Bioprocess Analyzers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429580 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Bioprocess Analyzers Market Size

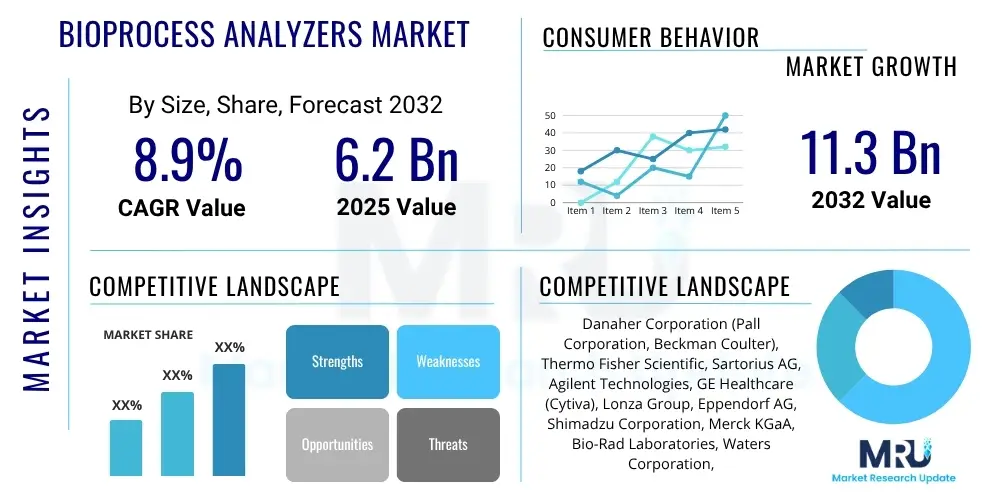

The Bioprocess Analyzers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.9% between 2025 and 2032. The market is estimated at USD 6.2 Billion in 2025 and is projected to reach USD 11.3 Billion by the end of the forecast period in 2032.

Bioprocess Analyzers Market introduction

The Bioprocess Analyzers Market encompasses advanced analytical instruments and systems designed for real-time or near real-time monitoring and control of various parameters in bioprocesses. These products, including sophisticated sensors, spectrometers, chromatographs, and cell counters, play a critical role in measuring key attributes such as pH, dissolved oxygen, glucose concentration, cell viability, and biomass within bioreactors and other biomanufacturing environments. Their primary application lies in biopharmaceutical manufacturing, enabling the efficient production of vaccines, antibodies, and other biologics, alongside significant use in academic research, food and beverage processing, and environmental monitoring.

The core benefits derived from employing bioprocess analyzers include enhanced process understanding, improved product quality, reduced manufacturing costs, and accelerated development timelines for biopharmaceutical products. By providing continuous insights into process dynamics, these analyzers facilitate optimal control strategies and compliance with stringent regulatory requirements. The market's growth is predominantly driven by the escalating demand for biologics and personalized medicine, increasing regulatory emphasis on Quality by Design (QbD) principles, and the persistent need for greater efficiency and automation in biomanufacturing processes.

Furthermore, technological advancements leading to more robust, accurate, and user-friendly analytical solutions are continually expanding the adoption of bioprocess analyzers. The integration of these tools supports critical decision-making from upstream cell culture to downstream purification, ensuring consistent product quality and process reproducibility. This growing reliance underscores their indispensable role in modern biotechnology and pharmaceutical production.

Bioprocess Analyzers Market Executive Summary

The Bioprocess Analyzers Market is experiencing robust expansion, primarily fueled by significant business trends such as the surging demand for biopharmaceuticals and the increasing adoption of Process Analytical Technology (PAT) tools to enhance manufacturing efficiency and product quality. Companies are investing heavily in automation and digitalization solutions to integrate real-time monitoring capabilities, thereby optimizing bioprocess control and reducing operational costs. Strategic collaborations and mergers and acquisitions are also prominent, as key players seek to expand their technological portfolios and market reach, particularly in advanced analytical solutions and data management platforms for bioprocesses.

From a regional perspective, North America and Europe currently dominate the market, attributed to their well-established biopharmaceutical industries, extensive research and development activities, and favorable regulatory frameworks that encourage the adoption of advanced analytical instruments. However, the Asia Pacific (APAC) region is projected to exhibit the fastest growth, driven by burgeoning biomanufacturing capacities, increasing investments in healthcare infrastructure, and rising outsourcing activities from global pharmaceutical companies. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as healthcare spending and biotechnological advancements gradually improve in these regions.

Segmentation trends indicate a strong shift towards in-line and on-line analyzers due to their ability to provide continuous, real-time data, which is crucial for achieving QbD objectives and efficient process control. The product segment is witnessing increased demand for advanced sensors and multi-parameter analysis systems that offer greater accuracy and reliability. Applications in biopharmaceutical manufacturing remain the largest segment, but there is also growing interest from contract manufacturing organizations (CMOs) and academic research institutes seeking to optimize their bioprocesses and accelerate drug development pipelines, further diversifying market opportunities.

AI Impact Analysis on Bioprocess Analyzers Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the Bioprocess Analyzers Market, focusing on its potential for enhanced data interpretation, predictive modeling, and automation. Key questions often revolve around AI's ability to process large datasets generated by analyzers, identify subtle process deviations, predict optimal operating conditions, and minimize human intervention. There is significant interest in AI's role in improving efficiency, reducing batch failures, accelerating development, and ensuring consistent product quality in complex biopharmaceutical manufacturing, alongside concerns about data security, integration challenges, and the need for specialized expertise to implement these advanced systems effectively.

- AI enhances real-time data analysis from bioprocess analyzers, uncovering hidden patterns and correlations.

- Predictive analytics powered by AI forecasts process excursions, enabling proactive intervention and reducing downtime.

- AI optimizes process parameters, leading to improved yields and reduced consumption of raw materials.

- Automated anomaly detection through AI identifies subtle deviations, ensuring early quality control.

- Accelerated bioprocess development and scale-up due to AI-driven insights and experimental design.

- Facilitates advanced process control strategies and closed-loop feedback systems.

- Integrates multi-omics data with analyzer outputs for a holistic understanding of biological systems.

- Reduces reliance on manual data interpretation and expert subjective analysis.

DRO & Impact Forces Of Bioprocess Analyzers Market

The Bioprocess Analyzers Market is significantly shaped by a confluence of driving factors, critical restraints, and substantial opportunities, all influenced by dynamic impact forces. A primary driver is the accelerating growth of the biopharmaceutical industry, particularly the expanding pipeline of biologics, biosimilars, and cell and gene therapies, which necessitate precise and real-time process monitoring for quality assurance and regulatory compliance. Stricter regulatory guidelines globally, emphasizing Quality by Design (QbD) and Process Analytical Technology (PAT), compel manufacturers to adopt advanced analytical solutions. The increasing demand for automation and integrated systems within biomanufacturing further propels market expansion by promising enhanced efficiency and reduced operational costs.

However, the market faces notable restraints, including the high initial capital investment required for purchasing and integrating sophisticated bioprocess analyzer systems, which can be a barrier for smaller companies or those with limited budgets. The complexity of integrating these advanced analytical tools with existing legacy systems, coupled with the need for specialized technical expertise for their operation and maintenance, also poses significant challenges. Furthermore, the extensive data generated by these analyzers requires robust data management and analysis capabilities, which can be an additional hurdle for adoption.

Despite these challenges, numerous opportunities exist for market growth. The emergence of personalized medicine and continuous bioprocessing opens new avenues for specialized analyzer applications. Developing novel, less invasive, and more compact analytical technologies, along with expanding into untapped markets in developing regions, offers substantial growth prospects. Strategic partnerships between technology providers and biopharmaceutical manufacturers to develop customized solutions and services will also be crucial. The primary impact forces influencing this market include rapid technological advancements in sensor design and data analytics, evolving regulatory landscapes pushing for higher quality standards, and economic factors dictating investment capacities and production efficiencies within the global biotech sector.

Segmentation Analysis

The Bioprocess Analyzers Market is comprehensively segmented across various dimensions, including product type, modality, application, and end-use, providing a granular view of market dynamics and growth opportunities. Each segment reflects distinct technological advancements, operational requirements, and strategic priorities within the biopharmaceutical and biotechnology industries. Understanding these segmentations is crucial for market participants to tailor their offerings and identify target customer groups effectively, catering to specific analytical needs from early-stage research to large-scale commercial production.

- By Product Type

- Sensors & Probes

- pH Sensors

- Dissolved Oxygen Sensors

- Redox Potential Sensors

- Temperature Sensors

- CO2 Sensors

- Conductivity Sensors

- Glucose Sensors

- Lactate Sensors

- Biomass Sensors

- Spectrometers

- Near-Infrared (NIR) Spectroscopy

- Raman Spectroscopy

- Mass Spectrometry

- Chromatographs

- High-Performance Liquid Chromatography (HPLC)

- Ultra-Performance Liquid Chromatography (UPLC)

- Gas Chromatography (GC)

- Cell Counters

- Osmometers

- Bioreactor Gas Analyzers

- Automated Cell Culture Analyzers

- Others (e.g., ELISA Readers, Flow Cytometers)

- Sensors & Probes

- By Modality

- In-line

- On-line

- At-line

- Off-line

- By Application

- Biopharmaceutical Manufacturing

- Academic & Research Institutes

- Contract Manufacturing Organizations (CMOs)

- Food & Beverage Industry

- Environmental Monitoring

- Others

- By End-Use

- Pharmaceutical & Biopharmaceutical Companies

- Contract Research Organizations (CROs)

- Academic & Research Institutions

- Food & Beverage Manufacturing Units

- Environmental Agencies

- By Region

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Bioprocess Analyzers Market

The value chain for the Bioprocess Analyzers Market begins with upstream activities focused on research and development, raw material sourcing, and component manufacturing. This stage involves specialized suppliers providing high-precision components such as optical sensors, electrodes, microfluidic chips, and specialized reagents, alongside software developers creating sophisticated algorithms for data acquisition and analysis. Key players in this phase invest heavily in R&D to innovate new measurement principles, improve sensor longevity, and enhance analytical capabilities, ensuring their offerings meet the evolving demands of bioprocessing for accuracy and reliability.

Midstream activities involve the design, assembly, and manufacturing of the complete bioprocess analyzer systems. This includes integrating various components into robust, user-friendly instruments that can withstand harsh bioprocessing environments, often involving sterile conditions and varying temperatures. Quality control and rigorous testing are paramount at this stage to ensure instruments deliver precise and reproducible results, adhering to industry standards and regulatory requirements. Companies also focus on developing comprehensive software platforms that facilitate data visualization, process control integration, and compliance documentation.

Downstream analysis in the value chain primarily involves distribution, sales, installation, customer training, and post-sales support, including maintenance and calibration services. Distribution channels are typically a mix of direct sales forces for major clients and strategic partnerships with regional distributors or agents, enabling broader market reach. Direct sales allow for closer customer relationships and customized solutions, while indirect channels provide access to diverse markets and leverage local expertise. Effective customer support and technical service are crucial for client satisfaction and retention, particularly given the technical complexity and critical role of these analyzers in biomanufacturing. This comprehensive value chain ensures that advanced analytical solutions reach end-users efficiently and are supported throughout their lifecycle.

Bioprocess Analyzers Market Potential Customers

The primary potential customers and end-users of bioprocess analyzers are entities heavily involved in the development, manufacturing, and quality control of biological products. This includes a broad spectrum of organizations across the life sciences and related industries. Leading the demand are biopharmaceutical companies, ranging from large multinational corporations to small and medium-sized enterprises (SMEs), which utilize these analyzers for the production of vaccines, monoclonal antibodies, recombinant proteins, and advanced therapies like cell and gene therapies. These companies rely on analyzers to optimize upstream cell culture, monitor fermentation processes, and control downstream purification, ensuring product efficacy, safety, and regulatory compliance.

Academic and research institutions constitute another significant customer segment. Universities and public or private research laboratories employ bioprocess analyzers for fundamental research into cellular metabolism, drug discovery, and process development studies. Their need often focuses on flexibility, precision, and the ability to integrate with diverse experimental setups to gain deeper insights into biological systems and optimize novel bioproduction methods. Contract Research Organizations (CROs) and Contract Manufacturing Organizations (CMOs) are also rapidly growing customer groups, as they offer specialized bioprocessing services to the biopharmaceutical industry. These organizations leverage advanced analyzers to provide efficient, high-quality services to their clients, often requiring scalable and versatile analytical solutions.

Furthermore, the food and beverage industry increasingly adopts bioprocess analyzers for fermentation control in products such as beer, wine, and dairy, focusing on quality, consistency, and yield optimization. Environmental monitoring agencies and companies involved in wastewater treatment or biofuel production also represent potential customers, using these analyzers to monitor microbial processes and optimize conversion efficiency or pollutant removal. The diverse applications underscore the broad utility and expanding customer base for bioprocess analyzers across various industrial and scientific domains.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.2 Billion |

| Market Forecast in 2032 | USD 11.3 Billion |

| Growth Rate | 8.9% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Danaher Corporation (Pall Corporation, Beckman Coulter), Thermo Fisher Scientific, Sartorius AG, Agilent Technologies, GE Healthcare (Cytiva), Lonza Group, Eppendorf AG, Shimadzu Corporation, Merck KGaA, Bio-Rad Laboratories, Waters Corporation, F. Hoffmann-La Roche AG, Nova Biomedical, Hamilton Company, Metrohm AG, Yokogawa Electric Corporation, Malvern Panalytical, Mettler-Toledo International Inc., Repligen Corporation, Sysmex Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bioprocess Analyzers Market Key Technology Landscape

The Bioprocess Analyzers Market is characterized by a dynamic and continuously evolving technology landscape, driven by the need for greater precision, real-time data, and integration capabilities in bioprocessing. Process Analytical Technology (PAT) tools form the cornerstone of this landscape, encompassing a range of analytical techniques implemented directly within the bioprocess environment. Advanced sensor technologies, including optical sensors, electrochemical sensors, and biosensors, are at the forefront, offering non-invasive or minimally invasive measurement of critical parameters like pH, dissolved oxygen, glucose, lactate, and cell density directly within bioreactors. These sensors are increasingly miniaturized and designed for single-use applications, reducing contamination risks and cleaning validation efforts.

Spectroscopic methods represent another significant technological area. Near-Infrared (NIR) and Raman spectroscopy are widely adopted for real-time, non-destructive analysis of complex matrices, providing insights into component concentrations, cell growth, and product quality attributes. Mass spectrometry (MS) is also gaining traction for detailed characterization of proteins, metabolites, and impurities, often integrated with chromatographic separations. Chromatography techniques such as High-Performance Liquid Chromatography (HPLC) and Ultra-Performance Liquid Chromatography (UPLC) remain indispensable for the separation and quantification of biomolecules, with efforts focused on developing faster and more automated at-line or on-line systems.

Beyond individual analytical instruments, the landscape is heavily influenced by the integration of automation, robotics, and advanced software solutions. Automated sampling systems reduce manual labor and improve data consistency. Data analytics platforms, often incorporating Artificial Intelligence (AI) and Machine Learning (ML) algorithms, are crucial for processing the vast amounts of data generated by these analyzers, enabling predictive modeling, anomaly detection, and advanced process control. The ongoing trend towards digitalization and the implementation of Industry 4.0 principles in biomanufacturing are driving the development of interconnected, smart analyzer systems that facilitate a holistic and optimized approach to bioprocess monitoring and control.

Regional Highlights

- North America: Dominates the Bioprocess Analyzers Market due to a robust biopharmaceutical industry, significant R&D investments, presence of key market players, and stringent regulatory requirements that encourage PAT adoption. The United States is the largest contributor, with a high concentration of biotech and pharmaceutical companies.

- Europe: Represents a substantial market share, driven by strong government support for biotechnology research, a well-developed biomanufacturing sector, and increasing adoption of advanced analytical technologies in countries like Germany, the UK, and Switzerland. Emphasis on quality and efficiency in bioproduction sustains demand.

- Asia Pacific (APAC): Expected to be the fastest-growing region during the forecast period. This growth is attributed to rising investments in biopharmaceutical manufacturing capabilities, expanding research and development activities, increasing healthcare expenditure, and a growing number of contract manufacturing organizations (CMOs) in countries such as China, India, Japan, and South Korea.

- Latin America: An emerging market for bioprocess analyzers, driven by improving healthcare infrastructure, increasing local production of biologics, and growing awareness of advanced bioprocessing technologies in countries like Brazil and Mexico.

- Middle East & Africa (MEA): Shows gradual growth, primarily due to increasing government initiatives to boost biotechnology and pharmaceutical sectors, coupled with a rising demand for healthcare services. Investment in modernizing bioproduction facilities is slowly contributing to market expansion in this region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bioprocess Analyzers Market.- Danaher Corporation (Pall Corporation, Beckman Coulter)

- Thermo Fisher Scientific

- Sartorius AG

- Agilent Technologies

- Cytiva (formerly GE Healthcare Life Sciences)

- Lonza Group

- Eppendorf AG

- Shimadzu Corporation

- Merck KGaA

- Bio-Rad Laboratories

- Waters Corporation

- F. Hoffmann-La Roche AG

- Nova Biomedical

- Hamilton Company

- Metrohm AG

- Yokogawa Electric Corporation

- Malvern Panalytical (part of Spectris plc)

- Mettler-Toledo International Inc.

- Repligen Corporation

- Sysmex Corporation

Frequently Asked Questions

What are bioprocess analyzers used for?

Bioprocess analyzers are used for real-time or near real-time monitoring and control of critical parameters in biotechnological processes, such as pH, dissolved oxygen, glucose, and cell viability, to optimize efficiency, ensure product quality, and meet regulatory standards in biopharmaceutical manufacturing and research.

How do bioprocess analyzers improve biomanufacturing?

They improve biomanufacturing by providing continuous insights into process dynamics, enabling precise control, early detection of deviations, reduced batch failures, accelerated process development, and ultimately, higher yields and consistent product quality.

What is the difference between in-line, on-line, and at-line analyzers?

In-line analyzers directly measure within the bioreactor without sampling; on-line analyzers continuously draw samples for analysis before returning them; and at-line analyzers involve automated sampling to an adjacent analytical instrument without returning the sample to the process.

What key technologies are driving innovation in this market?

Key technologies include advanced sensors (optical, electrochemical, biosensors), spectroscopic methods (NIR, Raman, Mass Spec), chromatography (HPLC, UPLC), automation, and integrated software platforms leveraging AI and Machine Learning for data analysis and predictive control.

Which regions are leading the adoption of bioprocess analyzers?

North America and Europe are leading the adoption due to their mature biopharmaceutical industries and significant R&D investments, while the Asia Pacific region is expected to show the fastest growth due to expanding biomanufacturing capacities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager