Breathable Lidding Film Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428371 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Breathable Lidding Film Packaging Market Size

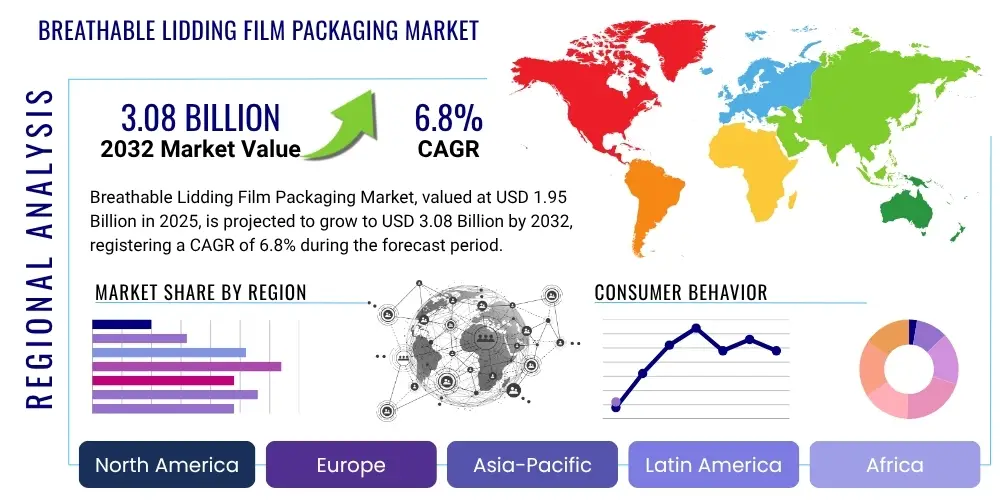

The Breathable Lidding Film Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $1.95 Billion in 2025 and is projected to reach $3.08 Billion by the end of the forecast period in 2032.

Breathable Lidding Film Packaging Market introduction

The Breathable Lidding Film Packaging market encompasses advanced packaging solutions designed to regulate the atmosphere within a package, primarily for perishable food products. These films possess selective permeability to gases such as oxygen, carbon dioxide, and water vapor, which is crucial for extending the shelf life of fresh produce, processed meats, and ready meals. By allowing a controlled exchange of gases, breathable lidding films help maintain product freshness, prevent spoilage, and preserve nutritional value and organoleptic properties.

The core product in this market is a specialized film, often multi-layered, engineered with precise perforation technologies or inherent material properties to achieve desired gas transmission rates (GTR). Major applications span across the food and beverage industry, including fresh fruits and vegetables, salads, poultry, seafood, dairy products, and various convenience food items. These films offer significant benefits such as reduced food waste, improved product presentation, and enhanced consumer convenience, particularly for items requiring modified atmosphere packaging (MAP) or equilibrium modified atmosphere packaging (EMAP).

Key driving factors for market growth include the escalating consumer demand for fresh, healthy, and minimally processed foods, coupled with a growing awareness of food waste reduction. Technological advancements in film materials and perforation techniques enable the development of highly customized solutions tailored to specific product respiration rates. Additionally, the increasing trend of urbanization and busier lifestyles fuels the demand for convenience foods that require extended shelf life and attractive packaging.

Breathable Lidding Film Packaging Market Executive Summary

The Breathable Lidding Film Packaging market is experiencing robust growth driven by evolving consumer lifestyles and a heightened focus on food preservation and sustainability. Business trends indicate a strong emphasis on innovation in material science, with manufacturers investing in research and development to create more sustainable, bio-based, and recyclable breathable film solutions. Companies are also expanding their product portfolios to cater to diverse food categories, offering customized permeability options and advanced sealing capabilities. Strategic collaborations and partnerships between film manufacturers and food processors are becoming more prevalent to develop integrated packaging solutions that optimize supply chain efficiency and product quality.

Regionally, the Asia Pacific market is poised for significant expansion, fueled by rapid urbanization, increasing disposable incomes, and the burgeoning organized retail sector. North America and Europe, as mature markets, continue to innovate, focusing on premiumization, convenience, and stringent sustainability mandates, pushing for films with enhanced environmental profiles. Latin America, the Middle East, and Africa represent emerging opportunities, with growing food processing industries and increasing adoption of modern retail formats driving demand for advanced packaging solutions.

Segment-wise, the fresh produce application maintains a dominant share due to its high demand for controlled respiration and extended shelf life. However, segments like processed meats, poultry, and ready meals are also showing substantial growth, propelled by the convenience food trend. In terms of materials, polyethylene (PE) and polypropylene (PP) continue to be widely used due to their versatility and cost-effectiveness, while the demand for bio-based and compostable films is steadily rising, reflecting a broader industry shift towards eco-friendly packaging alternatives.

AI Impact Analysis on Breathable Lidding Film Packaging Market

Common user questions regarding AI's impact on the Breathable Lidding Film Packaging market often revolve around efficiency gains, predictive capabilities, and sustainable practices. Users frequently inquire if AI can optimize packaging design for specific produce types, enhance quality control during manufacturing, or predict shelf life more accurately. There is also considerable interest in AI's role in supply chain management for perishable goods, particularly how it can minimize waste and improve logistics through smart packaging. Expectations include AI leading to more personalized and dynamic packaging solutions, enabling real-time monitoring of packaged goods, and driving the development of novel materials with superior breathable properties.

- AI-driven optimization of film permeability for specific product needs.

- Enhanced quality control through AI-powered visual inspection systems detecting film defects.

- Predictive analytics for shelf life estimation based on environmental factors and product respiration.

- Optimized inventory and supply chain management using AI to forecast demand for films.

- Development of smart packaging integrating AI for real-time monitoring of internal conditions.

- AI-assisted material science research for novel, more sustainable breathable film formulations.

- Automated machinery settings for precise perforation and film converting processes.

DRO & Impact Forces Of Breathable Lidding Film Packaging Market

The Breathable Lidding Film Packaging market is significantly influenced by a confluence of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. Key drivers include the ever-increasing global demand for fresh and convenience food products, which inherently require packaging solutions that extend shelf life and maintain quality. A growing consumer awareness regarding food waste reduction also propels the adoption of these films. Furthermore, continuous technological advancements in film materials, such as multi-layer co-extrusion and precision perforation techniques, enhance the performance and applicability of breathable lidding films, making them indispensable for various food categories. The rising disposable incomes in emerging economies further contribute to the demand for packaged fresh foods, indirectly boosting the market.

Despite these strong drivers, the market faces notable restraints. High initial investment costs associated with specialized packaging machinery capable of handling and sealing breathable films can be a barrier for smaller manufacturers. Volatility in raw material prices, particularly for polymers, can impact production costs and overall market stability. Additionally, stringent regulatory frameworks surrounding food contact materials and the complexities involved in recycling multi-layer flexible packaging pose significant challenges for market players, requiring constant innovation and compliance efforts. The technical complexity of balancing breathability with other film properties like strength and sealability also presents a continuous R&D hurdle.

However, substantial opportunities exist for market expansion and innovation. The growing demand for sustainable packaging solutions, including biodegradable, compostable, and recyclable breathable films, presents a lucrative avenue for product development and market differentiation. Expansion into new application areas beyond traditional food items, such as pharmaceuticals for sterile breathability or personal care products requiring moisture vapor transmission, could unlock new revenue streams. The increasing adoption of modified atmosphere packaging (MAP) and equilibrium modified atmosphere packaging (EMAP) across diverse food segments, particularly in developing regions, further creates significant growth potential for specialized breathable films. Finally, the integration of smart packaging technologies, enabling real-time monitoring and traceability, represents a future growth frontier.

Segmentation Analysis

The Breathable Lidding Film Packaging market is comprehensively segmented based on various factors, including material type, application, technology, and end-use industry, allowing for a detailed understanding of its dynamics and growth prospects across different categories. This segmentation helps identify key demand drivers and emerging trends within specific market niches, providing valuable insights for manufacturers, suppliers, and investors alike.

- By Material:

- Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Ethylene Vinyl Alcohol (EVOH)

- Polylactic Acid (PLA)

- Other Bio-based Polymers

- Aluminum Foil Laminates

- By Application:

- Fresh Produce (Fruits, Vegetables, Salads)

- Meat, Poultry, and Seafood

- Dairy Products (Yogurt, Cheese)

- Bakery and Confectionery

- Ready Meals and Convenience Foods

- Snacks

- Other Food Applications

- Pharmaceutical and Medical

- By Technology:

- Macro-perforation

- Micro-perforation

- Laser Perforation

- Active Ventilation

- Membrane Technology

- By End-Use Industry:

- Food and Beverage

- Pharmaceuticals

- Personal Care

- Others

Value Chain Analysis For Breathable Lidding Film Packaging Market

The value chain for the Breathable Lidding Film Packaging market begins with upstream activities involving the sourcing and production of raw materials, primarily various polymer resins such as PE, PP, PET, and specialized barrier polymers like EVOH, supplied by petrochemical and chemical companies. These raw materials are then processed by film manufacturers who extrude and co-extrude them into base films, applying advanced techniques to achieve specific mechanical and barrier properties. Further processing involves the incorporation of breathable features through technologies like macro- or micro-perforation, often using laser precision, or by integrating breathable membranes. This stage is critical as it defines the film's core functionality.

Midstream activities involve film converters and laminators who may add further layers, printing, and sealing capabilities to the breathable films, customizing them for specific applications and brands. These converted films are then supplied to packaging companies or directly to end-user industries, predominantly food processors. Downstream activities focus on the final packaging of products, where these lidding films are applied to trays or containers, typically through heat-sealing processes on high-speed packaging lines. The distribution channel is predominantly business-to-business (B2B), with direct sales from film manufacturers or converters to large food processing plants. Indirect channels involve distributors or packaging solution providers who offer a wider range of packaging materials and services to smaller or mid-sized end-users. The efficiency of the entire chain relies heavily on seamless coordination and technological integration to ensure optimal film performance and product integrity.

Breathable Lidding Film Packaging Market Potential Customers

Potential customers for breathable lidding film packaging are primarily entities within the food and beverage industry that require extended shelf life and quality preservation for perishable goods. This includes large-scale food processors involved in packaging fresh produce such as fruits, vegetables, and pre-cut salads, where controlled respiration is vital. Manufacturers of processed meats, poultry, and seafood also represent significant buyers, utilizing these films to maintain freshness and prevent spoilage. Dairy product manufacturers, particularly for items like yogurt and fresh cheeses, seek breathable solutions to manage moisture and gas exchange effectively.

Beyond these, the rapidly expanding ready meals and convenience food sector forms a substantial customer base, as these products often require modified atmosphere packaging to ensure a longer shelf life without compromising taste or texture. Supermarkets, hypermarkets, and other retail chains, both directly and through their suppliers, are key end-users driving demand for visually appealing and functional packaging that reduces waste and enhances customer satisfaction. Furthermore, sectors like pharmaceuticals and medical devices are emerging as potential niche customers for applications requiring sterile breathability or moisture regulation for sensitive products, indicating a broadening scope of end-user/buyers for advanced breathable film technologies.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.95 Billion |

| Market Forecast in 2032 | $3.08 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor Plc, Berry Global Inc., Sealed Air Corporation, Mondi Group, Coveris Holdings SA, Wipak Group, UFlex Ltd., CCL Industries Inc., Huhtamaki Oyj, Schur Flexibles Group, Bollore Films, RPC Group (Berry Global), Sonoco Products Company, Winpak Ltd., Plastopil Hazorea Company Ltd., Constantia Flexibles Group GmbH, Toray Plastics (America) Inc., Mitsubishi Chemical Corporation, Taj Group, Bemis Company Inc. (Amcor) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Breathable Lidding Film Packaging Market Key Technology Landscape

The Breathable Lidding Film Packaging market relies heavily on a sophisticated technological landscape to achieve precise gas and moisture transmission rates essential for extending product shelf life. A core technology involves advanced polymer extrusion, including co-extrusion techniques, which allow for the creation of multi-layered films combining different polymers to impart specific barrier, mechanical, and sealing properties alongside breathability. This enables manufacturers to tailor films for diverse product requirements, from highly breathable films for fresh produce to more selective barriers for meats. The ability to precisely control layer thickness and material composition is crucial in achieving desired performance characteristics.

Precision perforation techniques represent another cornerstone of this market's technology. Macro-perforation involves creating larger holes, suitable for products with high respiration rates, while micro-perforation creates nearly invisible, minute holes, often achieved through mechanical means or advanced laser technology. Laser perforation is particularly significant due to its ability to create extremely precise and consistent hole sizes and patterns, allowing for highly customized gas transmission rates specific to the respiration needs of individual food items. This precision helps in maintaining an optimal atmosphere within the package, significantly impacting shelf life and product quality. Beyond physical perforations, some films utilize inherent material porosity or integrated membrane technologies to achieve selective breathability.

Furthermore, innovations in Modified Atmosphere Packaging (MAP) and Equilibrium Modified Atmosphere Packaging (EMAP) film development are continuously evolving. These technologies involve engineering films that interact with the natural respiration of the packaged product to achieve and maintain an optimal gas composition (e.g., lower oxygen, higher carbon dioxide). Active packaging technologies, which might incorporate scavengers or emitters within the film structure to control gas or moisture, are also becoming more prevalent, further enhancing the functionality of breathable lidding films. Ongoing research focuses on developing bio-based and compostable breathable polymers and optimizing sealing technologies to ensure integrity while facilitating breathability, addressing both performance and sustainability demands.

Regional Highlights

- North America: A mature market characterized by high consumer demand for convenience foods and fresh produce. The region focuses on advanced packaging solutions, including those that offer enhanced sustainability. Innovations in material science and smart packaging integration are key trends. Strong regulatory frameworks also drive the adoption of safe and efficient breathable films.

- Europe: This region demonstrates a significant emphasis on reducing food waste and promoting sustainable packaging. Stringent environmental regulations and high consumer awareness drive the demand for bio-based, recyclable, and compostable breathable lidding films. Western European countries lead in adopting sophisticated MAP and EMAP technologies.

- Asia Pacific (APAC): The fastest-growing market, propelled by rapid urbanization, increasing disposable incomes, and the expansion of the organized retail sector. Countries like China and India are witnessing a surge in demand for packaged fresh foods and convenience items. Local manufacturers are investing in advanced packaging technologies to meet evolving consumer needs and modern retail demands.

- Latin America: An emerging market with significant growth potential due to increasing modernization of the food processing industry and rising consumer awareness about food safety and quality. Brazil and Mexico are key contributors, driven by expanding supermarket chains and a shift towards packaged goods.

- Middle East and Africa (MEA): This region is experiencing steady growth, primarily due to increasing population, rising disposable incomes, and developing food processing and retail infrastructure. The need for extended shelf life in challenging climatic conditions makes breathable lidding films a crucial packaging solution for fresh and perishable goods.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Breathable Lidding Film Packaging Market.- Amcor Plc

- Berry Global Inc.

- Sealed Air Corporation

- Mondi Group

- Coveris Holdings SA

- Wipak Group

- UFlex Ltd.

- CCL Industries Inc.

- Huhtamaki Oyj

- Schur Flexibles Group

- Bollore Films

- RPC Group (Berry Global)

- Sonoco Products Company

- Winpak Ltd.

- Plastopil Hazorea Company Ltd.

- Constantia Flexibles Group GmbH

- Toray Plastics (America) Inc.

- Mitsubishi Chemical Corporation

- Taj Group

- Bemis Company Inc. (Amcor)

Frequently Asked Questions

What is breathable lidding film packaging?

Breathable lidding film packaging refers to specialized films designed to cover food trays or containers, featuring selective permeability to gases like oxygen and carbon dioxide, which extends the shelf life of perishable products by regulating the internal atmosphere.

Which applications benefit most from breathable lidding films?

Fresh produce such as fruits, vegetables, and salads, along with processed meats, poultry, seafood, and ready meals, benefit significantly from breathable lidding films due to their specific respiration needs and requirement for extended freshness.

What are the primary materials used in breathable lidding films?

Common materials include polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and Ethylene Vinyl Alcohol (EVOH). There is also a growing trend towards bio-based and compostable polymers like Polylactic Acid (PLA) for sustainable options.

How do breathable lidding films contribute to sustainability?

These films primarily contribute to sustainability by reducing food waste through extended shelf life. Additionally, ongoing innovations focus on developing recyclable, biodegradable, and compostable film options, further enhancing their environmental profile.

What are the key technological advancements in this market?

Key technological advancements include precision laser perforation for customized gas transmission rates, advanced co-extrusion techniques for multi-layer films, and the integration of active packaging elements to further optimize the internal environment of the package.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager