Bamboo Engineered Wood Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430539 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Bamboo Engineered Wood Market Size

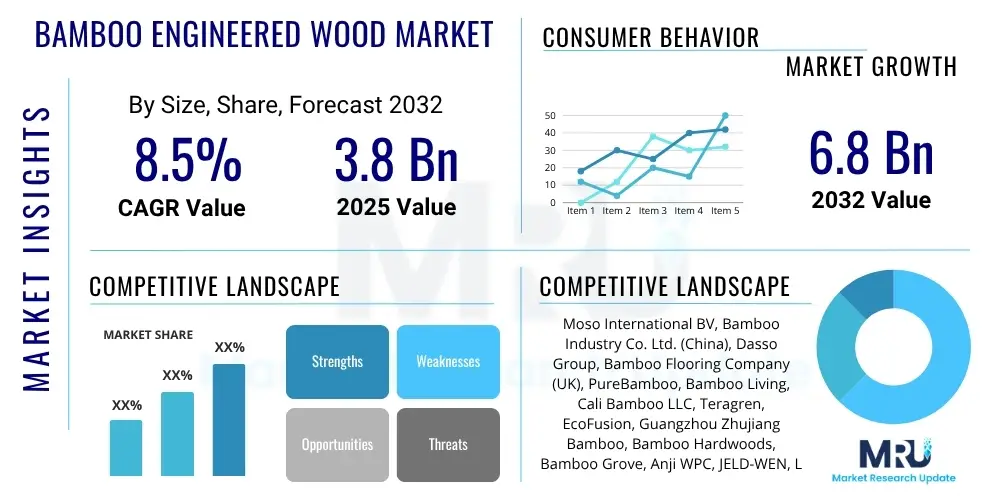

The Bamboo Engineered Wood Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2025 and 2032. The market is estimated at USD 3.8 Billion in 2025 and is projected to reach USD 6.8 Billion by the end of the forecast period in 2032.

Bamboo Engineered Wood Market introduction

The Bamboo Engineered Wood Market stands at the forefront of the sustainable construction and design industry, offering a compelling array of materials that address both environmental concerns and performance demands. This market segment specializes in transforming raw bamboo, a rapidly renewable natural resource, into high-performance engineered products through sophisticated manufacturing processes. The inherent characteristics of bamboo, such as its exceptional strength-to-weight ratio, remarkable flexibility, and rapid growth cycle, position it as an ideal alternative to conventional timber, which often faces challenges related to deforestation and slower regeneration. The market's growth is fundamentally driven by a global paradigm shift towards ecological responsibility, stringent environmental regulations, and an increasing consumer preference for green building materials that minimize ecological footprints without compromising on durability or aesthetic appeal. The versatility of engineered bamboo allows for its application across a broad spectrum of uses, enhancing its market penetration and long-term viability in a conscious global economy.

Product description highlights the sophisticated manufacturing techniques involved, where bamboo strips are meticulously processed, often carbonized for enhanced durability and color, and then laminated under high pressure and temperature using eco-friendly adhesives. This engineering process results in a range of products including flooring, panels, beams, and veneer, all exhibiting superior dimensional stability, hardness, and resistance to moisture, pests, and fire compared to traditional wood. Major applications encompass residential and commercial sectors, including high-traffic flooring solutions known for their resilience, robust outdoor decking, elegant indoor and outdoor furniture, sophisticated wall and ceiling cladding, and increasingly, innovative structural components in modern sustainable architecture. The significant benefits derived from bamboo engineered wood, such as its inherent anti-bacterial properties, consistent quality, aesthetic versatility, and contribution to healthier indoor environments by reducing VOCs when using low-emission adhesives, collectively act as powerful driving factors. These advantages, coupled with growing government support for green building initiatives and continuous advancements in processing technology that improve product performance and cost-effectiveness, are pivotal in accelerating the market's trajectory towards mainstream adoption and expanding its global presence in diverse construction and design applications.

Bamboo Engineered Wood Market Executive Summary

The global Bamboo Engineered Wood Market is poised for substantial growth, propelled by overarching business trends emphasizing sustainability, resource efficiency, and advanced material innovation. Key business trends indicate a concentrated effort by manufacturers to enhance product quality, diversify their portfolios, and streamline production processes through automation and smart technologies to meet rising demand. There is a notable movement towards vertical integration within the industry, where companies are seeking to control more stages of the value chain, from bamboo cultivation to final product distribution, ensuring consistency and cost efficiency. Strategic partnerships and collaborations between bamboo engineered wood producers and architectural firms, interior designers, and large-scale construction companies are becoming more prevalent, aimed at facilitating broader market penetration and educating the industry on the benefits of these sustainable materials. Furthermore, investment in research and development to explore new applications, improve adhesive technologies for greener products, and develop advanced composite materials is a central theme, reinforcing the market's commitment to innovation and environmental stewardship. The shift towards circular economy principles is also driving companies to consider the end-of-life cycle of their products, exploring recycling and repurposing options for bamboo materials.

Regional trends reveal that the Asia Pacific region maintains its dominance in the Bamboo Engineered Wood Market, primarily driven by vast bamboo resources, established manufacturing hubs, particularly in China, and robust construction activities across emerging economies like India and Southeast Asian nations. This region benefits from favorable policy support for eco-friendly products and a strong export orientation. North America and Europe are experiencing accelerated growth rates, fueled by stringent green building regulations, rising consumer awareness of sustainable living, and a strong preference for durable and aesthetically pleasing natural materials. Governments in these regions are increasingly providing incentives for using certified sustainable materials in construction, further catalyzing market expansion. Latin America and the Middle East & Africa are emerging as promising new frontiers, spurred by rapid urbanization, significant infrastructure development projects, and a growing, albeit nascent, appreciation for sustainable building solutions. Segment trends indicate that flooring continues to be the largest and most mature application segment due to bamboo's inherent durability and aesthetic appeal in both residential and commercial settings. However, significant growth is observed in diverse segments such as furniture manufacturing, outdoor decking solutions, and innovative applications in wall cladding and even structural components, underscoring the product's evolving versatility and increasing acceptance beyond traditional uses. The residential end-use sector remains a cornerstone of demand, while commercial and institutional projects are increasingly incorporating bamboo engineered wood, driven by their sustainability goals and desire for high-performance, attractive materials.

AI Impact Analysis on Bamboo Engineered Wood Market

Users frequently inquire about the transformative potential of artificial intelligence within the Bamboo Engineered Wood Market, with questions often centering on how AI can enhance efficiency, sustainability, and quality across the entire production and supply chain. Key themes that emerge from these questions include the optimization of raw material sourcing and cultivation, improvements in manufacturing precision and waste reduction, the development of new product designs, and more accurate market forecasting. Stakeholders are particularly interested in AI's role in making bamboo engineered wood production more cost-effective and environmentally friendly, thereby increasing its competitive edge against traditional materials. There is a palpable expectation that AI integration will lead to smarter, more adaptive systems capable of real-time adjustments and predictive capabilities, ultimately accelerating the adoption of bamboo engineered wood in mainstream construction and design while fortifying its sustainable credentials. The anticipation also extends to AI's capacity to facilitate advanced quality control, ensuring product consistency and adherence to global standards, which is crucial for building consumer trust and market reputation.

The integration of AI technologies is poised to fundamentally reshape the Bamboo Engineered Wood market, ushering in an era of unprecedented optimization and innovation from farm to finished product. In the upstream segment, AI-powered agricultural analytics can monitor bamboo growth, soil conditions, and climate patterns to recommend optimal cultivation practices and harvesting schedules, ensuring sustainable resource management and maximizing yields. During the critical manufacturing phase, AI-driven sensor networks and machine learning algorithms can continuously monitor and adjust parameters such as temperature, pressure, and adhesive application during lamination and pressing. This real-time feedback loop ensures consistent product quality, minimizes defects, and significantly reduces material waste, thereby boosting operational efficiency and economic viability. Furthermore, AI systems can process vast datasets from production lines to predict equipment maintenance needs, thereby preventing costly downtimes and extending machinery lifespan. Downstream, AI enhances supply chain logistics through intelligent demand forecasting, optimized inventory management, and route optimization, leading to faster, more efficient delivery and reduced carbon emissions. The application of AI also extends to advanced material science, enabling the simulation of new material compositions and structural designs, accelerating product development and customization for specific architectural requirements. This comprehensive integration of AI promises not only to streamline operations and improve sustainability but also to foster innovation, making bamboo engineered wood an even more competitive and sought-after material globally.

- AI-powered analytics for optimizing bamboo cultivation, harvesting, and yield prediction, ensuring sustainable raw material supply.

- Real-time monitoring and control systems in manufacturing, enhancing precision in lamination, pressing, and finishing processes for superior quality and reduced defects.

- Predictive maintenance algorithms for production machinery, minimizing downtime, increasing operational efficiency, and extending equipment lifespan.

- Intelligent supply chain management and logistics optimization, including demand forecasting, inventory control, and efficient transportation routing.

- AI-assisted design and material simulation for developing innovative bamboo engineered wood products and custom architectural solutions.

- Significant reduction in material waste and energy consumption through optimized process control and resource allocation.

- Advanced quality assurance systems utilizing computer vision and machine learning for rapid defect detection and classification, ensuring product consistency.

DRO & Impact Forces Of Bamboo Engineered Wood Market

The Bamboo Engineered Wood Market is navigating a dynamic landscape shaped by a confluence of Drivers, Restraints, and Opportunities, which collectively constitute the impact forces determining its growth trajectory. Among the primary drivers is the escalating global imperative for sustainable and environmentally friendly building materials. This demand is increasingly fueled by growing environmental awareness among consumers, coupled with stricter regulatory frameworks and governmental incentives that actively promote green building practices and sustainable construction. The inherent performance characteristics of bamboo engineered wood, such as its exceptional strength-to-weight ratio, superior hardness, enhanced dimensional stability, and natural resistance to moisture and pests, position it as a high-value alternative to conventional timber products. Moreover, the rapid renewability of bamboo, capable of reaching maturity within 3-5 years without the need for replanting, offers an unparalleled ecological advantage in an era of dwindling forest resources. These compelling attributes collectively contribute to a robust momentum driving the widespread adoption and expansion of engineered bamboo products across diverse construction and design applications worldwide, appealing to both ecological concerns and practical performance requirements for modern infrastructure.

Despite significant growth potential, the market also contends with several notable restraints. The relatively higher initial cost of specialized bamboo engineered wood products, particularly those with advanced finishes or structural capabilities, can sometimes be a barrier for price-sensitive projects or consumers when compared to cheaper, conventional alternatives. Furthermore, a lingering lack of widespread consumer and builder awareness in some nascent markets regarding the distinct benefits, performance attributes, and proper installation techniques of bamboo engineered wood can impede broader market penetration. This awareness gap is often compounded by a lack of globally standardized building codes and certifications specifically tailored for engineered bamboo, which can create uncertainty among specifiers and regulatory bodies. Supply chain vulnerabilities, including reliance on specific geographical regions for large-scale raw bamboo sourcing and potential fluctuations in raw material prices due to environmental factors or geopolitical issues, also present challenges. However, these restraints are counterbalanced by significant opportunities. Continuous technological advancements in processing, adhesive formulations (e.g., bio-based, low-VOC), and surface treatments are continually improving product performance and reducing manufacturing costs, enhancing competitiveness. The exploration of new application areas, such as modular construction, prefabricated housing components, and high-performance industrial uses, alongside aggressive market penetration into rapidly urbanizing emerging economies, represents substantial growth avenues. Strategic marketing campaigns and educational initiatives can effectively address awareness deficits, while robust investment in research and development can overcome material limitations and further diversify product offerings. The prevailing impact forces are thus a complex interplay of ecological necessity, economic viability, technological innovation, and evolving consumer and regulatory landscapes, all of which are critical for shaping the market's long-term success and integration into global construction practices.

Segmentation Analysis

The Bamboo Engineered Wood Market is meticulously segmented to offer a granular understanding of its diverse components, dynamics, and potential growth areas, enabling stakeholders to navigate its complexities with precision. This comprehensive segmentation provides critical insights into distinct product types, varied application areas, and diverse end-user categories, facilitating a targeted approach for market entry and expansion. By categorizing the market based on specific intrinsic characteristics of the products and their functional uses, market participants can effectively analyze evolving consumer preferences, identify key technological advancements, and discern regional market behaviors. This granular analysis is instrumental in accurately assessing market size, understanding growth rates, and mapping the competitive landscape within each defined segment. Such detailed insights empower businesses to strategically tailor their product offerings, refine marketing strategies, optimize distribution channels, and allocate resources efficiently to capitalize on the most promising opportunities while addressing specific challenges pertinent to each segment. The ability to precisely identify and respond to the unique demands of each segment is a cornerstone for sustainable growth and market leadership.

The market's segmentation extends across several pivotal dimensions, providing a holistic view of its structure and potential. By type, the market includes categories such as strand woven bamboo, renowned for its exceptional density and hardness, widely used in flooring; laminated bamboo, available in vertical and horizontal grain orientations, offering versatile panels and beams for various construction and furniture applications; and bamboo veneer, utilized for decorative finishes. Furthermore, bamboo lumber and beams represent emerging categories for structural uses. From an application perspective, the market is broadly divided into critical sectors including flooring (further sub-segmented into solid, engineered, and click-lock systems), furniture (encompassing both indoor and outdoor designs), decking and other outdoor structures, sophisticated wall panels and cladding, and innovative structural components like beams and columns. Specialty and other applications, such as kitchen countertops and cabinetry, also form a growing niche. The end-user segmentation differentiates between residential, commercial (including hospitality, corporate, retail, and institutional sectors), and industrial applications, each with unique demands concerning aesthetics, durability, and project scale. Geographically, the market is segmented into key regions: North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, acknowledging the significant variations in market maturity, regulatory environments, raw material availability, and consumer adoption rates across the globe. This intricate breakdown ensures a thorough and insightful analysis of the market's current state and future growth trajectories, enabling informed decision-making for all stakeholders involved in the bamboo engineered wood ecosystem.

- By Type:

- Strand Woven Bamboo

- Laminated Bamboo (Vertical Grain, Horizontal Grain)

- Bamboo Veneer

- Bamboo Lumber/Beams

- By Application:

- Flooring (Solid Bamboo Flooring, Engineered Bamboo Flooring, Click-Lock Systems)

- Furniture (Indoor Furniture, Outdoor Furniture)

- Decking & Outdoor Structures (Terrace Boards, Fencing, Pergolas)

- Wall Panels & Cladding (Interior Wall Panels, Exterior Cladding)

- Structural Components (Beams, Columns, Scaffolding)

- Specialty & Others (Kitchen Countertops, Cabinetry, Musical Instruments, Crafts)

- By End-Use:

- Residential (Single-Family Homes, Multi-Family Homes, Renovations)

- Commercial (Hospitality, Corporate Offices, Retail Spaces, Educational Institutions, Healthcare Facilities)

- Industrial (Warehouses, Workshops, Manufacturing Facilities)

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, UK, France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, ASEAN Countries, Rest of Asia Pacific)

- Latin America (Brazil, Argentina, Colombia, Rest of Latin America)

- Middle East & Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Bamboo Engineered Wood Market

The value chain for the Bamboo Engineered Wood Market is a complex and interconnected network of activities that transforms raw bamboo into finished, high-value engineered products, ultimately delivering them to end-users. This chain begins with upstream activities, which are foundational to the entire process. The initial stage involves the sustainable cultivation and meticulous harvesting of bamboo culms, often from dedicated plantations or well-managed forests. This phase is critical, focusing on practices that ensure the long-term renewability of bamboo resources, efficient harvesting techniques to maximize yield, and primary processing steps such as splitting, cleaning, and preliminary drying of the bamboo material. Key upstream players include bamboo farmers, cooperative aggregators, and raw material suppliers who are responsible for providing high-quality, sustainably sourced bamboo to manufacturers. Innovations in agroforestry, genetic selection for faster-growing or more robust bamboo varieties, and efficient mechanized harvesting are continuously enhancing the sustainability and cost-effectiveness of this initial value chain segment. The commitment to responsible sourcing directly impacts the environmental credibility and quality of the final engineered wood product, making it a pivotal stage for market differentiation.

Moving downstream, the value chain encompasses the sophisticated manufacturing processes where raw bamboo undergoes significant transformation into engineered wood products. This involves multiple intricate steps, including precision cutting, carbonization (for aesthetic and durability enhancements), advanced kiln-drying to achieve optimal moisture content, meticulous lamination of bamboo strips using specialized, often eco-friendly, adhesives, and high-pressure pressing to form dense boards or beams. Further processing includes milling, sanding, and application of protective finishes, leading to a diverse range of products. Following manufacturing, the products enter the crucial distribution channels that link manufacturers to end-users. Distribution can occur directly, where manufacturers engage in business-to-business (B2B) sales with large construction firms, architects, or furniture makers for high-volume or customized projects, often managing logistics themselves. Indirect channels involve a robust network of wholesalers, distributors, retail showrooms, and increasingly, e-commerce platforms. These intermediaries play a vital role in broadening market reach, managing inventory, providing logistics support, and offering local customer service, catering to individual homeowners, small-to-medium contractors, and interior design professionals. Effective management of both direct and indirect distribution channels, complemented by strong branding and efficient customer support, is essential for maximizing market penetration, ensuring product availability, and sustaining growth in the highly competitive Bamboo Engineered Wood Market. Continuous advancements in logistics and digital platforms are further optimizing these downstream operations, enabling faster delivery and enhanced accessibility for a global customer base.

Bamboo Engineered Wood Market Potential Customers

The Bamboo Engineered Wood Market targets a broad and continually expanding spectrum of potential customers, spanning various sectors from individual consumers to large-scale commercial and institutional entities. Primary end-users and buyers include environmentally conscious residential consumers who are seeking durable, aesthetically appealing, and sustainable materials for their homes. This segment typically invests in bamboo engineered wood for flooring, furniture, decking, and various interior finishing applications, driven by a growing awareness of ecological impact and a preference for natural, healthy living spaces. Architects and interior designers constitute another critical customer segment, as they are key specifiers of materials for a wide array of projects. Their adoption of bamboo engineered wood is largely influenced by its exceptional versatility, inherent design flexibility, and its capacity to contribute positively to green building certifications such as LEED, allowing them to create innovative and sustainable spaces that resonate with modern design principles. Engaging with these professionals through educational seminars, product showcases, and bespoke design collaborations is paramount for fostering widespread adoption and expanding market influence.

Beyond the residential and design communities, commercial builders, developers, and general contractors represent a substantial portion of potential customers, utilizing bamboo engineered wood for large-scale projects encompassing hotels, corporate offices, retail complexes, educational institutions, and public infrastructure. For these clients, factors such as material durability, low maintenance requirements, compliance with stringent building codes, and adherence to corporate or institutional sustainability goals are paramount. Furniture manufacturers are also significant buyers, integrating bamboo engineered wood into their product lines due to its remarkable strength, unique aesthetic characteristics, and eco-friendly credentials, thereby allowing them to cater to the escalating demand for sustainable and ethically sourced furnishings. Furthermore, governmental agencies and urban planning departments increasingly consider bamboo engineered wood for projects focused on sustainable urban development, public park infrastructure, and affordable housing initiatives, valuing its renewable nature and performance benefits. The inherent diversification of end-user applications underscores the wide-ranging appeal and growing acceptance of bamboo engineered wood as a highly versatile, responsible, and high-performance building material across the entire construction and design industries. Tailored educational campaigns that highlight the long-term value, environmental stewardship, and functional advantages of engineered bamboo are critical for driving deeper market penetration and ensuring sustained growth across these diverse customer segments.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.8 Billion |

| Market Forecast in 2032 | USD 6.8 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Moso International BV, Bamboo Industry Co. Ltd. (China), Dasso Group, Bamboo Flooring Company (UK), PureBamboo, Bamboo Living, Cali Bamboo LLC, Teragren, EcoFusion, Guangzhou Zhujiang Bamboo, Bamboo Hardwoods, Bamboo Grove, Anji WPC, JELD-WEN, Lumber Liquidators (LL Flooring), Yekalon Industry Inc., Jiangxi Co-Arts Industrial Co., Ltd., Kanger International Berhad, Shanghai Huating Bamboo Products Co., Ltd., Green Building Supply. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bamboo Engineered Wood Market Key Technology Landscape

The Bamboo Engineered Wood Market is significantly shaped by an evolving and innovative technological landscape, primarily focused on enhancing product attributes, optimizing manufacturing processes, and bolstering the sustainability credentials of the materials. Central to this landscape are advanced processing methods for raw bamboo culms, which include precision cutting, carbonization to achieve desired aesthetics and increased hardness, and highly efficient kiln-drying techniques to precisely control moisture content. Achieving optimal moisture levels is paramount for ensuring the dimensional stability and longevity of the engineered products, preventing warping or cracking after installation. Innovations in lamination technology are also critical, particularly the development and widespread adoption of formaldehyde-free and low-VOC (Volatile Organic Compound) adhesives, such as those derived from soy or other bio-based resins. This shift is vital for meeting stringent green building standards, improving indoor air quality, and reinforcing the ecological integrity of engineered bamboo, making it a healthier choice for both consumers and the environment. The continuous refinement of pressure and temperature control systems during the pressing phase is essential for producing high-density, consistently strong, and durable boards with uniform characteristics.

Further technological advancements span various aspects of production and finishing. Sophisticated milling and precision machining techniques, often utilizing Computer Numerical Control (CNC) technology, allow for the creation of diverse product profiles, intricate designs, and custom components with minimal material waste, catering to bespoke architectural and furniture requirements. Surface treatment technologies are undergoing continuous improvement, involving the application of advanced UV-cured coatings, high-performance sealing agents, and specialized finishes that significantly enhance the engineered wood's resistance to abrasion, moisture penetration, fire, and UV degradation. These treatments not only extend the product's lifespan but also reduce maintenance needs, contributing to its overall value proposition. Research and development efforts are also concentrated on exploring bamboo composite materials, where bamboo fibers or strips are combined with other sustainable materials or bio-resins to create even higher-performance products suitable for demanding structural engineering applications or specialized industrial uses. Furthermore, the increasing integration of automation and robotics into manufacturing facilities is boosting production throughput, ensuring greater product consistency, improving workplace safety, and reducing labor costs. These technological innovations collectively contribute to making bamboo engineered wood an increasingly versatile, cost-effective, and highly attractive material for modern construction and design, continuously pushing the boundaries of what is possible with sustainable resources.

Regional Highlights

- Asia Pacific (APAC): This region is the undisputed leader in the global Bamboo Engineered Wood Market, primarily driven by its vast natural bamboo resources, particularly in countries like China, which also boasts extensive manufacturing and processing capabilities. The rapid urbanization and robust growth in the construction and furniture industries across emerging economies such as India, Vietnam, and Indonesia are significant demand catalysts. Favorable governmental policies that support sustainable building materials and a strong export-oriented manufacturing base further consolidate APAC's market dominance. Innovations in production techniques and a vast consumer market make it a pivotal region for both supply and demand.

- North America: The North American market is experiencing substantial growth, fueled by a heightened environmental consciousness among consumers and a strong emphasis on green building certifications like LEED. Both the United States and Canada are leading the adoption of bamboo engineered wood, with architects, designers, and homeowners increasingly integrating these sustainable materials into residential, commercial, and institutional projects. The market benefits from sophisticated distribution networks, effective marketing campaigns, and a readiness to embrace high-performance, aesthetically pleasing natural alternatives. Investments in sustainable infrastructure also contribute to its upward trajectory.

- Europe: Characterized by a mature market with a consistent and growing demand for eco-friendly building solutions, especially in countries like Germany, the UK, France, and the Scandinavian nations. Europe's market growth is propelled by stringent environmental regulations, a strong focus on energy efficiency in construction, and a well-established consumer base that values high-quality, durable, and sustainably sourced flooring, furniture, and interior finishing products. European manufacturers and distributors often prioritize innovative design, advanced sustainable processing, and adherence to strict quality standards, catering to a discerning market.

- Latin America: Representing an emerging yet promising market, Latin America is experiencing increasing urbanization and a growing emphasis on sustainable development practices. Countries such as Brazil, Mexico, and Chile are showing burgeoning demand for bamboo engineered wood, driven by both expanding residential construction sectors and a burgeoning tourism infrastructure. While the market is currently smaller in scale compared to established regions, it offers substantial growth potential as local supply chains develop, consumer awareness increases, and governmental support for sustainable building initiatives gains momentum. Local resource availability and export potential are also key considerations.

- Middle East & Africa (MEA): This region is strategically positioned for future growth, particularly within the Gulf Cooperation Council (GCC) countries like the UAE and Saudi Arabia, which are undertaking ambitious construction projects and actively diversifying their economies away from oil. There is a nascent but growing interest in sustainable building practices and a preference for natural, durable materials in new developments. African countries are increasingly exploring bamboo as a locally abundant, renewable resource for construction, which could reduce reliance on imported materials and foster localized industries. Addressing awareness gaps and developing robust supply chain infrastructure remain critical opportunities for unlocking the full market potential in MEA.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bamboo Engineered Wood Market.- Moso International BV

- Bamboo Industry Co. Ltd. (China)

- Dasso Group

- Bamboo Flooring Company (UK)

- PureBamboo

- Bamboo Living

- Cali Bamboo LLC

- Teragren

- EcoFusion

- Guangzhou Zhujiang Bamboo

- Bamboo Hardwoods

- Bamboo Grove

- Anji WPC

- JELD-WEN

- Lumber Liquidators (LL Flooring)

- Yekalon Industry Inc.

- Jiangxi Co-Arts Industrial Co., Ltd.

- Kanger International Berhad

- Shanghai Huating Bamboo Products Co., Ltd.

- Green Building Supply

- US Floors Inc.

- Smith & Fong Company

- Forever Bamboo

Frequently Asked Questions

What are the primary environmental benefits of choosing bamboo engineered wood for construction and design projects?

Bamboo engineered wood offers a multitude of significant environmental advantages, making it a premier choice for sustainable building. Its standout benefit is its rapid renewability; bamboo is a fast-growing grass, capable of maturing and being harvested in as little as 3 to 5 years without the need for replanting, unlike hardwoods that can take decades or centuries. This rapid growth cycle significantly reduces pressure on traditional timber forests, helping to combat deforestation, preserve biodiversity, and mitigate climate change. Furthermore, bamboo cultivation typically requires minimal water and no pesticides or herbicides, contributing to healthier soil and water ecosystems. The manufacturing process for engineered bamboo often utilizes sustainable methods and can incorporate eco-friendly, low-VOC adhesives, which further reduces its environmental footprint and enhances indoor air quality. By choosing bamboo engineered wood, consumers and builders actively support a renewable resource that promotes ecological balance and reduces reliance on finite natural resources, aligning perfectly with modern green building principles and environmental stewardship goals.

How does the durability of bamboo engineered wood compare to that of traditional hardwoods in high-traffic applications?

Bamboo engineered wood is renowned for its exceptional durability, frequently outperforming many traditional hardwoods, especially in its strand woven variant. Its hardness is notably high on the Janka hardness scale, making it remarkably resistant to dents, scratches, and daily wear and tear, which is crucial for high-traffic areas in both residential and commercial environments. The engineering process, involving the lamination and compression of bamboo strips, imparts superior dimensional stability to the material, significantly reducing the likelihood of warping, cupping, or gapping that can occur in solid wood due due to fluctuations in humidity and temperature. This enhanced stability ensures a longer lifespan and maintains the aesthetic integrity of the installation over many years, even under demanding conditions. Furthermore, proper finishing and sealing can further augment its resistance to moisture and abrasion. Consequently, bamboo engineered wood stands as a highly resilient and long-lasting material, offering a robust and attractive solution that often exceeds the performance expectations set by many conventional hardwood options in demanding applications.

What are the most common and innovative applications for bamboo engineered wood products in contemporary architecture and interior design?

Bamboo engineered wood is exceptionally versatile, leading to its widespread adoption across a diverse range of applications in contemporary architecture and interior design. Its most prevalent use is in flooring, where its durability, aesthetic appeal, and sustainability make it a highly sought-after material for homes, offices, retail spaces, and educational institutions. Beyond flooring, it is extensively employed in furniture manufacturing for both indoor and outdoor pieces, valued for its strength, unique grain patterns, and eco-friendly attributes, catering to the growing demand for sustainable furnishings. Other significant applications include robust decking solutions for patios and outdoor structures, elegant wall panels and ceiling cladding that add a natural and sophisticated touch to interiors, and even structural components like beams and columns in modern green building projects. Emerging innovative applications also span specialty items such as kitchen countertops, cabinetry, stair treads, and even musical instruments or artistic installations. This wide array of uses underscores bamboo engineered wood's adaptability and growing acceptance as a high-performance, aesthetically pleasing, and environmentally responsible material capable of meeting diverse design and construction requirements across various sectors.

Is bamboo engineered wood resistant to moisture and common wood pests, and what measures enhance these properties?

While no wood-based product is entirely impervious to extreme or prolonged moisture exposure, bamboo engineered wood generally exhibits superior resistance to moisture compared to many traditional hardwoods, particularly when properly manufactured, sealed, and installed. Its dense, engineered composition inherently helps to minimize water absorption and improves its dimensional stability, making it less prone to swelling or shrinking in fluctuating humidity conditions. Regarding pests, bamboo contains natural silica, which acts as a deterrent to common wood-boring insects such as termites and carpenter ants. To further enhance these protective properties, manufacturers often incorporate specific treatments during the production process, such as carbonization, specialized kiln-drying, and the application of advanced sealants or protective finishes. These measures create a less hospitable environment for moisture penetration and pest infestation, significantly extending the product's lifespan and reducing the need for chemical treatments. Therefore, when correctly selected and maintained, bamboo engineered wood offers a robust and naturally resistant material choice for various environments, contributing to its durability and long-term value.

What factors primarily influence the overall cost of bamboo engineered wood products, and how does it compare to other flooring or building materials?

The overall cost of bamboo engineered wood products is influenced by several key factors, including the specific type of bamboo processing (e.g., strand woven varieties, due to their higher density and complex manufacturing, often command a premium), the manufacturing complexity, the quality and type of adhesives used (eco-friendly, low-VOC adhesives can add to cost), and the applied finishing treatments. The brand reputation, the origin of the raw bamboo material, adherence to stringent environmental certifications (such as FSC or LEED compatibility), and global market dynamics also play significant roles in pricing. While the initial purchase price of bamboo engineered wood might sometimes be comparable to or slightly higher than some conventional hardwoods or laminate flooring options, its long-term durability, low maintenance requirements, and substantial sustainability benefits often translate into a superior overall value proposition over the product's lifespan. Factors like reduced replacement frequency, enhanced indoor air quality, and contribution to green building ratings add to its perceived value. Regional supply chain efficiencies, import duties, and localized market demand can also cause variations in pricing, making it essential for consumers to consider total cost of ownership alongside upfront expenses.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager