Benzyl Chloride Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429654 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Benzyl Chloride Market Size

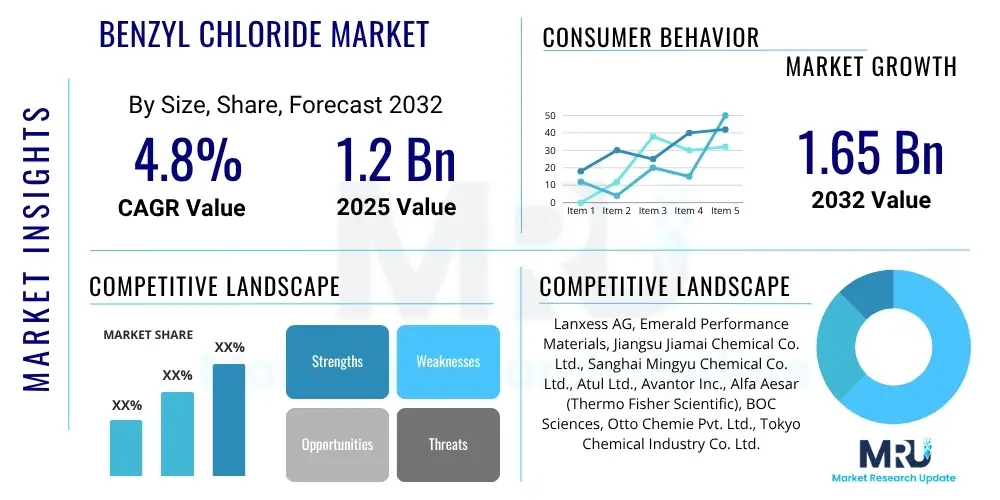

The Benzyl Chloride Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 1.2 Billion in 2025 and is projected to reach USD 1.65 Billion by the end of the forecast period in 2032.

Benzyl Chloride Market introduction

Benzyl chloride, a vital organic chemical intermediate, possesses a chemical formula of C6H5CH2Cl and is characterized by a benzene ring connected to a chloromethyl group. This compound is typically manufactured through the photochlorination of toluene, a process renowned for its efficiency and ability to produce a highly reactive and pure product essential for diverse downstream chemical syntheses. Its distinct reactivity stems from the labile chlorine atom, which readily participates in substitution reactions, making benzyl chloride an indispensable building block for creating a broad spectrum of complex organic molecules from simpler precursors. The inherent versatility and reactivity of benzyl chloride underscore its sustained importance across numerous industrial applications, establishing it as a cornerstone in organic chemical synthesis and a key component in the production of high-value end products. The reliability of its synthesis methods ensures a consistent supply chain for its derivatives, critical for various manufacturing sectors.

The applications of benzyl chloride are extensive and critical, spanning across key industries such as pharmaceuticals, agrochemicals, dyes and pigments, plasticizers, and the fragrance sector. Within the pharmaceutical industry, it serves as a crucial precursor for synthesizing various active pharmaceutical ingredients (APIs), including certain antihistamines, vasodilators, and anesthetics, playing an integral role in the development and production of essential medicines. For the agrochemical industry, benzyl chloride is fundamental to manufacturing effective herbicides, insecticides, and fungicides, which are vital for enhancing crop protection and maximizing agricultural yields to meet global food demand. Its utility further extends to the creation of vivid and stable organic dyes and pigments used in textiles, plastics, and various coating applications. In the realm of plasticizers, benzyl chloride derivatives are employed to improve the flexibility, durability, and processing characteristics of polymer products, particularly in polyvinyl chloride (PVC) formulations. These diverse applications highlight its broad industrial relevance and economic significance.

The market for benzyl chloride is significantly driven by its inherent benefits, including its high chemical reactivity, which facilitates efficient conversion into a multitude of desired derivatives, and the cost-effectiveness of its established production processes. These factors, combined with increasing global demand from end-use industries, propel market expansion. The pharmaceutical sector's continuous growth, fueled by an aging global population and rising healthcare expenditures, translates directly into sustained demand for benzyl chloride as a pharmaceutical intermediate. Similarly, the expanding agricultural industry, driven by the pressing need for enhanced food security and sustainable farming practices, necessitates an ongoing supply of agrochemicals derived from benzyl chloride. Furthermore, the rapid industrialization and urbanization in emerging economies worldwide, coupled with a burgeoning consumer base for specialty chemicals, personal care products, and durable goods, consistently contributes to the market's robust growth. Strict regulatory frameworks, particularly in pharmaceuticals, often mandate the use of high-purity and well-characterized chemical intermediates, reinforcing benzyl chloride's position as a preferred choice for compliant and effective synthesis.

Benzyl Chloride Market Executive Summary

The Benzyl Chloride Market is currently characterized by dynamic trends spanning business strategies, regional growth patterns, and segment-specific demands. In terms of business trends, the industry is witnessing a strategic consolidation driven by mergers, acquisitions, and collaborative ventures among leading manufacturers. These actions are primarily aimed at optimizing production capacities, achieving economies of scale, and strengthening global supply chain resilience. Companies are heavily investing in advanced research and development initiatives to explore novel applications for benzyl chloride derivatives, with a particular focus on developing products that offer enhanced performance or possess more favorable environmental profiles. This includes efforts to identify greener synthesis routes and implement waste minimization technologies in line with evolving sustainability mandates and consumer preferences. Process automation and the adoption of advanced control systems are also gaining prominence to improve manufacturing efficiency, reduce operational costs, and ensure consistent product quality, thereby securing a competitive edge in a demanding global market.

From a regional perspective, the Asia Pacific (APAC) region stands out as the predominant force in the benzyl chloride market, propelled by rapid industrial expansion, substantial population growth, and flourishing pharmaceutical and agrochemical industries, most notably in economic powerhouses like China and India. These countries benefit from strong domestic demand, robust manufacturing capabilities, and significant export volumes, making them central to the global supply of benzyl chloride. North America and Europe, while representing mature markets, exhibit stable demand driven by well-established specialty chemical and pharmaceutical sectors, underpinned by stringent quality and environmental regulations that favor high-grade chemical inputs. Meanwhile, emerging economies in Latin America and the Middle East and Africa (MEA) are demonstrating promising growth trajectories, stimulated by increasing investments in agricultural modernization, healthcare infrastructure development, and nascent industrialization efforts. Adapting to the diverse regulatory landscapes and market needs across these regions is critical for effective market penetration and sustained growth.

Segment-wise analysis reveals robust growth prospects for the pharmaceutical application segment, which is continually boosted by ongoing innovation in drug discovery and the increasing global prevalence of chronic diseases. The agrochemical sector maintains a consistent demand, driven by the critical need to enhance global food security through improved crop yields, although this segment is sensitive to seasonal cycles and evolving regulatory pressures concerning pesticide usage. The dyes and pigments segment, while significant, faces ongoing challenges from increasing environmental regulations and a gradual shift towards more sustainable or natural coloring alternatives, prompting innovation in cleaner manufacturing processes for synthetic dyes. Applications in plasticizers and other specialty chemicals continue to contribute meaningfully to market revenue, supported by the expanding construction, automotive, and consumer goods industries which require high-performance polymer additives. The overall market trajectory is thus intricately linked to these diverse industry dynamics, global economic health indicators, and the continuous advancement in chemical synthesis technologies, necessitating agile strategic responses from market participants.

AI Impact Analysis on Benzyl Chloride Market

Common user inquiries concerning the impact of Artificial Intelligence (AI) on the Benzyl Chloride Market primarily focus on operational efficiency, safety improvements, and accelerated innovation. Users frequently ask how AI can optimize complex chemical synthesis processes, leading to higher yields and reduced energy consumption in benzyl chloride production. There is also significant interest in AI's capability to implement predictive maintenance for critical plant equipment, thereby minimizing costly downtime and improving overall asset utilization. Furthermore, questions often arise regarding AI's role in expediting research and development for new benzyl chloride derivatives, particularly in modeling novel chemical reactions and predicting molecular properties, which could lead to breakthroughs in pharmaceutical and agrochemical applications. The overriding expectation is that AI will serve as a transformative tool, driving significant enhancements in productivity, safety, and product development across the entire value chain of the benzyl chloride industry, ensuring sustained competitiveness and innovation.

The integration of Artificial Intelligence and Machine Learning (ML) technologies is poised to significantly impact the Benzyl Chloride Market, primarily through advanced process optimization, enhanced predictive maintenance, and sophisticated quality control mechanisms. AI algorithms possess the capacity to analyze vast, complex datasets generated from chemical production lines, including real-time sensor data on temperature, pressure, flow rates, and reactant concentrations. By identifying intricate patterns and correlations, AI can precisely determine optimal operating parameters that maximize reaction yields, reduce byproduct formation, and significantly lower energy consumption, leading to substantial cost savings and improved environmental footprints. For example, AI-driven process control systems can make minute, real-time adjustments to reaction conditions, surpassing the capabilities of traditional human-controlled or rule-based automation systems. This data-centric approach minimizes variability in product quality and enhances overall operational efficiency, directly benefiting manufacturers by increasing throughput and reducing waste, which is particularly critical in large-scale chemical synthesis.

Beyond the manufacturing floor, AI is set to revolutionize research and development (R&D) efforts within the benzyl chloride ecosystem and its downstream applications. Machine learning models can be trained on extensive chemical databases to predict the properties and reactivity of new molecular structures, thereby accelerating the discovery and optimization of novel benzyl chloride derivatives for various industries. This includes designing new pharmaceutical intermediates, more effective agrochemicals, or innovative plasticizers with desired performance characteristics, significantly shortening the traditional drug and chemical development cycle. Furthermore, AI-powered solutions can enhance supply chain resilience and efficiency by accurately forecasting demand fluctuations, optimizing logistics routes, and intelligently managing inventory levels. Such predictive capabilities mitigate risks associated with raw material price volatility and supply chain disruptions. Crucially, AI also contributes to elevated safety standards through intelligent monitoring systems that continuously analyze environmental parameters and detect potential hazardous conditions in real-time, issuing proactive alerts to personnel. These integrated AI applications promise not only economic benefits but also a safer and more sustainable future for the benzyl chloride industry.

- AI-driven process optimization for maximizing reaction yields, minimizing energy consumption, and reducing waste in benzyl chloride production.

- Predictive maintenance analytics to anticipate and prevent equipment failures, thereby reducing costly downtime and extending the operational lifespan of machinery.

- Accelerated discovery and design of novel benzyl chloride derivatives and synthesis pathways through machine learning-based molecular modeling and property prediction.

- Enhanced supply chain management through AI-powered demand forecasting, logistics optimization, and intelligent inventory control to improve efficiency and resilience.

- Real-time safety monitoring systems leveraging AI to detect hazardous conditions, predict potential incidents, and issue timely alerts, improving workplace safety.

- Automated quality control systems ensuring consistent high product purity and adherence to stringent industry standards for various grades of benzyl chloride.

- Data-driven insights for strategic decision-making, market forecasting, and identifying competitive advantages through comprehensive data analysis.

DRO & Impact Forces Of Benzyl Chloride Market

The Benzyl Chloride Market's trajectory is profoundly influenced by a complex interplay of drivers, restraints, and opportunities, which together constitute the primary impact forces shaping its evolution. A significant driver is the escalating demand from the global pharmaceutical industry, where benzyl chloride serves as an indispensable intermediate for the synthesis of a myriad of active pharmaceutical ingredients (APIs) vital for various drug classes. The continuous growth of the global population, coupled with an increasing aging demographic and rising prevalence of chronic diseases, necessitates a consistent and expanding supply of pharmaceuticals, thereby sustaining and amplifying the demand for chemical precursors like benzyl chloride. Simultaneously, the expanding agrochemical sector stands as another critical consumer, driven by the imperative to enhance global food security and optimize crop yields amidst shrinking arable land. Benzyl chloride's role in producing essential herbicides, insecticides, and fungicides underpins this enduring demand. Furthermore, the robust growth of the specialty chemicals sector, encompassing dyes, fragrances, and plasticizers, contributes substantially to market expansion, spurred by ongoing industrialization in developing economies and increasing consumer demand for diverse manufactured goods and personal care products. Urbanization and evolving lifestyle preferences also subtly influence demand, translating into higher consumption rates for materials and products that utilize benzyl chloride derivatives.

Despite these powerful drivers, the market navigates several notable restraints that pose challenges to its unbridled growth. Benzyl chloride is classified as a hazardous substance due to its corrosive nature and potential health risks, necessitating extremely stringent handling, storage, and transportation protocols. Compliance with these rigorous environmental and occupational safety regulations incurs substantial investment in specialized infrastructure and operational training, directly increasing production costs for manufacturers. Moreover, the inherent volatility in the prices of key raw materials, predominantly toluene and chlorine, directly impacts the cost of manufacturing benzyl chloride, leading to fluctuating profit margins and potential price instability for end-users, complicating long-term planning. Heightened global environmental awareness and increasingly stringent regulatory frameworks concerning industrial emissions, chemical waste disposal, and product lifecycle assessments further constrain market players. These regulations compel manufacturers to invest significantly in capital-intensive green chemistry initiatives, advanced waste treatment technologies, or to actively seek alternative, less hazardous chemical intermediates, adding another layer of complexity to operations. The potential emergence and development of substitute products, though currently limited for core applications, also present a long-term restraint, as industries continuously search for safer or more sustainable chemical alternatives, potentially eroding benzyl chloride’s market share in specific niches.

Conversely, significant opportunities are emerging that could redefine the market landscape for benzyl chloride. The burgeoning demand for high-purity benzyl chloride, particularly from the stringently regulated pharmaceutical sector, opens lucrative avenues for manufacturers capable of consistently meeting exacting quality specifications and navigating complex regulatory compliance requirements. Extensive research and development efforts aimed at pioneering greener synthesis technologies and developing less hazardous benzyl chloride derivatives offer a pathway to mitigate environmental concerns and reduce regulatory burdens, fostering both innovation and sustainable growth. Strategic expansion into rapidly industrializing emerging economies in Asia Pacific, Latin America, and the Middle East and Africa presents substantial market growth opportunities, as these regions are witnessing burgeoning industrial bases and increasing investments in healthcare and agriculture sectors. Furthermore, the exploration of novel applications in niche markets, such as advanced materials science, specialized polymer additives, or highly customized chemical synthesis projects, could unlock entirely new revenue streams and broaden the market footprint. Strategic collaborations, joint ventures, mergers, and acquisitions among market players are increasingly seen as viable strategies to facilitate technological advancements, expand geographical reach, consolidate market share, and collectively respond more effectively to dynamic market forces. Adherence to circular economy principles and sustainable manufacturing practices will also provide a competitive differentiator, attracting environmentally conscious partners and customers.

Segmentation Analysis

The Benzyl Chloride Market is thoroughly segmented to provide an intricate and comprehensive understanding of its multifaceted landscape, thereby enabling the identification of key growth areas and strategic opportunities across various dimensions. This detailed segmentation facilitates a granular analysis of market dynamics, unveiling specific trends, demand patterns, competitive intensities, and the impact of regulatory frameworks within distinct application domains, product grades, and geographical regions. Such a structured approach is indispensable for market participants and investors to formulate effective strategic decisions, guide product development initiatives, and optimize market penetration strategies. Each market segment is uniquely influenced by a combination of economic factors, technological advancements, and specific regulatory environments, contributing to a diverse and highly dynamic market ecosystem that demands tailored and flexible approaches for achieving sustained success and capitalizing on emerging trends effectively. This deep dive into segments illuminates the intricate relationships between supply, demand, and market drivers.

Segmentation by application vividly highlights the primary end-use industries that fundamentally drive the demand for benzyl chloride. The pharmaceutical sector stands as a critical consumer, leveraging benzyl chloride as an essential intermediate for the sophisticated synthesis of a vast array of active pharmaceutical ingredients (APIs) and other vital drug intermediates. These include complex compounds crucial for medications ranging from cardiovascular treatments to anti-infectives. The agrochemical industry constitutes another substantial segment, utilizing benzyl chloride in the production of efficacious herbicides, insecticides, and fungicides, which are indispensable for protecting crops and enhancing agricultural productivity worldwide. The dyes and pigments sector extensively employs benzyl chloride as a key precursor for synthesizing a diverse spectrum of organic dyes and high-performance pigments that impart vibrant and lasting colors to textiles, plastics, coatings, and inks. Furthermore, the plasticizers segment relies on benzyl chloride derivatives to impart crucial properties such as flexibility, improved workability, and enhanced durability to polymer products, particularly in the manufacturing of polyvinyl chloride (PVC) goods like cables, films, and flooring. Other miscellaneous applications encompass its use in the flavor and fragrance industry for specific aroma chemicals, in the production of quaternary ammonium compounds for disinfectants, and in various other specialty chemical syntheses, underscoring its broad and indispensable industrial utility. This detailed application-based breakdown is vital for understanding specific industry requirements and forecasting future demand drivers.

Beyond the realm of specific applications, the Benzyl Chloride Market is further segmented by product grade and comprehensive geographical regions to offer a more refined and nuanced market perspective. Product grade segmentation typically distinguishes between Industrial Grade benzyl chloride and Pure Grade benzyl chloride, reflecting the differing purity requirements of various end-use sectors. Pure Grade benzyl chloride primarily caters to highly regulated industries such as pharmaceuticals and high-end specialty chemicals, where stringent purity standards are absolutely paramount for product efficacy and safety. Conversely, Industrial Grade benzyl chloride finds widespread use in less sensitive applications, including the production of certain dyes, general-purpose plasticizers, and other bulk chemical syntheses. The geographical segmentation systematically divides the global market into key regions, including North America, Europe, Asia Pacific (APAC), Latin America, and the Middle East and Africa (MEA). This regional breakdown is critical for discerning localized demand patterns, understanding region-specific regulatory landscapes, and identifying the concentration of key market players and prominent end-use industries. Each region presents unique characteristics in terms of industrial development, economic growth trajectories, and regulatory environments, all of which directly influence the consumption, production, and trade dynamics of benzyl chloride. A thorough analysis across these multi-layered segmentations empowers stakeholders to tailor their market strategies effectively, optimize resource allocation, and strategically capitalize on emerging opportunities specific to each segment and region.

- By Application

- Pharmaceuticals: Essential for synthesizing active pharmaceutical ingredients (APIs) and intermediates like benzyl penicillin.

- Agrochemicals: Crucial for manufacturing herbicides, insecticides, and fungicides for crop protection and yield enhancement.

- Dyes & Pigments: Key intermediate in the production of various organic dyes and vibrant pigments for textiles, plastics, and coatings.

- Plasticizers: Used to produce derivatives that enhance the flexibility, durability, and workability of polymer products, especially PVC.

- Fragrances: Employed in the synthesis of specific aroma chemicals and essential oils for perfumes and personal care products.

- Others (e.g., Quaternary Ammonium Compounds): Includes applications in disinfectants, photographic chemicals, and other specialized chemical syntheses.

- By Grade

- Industrial Grade: Used in applications where high purity is less critical, such as certain dyes and plasticizers.

- Pure Grade: Mandated for highly sensitive applications like pharmaceuticals and high-performance specialty chemicals due to stringent purity requirements.

- By Region

- North America: Mature market with stable demand from pharmaceutical and specialty chemical sectors, strong regulatory compliance.

- Europe: Established market driven by advanced pharmaceutical and agrochemical industries, strict environmental regulations influencing production.

- Asia Pacific (APAC): Largest and fastest-growing market due to rapid industrialization, burgeoning pharmaceutical and agrochemical sectors, especially in China and India.

- Latin America: Moderate growth fueled by agricultural expansion and developing industrial bases in countries like Brazil and Mexico.

- Middle East and Africa (MEA): Emerging market with potential growth driven by diversification efforts, investments in chemical manufacturing, and improving healthcare.

Value Chain Analysis For Benzyl Chloride Market

A comprehensive Value Chain Analysis for the Benzyl Chloride Market meticulously dissects the entire journey of the product, commencing from the initial sourcing of raw materials, traversing through the manufacturing processes, and extending to its ultimate consumption by a diverse array of end-use industries, including the intricate web of distribution channels. This detailed examination offers a holistic perspective on all interconnected activities that contribute to value creation at each stage, simultaneously pinpointing areas of operational efficiency, identifying key cost drivers, and highlighting potential opportunities for strategic optimization and value enhancement. Understanding the nuances of this value chain is absolutely critical for market players to identify and analyze key stakeholders, assess the relative bargaining power dynamics at different stages, and formulate robust strategies for improving profitability, enhancing competitive advantage, and fostering sustainable growth. It provides a clear roadmap of the entire ecosystem, from the foundational raw material extraction and processing to the final market reach, thereby revealing crucial interdependencies and potential avenues for vertical integration, horizontal diversification, or product differentiation strategies.

The upstream segment of the benzyl chloride value chain is primarily concerned with the procurement and initial processing of the fundamental raw materials required for its synthesis. The two principal raw materials are toluene and chlorine. Toluene is typically acquired from petrochemical refineries, where it is produced as a valuable aromatic byproduct of crude oil refining processes. Chlorine, on the other hand, is generally manufactured through the well-established industrial process of electrolysis of brine (sodium chloride solution). The consistent availability, consistent quality, and price stability of these essential raw materials are paramount, as they directly and significantly influence the cost structure, production efficiency, and ultimate profitability of benzyl chloride manufacturers. Establishing strong, reliable, and long-term relationships with a diverse base of reputable suppliers is therefore indispensable to ensure a continuous and cost-effective supply chain, mitigating risks associated with supply disruptions or price fluctuations. Following raw material acquisition, the subsequent manufacturing process involves the precise photochlorination of toluene, conducted under controlled conditions to yield benzyl chloride. This crucial stage demands specialized chemical engineering expertise, the deployment of advanced reactor technology, and the implementation of stringent quality control measures to guarantee optimal product purity, maximize reaction yields, and ensure operational safety. Continuous process optimization at this manufacturing stage is vital for minimizing waste generation, enhancing energy efficiency, and achieving superior conversion rates, thereby bolstering the economic viability and environmental performance of the production operation.

Downstream activities in the benzyl chloride value chain encompass the intricate processes of distributing the manufactured benzyl chloride to its myriad end-use industries and its subsequent transformation into various derivative products. Key downstream consumers include large-scale pharmaceutical manufacturers, prominent agrochemical companies, specialized producers of dyes and pigments, formulators of plasticizers, and established fragrance houses. Each of these diverse industries critically utilizes benzyl chloride as a pivotal intermediate for synthesizing their respective high-value end products. The distribution channel for benzyl chloride can be broadly categorized into direct sales and indirect sales. Direct sales typically involve substantial volume purchases by major industrial customers, often facilitated through long-term contractual agreements, which allow manufacturers to cultivate robust client relationships and ensure consistent product off-take. This approach often involves dedicated sales teams and technical support. Indirect sales primarily leverage an extensive network of chemical distributors, agents, and specialized trading companies who cater to a broader spectrum of smaller customers or those requiring more flexible purchasing options and logistical support. These distributors play a crucial role in enhancing market penetration, particularly in highly fragmented regional markets, by expertly managing inventory, providing efficient logistics, offering localized technical support, and facilitating credit terms. The overall effectiveness and responsiveness of these varied distribution networks are absolutely key to ensuring widespread market access, timely delivery to a diverse customer base, and ultimately, influencing the overall market reach, customer satisfaction, and sustained profitability for benzyl chloride producers. Efficient logistics and warehousing are particularly vital given the hazardous nature of the product, requiring specialized handling and transport solutions.

Benzyl Chloride Market Potential Customers

The potential customer base for benzyl chloride is exceptionally broad and diverse, encompassing a wide array of industrial sectors that depend on its unique chemical properties as a highly reactive and versatile intermediate. These end-users, or direct buyers, are the ultimate drivers of demand in the market, as they transform raw benzyl chloride into an extensive spectrum of value-added products that serve various societal and industrial needs. Accurately identifying, understanding, and segmenting these diverse customer groups is absolutely fundamental for market participants to effectively tailor their product offerings, refine their sales and marketing strategies, and optimize their intricate supply chain management. The intrinsic versatility of benzyl chloride allows it to cater to multiple high-value applications, rendering its demand robust and relatively resilient across varying economic cycles and technological advancements. Each distinct customer segment typically possesses specific purity requirements, unique volume needs, and adherence to particular regulatory considerations, thereby necessitating a customized and flexible approach from suppliers to efficiently meet market expectations and cultivate enduring, mutually beneficial relationships. This meticulous understanding of customer needs is paramount for long-term market success.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.2 Billion |

| Market Forecast in 2032 | USD 1.65 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Lanxess AG, Emerald Performance Materials, Jiangsu Jiamai Chemical Co. Ltd., Sanghai Mingyu Chemical Co. Ltd., Atul Ltd., Avantor Inc., Alfa Aesar (Thermo Fisher Scientific), BOC Sciences, Otto Chemie Pvt. Ltd., Tokyo Chemical Industry Co. Ltd. (TCI), Merck KGaA, VWR International (Avantor), Acros Organics (Thermo Fisher Scientific), Sigma-Aldrich (Merck KGaA), Santa Cruz Biotechnology Inc., HBCChem Inc., Kanto Chemical Co. Inc., Spectrochem Private Limited, Finar Limited, Chem-Impex International Inc., Hangzhou Hairui Chemical Co. Ltd., Shandong Haihua Group Co. Ltd., Anhui Bailing Chemical Co. Ltd., J&K Scientific Ltd., A. B. Enterprises. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Benzyl Chloride Market Key Technology Landscape

The technological landscape impacting the Benzyl Chloride Market is dynamically evolving, driven by an imperative to enhance production efficiency, significantly improve product purity, and rigorously ensure environmental sustainability across the entire manufacturing process. While the foundational production method, photochlorination of toluene, remains widely utilized, contemporary innovations are primarily concentrated on optimizing reactor designs and precisely tuning process parameters to maximize reaction yields, minimize the formation of undesirable byproducts, and improve energy utilization. Significant advancements in catalysis are playing an increasingly pivotal role, with ongoing intensive research and development efforts directed towards discovering and implementing more selective and highly efficient catalytic systems. These new catalytic approaches aim to substantially reduce energy consumption during synthesis and accelerate reaction kinetics, thereby boosting throughput and reducing operational costs. Furthermore, the strategic adoption of continuous flow reactors, as opposed to traditional batch processes, represents a significant technological shift. Continuous flow systems offer numerous benefits, including inherently improved safety profiles, superior control over critical reaction conditions, and significantly higher throughput capacities, which are particularly advantageous for large-scale industrial chemical synthesis. These sustained technological enhancements are absolutely crucial for driving down overall production costs, ensuring superior product quality, and maintaining consistent product characteristics, which are increasingly vital for demanding end-use applications such as pharmaceuticals and high-performance specialty chemicals.

Looking towards the future, the strategic integration of cutting-edge digital technologies, including Artificial Intelligence (AI) and Machine Learning (ML), is poised to profoundly transform the benzyl chloride production and utilization landscape. AI algorithms are increasingly being deployed for highly accurate predictive maintenance of critical manufacturing equipment, for optimizing dynamic reaction conditions in real-time based on complex data inputs, and even for simulating intricate chemical reactions to drastically accelerate research and development cycles for new derivatives or to design inherently safer and more efficient synthesis pathways. The judicious application of robotics and advanced automation is also steadily expanding into material handling, packaging, and hazardous chemical transfer operations, thereby significantly enhancing operational safety and overall efficiency within chemical plants. Concurrently, the continuous development and deployment of highly sensitive advanced sensors for real-time monitoring of chemical compositions, process parameters, and environmental metrics will further bolster safety protocols, ensure stringent regulatory compliance, and provide invaluable operational intelligence. These cumulative technological advancements are collectively aimed at making benzyl chloride production unequivocally more efficient, inherently safer, and significantly more environmentally responsible. This holistic approach ensures the industry can adapt effectively to evolving market demands and increasingly rigorous regulatory pressures, while simultaneously guaranteeing sustained market growth and fostering continuous innovation. Long-term transformative areas could include novel solvent-free reaction methodologies or the exploration of alternative, more sustainable feedstocks.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for benzyl chloride, characterized by a well-established chemical manufacturing infrastructure and robust, consistent demand originating from its sophisticated pharmaceutical and specialty chemicals sectors. The United States, in particular, stands as a major consumer, significantly driven by extensive research and development activities in biotechnology, advanced materials, and pharmaceutical innovation. Strict adherence to environmental regulations and comprehensive safety standards necessitates the implementation of high-quality production processes and often leads to a pronounced preference for domestically produced benzyl chloride or supplies from highly compliant international manufacturers. While the growth rates in North America may not exhibit the rapid expansion seen in emerging economies, the consistent demand for high-purity intermediates and specialized derivatives ensures a stable and resilient market trajectory. Furthermore, there is a strong and continuous focus on fostering innovation in sustainable chemical manufacturing practices, which actively influences market dynamics and future investment decisions across the region.

- Europe: The European market for benzyl chloride mirrors North America in its maturity and sophistication, with demand predominantly emanating from its highly developed pharmaceutical industry, a diverse and technologically advanced agrochemical sector, and a strong base of specialty chemical manufacturers. Key contributing countries include Germany, France, and the United Kingdom, which collectively boast formidable research and development capabilities and a profound emphasis on unparalleled product quality and robust environmental protection. Stringent regulatory frameworks, such as the EU's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), profoundly impact manufacturing practices and market entry strategies, compelling companies to adopt sustainable and fully compliant production methods. The region faces ongoing challenges from relatively high energy costs and intense competition from lower-cost imports; however, it effectively mitigates these through its focus on high-value applications, continuous technological innovation, and a strong commitment to quality and safety standards.

- Asia Pacific (APAC): APAC remains the undisputed largest and most rapidly growing market for benzyl chloride globally. This impressive growth is fueled by an unprecedented pace of industrialization, the continuous expansion of manufacturing bases, and substantial, ongoing investments in both the pharmaceutical and agrochemical industries, especially within economic giants like China and India. These nations benefit significantly from comparatively lower labor costs, abundant availability of raw materials, and a burgeoning domestic and export market for a wide array of chemicals. The escalating demand for enhanced food security, driven by massive population growth, and the increasing accessibility of affordable healthcare products collectively fuel continuous and substantial growth in the agrochemical and pharmaceutical sectors, respectively. Furthermore, robust economic development across Southeast Asian nations also plays a crucial role in contributing to the region's overall market expansion. While environmental regulations are progressively becoming stricter, the sheer scale of industrial output continues to drive exceptionally high consumption volumes, firmly establishing APAC as the critical global hub for both benzyl chloride production and demand.

- Latin America: The Latin American market for benzyl chloride is characterized by moderate but steady growth, primarily influenced by ongoing agricultural expansion and the gradual development of industrial sectors in prominent countries such as Brazil, Mexico, and Argentina. The agrochemical industry emerges as a particularly significant demand driver in this region, as these nations are major global producers and exporters of agricultural commodities, necessitating highly efficient and effective crop protection solutions. Concurrently, investments in healthcare infrastructure and pharmaceutical manufacturing capabilities are progressively increasing, contributing to a growing demand for essential chemical intermediates. Economic stability, coupled with attractive foreign direct investment, will undoubtedly play a crucial role in accelerating the overall market growth trajectory within this region. It is important to note that regulatory environments can vary considerably across different Latin American countries, which in turn influences specific market access strategies and operational approaches for chemical producers looking to expand their presence here.

- Middle East and Africa (MEA): The MEA region represents an emerging and promising market for benzyl chloride, with its growth prospects significantly bolstered by concerted diversification efforts aimed at reducing reliance on traditional oil-dependent economies, alongside increasing strategic investments in chemical manufacturing, agriculture, and healthcare infrastructure. Countries such as Saudi Arabia and the United Arab Emirates are actively investing in the development of large-scale petrochemical complexes, which are expected to substantially enhance local production capabilities for critical raw materials like toluene. Improving access to healthcare services and the pressing need to address pervasive food security concerns are collectively driving increased demand from both the pharmaceutical and agrochemical sectors across the region. While currently a relatively smaller market compared to the established giants like APAC or Europe, the MEA region offers considerable long-term growth potential, underpinned by ongoing industrial development initiatives, ambitious infrastructural expansion projects, and a growing consumer base. Political stability and the attraction of sustained foreign investment will remain key determinants of its future market trajectory and ultimate success.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Benzyl Chloride Market.- Lanxess AG

- Emerald Performance Materials

- Jiangsu Jiamai Chemical Co. Ltd.

- Sanghai Mingyu Chemical Co. Ltd.

- Atul Ltd.

- Avantor Inc.

- Alfa Aesar (Thermo Fisher Scientific)

- BOC Sciences

- Otto Chemie Pvt. Ltd.

- Tokyo Chemical Industry Co. Ltd. (TCI)

- Merck KGaA

- VWR International (Avantor)

- Acros Organics (Thermo Fisher Scientific)

- Sigma-Aldrich (Merck KGaA)

- Santa Cruz Biotechnology Inc.

- HBCChem Inc.

- Kanto Chemical Co. Inc.

- Spectrochem Private Limited

- Finar Limited

- Chem-Impex International Inc.

- Hangzhou Hairui Chemical Co. Ltd.

- Shandong Haihua Group Co. Ltd.

- Anhui Bailing Chemical Co. Ltd.

- J&K Scientific Ltd.

- A. B. Enterprises

Frequently Asked Questions

What is Benzyl Chloride and its primary uses in industry?

Benzyl Chloride (C6H5CH2Cl) is a significant organic chemical compound acting as a crucial intermediate in various industrial syntheses. It is primarily used in the pharmaceutical industry for synthesizing active pharmaceutical ingredients (APIs), in agrochemicals for herbicides and insecticides, and in the production of dyes, pigments, plasticizers, and fragrances. Its high reactivity, due to a labile chlorine atom, makes it invaluable as a versatile building block for creating complex organic molecules, underpinning its wide industrial application and economic importance across multiple sectors, ensuring the supply of essential products like medications and crop protection chemicals.

How is Benzyl Chloride typically manufactured?

Benzyl Chloride is typically manufactured through the photochlorination of toluene. This industrial process involves reacting toluene with chlorine gas under the influence of ultraviolet light. This highly efficient and established method yields a pure and reactive product. The availability and stable pricing of the key raw materials, toluene (derived from petrochemicals) and chlorine (produced via brine electrolysis), are critical factors influencing the overall production cost and the subsequent market dynamics of benzyl chloride, ensuring a consistent supply for derivative industries.

Which geographical region exhibits the highest demand for Benzyl Chloride?

The Asia Pacific (APAC) region currently demonstrates the highest demand for Benzyl Chloride and is projected to maintain its leading position throughout the forecast period. This strong market dominance is driven by rapid industrialization, substantial economic growth, and significant expansion within the pharmaceutical and agrochemical industries, particularly in populous and industrially active nations such as China and India. The region benefits from large-scale manufacturing capacities, competitive operational costs, and increasing domestic and export requirements for various chemicals, positioning it as a critical global hub for consumption and production.

What are the main regulatory and environmental concerns associated with Benzyl Chloride?

The main regulatory and environmental concerns regarding Benzyl Chloride stem from its classification as a hazardous and corrosive substance. This necessitates the implementation of stringent handling, storage, and transportation protocols, leading to increased operational costs for manufacturers due to extensive safety infrastructure and compliance requirements. Furthermore, growing environmental regulations concerning industrial emissions, chemical waste disposal, and product lifecycle assessments compel the industry to invest in greener synthesis technologies and advanced waste treatment solutions to minimize its ecological footprint and ensure adherence to global environmental standards, posing ongoing challenges and driving innovation.

In what ways can technological advancements, including AI, influence the Benzyl Chloride Market?

Technological advancements, particularly the integration of Artificial Intelligence (AI) and Machine Learning (ML), can profoundly influence the Benzyl Chloride Market by enhancing operational efficiency, improving safety, and accelerating innovation. AI enables advanced process optimization for higher yields and reduced energy consumption, facilitates predictive maintenance to minimize downtime, and speeds up research and development for new derivatives through molecular modeling. Furthermore, AI improves supply chain resilience and elevates safety standards through real-time monitoring, leading to a more efficient, sustainable, and competitive market landscape, adapting to future demands and fostering continuous product development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager