Bitumen Membrane Sheets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427972 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Bitumen Membrane Sheets Market Size

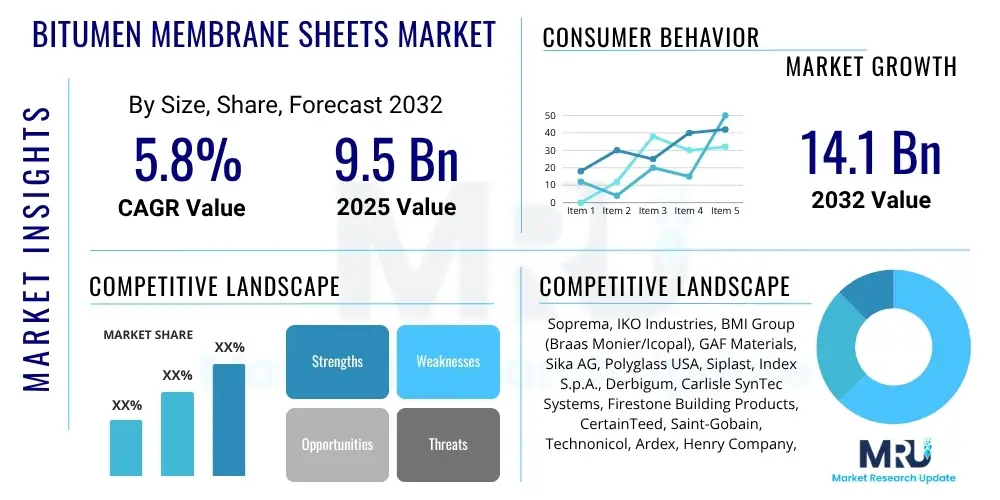

The Bitumen Membrane Sheets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 9.5 Billion in 2025 and is projected to reach USD 14.1 Billion by the end of the forecast period in 2032.

Bitumen Membrane Sheets Market introduction

Bitumen membrane sheets, a cornerstone in modern construction, are prefabricated waterproofing materials extensively utilized across various building envelopes. These engineered sheets consist primarily of asphalt-based compounds modified with polymers such as Atactic Polypropylene (APP) or Styrene-Butadiene-Styrene (SBS) to enhance their performance characteristics. Their core function lies in providing a robust, impermeable barrier against water ingress, protecting structures from moisture damage, and significantly extending their service life. This market is intrinsically linked to global construction trends, urbanization, and the increasing demand for resilient and sustainable building solutions that can withstand diverse environmental conditions.

The product range within the bitumen membrane sheets market encompasses a variety of types, each tailored for specific applications and performance requirements. Modified bitumen sheets, known for their excellent flexibility, elasticity, and resistance to extreme temperatures, are particularly prevalent. Torch-applied membranes, self-adhesive membranes, and liquid-applied bitumen membranes represent the primary application methodologies, offering distinct advantages in terms of installation speed, safety, and adhesion properties. These sheets find widespread use in roofing systems, basement waterproofing, foundation protection, bridge decks, and other civil engineering projects where durable waterproofing is paramount. Their adaptability to various substrates and climates underscores their versatility and market significance.

The inherent benefits of bitumen membrane sheets include superior waterproofing capabilities, high durability, excellent adhesion to various surfaces, and resistance to UV radiation and chemical exposure, especially for modified variants. They offer a reliable and long-lasting solution compared to traditional waterproofing methods. Key driving factors for market expansion include accelerating infrastructure development across emerging economies, a growing emphasis on green building standards requiring high-performance materials, increasing awareness regarding the importance of effective waterproofing, and the rising global population necessitating more residential and commercial constructions. Furthermore, renovation and retrofitting activities in developed regions contribute significantly to the sustained demand for these essential building materials.

Bitumen Membrane Sheets Market Executive Summary

The Bitumen Membrane Sheets Market is experiencing robust growth, primarily propelled by burgeoning construction activities worldwide and an escalating focus on durable and sustainable infrastructure. Business trends indicate a shift towards advanced polymer-modified bitumen (PMB) membranes, which offer enhanced flexibility, thermal resistance, and longevity, thereby catering to more demanding architectural and engineering specifications. Manufacturers are also concentrating on developing self-adhesive and cold-applied solutions to improve installation efficiency and safety, reducing the reliance on traditional torch-applied methods that carry inherent risks. Strategic collaborations between raw material suppliers and membrane manufacturers are becoming more common, aiming to optimize material performance and cost-effectiveness, fostering innovation in product composition and application techniques.

Regional trends reveal significant growth disparities and opportunities. Asia Pacific, driven by rapid urbanization and extensive infrastructure projects in countries like China, India, and Southeast Asian nations, stands as the largest and fastest-growing market. This region's demand is fueled by new residential, commercial, and industrial constructions, alongside massive public works. North America and Europe, while more mature, exhibit steady growth primarily due to stringent building codes, increased renovation and reroofing activities, and a strong emphasis on energy-efficient and resilient building envelopes. Latin America and the Middle East & Africa are also showing promising growth, attributed to rising investments in real estate, tourism infrastructure, and commercial developments, signaling a diversified global market landscape.

Segmentation trends highlight the dominance of SBS-modified bitumen membranes due to their superior low-temperature flexibility and elastic recovery, making them ideal for regions experiencing significant temperature fluctuations. APP-modified membranes continue to hold a strong position, particularly in warmer climates, owing to their excellent UV resistance and high-temperature performance. In terms of application, roofing remains the largest segment, encompassing both new installations and extensive repair/replacement projects. The waterproofing segment, including foundations, basements, and civil engineering applications, is also projected for substantial growth as awareness of preventative moisture protection intensifies. The preference for specific membrane types and application methods is evolving, influenced by regulatory frameworks, climate conditions, and installer preferences.

AI Impact Analysis on Bitumen Membrane Sheets Market

Users frequently inquire about how Artificial Intelligence (AI) could revolutionize traditional manufacturing processes and supply chain management within the bitumen membrane sheets sector. Common questions revolve around the potential for AI to optimize production lines, enhance quality control, predict material performance, and improve logistical efficiencies. There is also significant interest in AI's role in developing 'smart' or adaptive membrane materials, leveraging predictive analytics for maintenance schedules, and streamlining inventory management. The overarching theme from user questions indicates a strong expectation for AI to drive cost reductions, improve product consistency, and introduce novel functionalities in a traditionally hardware-intensive industry, transforming operations from raw material sourcing to end-user application.

- AI-driven optimization of manufacturing processes, including temperature control, mixing ratios, and extrusion speeds, leading to reduced waste and improved product consistency.

- Predictive maintenance analytics for manufacturing equipment, minimizing downtime and extending the lifespan of machinery used in bitumen membrane sheet production.

- Enhanced quality control through AI-powered visual inspection systems, capable of identifying defects in membrane sheets with high precision and speed.

- Supply chain optimization using AI algorithms for demand forecasting, inventory management, and route planning, leading to reduced logistics costs and improved delivery times.

- Development of AI-integrated smart membranes with embedded sensors for real-time monitoring of moisture levels, temperature fluctuations, and structural integrity, particularly for critical infrastructure.

- Accelerated material research and development by AI modeling of polymer-bitumen interactions, identifying optimal formulations for enhanced durability, flexibility, and UV resistance.

- Automated project management and installation scheduling for large-scale construction projects using AI, optimizing resource allocation and project timelines for bitumen membrane application.

DRO & Impact Forces Of Bitumen Membrane Sheets Market

The Bitumen Membrane Sheets Market is significantly influenced by a confluence of driving forces, inherent restraints, and emerging opportunities, all of which contribute to its dynamic market landscape. Key drivers include the global surge in construction and infrastructure development, particularly in developing economies, necessitating high-performance waterproofing solutions for various structures. Urbanization trends, coupled with increasing disposable incomes, fuel residential and commercial construction, which directly translates to higher demand for bitumen membranes. Furthermore, the growing awareness regarding energy efficiency and building longevity compels architects and builders to adopt superior waterproofing materials, positioning bitumen membranes as a preferred choice due to their durability and proven performance in diverse climatic conditions.

Despite robust growth, the market faces several notable restraints. The volatile pricing of crude oil, which is the primary raw material for bitumen, directly impacts production costs and profit margins for manufacturers. Environmental concerns associated with petroleum-based products and the energy-intensive manufacturing processes also present challenges, leading to increased scrutiny and regulatory pressures. The availability of alternative waterproofing materials, such as liquid-applied membranes and synthetic rubber membranes, offers competition and can sometimes divert market share. Additionally, the skilled labor shortage for installation, particularly for torch-applied membranes, can hinder market expansion and elevate project costs, presenting operational hurdles for contractors.

Opportunities within the market primarily stem from technological advancements and the increasing adoption of sustainable practices. Innovations in polymer modification, leading to the development of 'green' or bio-based bitumen membranes, present avenues for product differentiation and market penetration, appealing to environmentally conscious consumers and regulatory bodies. The rising demand for self-adhesive and cold-applied membranes, which offer easier and safer installation without the need for open flames, signifies a significant growth opportunity. Furthermore, expanding applications beyond traditional roofing to include civil engineering projects like tunnels, bridges, and water retention structures, coupled with increasing investments in repair and renovation of aging infrastructure, are poised to unlock new revenue streams and broaden the market's scope. Regulatory support for resilient building materials also acts as a positive impact force.

Segmentation Analysis

The Bitumen Membrane Sheets Market is extensively segmented based on various factors including product type, modification type, application method, and end-use industry, providing a granular view of its diverse landscape. This segmentation allows for a detailed understanding of market dynamics, consumer preferences, and growth opportunities within specific niches. The market's structure reflects the specialized requirements of different construction projects and the continuous innovation in material science aimed at enhancing performance and application efficiency.

- By Product Type:

- Modified Bitumen (MBM)

- Styrene-Butadiene-Styrene (SBS)

- Atactic Polypropylene (APP)

- Oxidized/Blown Bitumen

- Modified Bitumen (MBM)

- By Application Method:

- Torch-Applied Membranes

- Self-Adhered Membranes

- Cold-Applied/Liquid-Applied Membranes

- Mechanically Fastened Membranes

- By End-Use Industry:

- Residential Construction

- Non-Residential Construction

- Commercial Buildings

- Industrial Buildings

- Institutional Buildings

- Civil Engineering

- Roads and Bridges

- Tunnels

- Dams and Canals

- Waste Management Facilities

- By Application:

- Roofing (Flat Roofs, Pitched Roofs)

- Waterproofing (Foundations, Basements, Walls)

- Damp Proofing

- Tanking

- Lining

Value Chain Analysis For Bitumen Membrane Sheets Market

The value chain for the Bitumen Membrane Sheets Market commences with the upstream analysis, focusing on the sourcing and processing of fundamental raw materials. This stage primarily involves crude oil extraction and refining, which yields bitumen, the core component of these membranes. Alongside bitumen, the upstream segment includes suppliers of polymers (such as SBS, APP), reinforcing fabrics (polyester, fiberglass), fillers (limestone, sand), and various additives that enhance the membranes' performance characteristics. The quality and availability of these raw materials significantly impact the cost and final properties of the bitumen membrane sheets. Efficient sourcing and robust supplier relationships are crucial for manufacturers to maintain competitive pricing and consistent product quality, especially given the volatility in crude oil prices.

Following the manufacturing process, which involves blending bitumen with polymers and additives, saturating or coating reinforcing fabrics, and finishing with protective layers, the products move into the downstream segment of the value chain. This stage is dominated by distribution, installation, and end-use. Manufacturers often rely on a network of distributors, wholesalers, and specialized construction material suppliers to reach diverse markets. These intermediaries play a vital role in storage, logistics, and often provide technical support to contractors. The installation phase, typically carried out by certified roofing and waterproofing contractors, is critical, as the efficacy and longevity of the membrane largely depend on proper application techniques and adherence to industry standards.

Distribution channels for bitumen membrane sheets are multifaceted, encompassing both direct and indirect routes. Direct sales are common for large-scale projects or direct engagement with major construction companies, allowing manufacturers to maintain closer control over pricing and customer relationships. Indirect channels involve a broader network of building material distributors, hardware stores, and online marketplaces, catering to smaller contractors and individual projects. Strategic partnerships with roofing and waterproofing contractors are also a key element, as they not only purchase the materials but also serve as key influencers and specifiers. The choice of distribution channel is often dictated by market reach requirements, target customer segments, and logistical capabilities, with manufacturers constantly seeking to optimize these channels for efficiency and market penetration.

Bitumen Membrane Sheets Market Potential Customers

The potential customers for bitumen membrane sheets represent a broad spectrum of entities within the construction and infrastructure development sectors, reflecting the widespread applicability of these waterproofing solutions. Primarily, general contractors, specialized roofing contractors, and waterproofing contractors constitute a major segment of the buyer base. These professionals directly procure the membranes for installation in various projects, ranging from residential buildings to large commercial complexes and industrial facilities. Their purchasing decisions are often influenced by material performance, ease of installation, compliance with building codes, and overall cost-effectiveness, making them critical intermediaries in the market.

Beyond the direct installers, property developers and real estate companies are significant end-users, as they specify and integrate bitumen membrane sheets into their construction designs to ensure the longevity and structural integrity of their assets. Architects and civil engineers also play a crucial role as key influencers, recommending specific types and brands of bitumen membranes based on project requirements, climatic conditions, and desired performance characteristics. Government agencies and public sector undertakings involved in infrastructure projects, such as roads, bridges, tunnels, and water management systems, also represent a substantial customer segment, emphasizing durable and reliable waterproofing solutions for public assets. Homeowners undertaking renovation or self-build projects, though individually smaller, collectively contribute to market demand, typically sourcing through retailers or local contractors.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 9.5 Billion |

| Market Forecast in 2032 | USD 14.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Soprema, IKO Industries, BMI Group (Braas Monier/Icopal), GAF Materials, Sika AG, Polyglass USA, Siplast, Index S.p.A., Derbigum, Carlisle SynTec Systems, Firestone Building Products, CertainTeed, Saint-Gobain, Technonicol, Ardex, Henry Company, Johns Manville, W. R. Meadows, Keshik Roofing, Bitumat |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bitumen Membrane Sheets Market Key Technology Landscape

The Bitumen Membrane Sheets Market is characterized by a continuously evolving technological landscape, driven by the need for enhanced durability, easier installation, and improved environmental performance. A cornerstone technology involves the polymer modification of bitumen, primarily utilizing Styrene-Butadiene-Styrene (SBS) and Atactic Polypropylene (APP). SBS modification imparts superior elasticity, flexibility at low temperatures, and fatigue resistance, making membranes highly adaptable to structural movements and thermal cycles. APP modification, conversely, offers excellent UV resistance, high-temperature stability, and enhanced resistance to aging, making it suitable for warmer climates and exposed applications. These modifications are crucial for extending the service life and performance envelope of the membranes, adapting them to diverse climatic conditions and structural demands.

Further advancements include the development of self-adhesive and cold-applied bitumen membranes, representing a significant shift towards safer and more efficient installation methods. Self-adhesive membranes feature an adhesive layer that bonds directly to the substrate upon pressure, eliminating the need for torches or hot asphalt, thereby reducing fire hazards and installation time. Cold-applied liquid membranes, while distinct in form, offer similar safety benefits and conform seamlessly to complex geometries. These technologies address concerns related to skilled labor availability and site safety, expanding the applicability of bitumen membranes in sensitive environments. The integration of advanced reinforcement materials, such as non-woven polyester and fiberglass mats, also enhances tensile strength, dimensional stability, and puncture resistance, improving the overall integrity of the finished membrane.

The technological landscape also encompasses innovations in surface finishes and protective coatings, designed to improve the aesthetic appeal, UV reflectivity, and fire resistance of bitumen membrane sheets. Granulated surfaces, reflective coatings, and specialized mineral finishes contribute to reducing heat absorption in roofs, potentially lowering cooling costs for buildings. Furthermore, ongoing research focuses on developing bio-based bitumen and recycled content integration to enhance the sustainability profile of these products, aligning with green building initiatives. Automated manufacturing processes, precise blending technologies, and advanced quality control systems, often leveraging sensor technology and data analytics, ensure consistent product quality and optimized production efficiency, reflecting a forward-looking approach in the industry.

Regional Highlights

- North America: This region exhibits mature market characteristics with a strong emphasis on renovation, reroofing, and compliance with stringent building codes. Demand is driven by the need for durable and energy-efficient roofing solutions in diverse climates, alongside infrastructure repair. The U.S. and Canada are significant contributors, focusing on high-performance SBS-modified membranes.

- Europe: Europe is characterized by strict environmental regulations and a strong push for sustainable building practices. Demand for bitumen membrane sheets is robust due to extensive renovation activities, new construction, and the adoption of energy-efficient roofing systems. Countries like Germany, France, and the UK are leading players, with a growing interest in green and self-adhesive membrane technologies.

- Asia Pacific (APAC): The APAC region represents the fastest-growing market, propelled by rapid urbanization, significant infrastructure development, and a booming construction sector in emerging economies such as China, India, and Southeast Asian countries. Increasing investments in residential, commercial, and industrial projects are key drivers, with both APP and SBS modified membranes seeing high demand.

- Latin America: This region shows promising growth attributed to increasing investments in commercial and residential construction, particularly in countries like Brazil and Mexico. Economic development and urbanization are fostering demand for reliable waterproofing solutions, albeit with varying regulatory frameworks across nations.

- Middle East and Africa (MEA): The MEA region is witnessing substantial growth driven by large-scale infrastructure projects, expansion in tourism and hospitality sectors, and ongoing residential developments. Countries in the GCC region, fueled by oil wealth and diversification efforts, are significant markets, focusing on high-performance membranes suitable for extreme temperatures and harsh environments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bitumen Membrane Sheets Market.- Soprema

- IKO Industries

- BMI Group (Braas Monier/Icopal)

- GAF Materials

- Sika AG

- Polyglass USA

- Siplast

- Index S.p.A.

- Derbigum

- Carlisle SynTec Systems

- Firestone Building Products (now part of Holcim)

- CertainTeed (a Saint-Gobain company)

- Saint-Gobain

- Technonicol

- Ardex GmbH

- Henry Company (now part of Carlisle Companies)

- Johns Manville

- W. R. Meadows

- Keshik Roofing

- Bitumat Company Limited

Frequently Asked Questions

What are the primary types of bitumen membrane sheets available in the market?

The primary types of bitumen membrane sheets are categorized mainly by their polymer modifications: SBS (Styrene-Butadiene-Styrene) modified bitumen and APP (Atactic Polypropylene) modified bitumen. SBS membranes offer superior flexibility and elasticity, making them ideal for colder climates and structures prone to movement. APP membranes provide excellent UV resistance and high-temperature performance, suitable for warmer regions and exposed applications. Oxidized or blown bitumen sheets, while more traditional, are also available, offering a cost-effective solution for less demanding applications. These variations allow for selection based on specific project requirements, climatic conditions, and desired performance characteristics, ensuring optimal waterproofing and longevity for diverse structures.

What are the key advantages of using bitumen membrane sheets for waterproofing?

Bitumen membrane sheets offer numerous key advantages for waterproofing applications due to their inherent properties and engineered design. They provide a highly effective and durable impermeable barrier against water ingress, protecting building envelopes from moisture damage and significantly extending the lifespan of structures. Their excellent adhesion properties allow them to bond securely to various substrates, creating a monolithic seal. Modified bitumen sheets, particularly SBS and APP types, exhibit high flexibility, elasticity, and resistance to extreme temperatures, UV radiation, and chemical exposure, ensuring long-term performance in diverse environments. Furthermore, their pre-fabricated nature ensures consistent thickness and quality, reducing on-site variability and simplifying installation for qualified contractors, making them a reliable choice for comprehensive waterproofing solutions.

How is the Bitumen Membrane Sheets Market influenced by environmental regulations and sustainability trends?

The Bitumen Membrane Sheets Market is significantly influenced by evolving environmental regulations and the growing global emphasis on sustainability. Regulations concerning VOC emissions, waste management, and the use of petroleum-based products are driving manufacturers to innovate towards more environmentally friendly solutions. This includes the development of 'green' bitumen membranes, which may incorporate recycled content, bio-based polymers, or utilize cold-applied and self-adhesive technologies to reduce energy consumption and harmful fumes during installation. The demand for products with environmental product declarations (EPDs) and certifications for sustainable building initiatives, such as LEED, is also increasing. Manufacturers are responding by investing in research for sustainable raw materials, optimizing production processes for reduced carbon footprint, and offering products that contribute to energy efficiency in buildings through reflective surfaces. These trends encourage innovation, push for greener formulations, and reshape product offerings to align with global sustainability goals.

What role do self-adhesive bitumen membranes play in the market's growth?

Self-adhesive bitumen membranes play a crucial role in the market's growth by addressing key industry demands for enhanced safety, faster installation, and reduced labor requirements. Unlike traditional torch-applied membranes that necessitate the use of open flames, self-adhesive variants come with a factory-applied adhesive layer, eliminating fire hazards and simplifying the installation process. This makes them particularly suitable for sensitive environments, retrofitting projects, and areas with strict fire safety regulations. Their ease of application reduces reliance on highly skilled labor and accelerates project timelines, offering significant cost and time savings for contractors. The increasing adoption of self-adhesive technology reflects a broader market trend towards safer, more efficient, and user-friendly waterproofing solutions, positioning them as a high-growth segment within the overall bitumen membrane sheets market. This innovation broadens the market's appeal and expands its application across diverse construction scenarios.

What are the key applications for bitumen membrane sheets beyond traditional roofing?

While roofing remains a primary application, bitumen membrane sheets are increasingly utilized in a wide array of other critical waterproofing and protective applications. They are extensively used for waterproofing foundations and basements, forming a crucial barrier against groundwater infiltration and dampness, thereby protecting the structural integrity and interior environments of buildings. In civil engineering, these membranes are vital for sealing bridge decks, tunnels, and underground structures, providing robust protection against water and chemicals that could compromise infrastructure longevity. They also find application in water retention structures like canals and reservoirs, as well as in waste management facilities to line landfills and prevent leakage. Additionally, they are employed for damp proofing internal walls and floors, and for tanking applications in areas prone to high hydrostatic pressure, demonstrating their versatility and indispensable role in various construction and infrastructure projects beyond conventional roofing systems.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager