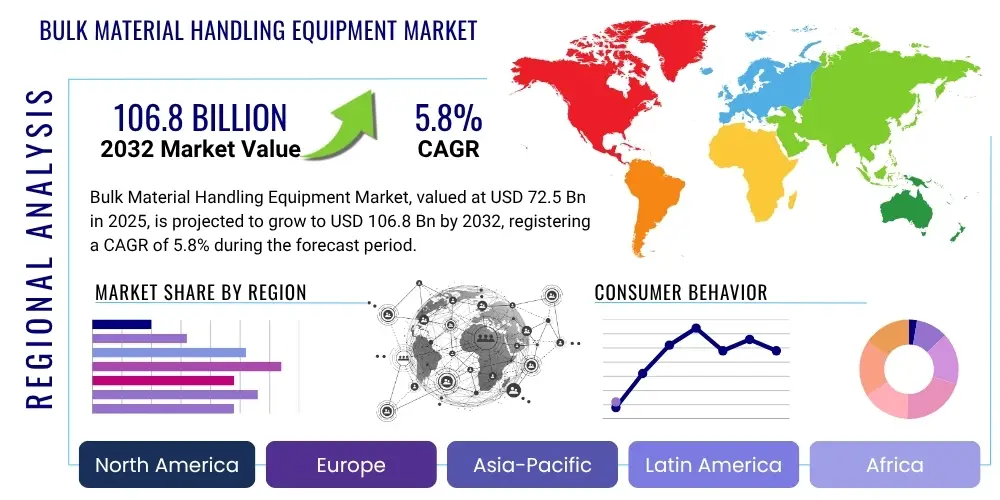

Bulk Material Handling Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430196 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Bulk Material Handling Equipment Market Size

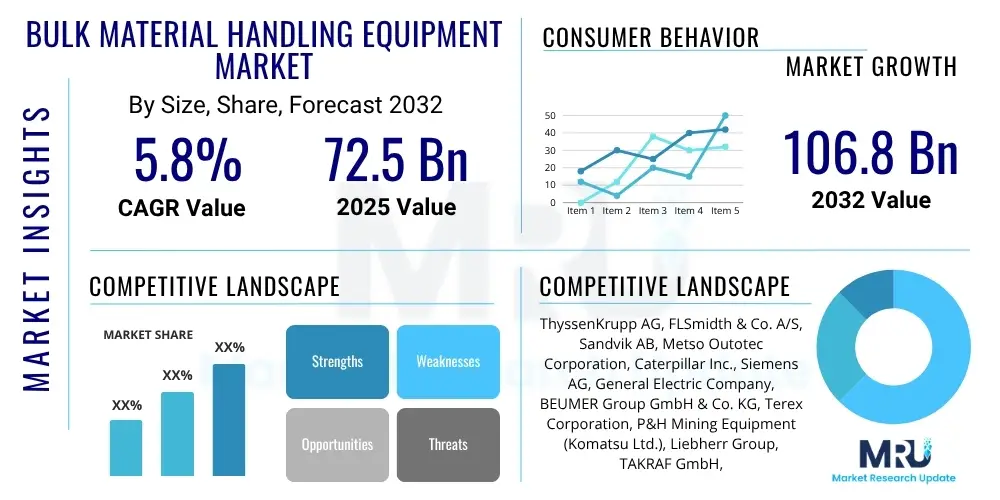

The Bulk Material Handling Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 72.5 Billion in 2025 and is projected to reach USD 106.8 Billion by the end of the forecast period in 2032.

Bulk Material Handling Equipment Market introduction

The Bulk Material Handling Equipment market encompasses a sophisticated range of machinery and integrated systems fundamentally designed for the efficient, safe, and economical management of materials in bulk form. These materials, which include powders, granules, aggregates, and slurries, are critical inputs and outputs across a multitude of industrial processes. The product portfolio within this market is extensive, featuring essential equipment such as various types of conveyor systems (belt, screw, pneumatic), robust stackers and reclaimers for large-scale storage, silos and hoppers for controlled dispensing, and a diverse range of lifting devices like cranes and hoists. The primary function of this equipment is to facilitate seamless movement, precise storage, and accurate weighing or sorting of materials, thereby optimizing operational workflows and significantly reducing the need for manual handling.

These specialized systems find critical applications across a broad spectrum of industries, including but not limited to mining and mineral processing, large-scale construction, power generation facilities (especially thermal plants), food and beverage processing, chemical manufacturing, and logistics at ports and terminals. The inherent benefits of deploying advanced bulk material handling equipment are manifold: they dramatically enhance productivity by ensuring continuous material flow, significantly improve workplace safety by minimizing human exposure to hazardous operations and heavy loads, and ultimately lead to substantial cost reductions through optimized labor, energy efficiency, and reduced material wastage. The sustained growth of this market is dynamically driven by several interconnected factors, including rapid global industrialization, substantial investments in critical infrastructure projects, the increasing imperative for process automation, and the escalating volumes of international trade requiring efficient and reliable material logistics solutions across continents. This confluence of factors underpins the market's trajectory towards continued innovation and expansion, as industries worldwide strive for greater efficiency and resilience in their supply chains.

Bulk Material Handling Equipment Market Executive Summary

The Bulk Material Handling Equipment market is currently navigating a period of significant evolution, marked by compelling business trends that prioritize operational intelligence and environmental stewardship. A dominant trend is the pervasive integration of automation and digitalization, where manufacturers are increasingly incorporating advanced sensor technologies, sophisticated Internet of Things (IoT) connectivity, and powerful data analytics platforms into their equipment. This technological convergence enables real-time performance monitoring, facilitates predictive maintenance strategies, and ultimately enhances overall operational efficiency while minimizing unforeseen downtime. Furthermore, the growing global emphasis on sustainability is profoundly influencing market dynamics, driving an intensified demand for energy-efficient solutions and equipment designed to reduce environmental footprints, including systems that incorporate renewable energy sources or are optimized for lower emissions. The market is also observing a distinct shift towards highly customized solutions, moving away from generic offerings to specifically engineered systems that meticulously address the unique and intricate requirements of diverse industrial applications.

From a regional perspective, the Asia Pacific region continues to assert its market dominance, underpinned by its robust trajectory of industrial expansion, extensive government-backed infrastructure investments, and flourishing manufacturing and mining sectors in economic powerhouses such as China, India, and Indonesia. In contrast, North America and Europe are characterized by their pioneering adoption of cutting-edge technologies and adherence to increasingly stringent safety and environmental regulations, which collectively stimulate demand for the most modern, automated, and compliant equipment available. Segment-wise, the ubiquitous conveyor systems segment consistently remains a pivotal contributor to market revenue, owing to its unparalleled versatility and applicability across nearly all bulk material handling operations. Concurrently, substantial capital investments in port infrastructure development and the ongoing modernization of global logistics networks are generating heightened demand for specialized, high-capacity loading and unloading equipment. The discernible trend towards integrated solutions, which seamlessly combine multiple material handling processes into cohesive and streamlined operational frameworks, is also gaining considerable traction, offering end-users comprehensive, highly efficient, and adaptable operational paradigms that deliver superior performance and return on investment.

AI Impact Analysis on Bulk Material Handling Equipment Market

User inquiries frequently highlight a profound interest in understanding the transformative potential of Artificial Intelligence (AI) within the Bulk Material Handling Equipment market. These questions often focus on how AI can significantly enhance core operational aspects such as overall efficiency, revolutionize maintenance strategies, profoundly improve workplace safety, and contribute to the holistic optimization of entire material handling systems. Common concerns and expectations center around AI's inherent capability to accurately predict potential equipment failures before they occur, dynamically optimize complex material flow paths, intelligently automate intricate and repetitive tasks, and empower superior data-driven decision-making across all levels of operation. There is considerable user interest in grasping the tangible, practical applications of AI in areas like continuous real-time monitoring of equipment health, facilitating truly autonomous operational modes for heavy machinery, and enabling intelligent resource allocation within vast industrial complexes. Concurrently, users express valid concerns regarding the significant initial implementation costs associated with AI integration, critical considerations around data privacy and cybersecurity, and the urgent necessity for a highly skilled workforce adequately trained to effectively manage and leverage these increasingly sophisticated AI-powered systems. Ultimately, users hold high expectations for AI to deliver smarter, inherently safer, and more economically viable bulk handling solutions, directly addressing long-standing industry challenges pertaining to labor efficiency, prolonged equipment downtime, and the pursuit of operational excellence.

- Predictive Maintenance: AI algorithms meticulously analyze vast datasets from embedded sensors, including vibration, temperature, and current, to accurately forecast potential equipment failures, enabling proactive maintenance interventions, minimizing unscheduled downtime, and extending asset lifespan significantly.

- Optimized Material Flow: AI-powered control systems dynamically adjust operational parameters such as conveyor speeds, feeder rates, and routing paths in real-time, based on material characteristics and demand fluctuations, thereby optimizing throughput, reducing energy consumption, and proactively preventing costly bottlenecks.

- Autonomous Operations: The sophisticated integration of AI with advanced robotics facilitates the deployment of autonomous bulk material handling vehicles, such as self-driving loaders and automated cranes, substantially reducing the reliance on manual labor, mitigating human error, and dramatically increasing operational safety in hazardous environments.

- Enhanced Safety: AI-powered computer vision systems and advanced analytics continuously monitor operational areas to detect potential hazards, identify unsafe worker behaviors, and ensure strict compliance with safety protocols, triggering immediate alerts and preventing serious accidents in dynamic industrial settings.

- Quality Control and Sorting: AI can analyze various material characteristics, including particle size, moisture content, and chemical composition, during the handling process. This capability allows for precise sorting, identification of contaminants, and ensures consistent product quality, reducing waste and improving product integrity.

- Energy Management: AI algorithms meticulously optimize equipment usage schedules and power consumption patterns across entire material handling fleets, dynamically adjusting to demand and energy prices, which leads to significant reductions in overall energy costs and a marked improvement in the environmental sustainability of operations.

- Inventory Management: AI-driven insights provide real-time, highly accurate inventory tracking within large-scale storage facilities like silos and warehouses, optimizing storage utilization, reducing inventory carrying costs, and ensuring materials are available precisely when needed for production.

- Remote Monitoring and Control: AI capabilities facilitate exceptionally sophisticated remote diagnostics, performance monitoring, and precise control of bulk material handling operations from centralized command centers, allowing for efficient management of geographically dispersed assets and enhanced response times.

- Customization and Adaptability: AI-powered systems enable rapid configuration and adaptation of handling systems to accommodate varying material properties, fluctuating production volumes, or changing operational demands, significantly enhancing system flexibility and resilience in dynamic industrial environments.

- Process Optimization: AI analyzes historical and real-time operational data to identify inefficiencies, suggest process improvements, and simulate optimal operational strategies, leading to continuous performance enhancements and increased overall system reliability.

DRO & Impact Forces Of Bulk Material Handling Equipment Market

The Bulk Material Handling Equipment market is intricately shaped by a potent combination of drivers, significant restraints, evolving opportunities, and transformative impact forces that collectively dictate its growth trajectory and competitive landscape. A primary driver is the relentless expansion of various end-use industries, including the burgeoning mining sector, global construction boom, and diversified manufacturing operations, all of which exhibit an insatiable demand for the efficient and continuous movement and storage of vast quantities of raw materials and finished goods. Concurrently, rapid urbanization trends across emerging economies, coupled with escalating global trade volumes, necessitate robust and high-capacity material handling infrastructure, particularly in port logistics and intermodal transportation networks, further propelling market demand. The compelling imperative for greater automation across industrial processes, driven by the desire to enhance operational efficiency, mitigate escalating labor costs, and profoundly improve workplace safety standards, also acts as a powerful catalyst for market expansion, particularly with the seamless integration of smart technologies and advanced robotics into conventional systems.

Despite these strong drivers, the market contends with several notable restraints. Foremost among these is the inherently high initial capital expenditure required for the acquisition, installation, and commissioning of sophisticated bulk material handling systems, which can present a formidable barrier to entry and expansion, particularly for smaller and medium-sized enterprises with limited investment capacity. The operational complexities associated with the ongoing maintenance of this specialized equipment, which frequently demands highly specialized technical skills, costly spare parts, and extended downtime, also pose a significant challenge to operational continuity. Furthermore, the increasingly stringent global environmental regulations concerning particulate matter emissions (dust), noise pollution, and energy consumption necessitate continuous innovation in equipment design and operational practices to ensure compliance, thereby adding considerable complexity and cost to both development and operational phases. However, the market is rife with significant opportunities. The growing demand for highly customized and modular solutions, which offer unparalleled flexibility and adaptability to meet the unique and evolving needs of diverse client operations, represents a substantial growth avenue. The accelerating trend towards environmentally sustainable and energy-efficient equipment designs, coupled with the immense growth potential offered by modern infrastructure development in rapidly industrializing emerging economies, provides fertile ground for market expansion. Furthermore, breakthrough technological advancements, particularly in the fields of the Internet of Things (IoT), Artificial Intelligence (AI), and advanced robotics, are continually creating novel possibilities for developing highly intelligent, fully autonomous, and interconnected material handling systems, promising unprecedented levels of efficiency, precision, and safety. Impact forces such as unpredictable global economic fluctuations, escalating geopolitical tensions influencing critical supply chains, and the rapid pace of technological obsolescence further complicate market dynamics, underscoring the critical need for companies to remain exceptionally agile, adaptable, and continuously innovative to maintain a sustainable competitive advantage in this dynamic industry.

Segmentation Analysis

The Bulk Material Handling Equipment market undergoes a meticulous and multi-faceted segmentation based on a diverse array of criteria, allowing for a profoundly granular understanding of its intricate components, specialized product offerings, and varied application domains. This comprehensive segmentation framework is absolutely critical for market participants, as it facilitates the precise identification of specific market niches, provides invaluable insights into evolving end-user preferences, and enables the strategic tailoring of product portfolios and service offerings to meticulously address the heterogeneous requirements of a vast range of industrial clients. The principal segmentation criteria typically encompass the specific type of equipment utilized, the distinct industrial application sectors where these systems are deployed, and the inherent characteristics of the material being processed, all of which collectively reflect the highly specialized and often custom-engineered nature of modern bulk material handling solutions. Each defined market segment invariably experiences unique growth impetus and confronts a distinct set of operational and technological challenges, thereby contributing to the overarching complexity, dynamic opportunities, and competitive intensity prevalent within the broader market landscape. Understanding these nuanced interdependencies across segments is vital for effective strategic planning and market penetration.

- By Equipment Type:

- Conveyor Systems:

- Belt Conveyors: Widely used for continuous movement of various bulk materials over long distances.

- Chain Conveyors: Ideal for heavy-duty applications and abrasive materials.

- Screw Conveyors: Suitable for powdery, granular, or sticky materials in confined spaces.

- Roller Conveyors: Best for unit loads, often integrated with automated systems.

- Pneumatic Conveyors: Used for transporting dry, bulk granular materials using air pressure.

- Stackers and Reclaimers: Equipment for efficient piling and retrieval of bulk materials in large storage yards.

- Hoppers and Silos: Storage structures for various bulk materials, facilitating controlled discharge.

- Elevators:

- Bucket Elevators: Vertically convey bulk materials using buckets attached to a belt or chain.

- Vertical Conveyors: Elevate goods and materials in a continuous flow.

- Cranes and Hoists:

- Bridge Cranes: Overhead cranes spanning a bay, often used in manufacturing and heavy industry.

- Gantry Cranes: Similar to bridge cranes but supported on legs running on rails, common in shipyards and outdoor storage.

- Jib Cranes: Small, versatile cranes with a horizontal arm, used for localized lifting tasks.

- Loaders and Unloaders:

- Ship Loaders and Unloaders: High-capacity systems for efficient transfer of bulk materials to and from vessels.

- Wagon Loaders and Unloaders: Specialized equipment for railcar bulk material transfer.

- Truck Loaders and Unloaders: Systems for rapid loading and unloading of bulk materials into road vehicles.

- Forklifts: Versatile vehicles for lifting and moving materials short distances, though often associated with palletized goods, also crucial for bulk container handling.

- Automated Storage and Retrieval Systems (AS/RS): Computer-controlled systems for automatically placing and retrieving loads from storage locations.

- Excavators and Dumps: Heavy machinery used for earthmoving and large-scale bulk material relocation, especially in mining and construction.

- Other Material Handling Equipment: Includes vibratory feeders, screens, crushers, and various specialized conveying accessories.

- Conveyor Systems:

- By Application:

- Mining: Extraction and processing of coal, metallic ores, industrial minerals, and aggregates.

- Construction: Handling of cement, sand, gravel, stone, and other building materials.

- Power Generation: Management of coal, biomass, and ash in thermal power plants.

- Food and Beverage: Conveying and storing grains, sugar, flour, and other food ingredients.

- Chemical and Petrochemical: Transporting and storing chemical powders, pellets, and granules.

- Ports and Terminals: Efficient loading and unloading of bulk cargo for maritime and intermodal transport.

- Manufacturing: Internal logistics for raw materials, work-in-progress, and finished goods in industries like cement, steel, paper, and automotive.

- Agriculture: Handling of seeds, fertilizers, harvested crops, and animal feed.

- Pharmaceuticals: Controlled handling of active pharmaceutical ingredients and excipients.

- Logistics and Warehousing: Systems for internal movement and storage within large distribution centers.

- By Industry Vertical:

- Heavy Industry: Sectors like mining, steel, cement, and power generation requiring robust, large-scale systems.

- Light Industry: Manufacturing sectors with lighter loads, often requiring precision and automation.

- By Material Type:

- Powders and Granules: Fine, free-flowing materials like cement, sugar, chemicals, and plastics.

- Lumps and Aggregates: Coarse, irregularly shaped materials such as coal, ores, gravel, and stone.

- Slurries: Semi-liquid mixtures of solids and liquids, often requiring specialized pumping and conveying.

- Sheets and Blocks: Large, solid forms of materials, typically handled by cranes or forklifts.

- By System Type:

- Continuous Bulk Handling: Systems designed for uninterrupted material flow, such as conveyor belts.

- Batch Bulk Handling: Systems that process materials in discrete batches, often involving hoppers and weigh feeders.

Value Chain Analysis For Bulk Material Handling Equipment Market

The value chain for the Bulk Material Handling Equipment market is a multi-layered ecosystem, commencing with robust upstream activities that focus intensely on the procurement of critical raw materials and the precision manufacturing of specialized components. This foundational stage involves a vast network of suppliers providing essential inputs such as high-grade metals (e.g., steel, aluminum, stainless steel), advanced industrial plastics, sophisticated electronic control units, powerful motors, and complex hydraulic and pneumatic systems. Innovation in materials science, coupled with advancements in component design and manufacturing precision at this initial stage, directly and profoundly influences the overall efficiency, long-term durability, and ultimate cost-effectiveness of the final bulk material handling equipment. Key market players frequently engage in meticulously structured strategic partnerships and long-term supply agreements with these upstream providers to rigorously ensure consistent material quality, secure supply chain stability, and often co-develop bespoke components tailored to specific equipment designs. Following the component acquisition, the core manufacturing process unfolds, encompassing intricate stages of advanced engineering design, precise fabrication, meticulous assembly, and rigorous testing of the diverse range of material handling equipment. This phase often integrates cutting-edge automation technologies and adheres to stringent industry standards and client-specific technical specifications to guarantee optimal performance and reliability.

Transitioning downstream, the sophisticated distribution channel assumes an absolutely pivotal role in effectively connecting the manufacturers of bulk material handling equipment with their extensive and varied base of industrial end-users. This critical stage typically operates through a hybrid model, combining direct sales approaches from Original Equipment Manufacturers (OEMs) to major industrial clients and large-scale project developers, with robust indirect sales facilitated by an expansive network of authorized distributors, specialized dealers, and expert system integrators. These vital intermediaries often provide localized sales support, highly skilled installation services, indispensable after-sales maintenance, and readily available spare parts, all of which are paramount for ensuring maximum equipment uptime and operational continuity for the end-user. System integrators, in particular, play an increasingly crucial role for complex and large-scale industrial projects, as they possess the expertise to combine various types of individual equipment into highly customized, comprehensive, and fully integrated solutions that are meticulously designed to meet precise operational requirements. The culmination of the value chain lies in the actual deployment and continuous operation of the equipment by a diverse array of industries. In this final stage, ongoing requirements for preventative maintenance, necessary system upgrades, and eventual equipment replacement cycles collectively drive a persistent demand for aftermarket services and stimulate the continuous purchase of new machinery, thereby underscoring the critical importance of cultivating and maintaining a robust service network and exceptionally strong customer relationship management strategies throughout the entire lifecycle of the equipment. This holistic approach ensures sustained value delivery and market presence.

Bulk Material Handling Equipment Market Potential Customers

The primary potential customers and discerning end-users of Bulk Material Handling Equipment represent a broad and diverse spectrum of industries that are inherently reliant on the exceptionally efficient, safe, and cost-effective movement and systematic storage of colossal quantities of raw, semi-processed, or finished materials. These critical clients encompass large-scale industrial operations where the handling of bulk commodities forms the absolute cornerstone of their production processes, alongside vast logistical hubs and distribution centers that meticulously manage immense volumes of goods for global trade. The motivations driving significant investment decisions in such equipment are multifaceted and strategic, predominantly fueled by an urgent imperative for dramatically increased operational efficiency, profoundly enhanced workplace safety protocols, stringent compliance with an evolving landscape of environmental regulations, and a decisive reduction in labor-intensive operational costs. Consequently, advanced bulk material handling systems have evolved from mere utility to indispensable, strategic assets for contemporary industrial infrastructure, offering a competitive edge through optimized throughput and reduced operational overheads. Strategic deployment of these systems is seen as a long-term investment yielding substantial returns through sustained productivity gains and significant operational cost savings.

Key segments constituting this expansive customer base include leading global mining corporations engaged in the extraction and primary processing of essential resources such as coal, metallic ores (e.g., iron, copper), industrial minerals, and various aggregates. Large construction firms are consistently in need of solutions for handling vast volumes of cement, sand, gravel, and crushed stone. Power generation plants, particularly those reliant on fossil fuels, require sophisticated systems for fuel intake (e.g., coal, biomass) and efficient ash disposal. Critical infrastructure like international ports and marine terminals demand high-capacity equipment for the rapid and precise loading and unloading of bulk cargo from massive container ships, bulk carriers, and freight trains. Furthermore, a wide array of manufacturing sectors, including cement production, steel mills, paper and pulp industries, and automotive assembly lines, heavily utilize these systems for streamlined internal material flow management. The food processing sector, handling grains, sugar, and various agricultural products, alongside the chemical and petrochemical industries processing powders, pellets, and granules, also represent substantial customer segments. Lastly, large-scale logistics and warehousing facilities continually invest in these systems to optimize their internal movement, storage, and retrieval operations. These diverse buyers are perpetually seeking robust, reliable, highly durable, and often extensively customized solutions that are capable of performing consistently under harsh and demanding operating conditions, while simultaneously delivering a superior return on investment through optimized material flow, minimized operational bottlenecks, and enhanced overall supply chain resilience.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 72.5 Billion |

| Market Forecast in 2032 | USD 106.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ThyssenKrupp AG, FLSmidth & Co. A/S, Sandvik AB, Metso Outotec Corporation, Caterpillar Inc., Siemens AG, General Electric Company, BEUMER Group GmbH & Co. KG, Terex Corporation, P&H Mining Equipment (Komatsu Ltd.), Liebherr Group, TAKRAF GmbH, Vistamation Inc., Dematic (Kion Group AG), Daifuku Co., Ltd., Fives Group, Schade Lagertechnik GmbH, HAVER & BOECKER OHG, Trelleborg AB, Bühler AG, Eriez Magnetics, Kawasaki Heavy Industries, Ltd., Vermeer Corporation, Astec Industries, Inc., Rexnord Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bulk Material Handling Equipment Market Key Technology Landscape

The Bulk Material Handling Equipment market is currently undergoing an accelerated and profound technological transformation, fundamentally driven by an escalating global demand for unparalleled operational efficiency, significantly enhanced safety protocols, and superior operational intelligence across all stages of material handling. The pervasive integration of advanced digital technologies is proving paramount, systematically moving traditional mechanical systems towards becoming highly intelligent, seamlessly interconnected, and inherently adaptive solutions. This encompasses the widespread and strategic adoption of the Internet of Things (IoT), where a multitude of sophisticated sensors meticulously embedded within equipment components continuously collect vast, real-time datasets pertaining to performance metrics, wear and tear indicators, and dynamic environmental conditions. This invaluable data is subsequently leveraged for sophisticated real-time monitoring and advanced predictive analytics, facilitating a crucial paradigm shift from reactive, break-fix maintenance strategies to highly proactive and condition-based maintenance regimes. Predictive maintenance, powered by advanced Artificial Intelligence (AI) and Machine Learning (ML) algorithms, diligently analyzes these continuous data streams to anticipate potential equipment failures with remarkable accuracy, thereby minimizing unscheduled downtime, optimizing maintenance schedules, and significantly reducing overall operational costs while substantially extending the lifespan of critical assets. This proactive approach ensures maximum uptime and resource utilization.

Further driving this technological evolution is the increasing and strategic deployment of sophisticated automation and advanced robotics, particularly for tasks that are inherently hazardous, physically demanding, or highly repetitive in nature. Autonomous vehicles (e.g., self-driving loaders, automated guided vehicles) and robotic systems are being effectively utilized for precision material transport, systematic stacking, and efficient retrieval operations, thereby dramatically enhancing safety by minimizing human exposure to dangerous or strenuous environments, concurrently improving throughput accuracy, and ensuring consistent operational quality. Digital twin technology is rapidly gaining significant traction, enabling the creation of virtual, high-fidelity models and simulations of entire material handling systems. This innovative capability allows for meticulous optimization of facility layouts, rigorous testing of diverse operational scenarios, and precise troubleshooting of potential issues without any adverse impact on physical operations, ultimately leading to more efficient design processes, accelerated commissioning, and improved operational resilience. Moreover, advanced control systems, increasingly powered by AI, are meticulously optimizing material flow dynamics, energy consumption profiles, and precise load balancing across highly complex and interconnected networks of conveyors, stackers, reclaimers, and various processing units. The unwavering industry commitment to developing more energy-efficient motors, integrating advanced regenerative braking systems, and exploring alternative, sustainable power sources (e.g., solar, electric drives) further underscores the market's dedication to environmental stewardship and a substantial reduction in carbon footprints, profoundly shaping the future of comprehensive bulk material handling solutions toward greater sustainability and operational excellence.

Regional Highlights

- North America: This region is characterized by substantial and ongoing investments in infrastructure modernization, a profound and accelerating focus on process automation, and the pervasive adoption of advanced digital technologies aimed at rigorously enhancing operational efficiency across vital industries such as mining, construction, and manufacturing. Strict environmental and safety regulations act as a powerful catalyst, driving persistent demand for compliant, technologically superior, and often highly automated equipment. A robust technological ecosystem, coupled with the strategic presence of numerous major market players, further contributes significantly to market growth, with a pronounced and increasing emphasis on smart warehousing, intelligent logistics solutions, and integrated supply chain management.

- Europe: European nations are at the absolute forefront of pioneering the adoption of highly sustainable and exceptionally energy-efficient bulk material handling solutions. The confluence of stringent environmental protection policies and demanding labor safety standards vigorously drives continuous innovation towards developing ecologically sound, low-emission, and extensively automated systems. Germany, notably, stands as a preeminent hub for advanced manufacturing and precision engineering, consequently generating high demand for highly sophisticated, custom-engineered, and technologically integrated equipment. The region also benefits immensely from its meticulously developed port infrastructure, which robustly supports extensive international trade and necessitates the deployment of highly efficient, high-capacity loading and unloading systems to manage colossal cargo volumes.

- Asia Pacific (APAC): APAC indisputably represents the largest and most rapidly expanding market globally for bulk material handling equipment. This exponential growth is primarily fueled by relentless industrialization, a multitude of colossal infrastructure development projects (e.g., Belt and Road Initiative), and substantial, continuous investments in the booming manufacturing, mining, and construction sectors across economic giants like China, India, Indonesia, and Vietnam. The region's persistently expanding population, coupled with accelerating urbanization trends, generates an immense and unceasing demand for raw materials and essential commodities, thereby mandating the deployment of increasingly advanced and high-capacity bulk handling solutions. Proactive government initiatives actively supporting industrial expansion and critical infrastructure development further significantly accelerate market growth, though the pace and scale of technology adoption and the stringency of environmental regulations can vary considerably across individual countries within the region.

- Latin America: This dynamic region presents considerable and largely untapped growth opportunities, primarily underpinned by its abundant natural mineral resources and the vigorous expansion of mining activities in key countries such as Brazil, Chile, Peru, and Mexico. Significant ongoing investments in essential infrastructure development, including the modernization and expansion of ports and comprehensive transportation networks, also contribute substantially to burgeoning market demand for advanced handling solutions. The regional market is increasingly transitioning towards the adoption of modern, high-efficiency equipment to profoundly improve operational productivity and effectively reduce long-term operational costs, systematically phasing out older, less efficient systems. However, intermittent economic volatility, fluctuating commodity prices, and political uncertainties in certain sub-regions can occasionally temper investment decisions and influence market stability.

- Middle East and Africa (MEA): The MEA region is experiencing robust market growth, predominantly propelled by colossal ongoing infrastructure mega-projects, especially within the rapidly expanding construction and logistics sectors. This is synergistically combined with substantial and strategic investments in the vital mining and flourishing oil and gas industries across key nations. Countries within the Gulf Cooperation Council (GCC) are dedicating immense capital to extensively modernize existing port facilities and construct entirely new industrial complexes and free zones, thereby creating a compelling demand for sophisticated bulk material handling systems. However, the diverse local market conditions, widely varying economic landscapes, and fluctuating levels of political stability and regulatory frameworks across different sub-regions can profoundly influence both the pace and the overall scale of technology adoption and market penetration, requiring tailored market approaches.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bulk Material Handling Equipment Market.- ThyssenKrupp AG

- FLSmidth & Co. A/S

- Sandvik AB

- Metso Outotec Corporation

- Caterpillar Inc.

- Siemens AG

- General Electric Company

- BEUMER Group GmbH & Co. KG

- Terex Corporation

- P&H Mining Equipment (Komatsu Ltd.)

- Liebherr Group

- TAKRAF GmbH

- Vistamation Inc.

- Dematic (Kion Group AG)

- Daifuku Co., Ltd.

- Fives Group

- Schade Lagertechnik GmbH

- HAVER & BOECKER OHG

- Trelleborg AB

- Bühler AG

- Eriez Magnetics

- Kawasaki Heavy Industries, Ltd.

- Vermeer Corporation

- Astec Industries, Inc.

- Rexnord Corporation

Frequently Asked Questions

What precisely constitutes bulk material handling equipment?

Bulk material handling equipment refers to specialized mechanical systems and diverse machinery explicitly designed for the exceptionally efficient, safe, and controlled transport, precise storage, and accurate processing of materials in large, loose quantities. This includes various forms such as fine powders, granular substances, coarser aggregates, and even semi-liquid slurries. Illustrative examples encompass robust conveyor belts, tall storage silos, versatile stackers, and powerful reclaimers, all of which are absolutely vital components within modern industrial production and logistics networks, facilitating seamless material flow.

What are the predominant factors propelling the growth of the Bulk Material Handling Equipment market?

The sustained expansion of the Bulk Material Handling Equipment market is primarily driven by several powerful and interconnected factors. These include significant global industrialization, substantial and continuous investments in critical infrastructure projects worldwide, the widespread and accelerating adoption of sophisticated automation technologies aimed at maximizing operational efficiency, and the ever-increasing volumes of international trade which necessitate highly reliable and advanced logistics solutions for the efficient movement of bulk commodities across vast geographical distances and complex supply chains.

How is Artificial Intelligence (AI) actively transforming the Bulk Material Handling Equipment market?

Artificial Intelligence (AI) is profoundly transforming the Bulk Material Handling Equipment market by introducing unprecedented levels of operational intelligence and automation. Key impacts include the enablement of highly accurate predictive maintenance capabilities, which anticipate equipment failures and minimize downtime; the dynamic optimization of complex material flow paths to maximize throughput and reduce energy consumption; the facilitation of truly autonomous operations through robotics; significant enhancements in workplace safety protocols via intelligent monitoring systems; and the strategic improvement of energy management across entire fleets of equipment. These advancements collectively lead to substantially increased efficiency, significant cost reductions, and superior operational resilience in demanding industrial environments.

Which specific industries represent the major end-users of bulk material handling equipment?

The major end-user industries for bulk material handling equipment are diverse and include critical sectors such as mining and mineral extraction, large-scale construction, various forms of power generation (especially coal-fired and biomass plants), the global food and beverage processing sector, the chemical and petrochemical manufacturing industries, vital international ports and maritime terminals, and a wide array of general manufacturing processes (e.g., cement, steel, paper, automotive). These industries fundamentally rely on robust, high-capacity systems for the continuous and efficient movement, storage, and processing of their core materials, forming the backbone of their operations and supply chains.

What are the key obstacles and challenges currently confronting the Bulk Material Handling Equipment market?

The Bulk Material Handling Equipment market faces several significant obstacles. These include the substantial initial capital investment required for procuring and deploying advanced equipment, which can be a barrier for many enterprises; the inherent complexities and considerable costs associated with the ongoing maintenance and repair of specialized machinery, often demanding expert technical skills and specific spare parts; and the increasing pressure to comply with ever more stringent environmental regulations pertaining to dust emissions, noise pollution, and overall energy consumption, which necessitate continuous technological innovation and adherence to evolving sustainability standards. These challenges require strategic planning and investment in research and development.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager