle assembly, making purchasing decisions based on performance, reliability, cost-effectiveness, and compliance with national and international safety standards. Their demand is directly correlated with commercial vehicle production volumes and their continuous efforts to enhance vehicle safety and performance through advanced component integration.

Beyond the OEM segment, a substantial portion of the market caters to the extensive network of fleet owners and operators. These include large logistics and freight companies, public transportation authorities, construction firms, waste management services, and other enterprises that operate commercial vehicle fleets for various purposes. For these end-users, the purchase of slack adjusters is driven by the need for maintenance, repair, and replacement of existing units to ensure continuous operational safety and uptime. Their purchasing decisions are heavily influenced by product durability, ease of maintenance, availability of spare parts, and the potential for reduced total cost of ownership over the lifespan of their vehicles. They often seek automatic slack adjusters to minimize manual adjustments, thereby reducing labor costs and improving overall fleet efficiency.

Furthermore, independent workshops, garages, and specialized automotive service centers constitute another significant customer base. These entities procure slack adjusters to service the diverse commercial vehicles brought in by individual owners or smaller fleet operators for maintenance and repair. Their demand is typically for a wide range of products compatible with various vehicle models and ages, often balancing quality with affordability. Additionally, government agencies and military organizations, operating their own fleets of heavy-duty vehicles, also represent a segment of potential customers, often prioritizing robust performance and long-term reliability under extreme conditions. The increasing demand for improved operational efficiency and adherence to stringent safety regulations across all these segments collectively drives the procurement of automotive slack adjusters.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 2.83 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Haldex, Meritor (now Cummins-Meritor), Bendix (Knorr-Bremse AG), WABCO (ZF Friedrichshafen AG), SAF-Holland SE, Stemco (EnPro Industries), Zhejiang Vie Science & Technology Co., Ltd., SORL Auto Parts, Inc., Fuwa, Dongfeng Commercial Vehicle Co., Ltd., Hunan Fangsheng Auto Parts Co., Ltd., Jiangsu Huaxin Auto Parts Co., Ltd., Zhejiang Jingu Co., Ltd., BPW Bergische Achsen KG, PACCAR Inc., JOST Werke AG, Continental AG, Hendrickson International, AxleTech International, ArvinMeritor Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Automotive Slack Adjuster Market Key Technology Landscape

The Automotive Slack Adjuster Market is continuously evolving, driven by advancements in materials science, manufacturing processes, and sensor integration, all aimed at enhancing the performance, durability, and intelligence of these critical braking components. The fundamental technology underpinning automatic slack adjusters involves intricate gear and pawl mechanisms that precisely adjust brake shoe clearance. Recent technological strides focus on improving the precision and longevity of these internal mechanisms, utilizing advanced metallurgy for gears and high-strength alloys for housing, which contributes to greater resistance against wear, corrosion, and extreme operating temperatures. This precision manufacturing ensures consistent and reliable adjustment over extended periods, reducing the frequency of maintenance and prolonging the service life of the entire brake system.

Beyond mechanical enhancements, the key technology landscape is increasingly defined by the integration of smart functionalities. This includes the incorporation of sensor technology to monitor slack adjuster position, brake stroke, and even environmental factors, providing real-time data on brake system health. These sensors often interface with the vehicle's electronic control unit (ECU) or telematics systems, enabling advanced diagnostics, predictive maintenance alerts, and seamless communication with other vehicle systems like Advanced Driver-Assistance Systems (ADAS). Such integration allows for a more proactive approach to fleet management, where potential issues can be identified and addressed before they lead to critical failures or unscheduled downtime, significantly improving operational efficiency and safety across commercial fleets.

Furthermore, the drive for lightweighting in commercial vehicles, aimed at improving fuel efficiency and increasing payload capacity, has spurred the adoption of composite materials and innovative design approaches in slack adjuster manufacturing. While traditional materials like steel remain prevalent, research and development are exploring lighter, yet equally durable, alternatives without compromising structural integrity or performance. Improved sealing mechanisms are also a critical technological focus, designed to protect internal components from dirt, moisture, and corrosive elements, which are common challenges in heavy-duty commercial operations. These combined technological advancements are pushing the boundaries of what slack adjusters can achieve, transforming them into more resilient, intelligent, and integral parts of modern commercial vehicle braking solutions.

Regional Highlights

- North America: A mature market characterized by stringent safety regulations and a high adoption rate of automatic slack adjusters in heavy-duty commercial vehicles. The region exhibits a strong replacement market and a focus on advanced, durable solutions due to high operational demands and a well-established transportation infrastructure.

- Europe: Driven by strict environmental and safety directives (e.g., ECE R13), Europe has a high penetration of automatic slack adjusters. The region emphasizes technological sophistication, quality, and the integration of braking systems with vehicle dynamics control and telematics for enhanced safety and efficiency.

- Asia Pacific (APAC): The fastest-growing region in the automotive slack adjuster market, propelled by rapidly expanding commercial vehicle production in countries like China and India, coupled with significant infrastructure development. Increasing awareness of vehicle safety and the gradual implementation of stricter regulations are key growth factors.

- Latin America: An emerging market with growing demand for commercial vehicles, fueled by economic development and increased trade activities. The adoption of automatic slack adjusters is on an upward trend, though price sensitivity and the prevalence of older fleets still contribute to a significant manual adjuster aftermarket.

- Middle East and Africa (MEA): This region is experiencing steady growth, primarily driven by investments in infrastructure projects, urbanization, and the expansion of logistics sectors. Demand for reliable and efficient commercial vehicles is rising, leading to a gradual shift towards automatic slack adjusters and an increasing focus on vehicle safety standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Automotive Slack Adjuster Market.- Haldex

- Meritor (now Cummins-Meritor)

- Bendix (Knorr-Bremse AG)

- WABCO (ZF Friedrichshafen AG)

- SAF-Holland SE

- Stemco (EnPro Industries)

- Zhejiang Vie Science & Technology Co., Ltd.

- SORL Auto Parts, Inc.

- Fuwa

- Dongfeng Commercial Vehicle Co., Ltd.

- Hunan Fangsheng Auto Parts Co., Ltd.

- Jiangsu Huaxin Auto Parts Co., Ltd.

- Zhejiang Jingu Co., Ltd.

- BPW Bergische Achsen KG

- PACCAR Inc.

- JOST Werke AG

- Continental AG

- Hendrickson International

- AxleTech International

- ArvinMeritor Inc.

Frequently Asked Questions

Analyze common user questions about the Automotive Slack Adjuster market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary benefits of automatic slack adjusters over manual ones?

Automatic slack adjusters offer superior benefits, including consistent braking performance by continuously maintaining optimal clearance, significantly enhanced vehicle safety by reducing the risk of brake failure due to improper adjustment, and substantial reductions in maintenance time and costs. They eliminate the need for manual adjustments, leading to improved fleet operational uptime and extended lifespan of brake components. This automation ensures compliance with stringent safety regulations and contributes to a lower total cost of ownership for commercial vehicles.

How do global safety regulations impact the demand for automotive slack adjusters?

Global safety regulations, such as FMVSS 121 in North America and ECE R13 in Europe, play a pivotal role in driving the demand for automatic slack adjusters. These regulations mandate their installation in new commercial vehicles to ensure superior braking performance and prevent accidents caused by poorly adjusted brakes. The continuous tightening and broader enforcement of these safety standards worldwide compel vehicle manufacturers and fleet operators to adopt automatic slack adjusters, thereby acting as a powerful growth catalyst for the market.

What role does AI integration play in the future of automotive slack adjusters?

AI integration is set to transform the future of automotive slack adjusters by introducing capabilities such as predictive maintenance, real-time diagnostics, and optimized braking performance. AI algorithms can analyze sensor data to anticipate wear and potential failures, allowing for proactive maintenance and reducing unscheduled downtime. Furthermore, AI-enhanced slack adjusters can communicate with ADAS and autonomous driving systems, providing precise and adaptive braking crucial for the next generation of intelligent commercial vehicles. This will lead to safer, more efficient, and more reliable braking systems.

Which geographical regions are leading the growth in the slack adjuster market, and why?

The Asia Pacific region, particularly countries like China and India, is leading the growth in the automotive slack adjuster market. This surge is primarily attributed to rapid industrialization, robust growth in commercial vehicle production, extensive infrastructure development, and increasing governmental focus on vehicle safety standards. North America and Europe, while mature markets, continue to demonstrate steady demand driven by replacement cycles, fleet modernization, and continuous adherence to high safety and performance benchmarks for commercial vehicles.

What are the key technological advancements shaping the automotive slack adjuster market?

Key technological advancements include the use of advanced metallurgy and precision manufacturing for enhanced durability and wear resistance of internal mechanisms. The integration of sensor technology for real-time monitoring of brake stroke and performance is also crucial, enabling predictive maintenance and advanced diagnostics. Additionally, the development of lightweight materials like composites aims to improve fuel efficiency, while improved sealing mechanisms enhance product longevity. These innovations collectively lead to more reliable, efficient, and intelligent braking systems for commercial vehicles.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager