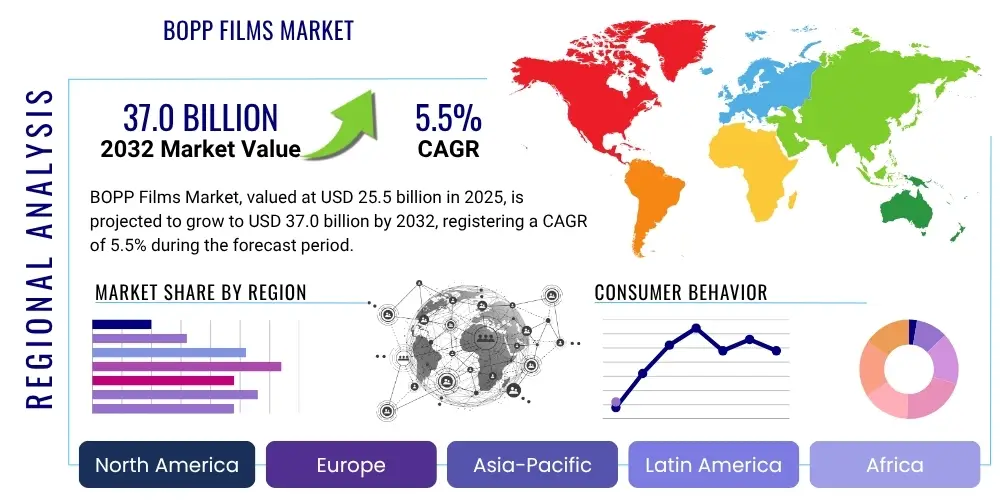

BOPP Films Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428724 | Date : Oct, 2025 | Pages : 241 | Region : Global | Publisher : MRU

BOPP Films Market Size

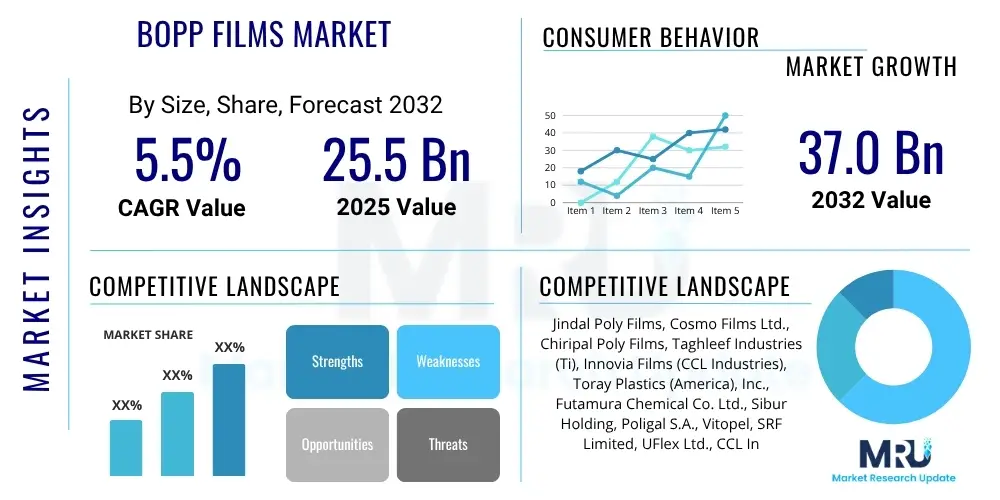

The BOPP Films Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.5% between 2025 and 2032. The market is estimated at USD 25.5 billion in 2025 and is projected to reach USD 37.0 billion by the end of the forecast period in 2032.

BOPP Films Market introduction

The BOPP Films Market encompasses the global production and consumption of Biaxially Oriented Polypropylene films, a versatile packaging material known for its excellent clarity, high tensile strength, barrier properties, and heat sealability. These films are produced by stretching polypropylene resin in both machine and transverse directions, which enhances their physical and optical characteristics. BOPP films have emerged as a preferred material across various industries due to their cost-effectiveness, lightweight nature, and protective qualities, offering superior resistance to moisture, chemicals, and punctures compared to other flexible packaging options. Their ability to be easily printed, laminated, and coated further broadens their application spectrum, making them indispensable in modern packaging solutions.

Major applications for BOPP films span a wide range, primarily dominating the flexible packaging sector for food and beverages, personal care products, and tobacco. They are also extensively utilized in the production of labels, adhesive tapes, and lamination films, providing a protective and aesthetically pleasing finish to diverse products. The intrinsic benefits of BOPP films, such as their outstanding barrier properties against moisture and oxygen, robust mechanical strength, and excellent optical clarity, contribute significantly to product preservation and brand presentation. These attributes help extend shelf life, reduce spoilage, and enhance consumer appeal, making them a cornerstone of efficient packaging strategies.

The market's growth is predominantly driven by several key factors. The expanding global packaging industry, particularly the robust demand for flexible packaging solutions that offer convenience and sustainability, is a primary catalyst. The rapid growth of e-commerce necessitates lightweight, durable, and protective packaging, a requirement effectively met by BOPP films. Furthermore, rising disposable incomes in emerging economies are fueling consumption of packaged goods, thereby increasing the demand for high-quality packaging materials. Technological advancements in film manufacturing, leading to thinner, stronger, and more functional BOPP films, also play a crucial role in market expansion, offering enhanced performance characteristics for various end-use applications.

BOPP Films Market Executive Summary

The global BOPP Films Market is experiencing dynamic shifts, characterized by evolving business trends, significant regional expansion, and diverse segment growth. A prevalent business trend involves consolidation among manufacturers, aiming to achieve economies of scale and enhance competitive advantage, alongside a strong focus on innovation in sustainable film solutions. Companies are investing in research and development to produce recyclable, compostable, or bio-based BOPP films, responding to increasing environmental concerns and regulatory pressures. Furthermore, there is a rising demand for high-performance films with enhanced barrier properties, optical clarity, and specialized coatings to cater to sophisticated packaging requirements across various end-use industries, driving market value through premium product offerings and technological differentiation.

Regionally, Asia Pacific continues to dominate the market, driven by its large manufacturing base, expanding consumer population, and rapid urbanization, which fuels the demand for packaged goods. Countries like China and India are at the forefront of this growth, benefiting from increasing disposable incomes and the proliferation of organized retail and e-commerce platforms. North America and Europe, while mature markets, are experiencing growth propelled by the adoption of specialty BOPP films for niche applications and a strong emphasis on sustainable and advanced packaging solutions. These regions are also witnessing a shift towards sophisticated labeling and lamination applications, leveraging the superior printability and durability of BOPP films. Latin America, the Middle East, and Africa represent emerging markets with significant growth potential, as industrialization and consumerism increase.

Segment trends within the BOPP films market highlight the enduring supremacy of food packaging as the largest application area, driven by the need for extended shelf life and attractive presentation of various food products. Non-food packaging, including personal care, industrial, and textile packaging, is also experiencing robust growth, supported by the versatility and protective qualities of BOPP films. The labels segment is witnessing substantial expansion due to the demand for durable and visually appealing product labels, while the adhesive tapes segment benefits from the film's strength and adhesion properties. A notable trend across all segments is the increasing adoption of thinner films, which contribute to source reduction and cost efficiency, without compromising performance, further enhancing the material's appeal in a resource-conscious global economy.

AI Impact Analysis on BOPP Films Market

Users are increasingly seeking to understand how artificial intelligence (AI) can revolutionize various aspects of the BOPP Films Market, with common questions centering on operational efficiency, quality control, supply chain optimization, and sustainable manufacturing practices. Key themes emerging from these inquiries include the potential for AI-driven analytics to predict equipment failures, optimize production parameters for reduced waste, enhance material science for novel film development, and improve logistics for faster market delivery. There is a strong expectation that AI will lead to more intelligent, responsive, and resource-efficient manufacturing processes, mitigating traditional challenges such as quality inconsistencies and supply chain disruptions. Furthermore, users are curious about AI's role in developing next-generation, environmentally friendly BOPP solutions, addressing the industry's push towards greater sustainability and circular economy principles, demonstrating a holistic view of AI's transformative potential.

- AI optimizes manufacturing processes through predictive analytics, leading to reduced downtime and increased throughput.

- Enhanced quality control systems leverage AI for real-time defect detection and classification, minimizing product wastage.

- AI-powered supply chain management improves forecasting, inventory optimization, and logistics, ensuring efficient material flow.

- Research and development efforts benefit from AI in material formulation and property prediction for innovative BOPP film creation.

- Predictive maintenance implemented with AI significantly extends equipment lifespan and reduces unexpected operational interruptions.

- AI aids in developing more sustainable BOPP film solutions by optimizing resource usage and identifying opportunities for circularity.

DRO & Impact Forces Of BOPP Films Market

The BOPP Films Market is shaped by a complex interplay of drivers, restraints, opportunities, and underlying impact forces that collectively dictate its growth trajectory and competitive landscape. Key drivers propelling the market forward include the burgeoning demand for flexible packaging solutions, particularly in the food and beverage sector, where BOPP films offer excellent barrier properties, aesthetic appeal, and cost-effectiveness. The exponential growth of e-commerce platforms globally also significantly contributes to this demand, as BOPP films provide durable, lightweight, and protective packaging suitable for shipping. Furthermore, continuous technological advancements leading to the development of high-performance and specialty films, coupled with rising disposable incomes in emerging economies, are expanding the consumer base for packaged goods, thereby boosting the consumption of BOPP films across diverse applications.

Conversely, the market faces several significant restraints. Volatility in the prices of raw materials, primarily polypropylene resin, poses a considerable challenge, impacting production costs and profit margins for manufacturers. Environmental concerns regarding plastic waste and pollution present a persistent hurdle, leading to increased scrutiny and regulatory pressures, even though BOPP films are recyclable. While recyclable, the current infrastructure for collection and recycling of flexible packaging remains a developing area in many regions. Intense competition within the market, characterized by numerous global and regional players, often leads to pricing pressures, especially for commodity-grade films. These factors necessitate innovation and strategic differentiation for market participants to maintain growth and profitability in a dynamic operating environment.

Despite these restraints, the market is ripe with opportunities for innovation and expansion. The growing focus on sustainable packaging solutions presents a substantial avenue for growth, driving the development of biodegradable, compostable, and enhanced recyclable BOPP films that align with circular economy principles. Penetration into new and emerging applications, such as advanced agricultural films, pharmaceutical packaging, and specific industrial uses, offers diversified revenue streams. Furthermore, the robust growth in developing economies, characterized by rapid urbanization and increasing consumer spending, represents an untapped market potential for BOPP films. The integration of advanced barrier technologies and smart packaging features into BOPP films to meet evolving consumer demands for freshness, convenience, and traceability also provides significant growth prospects, allowing for premium product offerings and competitive advantages.

Segmentation Analysis

The BOPP Films Market is comprehensively segmented across various parameters including type, application, end-use industry, and thickness, allowing for a detailed understanding of its diverse landscape and market dynamics. This granular segmentation helps in identifying key growth areas, consumer preferences, and technological shifts within the industry. By analyzing these distinct segments, stakeholders can better tailor their strategies, product offerings, and market penetration efforts to address specific demands and capitalize on emerging trends. Each segment reflects unique characteristics in terms of demand drivers, competitive intensity, and potential for innovation, underscoring the versatility and adaptability of BOPP films in meeting a wide array of industrial and consumer needs. This multi-faceted approach to market segmentation provides crucial insights into both established and nascent market opportunities.

The market's segmentation by type, for instance, highlights the prevalence of transparent, opaque, and metallized films, each serving distinct functional and aesthetic purposes. Transparent films are favored for their clarity and visual appeal, opaque films for branding and light barrier properties, and metallized films for superior oxygen and moisture barrier characteristics. Application-based segmentation underscores the dominance of food and beverage packaging, but also reveals significant growth in non-food packaging, labels, and tapes, showcasing the material's broad utility. End-use industry segmentation further refines this view, detailing the consumption patterns across sectors like food and beverages, personal care, tobacco, and industrial applications. Lastly, segmentation by thickness addresses the industry's drive towards source reduction and efficiency, with various micron ranges catering to specific strength and barrier requirements.

- By Type

- Transparent Films

- Opaque Films

- Metallized Films

- Matte Films

- White Opaque Films

- Others (e.g., Pearlized, Cavitated)

- By Application

- Food Packaging

- Non-Food Packaging

- Labels

- Tapes

- Lamination

- Tobacco Packaging

- Textile Packaging

- Industrial Packaging

- By End-Use Industry

- Food & Beverages

- Personal Care & Cosmetics

- Electrical & Electronics

- Healthcare & Pharmaceuticals

- Industrial

- Tobacco

- Others (e.g., Agriculture, Stationery)

- By Thickness

- Below 18 Micron

- 18-30 Micron

- Above 30 Micron

Value Chain Analysis For BOPP Films Market

The value chain for the BOPP Films Market begins with the upstream segment, which primarily involves the procurement and processing of raw materials. The most critical raw material is polypropylene (PP) resin, a thermoplastic polymer derived from petroleum. Key players in this stage include major petrochemical companies that produce PP resin. Other essential inputs include various additives such as masterbatches, stabilizers, antistatic agents, and slip agents, supplied by specialized chemical manufacturers. The quality and cost of these raw materials significantly influence the final product's performance and pricing, making supplier relationships and raw material sourcing a strategic imperative for BOPP film manufacturers. Efficient management of upstream activities ensures consistent supply and cost control, which are vital for maintaining competitive pricing and production continuity.

Moving downstream, the value chain encompasses the manufacturing of BOPP films through complex extrusion and biaxial stretching processes. After film production, these master rolls are then sold to converters. Converters are crucial intermediaries who transform the plain BOPP films into finished packaging materials. Their operations typically involve printing (flexographic, rotogravure, digital), laminating with other film types (e.g., PET, PE) for enhanced barrier or mechanical properties, coating for specific functions (e.g., heat seal, anti-fog), and slitting into desired widths and lengths. These customized films are then supplied to various end-use industries for their specific packaging needs. The efficiency and technological capabilities of converters directly impact the quality and functionality of the final packaging, adding significant value through customization and specialized processing.

The distribution channel for BOPP films and converted products involves both direct and indirect sales approaches. Direct sales are common for large volume orders where film manufacturers or major converters supply directly to large-scale end-users, such as multinational food and beverage companies, or major label printers, ensuring close collaboration and customized solutions. Indirect channels involve distributors, agents, and wholesalers who serve smaller businesses, regional markets, or provide specialized logistics and inventory management. These intermediaries play a vital role in market penetration, especially in fragmented markets, by offering localized support, warehousing, and access to a broader customer base. The choice of distribution strategy often depends on the customer's size, geographic location, and specific service requirements, with a balanced approach often yielding optimal market reach and responsiveness.

BOPP Films Market Potential Customers

The potential customers for the BOPP Films Market are incredibly diverse, reflecting the versatility and widespread applicability of these films across a multitude of industries. At the core, end-users are those entities that purchase and incorporate BOPP films or converted BOPP products into their final offerings. Food and beverage manufacturers represent the largest segment of buyers, utilizing BOPP films for packaging snacks, baked goods, confectionery, fresh produce, and processed foods due to the films' excellent barrier properties, clarity, and printability. These companies seek solutions that extend shelf life, maintain product freshness, and enhance brand appeal, all of which BOPP films effectively provide. The burgeoning demand for convenience food and ready-to-eat meals further solidifies this sector's position as a primary customer base.

Beyond food and beverages, the personal care and cosmetics industry constitutes a significant customer segment. Companies manufacturing personal hygiene products, skincare, hair care, and beauty products rely on BOPP films for aesthetically pleasing and protective packaging, as well as for durable labels that withstand moisture and handling. Pharmaceutical and healthcare companies also increasingly adopt BOPP films for unit-dose packaging, medical device pouches, and labels, where sterility, barrier properties, and tamper-evident features are paramount. The industrial sector, including manufacturers of electrical and electronic components, textiles, and various consumer goods, utilizes BOPP films for protective wraps, adhesive tapes, and packaging to ensure product integrity during storage and transit. E-commerce retailers, either directly or through their packaging suppliers, are also emerging as substantial buyers, seeking lightweight yet robust packaging to minimize shipping costs and prevent damage.

Additionally, specialized segments such as label printers and adhesive tape manufacturers are direct buyers of BOPP films, converting them into finished products for their respective markets. Tobacco companies consistently use BOPP films for packaging cigarettes and other tobacco products, valuing their moisture barrier and visual appeal. The agricultural sector uses BOPP films for specific packaging applications for seeds and other delicate produce, requiring protection from environmental factors. This wide array of end-users underscores the integral role BOPP films play in various commercial and industrial ecosystems, providing essential functionalities that support product integrity, brand visibility, and supply chain efficiency across global markets.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 25.5 billion |

| Market Forecast in 2032 | USD 37.0 billion |

| Growth Rate | 5.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Jindal Poly Films, Cosmo Films Ltd., Chiripal Poly Films, Taghleef Industries (Ti), Innovia Films (CCL Industries), Toray Plastics (America), Inc., Futamura Chemical Co. Ltd., Sibur Holding, Poligal S.A., Vitopel, SRF Limited, UFlex Ltd., CCL Industries Inc., Inteplast Group, Impak Films, Max Speciality Films, Treofan (Flex Films Europa GmbH), Vacmet India Ltd., Formosa Plastics Corporation, Shiefford, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

BOPP Films Market Key Technology Landscape

The BOPP Films Market is characterized by a continuously evolving technological landscape, driven by the need for enhanced performance, cost efficiency, and sustainable solutions. The core manufacturing processes involve sophisticated extrusion techniques, primarily the tenter frame process and the tubular process, each offering distinct advantages in terms of film properties and production flexibility. Tenter frame lines are favored for high-volume production of films with superior optical and mechanical properties, while tubular processes are often used for specialized films or smaller runs. Advancements in these extrusion technologies focus on increasing line speeds, improving film uniformity, and enabling the production of multi-layer co-extruded films that combine different polymers to achieve a blend of desired barrier, seal, and strength characteristics, catering to complex packaging requirements.

Beyond basic film formation, a range of secondary processing technologies is crucial for enhancing the functionality and market appeal of BOPP films. Coating technologies play a significant role, with various types of coatings applied to impart specific attributes such as improved oxygen or moisture barrier, heat sealability, anti-fog properties, or enhanced print receptivity. Examples include PVDC (Polyvinylidene chloride), acrylic, and EVA (Ethylene-vinyl acetate) coatings. Metallization, another critical technology, involves depositing a thin layer of aluminum onto the film surface in a vacuum chamber, significantly improving barrier properties against gases and moisture, and providing a distinctive metallic look often used for branding and product differentiation. Surface treatments like corona discharge or plasma treatment are also extensively employed to modify the film surface, enhancing ink adhesion and lamination bond strength, which are vital for subsequent printing and converting processes.

The current technology landscape is also heavily influenced by innovations aimed at sustainability and high-performance applications. The development of ultra-thin BOPP films allows for material reduction without compromising strength or barrier, contributing to source reduction and a lighter environmental footprint. Research and development efforts are focused on creating BOPP films with advanced barrier properties that rival conventional multi-material laminates, offering solutions for sensitive products requiring extended shelf life. Furthermore, the integration of bio-based or biodegradable additives into BOPP formulations is gaining traction, signaling a shift towards more environmentally friendly alternatives. Digital printing compatibility, anti-static films for sensitive electronics packaging, and retortable films capable of withstanding high-temperature sterilization are other key technological advancements that expand the utility and market reach of BOPP films, continuously pushing the boundaries of what this versatile material can achieve.

Regional Highlights

- Asia Pacific (APAC): Dominates the global BOPP Films Market, accounting for the largest share in both production and consumption. This growth is primarily fueled by rapid industrialization, urbanization, and a burgeoning population in countries like China, India, and Southeast Asian nations. The region benefits from a large manufacturing base, increasing disposable incomes, and the expansion of the food and beverage, personal care, and e-commerce sectors, which are major consumers of flexible packaging. Investments in new production capacities and technological advancements are also significant in APAC.

- Europe: A mature market characterized by a strong focus on sustainable and specialty BOPP films. Western European countries like Germany, Italy, and the UK are key players, driving demand for films with enhanced barrier properties, recyclability, and lightweight designs to meet stringent environmental regulations and consumer preferences. The region also exhibits significant innovation in premium labels and high-performance flexible packaging, with an emphasis on advanced coatings and metallization for value-added applications.

- North America: Exhibits steady growth, driven by the increasing demand for high-quality, convenient, and safe food packaging, particularly in the United States and Canada. There is a growing trend towards sustainable packaging solutions, including recyclable and post-consumer recycled (PCR) content BOPP films. The region also sees robust demand from the labeling, industrial, and personal care sectors, alongside a strong emphasis on automation and technological integration in film manufacturing and converting processes to enhance efficiency.

- Latin America: An emerging market with considerable growth potential, primarily driven by expanding retail sectors, increasing disposable incomes, and growing consumer awareness of packaged goods in countries like Brazil, Mexico, and Argentina. The demand for flexible packaging is on the rise, supporting the growth of BOPP films in food, beverage, and personal care applications. Investments in local manufacturing capabilities are gradually increasing, aiming to reduce reliance on imports and cater to regional market needs.

- Middle East and Africa (MEA): A developing market with promising growth prospects, propelled by economic diversification, infrastructure development, and increasing consumer spending, particularly in the GCC countries (UAE, Saudi Arabia) and South Africa. The region's hot and arid climate necessitates packaging with superior barrier properties for food preservation, making BOPP films an attractive option. The growth of the organized retail sector and a rising demand for processed and packaged foods are key market drivers in MEA, alongside investments in local production facilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the BOPP Films Market.- Jindal Poly Films

- Cosmo Films Ltd.

- Chiripal Poly Films

- Taghleef Industries (Ti)

- Innovia Films (CCL Industries)

- Toray Plastics (America), Inc.

- Futamura Chemical Co. Ltd.

- Sibur Holding

- Poligal S.A.

- Vitopel

- SRF Limited

- UFlex Ltd.

- CCL Industries Inc.

- Inteplast Group

- Impak Films

- Max Speciality Films

- Treofan (Flex Films Europa GmbH)

- Vacmet India Ltd.

- Formosa Plastics Corporation

- Shiefford, Inc.

- Transcendia Inc.

- Propak Flexible Packaging

- OPP Co. Ltd.

- Guangdong Decro Film Co. Ltd.

- PT. Argha Karya Prima Industry Tbk

Frequently Asked Questions

What are BOPP films primarily used for?

BOPP films are primarily used for flexible packaging, especially in the food and beverage sector due to their excellent barrier properties, clarity, and printability. They are also extensively used for labels, adhesive tapes, and lamination in various other industries.

How do BOPP films contribute to sustainability?

BOPP films contribute to sustainability through their recyclability, lightweight nature (reducing material consumption and transport emissions), and potential for incorporating bio-based or recycled content. Ongoing innovations aim to enhance their circularity and environmental footprint.

What drives the growth of the BOPP films market?

The market's growth is driven by the increasing global demand for flexible packaging, the rapid expansion of e-commerce, rising disposable incomes in emerging economies, and continuous technological advancements leading to high-performance and specialty film solutions.

What are the key properties of BOPP films?

Key properties of BOPP films include high tensile strength, excellent clarity, superior moisture barrier, good heat sealability, chemical resistance, and printability. These attributes make them highly versatile for diverse packaging and labeling applications.

How is AI impa

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager