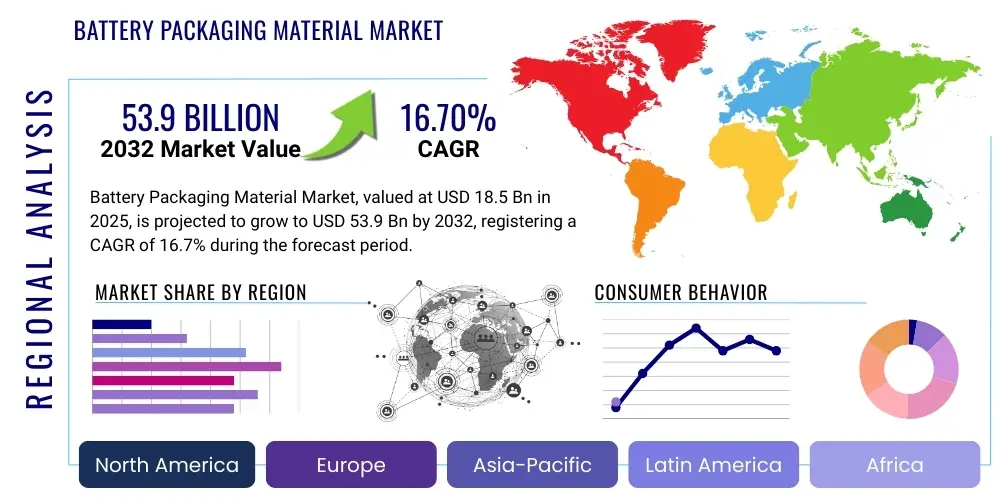

Battery Packaging Material Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427622 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Battery Packaging Material Market Size

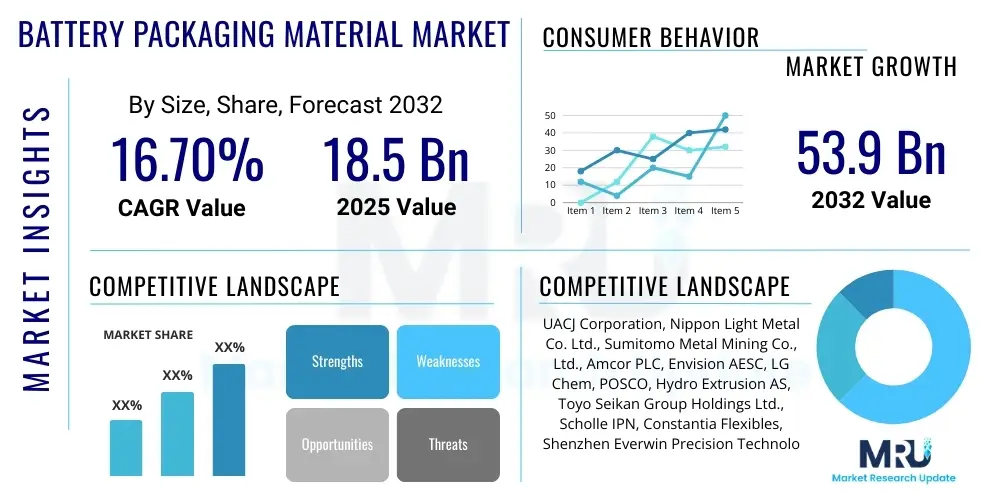

The Battery Packaging Material Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 16.7% between 2025 and 2032. The market is estimated at USD 18.5 Billion in 2025 and is projected to reach USD 53.9 Billion by the end of the forecast period in 2032. This substantial growth is primarily driven by the escalating demand for electric vehicles (EVs), the rapid expansion of renewable energy storage systems, and the continuous innovation within the consumer electronics sector, all of which heavily rely on advanced battery technologies requiring robust and efficient packaging solutions.

Battery Packaging Material Market introduction

The Battery Packaging Material Market encompasses a diverse range of materials and technologies designed to enclose, protect, and optimize the performance of various battery types, from small portable cells to large industrial energy storage units. These materials are critical for ensuring safety, thermal management, structural integrity, and overall longevity of batteries, which are increasingly integral to modern technology. The primary function of battery packaging extends beyond simple containment; it actively contributes to the prevention of thermal runaway, offers mechanical protection against shock and vibration, and facilitates efficient heat dissipation, all vital for operational reliability and user safety.

Products within this market segment include a variety of metal alloys such as aluminum and steel, various plastic polymers like polypropylene (PP) and polyamide (PA), and advanced composite materials, each selected based on specific battery chemistry, application requirements, and environmental considerations. Packaging solutions range from simple casings for individual cells to complex module and pack enclosures for large-scale applications like electric vehicle battery packs or grid-level energy storage systems. The choice of material often depends on factors such as weight reduction needs, thermal conductivity, electrical insulation properties, and resistance to environmental stressors, ensuring optimal performance and safety under diverse operating conditions.

Major applications for battery packaging materials span across multiple high-growth industries, notably electric vehicles, where lightweight and crash-resistant packaging is paramount, and consumer electronics, demanding compact and durable solutions for devices ranging from smartphones to laptops. Furthermore, the burgeoning renewable energy sector relies heavily on sophisticated battery packaging for large-scale energy storage systems, ensuring long-term reliability and safety for grid stabilization and off-grid power solutions. The inherent benefits include enhanced battery lifespan, improved safety standards through thermal and mechanical protection, and overall system efficiency, which collectively act as significant driving factors for market expansion alongside increasing global electrification trends and stringent regulatory frameworks.

Battery Packaging Material Market Executive Summary

The Battery Packaging Material Market is undergoing a transformative period, largely influenced by accelerating global demand for sustainable energy solutions and advanced portable power. Current business trends indicate a strong shift towards lightweight, high-strength, and thermally efficient materials that can accommodate the evolving demands of next-generation batteries, particularly those with higher energy densities. Manufacturers are increasingly focusing on the development of recyclable and environmentally friendly packaging solutions to align with global sustainability initiatives and stricter environmental regulations. Innovation in material science, including the integration of smart materials for real-time monitoring and improved insulation, is also a prominent trend shaping market dynamics and fostering competitive differentiation among key players.

Regionally, Asia-Pacific dominates the market, primarily driven by its robust manufacturing base for batteries and electric vehicles in countries like China, South Korea, and Japan, coupled with significant investments in renewable energy infrastructure. This region benefits from established supply chains and a high concentration of key market participants, facilitating rapid adoption of new packaging technologies. North America and Europe are also experiencing substantial growth, propelled by ambitious electrification targets, increasing consumer adoption of EVs, and significant government support for domestic battery production and energy storage projects. These regions are emphasizing advanced research and development, particularly in areas like thermal management and fire suppression within battery packs, reflecting a strong commitment to safety and performance enhancements.

Segment-wise, the market is primarily segmented by material type, battery type, and application. The metallic packaging segment, particularly aluminum and steel, maintains a significant share due to its excellent mechanical strength and thermal conductivity, essential for large format batteries. However, plastic and composite materials are rapidly gaining traction, especially in applications where weight reduction and design flexibility are crucial, such as in consumer electronics and certain EV components. The electric vehicle application segment is anticipated to be the fastest-growing category, driven by the global transition away from internal combustion engines. This segment demands packaging that can withstand extreme conditions, including high temperatures, vibrations, and potential crash impacts, necessitating continuous innovation in material properties and structural design.

AI Impact Analysis on Battery Packaging Material Market

User questions regarding the impact of AI on the Battery Packaging Material Market frequently revolve around how artificial intelligence can enhance material selection, optimize manufacturing processes, and improve the overall safety and performance of battery packs. Key themes include AIs role in predictive maintenance for packaging integrity, accelerating new material discovery, and enabling more efficient thermal management strategies. There is significant interest in how AI can contribute to lightweighting efforts, cost reduction, and the development of intelligent packaging solutions that integrate sensors for real-time monitoring and adaptive protection, ultimately leading to more reliable and sustainable battery systems across various applications.

- AI can optimize material selection and design through data-driven simulations, identifying the most suitable materials for specific battery chemistries and application environments based on performance, cost, and safety parameters.

- AI-powered predictive analytics can forecast potential packaging failures or degradation, enabling proactive maintenance and extending the lifespan of battery packs by ensuring their protective enclosures remain robust.

- Automated manufacturing processes, leveraging AI for quality control and robotic assembly, can significantly enhance the precision and efficiency of battery packaging production, reducing defects and optimizing resource utilization.

- AI algorithms can analyze vast datasets from battery performance and operational conditions to refine thermal management strategies, designing packaging that more effectively dissipates heat and prevents thermal runaway incidents.

- Machine learning can accelerate the discovery and development of novel battery packaging materials with enhanced properties, such as improved fire resistance, lighter weight, or superior mechanical strength, by rapidly evaluating countless material combinations.

- AI supports the creation of intelligent packaging solutions that integrate embedded sensors for real-time monitoring of internal battery conditions, providing critical data for system optimization and safety alerts.

- Supply chain optimization through AI can lead to more efficient procurement of raw materials and streamline logistics for battery packaging components, reducing lead times and improving cost-effectiveness.

DRO & Impact Forces Of Battery Packaging Material Market

The Battery Packaging Material Market is significantly shaped by a dynamic interplay of drivers, restraints, and opportunities, all influenced by various impact forces. A primary driver is the exponential growth of the electric vehicle industry, which mandates robust, lightweight, and thermally efficient packaging solutions to ensure safety and performance of high-density battery packs. Concurrently, the increasing deployment of renewable energy sources, such as solar and wind, necessitates advanced energy storage systems that rely on durable and protective battery packaging for grid stabilization and off-grid applications. The continuous innovation in consumer electronics, pushing for smaller, more powerful devices, also fuels demand for compact and efficient packaging materials, while stringent safety regulations globally mandate enhanced protective features in battery designs, thereby driving material development and adoption.

Despite these strong drivers, the market faces several notable restraints. The volatility in raw material prices, particularly for metals like aluminum and specialty polymers, poses a significant challenge, impacting production costs and profit margins for manufacturers. Complex and often fragmented global supply chains, exacerbated by geopolitical tensions and logistics bottlenecks, can lead to delays and increased operational expenses. Furthermore, the inherent design complexity and high R&D costs associated with developing next-generation packaging materials that meet evolving performance and safety standards can be prohibitive for smaller players, hindering market entry and widespread innovation. Moreover, the environmental impact of certain non-recyclable packaging materials and the challenges of end-of-life battery recycling present ongoing sustainability concerns that require continuous attention and investment.

Opportunities within the market largely stem from the ongoing technological advancements and the increasing focus on sustainability. The development of advanced composite materials, offering superior strength-to-weight ratios and improved thermal management, presents a significant avenue for growth, particularly in the EV sector where lightweighting is critical. Innovations in smart packaging, integrating sensors and monitoring capabilities, open doors for enhanced safety, performance optimization, and predictive maintenance. Furthermore, the growing emphasis on the circular economy and battery recycling initiatives creates opportunities for packaging materials that are easier to disassemble, recover, and reuse, driving demand for more sustainable and eco-friendly solutions. Collaborations between material suppliers, battery manufacturers, and OEMs are also fostering customized packaging solutions tailored to specific application needs, enhancing market responsiveness and specialization.

Segmentation Analysis

The Battery Packaging Material Market is comprehensively segmented to provide a detailed understanding of its diverse components and evolving dynamics. This segmentation helps in identifying key growth areas, understanding market demands, and strategizing for future developments across various material types, battery chemistries, and end-use applications. The market is typically analyzed by material type, which includes metals, plastics, and composites, each offering distinct advantages in terms of strength, weight, thermal properties, and cost. Further segmentation by battery type differentiates between lithium-ion, lead-acid, nickel-cadmium, and other emerging chemistries, as each requires specific packaging considerations for optimal performance and safety. Lastly, application-based segmentation highlights critical end-user sectors such as electric vehicles, consumer electronics, and energy storage systems, demonstrating where demand for advanced packaging is most concentrated and rapidly expanding.

- By Material Type:

- Metal (Aluminum, Steel): Valued for high strength, thermal conductivity, and mature manufacturing processes, widely used in large format batteries and EV packs.

- Plastic (PP, PA, ABS, PET): Preferred for lightweight properties, design flexibility, electrical insulation, and cost-effectiveness, common in consumer electronics and certain module casings.

- Composites (Fiberglass, Carbon Fiber): Gaining traction for exceptional strength-to-weight ratio, superior impact resistance, and customizable thermal properties, increasingly adopted in high-performance EVs.

- Others (Ceramics, Specialty Foams): Emerging materials for enhanced thermal insulation, fire retardation, and specific niche applications requiring advanced protective features.

- By Battery Type:

- Lithium-ion Batteries: Dominant segment requiring advanced thermal management and robust protection due to high energy density and sensitivity.

- Lead-Acid Batteries: Mature segment with established packaging solutions, primarily used in automotive starter batteries and industrial applications.

- Nickel-Cadmium (NiCd) and Nickel-Metal Hydride (NiMH) Batteries: Specialized applications requiring specific packaging for durability and safety.

- Solid-State Batteries and Other Advanced Batteries: Future growth areas demanding innovative packaging for enhanced safety and performance.

- By Application:

- Electric Vehicles (EVs) and Hybrid Electric Vehicles (HEVs): Fastest-growing segment driven by stringent safety standards, lightweighting mandates, and high demand for durable, crash-resistant packaging.

- Consumer Electronics (Smartphones, Laptops, Wearables): Requires compact, lightweight, and aesthetically pleasing packaging solutions.

- Energy Storage Systems (ESS) and Grid Applications: Demands large-scale, long-duration, and highly secure packaging for utility-scale and commercial energy storage.

- Industrial and Commercial (Forklifts, Power Tools): Requires robust and resilient packaging for demanding operational environments.

- Medical Devices: Niche applications demanding highly reliable and sterile packaging solutions for critical healthcare equipment.

Battery Packaging Material Market Value Chain Analysis

The Battery Packaging Material Markets value chain commences with the upstream analysis, focusing on the sourcing and processing of fundamental raw materials. This stage involves the extraction and refinement of metals such as aluminum and steel, as well as the production of various polymers like polypropylene, polyamide, and advanced resins for composite materials. Key players in this segment include chemical companies, metal refiners, and plastic resin manufacturers, who supply the basic building blocks. The quality and cost-effectiveness of these raw materials significantly influence the properties and overall cost of the final packaging solutions. Innovation at this stage, particularly in developing sustainable and high-performance materials, is crucial for advancing the entire market.

Moving downstream, the value chain progresses to the manufacturing and assembly of battery packaging components. This involves fabricators, molders, and specialized packaging solution providers who transform raw materials into specific enclosures, trays, lids, and protective layers for individual cells, modules, and complete battery packs. These manufacturers often specialize in particular materials or processing techniques, such as stamping for metal casings or injection molding for plastic parts, and integrate advanced features like thermal management systems and fire suppression technologies. Their ability to deliver customized, high-precision packaging that meets stringent industry standards and tight tolerances is vital for the performance and safety of the final battery product, directly impacting battery manufacturers capabilities and end-product quality.

The distribution channels for battery packaging materials are multifaceted, encompassing both direct and indirect approaches. Direct distribution typically involves large-scale contracts where packaging manufacturers supply directly to major battery manufacturers or electric vehicle original equipment manufacturers (OEMs). This often includes co-development projects for highly specialized and integrated packaging solutions. Indirect channels involve distributors and specialized component suppliers who serve smaller battery assemblers, consumer electronics companies, and various industrial clients. These intermediaries often provide a broader range of standard packaging components and facilitate logistics, allowing smaller players to access diverse solutions without direct manufacturing partnerships. The efficiency and reliability of these distribution networks are critical for ensuring timely delivery and supporting the rapid growth of the battery industry globally.

Battery Packaging Material Market Potential Customers

The primary potential customers for battery packaging materials are the manufacturers within the electric vehicle (EV) industry, encompassing both established automotive giants and emerging EV startups. These companies require robust, lightweight, and highly engineered packaging solutions for their battery packs, which are central to vehicle performance, safety, and range. As the automotive industry rapidly transitions towards electrification, the demand from this segment is surging, driven by the need for packaging that can withstand harsh operating conditions, provide superior crash protection, and contribute to the overall energy efficiency of the vehicle. OEMs are constantly seeking innovative packaging that can integrate advanced thermal management, simplify assembly processes, and meet increasingly strict safety and environmental regulations.

Another significant segment of potential customers includes consumer electronics companies, ranging from global technology leaders to niche device manufacturers. This segment requires compact, aesthetically pleasing, and durable battery packaging for a vast array of products such as smartphones, laptops, wearable devices, and portable power tools. The packaging must be thin, lightweight, and often designed to fit complex geometries, while also providing adequate protection against impacts, short circuits, and thermal events. As consumer devices continue to shrink and integrate more powerful batteries, the demand for sophisticated, space-efficient, and thermally managed packaging solutions from this sector remains consistently high, driving innovation in material properties and miniaturization capabilities.

Furthermore, the rapidly expanding energy storage systems (ESS) sector, including utility-scale grid storage, commercial and industrial battery systems, and residential energy storage solutions, represents a substantial customer base. These applications demand large-scale, long-duration battery packaging that prioritizes safety, reliability, and longevity. The packaging must protect against environmental factors, ensure thermal stability over extended periods, and often facilitate modular design for scalability. As global investment in renewable energy and grid modernization intensifies, the need for robust and efficient packaging for large battery arrays will continue to grow, making ESS providers key buyers in the market. Additionally, niche markets like medical devices, defense, and aerospace also serve as important, albeit smaller, customer segments, requiring highly specialized and ultra-reliable packaging for mission-critical applications.

Battery Packaging Material Market Key Technology Landscape

The Battery Packaging Material Market is characterized by a dynamic technology landscape driven by the incessant demand for enhanced battery performance, safety, and longevity across various applications. A pivotal technological focus lies in advanced polymer and composite materials, which are increasingly being developed to offer superior strength-to-weight ratios compared to traditional metals. Innovations in these materials, such as fiber-reinforced plastics and specialized polymer blends, provide excellent mechanical protection against impact, reduce overall battery pack weight, and often simplify complex manufacturing processes. These advancements are crucial for the electric vehicle industry, where lightweighting directly contributes to extended range and improved energy efficiency, while also offering enhanced design flexibility for diverse battery pack configurations.

Thermal management solutions represent another critical area of technological development within battery packaging. As batteries become more powerful and energy-dense, managing heat dissipation efficiently is paramount to prevent thermal runaway and ensure operational safety and lifespan. This involves integrating advanced heat sinks, phase-change materials, and efficient cooling channels directly into the packaging design. Technologies like liquid cooling plates made from aluminum or specialized plastics, as well as fire-retardant coatings and intumescent materials, are becoming standard features in high-performance battery packs. Research also focuses on smart thermal management systems that can actively monitor and adjust cooling based on real-time battery conditions, further enhancing safety and extending battery life.

Furthermore, the market is witnessing significant advancements in structural integration and modular design methodologies. Modern battery packaging is moving beyond simple enclosures to become an integral, structural component of the overall device or vehicle, offering enhanced rigidity and crash protection. This involves designing battery packs that are load-bearing structures, seamlessly integrated into the vehicle chassis or device framework. Automation and advanced manufacturing techniques, including precision welding, additive manufacturing (3D printing), and robotic assembly, are enabling the production of highly complex, customized, and precisely engineered packaging solutions with reduced lead times and improved quality. These technological innovations collectively contribute to the development of safer, more efficient, and longer-lasting battery systems, meeting the rigorous demands of emerging high-power applications.

Regional Highlights

- Asia-Pacific: This region dominates the global Battery Packaging Material Market, driven by the presence of major battery manufacturers and the largest electric vehicle production base globally, particularly in China, South Korea, and Japan. Significant government incentives for EV adoption and robust investments in renewable energy infrastructure further fuel market growth, leading to a high demand for advanced and cost-effective packaging solutions for various battery types.

- North America: The market in North America is experiencing substantial growth, propelled by the increasing consumer adoption of electric vehicles, supportive government policies like the Inflation Reduction Act promoting domestic battery manufacturing, and significant R&D investments in advanced battery technologies. The region is focusing on developing sustainable and highly safe packaging solutions, with a strong emphasis on materials that can withstand extreme environmental conditions and enhance vehicle safety.

- Europe: Europe represents a rapidly expanding market, driven by stringent emission regulations, ambitious electrification targets, and significant investments in Gigafactories for battery production. Countries like Germany, France, and the UK are at the forefront of battery technology and EV adoption, creating a high demand for innovative, high-performance, and recyclable packaging materials that comply with strict environmental and safety standards, pushing for localized supply chains.

- South America: While currently a smaller market, South America is showing promising growth potential, primarily driven by increasing interest in electric mobility and renewable energy projects. Countries like Brazil and Chile are beginning to invest in EV infrastructure and energy storage solutions, which will gradually increase the demand for battery packaging materials, often relying on imports but with a growing desire for local manufacturing capabilities in the long term.

- Middle East and Africa (MEA): This region is an emerging market for battery packaging materials, with growth spurred by government initiatives to diversify economies away from oil, invest in renewable energy projects, and improve transportation infrastructure. Large-scale energy storage projects and nascent EV markets in countries like the UAE and Saudi Arabia are creating initial demand, focusing on durable and reliable packaging solutions suitable for challenging climatic conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Battery Packaging Material Market.- UACJ Corporation

- Nippon Light Metal Co. Ltd.

- Sumitomo Metal Mining Co., Ltd.

- Amcor PLC

- Envision AESC

- LG Chem

- POSCO

- Hydro Extrusion AS

- Toyo Seikan Group Holdings Ltd.

- Scholle IPN

- Constantia Flexibles

- Shenzhen Everwin Precision Technology Co., Ltd.

- Celanese Corporation

- Covestro AG

- DuPont de Nemours, Inc.

Frequently Asked Questions

What are the primary drivers for the Battery Packaging Material Market growth?

The primary drivers for the Battery Packaging Material Market growth include the accelerating global demand for electric vehicles (EVs), significant investments in grid-scale and residential energy storage systems (ESS) to support renewable energy integration, and the continuous innovation within the consumer electronics sector, all of which require advanced and safe battery solutions. Additionally, stringent safety regulations and the increasing emphasis on thermal management and lightweighting in battery design are further propelling market expansion.

How do safety regulations impact the design of battery packaging materials?

Safety regulations significantly impact the design of battery packaging materials by mandating enhanced features to prevent hazards such as thermal runaway, fire, and mechanical damage. These regulations often require packaging to offer superior fire resistance, improved thermal insulation, robust impact protection, and efficient venting mechanisms. Compliance with standards like UN 38.3, ECE R100, and UL 1642 drives innovation towards more resilient, fire-retardant, and structurally sound materials, ensuring the safe operation and transportation of batteries across various applications.

What role do composite materials play in modern battery packaging?

Composite materials play a crucial role in modern battery packaging by offering an exceptional combination of lightweight properties, high mechanical strength, and customizable thermal performance, often surpassing traditional metal or plastic alternatives. Materials like fiberglass and carbon fiber reinforced polymers are increasingly used in electric vehicle battery packs to reduce overall vehicle weight, improve crash safety, and provide superior thermal insulation. Their design flexibility also allows for complex geometries, optimizing space utilization and integration within advanced battery systems.

Which regions are leading the innovation and adoption in this market?

Asia-Pacific is currently leading the innovation and adoption in the Battery Packaging Material Market, driven by its extensive battery manufacturing capabilities and significant EV production in countries such as China, South Korea, and Japan. However, North America and Europe are rapidly catching up, with substantial investments in domestic battery production, advanced R&D, and stringent regulatory frameworks pushing for localized innovation in sustainable, high-performance, and safe packaging solutions. These regions are focusing heavily on developing advanced thermal management and fire protection technologies.

What are the key challenges faced by manufacturers in the Battery Packaging Material Market?

Key challenges faced by manufacturers in the Battery Packaging Material Market include the volatility of raw material prices, which directly impacts production costs and supply chain stability. Additionally, the increasing complexity of battery designs and evolving safety standards necessitate continuous investment in research and development for new materials and manufacturing processes. Balancing the demand for lightweighting with the need for robust protection, along with navigating intricate global supply chains and addressing environmental concerns related to recyclability, also pose significant hurdles for market participants.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager