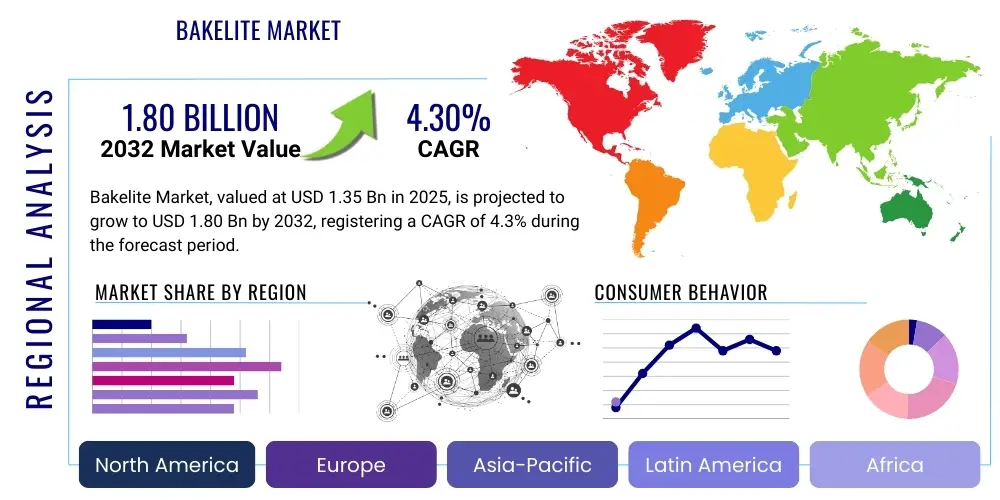

Bakelite Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427762 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Bakelite Market Size

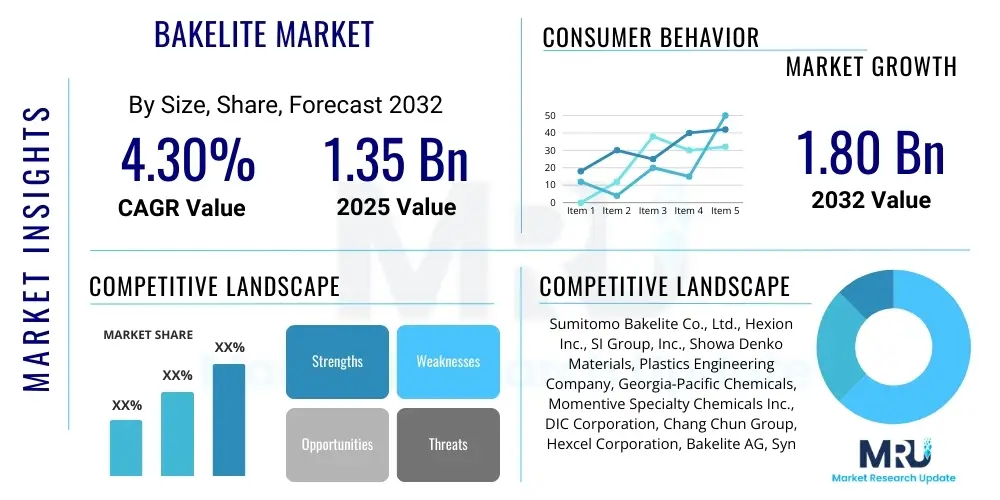

The Bakelite Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.3% between 2025 and 2032. The market is estimated at USD 1.35 billion in 2025 and is projected to reach USD 1.80 billion by the end of the forecast period in 2032.

Bakelite Market introduction

The Bakelite market, rooted in one of the earliest synthetic plastics, continues to command relevance across a diverse range of industrial and specialized applications, despite the proliferation of modern polymers. Bakelite, formally known as polyoxybenzylmethylenglycolanhydride, is a thermosetting phenol-formaldehyde resin, recognized for its exceptional thermal stability, electrical insulation properties, and chemical resistance. This unique combination of attributes positions it as a material of choice in environments demanding high performance under challenging conditions. Its inherent rigidity, coupled with impressive mechanical strength, ensures durability and reliability in critical components. The market encompasses a variety of product forms, including molding compounds, laminating resins, and varnishes, each tailored for specific industrial processes and end-use requirements, from intricate electronic parts to robust automotive components and industrial equipment.

The primary applications of Bakelite are predominantly found in sectors where its superior properties are indispensable. These include the electrical and electronics industry, where it is utilized for switches, circuit breakers, and insulation due to its excellent dielectric strength and non-conductivity. In the automotive sector, Bakelite is valued for brake linings, clutch plates, and various electrical system components that require high heat resistance and mechanical integrity. Industrial machinery and equipment also leverage Bakelite for gears, bearings, and structural components designed to withstand harsh operating conditions. Furthermore, its historical significance and unique aesthetic appeal continue to drive demand in niche markets such as vintage restoration, collectible items, and high-end consumer goods, where its characteristic look and feel are highly sought after. Key driving factors for the Bakelite market include the ongoing demand for durable and heat-resistant materials in core manufacturing sectors, the need for reliable electrical insulation in expanding infrastructure, and the continuous innovation in resin formulations to meet stricter performance and environmental standards. The ability of Bakelite to offer a cost-effective solution for specific high-performance requirements further underpins its market stability and projected growth.

Bakelite Market Executive Summary

The Bakelite market is characterized by a blend of established industrial demand and emerging niche opportunities, reflecting a strategic adaptation to the evolving materials landscape. Business trends indicate a focus on optimizing production processes for efficiency and sustainability, driven by increasing regulatory scrutiny and a global emphasis on environmentally responsible manufacturing. Companies are investing in research and development to explore new applications, particularly in advanced composites where Bakelite’s thermosetting properties can enhance structural integrity and thermal performance. There is also a growing interest in developing bio-based or formaldehyde-free Bakelite alternatives to address environmental concerns associated with traditional formulations, positioning the market for incremental innovation rather than radical disruption. Supply chain resilience, raw material price volatility, and geopolitical factors continue to influence operational strategies, compelling market participants to diversify sourcing and production capabilities to mitigate risks and ensure consistent supply.

Regional trends highlight distinct growth patterns and market dynamics. Asia-Pacific stands as the dominant region, fueled by robust manufacturing bases in electronics, automotive, and industrial machinery, particularly in countries like China, India, and South Korea. Rapid industrialization and urbanization in these economies necessitate reliable and cost-effective materials like Bakelite for essential infrastructure and consumer goods production. North America and Europe, while representing mature markets, demonstrate steady demand, primarily driven by specialized, high-performance applications in aerospace, defense, and high-precision electrical systems, as well as the growing retro and antique restoration segments. Regulatory frameworks concerning chemical emissions and worker safety are particularly stringent in these regions, influencing product development towards safer and more sustainable Bakelite formulations. Segment trends show the electrical and electronics sector maintaining its largest share due to Bakelite’s unparalleled insulation capabilities. The automotive segment is experiencing consistent growth, propelled by the increasing complexity of vehicle electrical systems and the enduring need for heat-resistant components. Industrial applications, encompassing machinery, tools, and construction, also contribute significantly, benefiting from Bakelite’s durability and resistance to harsh operating conditions. The market also observes an expanding, albeit smaller, segment dedicated to consumer goods and artistic applications, where Bakelites unique aesthetic and historical value are key selling propositions.

AI Impact Analysis on Bakelite Market

The integration of Artificial Intelligence (AI) presents a transformative paradigm for the Bakelite market, addressing long-standing challenges in material science, manufacturing efficiency, and supply chain optimization. Common user questions frequently revolve around how AI can enhance the inherent properties of Bakelite, streamline its production, and mitigate its environmental footprint. Users are keen to understand AIs role in the discovery of novel Bakelite formulations, particularly those with improved sustainability profiles or enhanced performance characteristics to compete with advanced modern polymers. Furthermore, there is significant interest in AIs capacity to optimize complex manufacturing processes, from resin synthesis to molding, predicting potential defects, and ensuring consistent product quality. The overarching theme of these inquiries is the expectation that AI will unlock new levels of precision, efficiency, and innovation, enabling Bakelite to maintain and even expand its relevance in a highly competitive materials landscape while navigating environmental and operational complexities.

AIs influence is poised to revolutionize several critical facets of the Bakelite value chain. In material research and development, AI algorithms can analyze vast datasets of chemical structures and properties, accelerating the identification of optimal phenol-formaldehyde ratios, novel additives, or alternative monomers to create Bakelite variants with tailored characteristics such as increased flexibility, reduced cure times, or enhanced fire retardancy. This predictive modeling minimizes costly and time-consuming experimental trials. In manufacturing, AI-powered systems can enable predictive maintenance for molding equipment, reducing downtime and operational costs by forecasting potential failures before they occur. Real-time quality control, managed by AI vision systems, can detect subtle defects in Bakelite products, ensuring consistency and minimizing waste. Moreover, AI can optimize curing cycles and processing parameters, leading to energy savings and improved material performance. Supply chain management benefits from AI by forecasting demand more accurately, optimizing inventory levels, and identifying potential disruptions, thereby enhancing resilience and responsiveness for raw material sourcing and finished product distribution. The application of AI also extends to life cycle assessment, helping manufacturers identify areas for environmental improvement, from raw material extraction to end-of-life considerations, fostering a more sustainable approach to Bakelite production.

- AI-driven material innovation for enhanced Bakelite properties and sustainable formulations.

- Predictive maintenance and process optimization in Bakelite manufacturing, reducing operational costs and downtime.

- Real-time quality control using AI vision systems to ensure product consistency and minimize defects.

- Optimized supply chain management for Bakelite, improving demand forecasting and inventory efficiency.

- AI-assisted environmental impact assessment and carbon footprint reduction strategies for Bakelite production.

DRO & Impact Forces Of Bakelite Market

The Bakelite market is influenced by a dynamic interplay of drivers, restraints, opportunities, and external impact forces that collectively shape its trajectory and competitive landscape. Key drivers for market growth stem from Bakelites inherent and superior material properties, particularly its exceptional heat resistance, electrical insulation capabilities, and mechanical strength, which remain critical for demanding applications in the electrical, electronics, and automotive industries. The increasing global demand for reliable and durable components in power transmission, industrial machinery, and transportation systems continues to underpin Bakelites market presence. Furthermore, its cost-effectiveness compared to certain high-performance engineering plastics in specific applications, coupled with its historical appeal in vintage and niche markets, adds to its sustained demand. The growing complexity of electronic devices and the imperative for robust insulating materials in advanced electrical systems also serve as significant market accelerators. However, the market faces notable restraints, including intense competition from a wide array of modern thermoplastic and thermosetting polymers that offer diverse property profiles, sometimes at lower processing costs or with greater design flexibility. Environmental concerns, primarily related to the use of formaldehyde in its production and the thermoset nature of Bakelite which makes it non-recyclable in traditional methods, pose significant challenges, driving regulatory pressures and shifting consumer preferences towards more sustainable alternatives. Processing limitations, such as the brittle nature of some Bakelite formulations and the relatively slower curing cycles compared to thermoplastics, also act as hindrances to broader adoption.

Despite these restraints, significant opportunities exist for Bakelite market expansion and innovation. The development of advanced Bakelite composites, integrating fillers and reinforcements, can enhance its mechanical properties, opening doors to new high-performance applications in aerospace, defense, and specialized industrial sectors. Research into bio-based precursors and formaldehyde-free resins offers a promising avenue for addressing environmental concerns and improving Bakelites sustainability profile, potentially attracting new environmentally conscious end-users. The expanding market for electrical vehicle components and charging infrastructure also presents a substantial opportunity, given Bakelites excellent dielectric properties and thermal management capabilities required for these systems. Niche applications, such as high-temperature resistant coatings and specialty adhesives, also provide avenues for growth. External impact forces play a crucial role in shaping the market. Technological advancements in polymer science and manufacturing processes influence material development and production efficiency, potentially mitigating some of Bakelites traditional processing challenges. Regulatory changes related to chemical usage, emissions, and waste management directly affect production costs and market access, necessitating continuous adaptation and compliance. Fluctuations in the prices and availability of key raw materials, such as phenol and formaldehyde, can significantly impact manufacturing costs and profitability. Moreover, evolving consumer preferences, driven by sustainability consciousness and the demand for lighter, more versatile materials, compel Bakelite manufacturers to innovate and differentiate their offerings, ensuring the material remains competitive and relevant in an ever-changing industrial landscape.

Segmentation Analysis

The Bakelite market is systematically segmented to reflect the diverse applications, forms, and end-use industries that utilize this versatile thermosetting polymer, enabling a granular understanding of market dynamics and targeted strategic development. This comprehensive segmentation allows market participants to identify specific growth areas, assess competitive landscapes within distinct niches, and tailor product offerings to meet the precise requirements of various industrial and commercial users. The primary basis for segmentation typically includes product type, application area, and the end-use industry, each revealing unique market characteristics and growth trajectories. Understanding these segments is crucial for stakeholders to refine their marketing strategies, optimize resource allocation, and capitalize on emerging trends within specific market verticals. For instance, the demand drivers and competitive factors for Bakelite used in electrical insulation differ significantly from those in the automotive sector or for decorative consumer goods.

Further analysis of these segments highlights the critical role of Bakelite’s material properties in driving market demand. Within product types, Bakelite is primarily categorized into molding compounds, laminating resins, and varnishes. Molding compounds, often supplied as powders or pellets, are extensively used for compression or injection molding of intricate parts requiring high thermal and electrical insulation. Laminating resins serve as binders for creating robust, heat-resistant, and electrically insulating laminates, essential in printed circuit boards and industrial applications. Varnishes provide protective coatings for electrical windings and components, enhancing their durability and resistance to environmental factors. Application-wise, the electrical and electronics segment remains the largest consumer, leveraging Bakelite’s dielectric strength for switches, connectors, circuit breakers, and various insulating components. The automotive sector utilizes Bakelite for brake components, clutch facings, and under-the-hood electrical parts due to its heat resistance. Industrial applications encompass the manufacturing of gears, bushings, chemical-resistant linings, and abrasive binders. The consumer goods segment, though smaller, values Bakelite for cookware handles, kitchenware, and artistic items, often capitalizing on its classic aesthetic. This multi-faceted segmentation underscores Bakelite’s adaptability and its enduring importance across a broad spectrum of industries.

- By Product Type: Molding Compounds, Laminating Resins, Varnishes, Others (adhesives, coatings).

- By Application: Electrical and Electronics, Automotive, Industrial, Consumer Goods, Others (aerospace, medical).

- By End-Use Industry: Electrical Manufacturing, Automotive Manufacturing, Industrial Machinery, Construction, Household Appliances, Specialty/Niche Markets.

Bakelite Market Value Chain Analysis

The Bakelite markets value chain is a multi-tiered structure encompassing various stages, from the sourcing of fundamental raw materials to the distribution of finished Bakelite products, highlighting the interconnectedness of specialized operations. The upstream segment of the value chain is dominated by the chemical industry, which provides the primary raw materials: phenol and formaldehyde. These petrochemical derivatives are critical precursors, and their availability, quality, and pricing significantly influence the entire Bakelite production cost and market dynamics. Manufacturers of these basic chemicals often operate on a global scale, supplying Bakelite producers who then synthesize the phenol-formaldehyde resin. This stage also includes the sourcing of various additives, fillers, and catalysts that are crucial for modifying Bakelite properties, such as flame retardants, reinforcing fibers, and curing agents, ensuring the final product meets specific performance requirements. Efficient procurement and stable supply relationships with these upstream suppliers are paramount for maintaining consistent production and competitive pricing within the Bakelite industry, directly impacting the profitability and market position of resin manufacturers.

Moving downstream, the value chain extends to Bakelite resin producers who formulate the base resin and convert it into various forms, such as molding compounds, liquid resins, or varnishes. These producers often customize formulations based on specific client requirements for applications like compression molding, injection molding, or lamination. Further down, the value chain involves fabricators and component manufacturers who process these Bakelite forms into finished products. This includes companies specializing in electrical components, automotive parts, industrial machinery, and consumer goods. These manufacturers employ sophisticated molding, machining, and assembly processes to create the final Bakelite products that are ready for end-use. The distribution channel for Bakelite products is diverse, incorporating both direct and indirect sales strategies. Direct sales are common for large industrial clients or specialized applications where technical consultation and customized solutions are required, fostering strong direct relationships between manufacturers and end-users. Indirect distribution, through a network of distributors, wholesalers, and specialized chemical or plastics suppliers, broadens market reach, particularly for smaller orders or standard Bakelite products, providing wider accessibility to a diverse customer base across various regions. This multifaceted distribution approach ensures that Bakelite products reach a wide array of end-users efficiently, adapting to the varying scales and technical demands of the market.

Bakelite Market Potential Customers

The Bakelite market caters to a diverse spectrum of end-users and buyers, each driven by specific performance requirements, application needs, and economic considerations. At its core, potential customers are organizations and entities that require materials possessing high thermal stability, exceptional electrical insulation, chemical resistance, and robust mechanical properties, often for demanding industrial environments. The largest segment of end-users includes manufacturers within the electrical and electronics industry, ranging from producers of household appliances to sophisticated industrial switchgear, circuit breakers, terminal blocks, lamp holders, and connectors. These buyers prioritize Bakelite for its superior dielectric strength, arc resistance, and ability to withstand high temperatures without degradation, ensuring safety and reliability in electrical systems. Similarly, the automotive sector represents a significant customer base, encompassing original equipment manufacturers (OEMs) and aftermarket suppliers who utilize Bakelite for critical components such as brake linings, clutch plates, distributor caps, and various electrical system parts, where its heat resistance and mechanical integrity are indispensable for vehicle performance and safety.

Beyond these primary sectors, the Bakelite market extends to a variety of specialized industrial applications and niche markets. Manufacturers of industrial machinery and equipment, including those producing pumps, valves, gears, and bearings, leverage Bakelite for its wear resistance and structural stability in harsh operating conditions. The construction industry employs Bakelite-based laminates for durable and fire-resistant interior panels and electrical fittings. In the realm of consumer goods, while less prominent than in its heyday, Bakelite still finds application in high-end kitchenware handles, antique reproductions, and specialty items where its characteristic look, feel, and heat resistance are valued. Furthermore, the market includes customers involved in restoration projects for vintage vehicles, electronics, and household items, who specifically seek authentic Bakelite components for historical accuracy. The diversity of these potential customers underscores Bakelites enduring utility and its ability to meet exacting standards across a broad industrial landscape, from mass-produced electrical components to bespoke, high-performance engineering applications and collectible artifacts.

Bakelite Market Key Technology Landscape

The Bakelite markets technology landscape is characterized by a mature yet continuously evolving set of processes and material science innovations aimed at optimizing production, enhancing product performance, and addressing sustainability concerns. The foundational technology revolves around the polycondensation reaction between phenol and formaldehyde, leading to the formation of thermosetting resins. Traditional manufacturing processes, primarily compression molding, remain prevalent for producing intricate and high-precision Bakelite components due to their ability to handle the materials rigid nature and thermoset characteristics effectively. However, advancements in injection molding techniques, particularly for modified or filled Bakelite compounds, have expanded the range of possible component geometries and increased production efficiency for certain applications. These molding technologies are continuously refined to improve cycle times, reduce material waste, and achieve tighter dimensional tolerances, responding to the demand for higher precision and cost-effectiveness in end-user industries.

Beyond basic synthesis and molding, the technology landscape includes significant developments in resin formulation and compounding. This involves the incorporation of various fillers, such as wood flour, mineral fibers, glass fibers, or carbon fibers, to enhance mechanical strength, impact resistance, and thermal conductivity, thereby extending Bakelites utility into more demanding engineering applications. Research and development efforts are also focused on developing advanced flame retardant systems and low-smoke additives to meet stringent safety regulations, particularly in the electrical and transportation sectors. A growing area of technological innovation is the pursuit of sustainable Bakelite variants. This includes exploring bio-based phenols and formaldehyde alternatives derived from renewable resources to reduce reliance on petrochemicals, as well as developing formaldehyde-free or low-formaldehyde formulations to mitigate environmental and health concerns. Furthermore, process innovations aimed at reducing energy consumption during synthesis and curing, alongside methods for utilizing industrial waste as fillers, are gaining traction. The integration of digital technologies, such as advanced process control systems and data analytics, is also becoming more prevalent to optimize reaction parameters, ensure product consistency, and enhance overall manufacturing efficiency, marking a strategic shift towards more intelligent and environmentally conscious production of Bakelite products.

Regional Highlights

- Asia-Pacific: This region holds the largest market share, driven by rapid industrialization, burgeoning electronics manufacturing, and robust automotive production in countries like China, India, Japan, and South Korea. The demand for electrical insulation materials and heat-resistant components is consistently high.

- North America: Characterized by stable demand in specialized, high-performance applications across the automotive, aerospace, and electrical sectors. Focus on innovation in composite Bakelite materials and niche markets for restoration and high-end consumer goods.

- Europe: A mature market with steady consumption, particularly in Germany, France, and the UK, for industrial machinery, automotive components, and high-precision electrical systems. Strict environmental regulations are driving demand for sustainable and low-emission Bakelite formulations.

- Latin America: Experiencing moderate growth, fueled by developing industrial sectors and infrastructure projects. Brazil and Mexico are key contributors, with increasing demand for electrical and construction applications.

- Middle East & Africa: An emerging market with growth potential, driven by infrastructure development, oil and gas industry requirements, and expanding manufacturing capabilities. Demand is primarily for robust electrical and industrial components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bakelite Market.- Sumitomo Bakelite Co., Ltd.

- Hexion Inc.

- SI Group, Inc.

- Showa Denko Materials (formerly Hitachi Chemical Co., Ltd.)

- Plastics Engineering Company (Plenco)

- Georgia-Pacific Chemicals

- Momentive Specialty Chemicals Inc.

- DIC Corporation

- Chang Chun Group

- Hexcel Corporation

- Bakelite AG

- Synthite Industries Pvt. Ltd.

Frequently Asked Questions

What is Bakelite and what are its primary industrial applications?

Bakelite is a historically significant thermosetting plastic, specifically a phenol-formaldehyde resin, renowned for its exceptional heat resistance, non-conductivity (electrical insulation), and chemical inertness. Its primary industrial applications include the manufacturing of electrical components like switches, circuit breakers, and lamp holders, automotive parts such as brake linings and clutch plates, and various industrial equipment components requiring high thermal and mechanical stability, owing to its robust and durable nature under demanding conditions.

How does Bakelites performance compare to modern engineering plastics?

While modern engineering plastics offer greater design flexibility and often easier processing, Bakelite maintains a competitive edge in specific high-performance areas. It exhibits superior heat resistance, maintaining structural integrity at temperatures where many thermoplastics would soften or degrade. Its excellent dielectric strength and arc resistance make it a preferred material for electrical insulation where other plastics might fail. Although it typically lacks the impact strength or flexibility of some advanced polymers, its rigidity and chemical resistance remain unparalleled for applications demanding these specific traits.

Is Bakelite environmentally friendly, and are there sustainable alternatives?

Traditional Bakelite production involves formaldehyde, which raises environmental and health concerns, and as a thermoset plastic, it is not readily recyclable through conventional methods, contributing to landfill waste. However, the industry is actively pursuing more sustainable solutions. Research is focused on developing bio-based precursors for phenol and formaldehyde, exploring formaldehyde-free resin formulations, and investigating chemical recycling methods or opportunities to use Bakelite waste as a filler in other materials. These efforts aim to reduce the environmental footprint and offer greener Bakelite alternatives.

What are the key drivers for growth in the current Bakelite market?

The Bakelite markets growth is primarily driven by persistent demand from the electrical and electronics industry for reliable insulation and heat-resistant components, especially with the expansion of power infrastructure and complex electronic devices. The automotive sectors need for durable, heat-stable parts also contributes significantly. Furthermore, niche applications requiring Bakelites unique combination of properties, such as in high-temperature industrial settings or the growing market for vintage restoration, provide ongoing impetus. Continuous innovation in formulation to enhance performance and address sustainability concerns further supports its market stability.

Which industries are the largest consumers of Bakelite products today?

The electrical and electronics industry remains the largest consumer, valuing Bakelite for its exceptional electrical insulation, heat resistance, and fire-retardant properties in components like connectors, switches, and printed circuit boards. The automotive industry is another major consumer, utilizing Bakelite for critical components such as brake pads, clutch facings, and various electrical parts that must withstand high temperatures and mechanical stress. Industrial machinery and equipment manufacturers also depend on Bakelite for durable gears, bearings, and structural components in demanding operational environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager