Baler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428781 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Baler Market Size

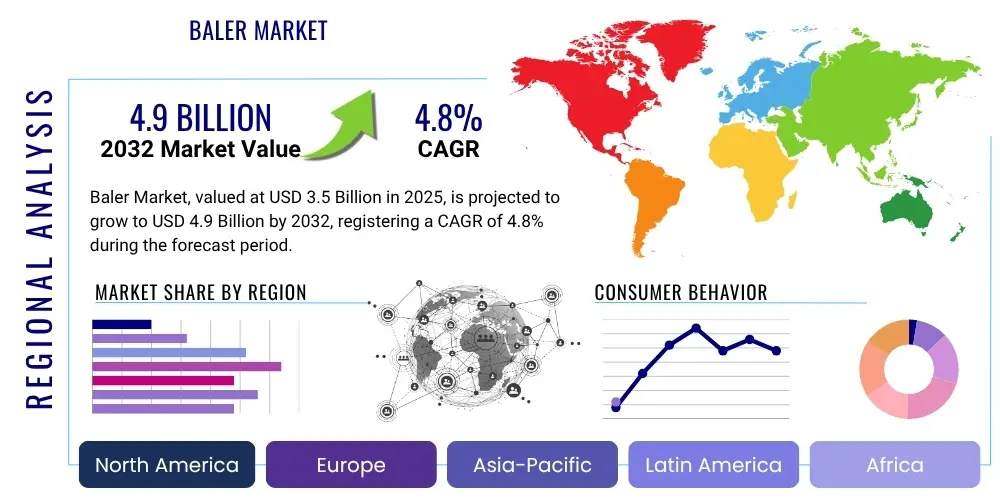

The Baler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 3.5 Billion in 2025 and is projected to reach USD 4.9 Billion by the end of the forecast period in 2032.

Baler Market introduction

The baler market encompasses a diverse range of machinery designed to compress various materials into compact, manageable bales for easier handling, storage, and transportation. These machines are integral across multiple sectors, offering solutions for volume reduction and efficient material management. Products within this market include agricultural balers for hay and silage, and industrial or recycling balers for materials such as cardboard, plastic, paper, metal scraps, and textiles. The primary function of a baler is to optimize logistics and reduce operational costs by minimizing the physical space required for waste or harvested crops.

Major applications for balers are prominently found in the agriculture sector, where they are essential for preserving fodder, and in waste management and recycling facilities, where they are crucial for processing recyclable materials and reducing landfill volumes. Beyond these primary uses, balers also serve industrial purposes in manufacturing, textile industries, and logistics for compressing packaging waste. The key benefits derived from using balers include significant savings in storage space, reduced transportation expenses, improved safety by consolidating loose materials, and enhanced overall operational efficiency, contributing to more sustainable practices.

Several driving factors are propelling the growth of the global baler market. These include the escalating demand for effective waste management solutions driven by urbanization and industrialization, increased focus on agricultural productivity and mechanization, and the growing imperative for sustainable practices and circular economy initiatives across industries. Additionally, stringent environmental regulations regarding waste disposal and the rising prices of raw materials further incentivize the adoption of baling equipment for material recovery and recycling, ensuring continuous market expansion.

Baler Market Executive Summary

The Baler Market is undergoing significant transformation, characterized by evolving business, regional, and segment trends. Key business trends include a pronounced shift towards automation and smart baling solutions, integrating technologies such as IoT, AI, and telematics for enhanced operational efficiency and predictive maintenance. There is also a growing adoption of electric and hybrid balers to meet sustainability goals and reduce operating costs, alongside the expansion of equipment rental and leasing models to improve accessibility for smaller enterprises and agricultural operations. Companies are focusing on developing versatile balers capable of processing a wider array of materials, responding to the complex demands of modern waste streams and diverse agricultural needs.

From a regional perspective, the Asia Pacific region is poised for robust growth, driven by rapid industrialization, increasing agricultural mechanization, and burgeoning waste generation coupled with developing recycling infrastructures. North America and Europe, while mature markets, are leading in the adoption of advanced baling technologies and precision agriculture, supported by stringent environmental regulations and high labor costs that necessitate automated solutions. Latin America, the Middle East, and Africa are emerging markets, experiencing growing demand for baling equipment due to expanding agricultural activities, urbanization, and the nascent development of organized waste management systems, presenting significant opportunities for market penetration and infrastructure development.

Segment-wise, the agricultural balers segment continues to innovate with a focus on bale quality, density, and autonomous operation, aligning with precision farming trends to optimize yield and resource utilization. In the industrial and recycling sectors, the demand for high-capacity, heavy-duty balers is escalating due to the global push for a circular economy, regulatory mandates for waste reduction, and the increasing value of recycled materials. This segment is also witnessing a rise in compact balers for localized waste management in commercial and retail environments. Overall, the market is characterized by a drive towards higher efficiency, greater sustainability, and intelligent operational capabilities across all key application areas.

AI Impact Analysis on Baler Market

Common user inquiries regarding AI's impact on the Baler Market frequently revolve around how artificial intelligence can enhance operational efficiency, reduce costs, and improve the quality of bales. Users are keen to understand the practical benefits, such as predictive maintenance, optimization of baling parameters, and the potential for autonomous operation. There is also interest in the types of data AI systems collect and how these insights can be leveraged for better decision-making and sustainable practices in both agricultural and industrial applications. Concerns often include the initial investment costs, the complexity of integrating AI into existing machinery, and the need for skilled personnel to manage these advanced systems.

The primary themes emerging from these questions highlight a strong user expectation for AI to deliver quantifiable improvements in baler performance and contribute to overall operational intelligence. Users anticipate that AI integration will lead to more consistent bale density, minimized material wastage, and prolonged equipment lifespan through early fault detection. The market expects AI to transform baling from a manual or semi-automatic process into a highly optimized, data-driven operation, capable of self-correction and continuous improvement, thereby addressing labor shortages and boosting productivity across the board.

- AI optimizes bale density and consistency, ensuring uniform bale quality.

- Predictive maintenance driven by AI algorithms reduces downtime and extends machine lifespan.

- AI-powered vision systems improve material sorting and contamination detection in recycling balers.

- Autonomous baling operations are enabled, reducing the need for constant human supervision.

- Real-time data analytics from AI systems provide actionable insights for operational efficiency and resource allocation.

- Enhanced safety features through AI-driven anomaly detection and automated emergency stops.

- AI supports optimized fuel consumption and energy usage in baling processes.

- Integration with farm management systems for comprehensive agricultural data analysis.

DRO & Impact Forces Of Baler Market

The Baler Market is significantly influenced by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include stringent waste reduction mandates globally, compelling industries and municipalities to adopt efficient baling solutions. Simultaneously, an increasing demand for recycled materials across various sectors, coupled with rising awareness of environmental sustainability, encourages investments in baling equipment. In the agricultural sector, labor shortages and the continuous drive for mechanization and operational efficiency are significant motivators for adopting advanced balers. Furthermore, the economic benefits of volume reduction in terms of storage and transportation costs heavily influence purchasing decisions.

However, the market faces several restraints that could impede its growth. The high initial capital investment required for purchasing advanced baling machinery can be a barrier for small and medium-sized enterprises (SMEs) and individual farmers. Maintenance costs and the need for specialized spare parts also contribute to the overall operational expenditure. In some developing regions, the lack of skilled operators and technicians capable of managing sophisticated baling equipment presents a significant challenge. Additionally, economic downturns or fluctuations in raw material prices can directly impact investment cycles in both the agricultural and industrial sectors, potentially slowing market expansion.

Despite these challenges, numerous opportunities exist for market expansion and innovation. The burgeoning demand for balers in emerging economies, driven by rapid industrialization and improving agricultural practices, offers substantial growth prospects. The development of smart and connected balers, integrated with IoT and AI technologies, provides avenues for enhanced efficiency, remote monitoring, and data-driven decision-making. Furthermore, the rising focus on processing biodegradable packaging waste and new applications in biomass energy production present untapped markets for baler manufacturers. Impact forces, such as technological advancements in automation and sensor integration, evolving regulatory landscapes regarding waste management, and increasing global environmental concerns, continually reshape market dynamics and push for more efficient and sustainable baling solutions.

Segmentation Analysis

The Baler Market is segmented across various dimensions, including type, application, end-use industry, operating mechanism, and material type, to provide a granular understanding of its diverse landscape. This segmentation allows for targeted analysis of market dynamics, identification of high-growth areas, and strategic positioning for manufacturers and suppliers. Each segment reflects distinct operational requirements and technological preferences, driving innovation and product development to cater to specific user needs. Understanding these segments is crucial for stakeholders to effectively navigate the market and capitalize on emerging trends and opportunities, ensuring comprehensive market coverage.

- By Type

- Round Balers

- Square Balers

- Small Square Balers

- Large Square Balers

- Vertical Balers

- Horizontal Balers

- Compactors

- Tie Balers

- By Application

- Agricultural

- Industrial

- Waste Management & Recycling

- Other (Textile, Biomass)

- By End-Use Industry

- Agriculture & Farming

- Paper & Pulp Industry

- Plastic & Rubber Industry

- Metal Processing Industry

- Logistics & Warehousing

- Textile Industry

- Retail & Commercial Establishments

- Other Manufacturing

- By Operating Mechanism

- Manual Balers

- Semi-Automatic Balers

- Automatic Balers

- By Material Type

- Cardboard & Paper

- Plastic (Film, Bottles)

- Metal Scraps

- Hay & Forage

- Cotton & Fiber

- Municipal Solid Waste (MSW)

- Textiles

Value Chain Analysis For Baler Market

The value chain for the Baler Market begins with upstream activities, involving the sourcing of raw materials and the manufacturing of essential components. This stage includes suppliers of high-grade steel, hydraulic systems, engines, electronic control units, sensors, and various precision parts. Manufacturers rely heavily on a robust supply chain to ensure the quality and availability of these core components, which directly impact the performance and durability of the final baler products. Relationships with these upstream partners are critical for cost efficiency, innovation, and maintaining consistent production schedules.

Midstream activities involve the design, assembly, and manufacturing of the baler machinery itself. This includes research and development to integrate new technologies like IoT, AI, and automation, as well as production processes to build different types of balers for varied applications. Once manufactured, the downstream segment of the value chain focuses on distribution, sales, and after-sales support. Balers reach end-users through various distribution channels, which can be broadly categorized into direct and indirect methods, tailored to the specific market and customer segment.

Direct distribution typically involves large manufacturers selling directly to major agricultural cooperatives, large industrial clients, or government waste management entities, often involving customized solutions and direct contractual agreements. Indirect channels are more prevalent for broader market reach, utilizing a network of authorized dealers, distributors, and retailers. These intermediaries provide local sales support, technical expertise, installation services, and crucial after-sales support, including maintenance, repairs, and spare parts supply. The effectiveness of these channels is paramount for market penetration and ensuring customer satisfaction and loyalty. Rental companies also form a significant part of the downstream value chain, providing access to baler equipment without the large capital expenditure, catering to seasonal or project-specific needs.

Baler Market Potential Customers

The Baler Market serves a diverse range of end-users and buyers whose operational needs necessitate efficient material compression and handling. In the agricultural sector, primary potential customers include individual farmers, large-scale farming enterprises, and agricultural cooperatives who utilize balers for harvesting and packaging hay, silage, straw, and other forage crops. These customers prioritize machine reliability, bale density, and operational speed to maximize productivity and preserve feed quality.

Beyond agriculture, a significant segment of potential customers resides within the waste management and recycling industries. This includes municipal waste management companies, private recycling facilities, material recovery facilities (MRFs), and industrial waste processors. Their demand for balers is driven by the need to efficiently process and compact various recyclable materials such as cardboard, plastic, paper, and metal scraps, reducing volume for cost-effective transportation and maximizing revenue from sorted materials. The focus here is on high throughput, durability, and the ability to handle diverse waste streams.

Furthermore, the market extends to various industrial and commercial end-users such as manufacturing plants, distribution centers, logistics companies, retail chains, supermarkets, and textile mills. These entities use balers primarily for compressing packaging waste, production scraps, and other generated waste materials to minimize disposal costs, optimize storage space, and often to prepare materials for recycling. Each customer group has specific requirements regarding baler type, capacity, automation level, and material compatibility, making market segmentation and targeted product development crucial for manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.5 Billion |

| Market Forecast in 2032 | USD 4.9 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Deere & Company, CNH Industrial N.V. (New Holland, Case IH), AGCO Corporation, Kubota Corporation, Vermeer Corporation, McHale, Krone GmbH, Fendt (AGCO), CLAAS KGaA mbH, SIPMA S.A., Presto Recycling Solutions, Orwak, American Baler Company, BHS-Sonthofen GmbH, Macpresse Europa Srl, Bramidan, Kadant Inc., Mil-tek, Marathon Equipment, Wastequip |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Baler Market Key Technology Landscape

The Baler Market is undergoing significant technological evolution, driven by the demand for increased efficiency, automation, and data-driven insights. Key technologies being integrated include advanced hydraulic systems for more powerful and efficient compression, optimizing bale density and reducing cycle times. The shift towards electric and hybrid power trains is gaining traction, particularly in smaller and medium-sized balers, aiming to reduce fuel consumption, emissions, and noise levels, aligning with global sustainability goals and stricter environmental regulations. These developments are enhancing the operational footprint of baling equipment across various applications.

The integration of digital technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning is profoundly impacting the baler market. IoT sensors enable real-time monitoring of machine performance, bale density, moisture levels, and operational parameters, transmitting data for remote analysis and proactive maintenance. AI algorithms are employed for predictive maintenance, optimizing baling processes, and even supporting autonomous operation in certain advanced agricultural balers. Telematics systems provide GPS tracking, operational analytics, and connectivity to farm or waste management platforms, allowing for better fleet management and resource allocation.

Furthermore, innovations in control systems, including advanced programmable logic controllers (PLCs) and user-friendly human-machine interfaces (HMIs), are making balers easier to operate and more precise. The development of sophisticated sensors for material type recognition and contamination detection is crucial for recycling balers, improving sorting accuracy and the quality of recycled outputs. These technological advancements collectively contribute to higher productivity, reduced operational costs, enhanced safety, and improved environmental performance across the diverse applications of baling equipment, positioning the market for continued growth through innovation.

Regional Highlights

- North America: This region is a mature market characterized by high adoption of advanced agricultural machinery and robust waste management infrastructure. Strict environmental regulations and a focus on operational efficiency drive demand for automated and intelligent baling solutions. The United States and Canada are leading in embracing precision agriculture technologies and high-capacity industrial balers.

- Europe: Europe is another key market, driven by stringent recycling targets and a strong emphasis on sustainability and circular economy principles. Countries like Germany, France, and the UK show high demand for innovative, energy-efficient balers for both agricultural and industrial waste processing. Technological advancements and environmental compliance are major market drivers.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate, fueled by rapid industrialization, urbanization, and increasing agricultural mechanization in countries like China, India, and Japan. Rising waste generation coupled with developing waste management infrastructure presents significant opportunities. Government initiatives promoting recycling and sustainable practices also contribute to market expansion.

- Latin America: This region presents a growing market, largely driven by the expansion of agricultural activities and increasing investments in modern farming techniques, particularly in Brazil and Argentina. Developing waste management sectors in urban areas also contribute to the demand for baling equipment, although adoption rates are still lower compared to developed regions.

- Middle East and Africa (MEA): The MEA region is an emerging market for balers, with growth spurred by increasing agricultural investments, infrastructure development, and nascent waste management and recycling initiatives. Countries like Saudi Arabia and South Africa are gradually adopting baling solutions to address growing waste volumes and improve agricultural productivity. However, market growth can be constrained by economic volatility and limited technological adoption in some areas.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Baler Market.- Deere & Company

- CNH Industrial N.V. (New Holland, Case IH)

- AGCO Corporation

- Kubota Corporation

- Vermeer Corporation

- McHale

- Krone GmbH

- Fendt (AGCO)

- CLAAS KGaA mbH

- SIPMA S.A.

- Presto Recycling Solutions

- Orwak

- American Baler Company

- BHS-Sonthofen GmbH

- Macpresse Europa Srl

- Bramidan

- Kadant Inc.

- Mil-tek

- Marathon Equipment

- Wastequip

Frequently Asked Questions

What is a baler used for?

A baler is a machine used to compress various materials, such as hay, silage, cardboard, plastic, paper, or metal scraps, into compact, dense bales for easier handling, storage, and transportation, reducing volume and optimizing logistics.

How does AI improve baler efficiency?

AI enhances baler efficiency through predictive maintenance, optimizing bale density, automating operational settings, real-time performance monitoring, and providing data analytics for improved decision-making, thereby reducing downtime and operational costs.

What are the main types of balers?

The main types of balers include round balers and square balers (for agriculture), and industrial balers such as vertical balers, horizontal balers, and compactors, categorized by their design and material handling capabilities.

Which region leads the baler market?

North America and Europe currently lead the baler market in terms of advanced technology adoption and market value, driven by mature agricultural and recycling infrastructures, while Asia Pacific is projected to exhibit the highest growth.

What are the environmental benefits of using balers?

Using balers significantly reduces waste volume, leading to less landfill space occupied, decreased transportation emissions, and increased efficiency in recycling processes, thereby supporting a circular economy and reducing environmental impact.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Agricultural Round Baler Market Statistics 2025 Analysis By Application (Rice and Wheat, Corn, Cotton, Others), By Type (Fixed Speed, Variable Speed), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Agricultural Square Baler Market Statistics 2025 Analysis By Application (Rice and Wheat, Corn, Cotton, Others), By Type (Small Baler, Large Baler), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Small Baler Market Statistics 2025 Analysis By Application (Rice and Wheat, Corn, Cotton, Others), By Type (Round Baler, Square Baler), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Large Baler Market Statistics 2025 Analysis By Application (Rice and Wheat, Corn, Cotton, Others), By Type (Round Baler, Square Baler), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Vertical Baler Market Statistics 2025 Analysis By Application (Handle Paper, Handle Plastic, Handle Cardboard, Other), By Type (Small Single Vertical Baler, Medium Single Chamber Vertical Baler, Multi Chamber Baler, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager