Camshaft Lifters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431256 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Camshaft Lifters Market Size

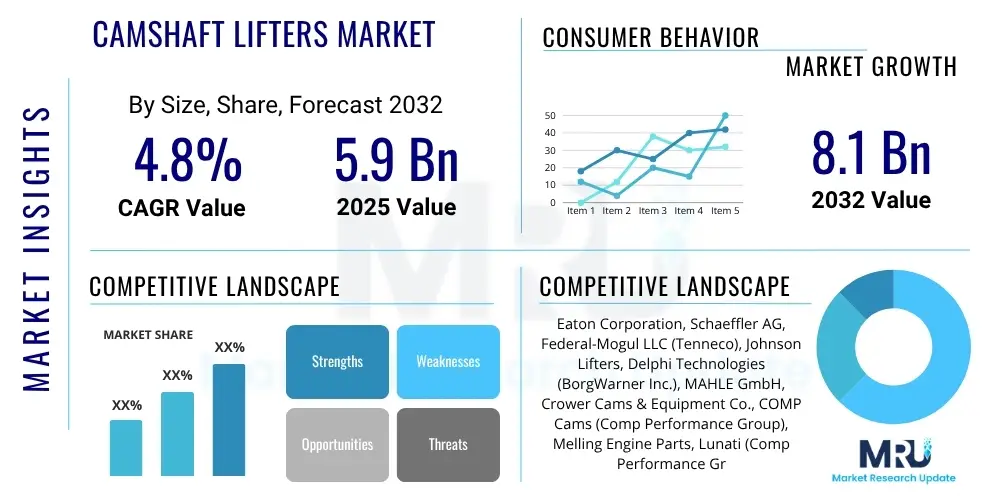

The Camshaft Lifters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2025 and 2032. The market is estimated at USD 5.9 Billion in 2025 and is projected to reach USD 8.1 Billion by the end of the forecast period in 2032.

Camshaft Lifters Market introduction

Camshaft lifters, also known as tappets or followers, are critical components within an internal combustion engine's valvetrain system. Their primary function is to translate the rotational motion of the camshaft lobes into linear motion, effectively actuating the intake and exhaust valves. This precise mechanical action ensures optimal engine performance, facilitating the intake of air and fuel mixture and the expulsion of combustion gases. The efficiency and durability of these components directly influence an engine's power output, fuel economy, and emission characteristics. As automotive technology advances, the demand for high-precision, low-friction, and durable camshaft lifters continues to grow.

The market encompasses a range of product types, including hydraulic roller lifters, mechanical lifters (flat tappet), and hydraulic flat tappet lifters, each designed for specific engine configurations and performance requirements. Hydraulic roller lifters, for instance, are increasingly favored due to their superior performance, reduced friction, and lower maintenance needs compared to their mechanical counterparts. Major applications span across passenger cars, commercial vehicles, marine engines, and various industrial machinery, highlighting their indispensable role in a broad spectrum of power generation systems.

The benefits associated with advanced camshaft lifters are multifaceted, contributing significantly to modern engine design. These include enhanced engine responsiveness, improved fuel efficiency through optimized valve timing, reduced noise, vibration, and harshness (NVH) levels, and a substantial decrease in harmful exhaust emissions. Driving factors for market growth are primarily stringent emission regulations, the global increase in vehicle production, ongoing advancements in engine downsizing and turbocharging technologies, and the persistent demand for higher fuel economy in both developed and emerging economies. The continuous innovation in materials and manufacturing processes also plays a pivotal role in shaping market dynamics.

Camshaft Lifters Market Executive Summary

The Camshaft Lifters Market is characterized by robust business trends driven by technological evolution and regulatory imperatives. A notable trend is the escalating adoption of hydraulic roller lifters, which offer superior performance and efficiency, particularly in modern, high-performance engines. Manufacturers are intensely focused on integrating advanced materials like specialized steel alloys and composite compounds to enhance durability, reduce weight, and minimize friction, thereby contributing to better fuel efficiency and lower emissions. The market is also witnessing increased automation and precision in manufacturing processes, crucial for meeting the stringent quality and performance demands of automotive OEMs. Furthermore, the push towards electrification in the automotive sector, while a long-term restraint, simultaneously drives innovation in hybrid engine components, maintaining a certain level of demand for sophisticated valvetrain components in these transitional powertrains.

Regionally, the Asia Pacific continues to be the dominant force in the camshaft lifters market, primarily due to high vehicle production volumes in countries like China, India, and Japan. This region benefits from a thriving automotive manufacturing base and a rapidly expanding consumer market for both passenger and commercial vehicles. North America and Europe, while representing mature automotive markets, exhibit steady demand driven by stringent emission standards and a strong focus on advanced engine technologies and performance vehicles. These regions also lead in the adoption of premium and high-performance lifter types, emphasizing innovation and quality. Latin America and the Middle East and Africa regions are expected to demonstrate consistent growth, fueled by increasing industrialization, infrastructure development, and growing automotive penetration.

Segment-wise, the market is predominantly influenced by the Hydraulic Roller Lifters segment, which is projected to maintain its leading position due to its inherent advantages in performance and longevity. The Passenger Car application segment constitutes the largest share, propelled by global automotive sales, although the Commercial Vehicles segment is also growing steadily, particularly with the expansion of logistics and construction industries worldwide. The OEM channel holds the lion's share, reflecting the direct integration of these components into new engine assemblies. However, the aftermarket segment is also experiencing stable growth, driven by vehicle maintenance, repairs, and performance upgrades. Material innovation, particularly in lightweight yet robust alloys, continues to be a critical segment trend, addressing fuel efficiency and emission reduction goals across all engine types.

AI Impact Analysis on Camshaft Lifters Market

User inquiries regarding the impact of Artificial Intelligence on the Camshaft Lifters Market frequently center on how AI can enhance design optimization, manufacturing precision, quality control, and predictive maintenance. Users are keen to understand how AI algorithms can simulate component performance under various operational stresses, predict potential failures, and streamline production processes. Key themes emerging from these questions include the desire for increased product reliability, reduced manufacturing costs, and faster innovation cycles, all driven by AI-powered analytics and automation. There is also an expectation that AI will lead to more personalized or application-specific lifter designs, moving beyond traditional mass production methodologies.

- AI-driven generative design for optimal lifter geometries and material compositions, improving performance and durability.

- Predictive analytics for manufacturing equipment maintenance, reducing downtime and improving production efficiency.

- Enhanced quality control through AI-powered visual inspection systems, detecting micro-defects invisible to human operators.

- Simulation and modeling of lifter wear and tear under various engine conditions, accelerating R&D and product validation.

- Supply chain optimization using AI for demand forecasting and inventory management, ensuring timely component availability.

- AI-assisted fault detection and diagnostics in engine systems, contributing to improved aftermarket service and component longevity.

DRO & Impact Forces Of Camshaft Lifters Market

The Camshaft Lifters Market is influenced by a complex interplay of drivers, restraints, opportunities, and competitive forces. Key drivers include increasingly stringent global emission regulations, which necessitate more efficient and precise valvetrain components to reduce pollutants. The steady growth in global vehicle production, particularly in emerging economies, provides a continuous demand base for new engine assemblies. Furthermore, the pervasive trend of engine downsizing and turbocharging in modern vehicles demands high-performance, durable lifters capable of operating under increased stress. The persistent industry focus on improving fuel efficiency across all vehicle types also significantly boosts the adoption of advanced lifter technologies that minimize friction and optimize valve actuation.

Conversely, several restraints impede market expansion. The most significant is the accelerating shift towards electric vehicles (EVs), which do not utilize traditional internal combustion engine components like camshaft lifters, posing a long-term threat to market growth. High research and development costs associated with designing and testing new materials and advanced lifter technologies can be prohibitive for smaller manufacturers. Volatility in raw material prices, particularly for specialized steel alloys and other high-performance materials, can impact manufacturing costs and profit margins. Additionally, the inherent complexity and precision required in the manufacturing process of these components create high barriers to entry, limiting competitive diversity.

Opportunities within the market largely stem from the growth of hybrid electric vehicles (HEVs), which still rely on internal combustion engines and therefore require advanced valvetrain components. The ongoing development and integration of lightweight, high-strength materials, such as advanced composites and specialized ceramics, present avenues for innovation and product differentiation. Furthermore, the expanding aftermarket segment, driven by vehicle repairs, maintenance, and performance enthusiasts seeking upgrades, offers sustained revenue streams. Customization and specialized solutions for performance applications or niche industrial engines also represent valuable growth opportunities for manufacturers capable of offering tailored products. The impact forces within the market, such as the bargaining power of buyers (large OEMs) and suppliers (raw material providers), the threat of new entrants (due to high R&D and capital costs), the threat of substitute products (EVs), and the intensity of industry rivalry, all shape pricing strategies, product development, and market competition.

Segmentation Analysis

The Camshaft Lifters Market is comprehensively segmented to provide a detailed understanding of its diverse facets, enabling precise market analysis and strategic planning. These segmentations are crucial for identifying key trends, understanding demand patterns, and evaluating competitive landscapes across different product types, applications, sales channels, and material compositions. Each segment reflects distinct market characteristics, growth drivers, and challenges, contributing to the overall dynamics of the industry.

- By Type

- Hydraulic Roller Lifters

- Mechanical Lifters (Flat Tappet)

- Hydraulic Flat Tappet Lifters

- By Application

- Passenger Cars

- Commercial Vehicles

- Marine

- Industrial

- By Sales Channel

- Original Equipment Manufacturer (OEM)

- Aftermarket

- By Material

- Steel

- Cast Iron

- Aluminum Alloys

- Composites

- Other Advanced Materials

Value Chain Analysis For Camshaft Lifters Market

The value chain for the Camshaft Lifters Market begins with the upstream activities involving raw material procurement and initial component manufacturing. This stage primarily includes suppliers of specialized metals such as high-strength steel, cast iron, and various alloys, which are critical for the durability and performance of lifters. These materials undergo precision machining, heat treatment, and surface finishing processes by specialized component manufacturers who then supply semi-finished or finished lifter bodies to the primary lifter manufacturers. The quality and cost-effectiveness of these upstream processes significantly influence the final product's attributes and market competitiveness.

Further down the value chain, the core manufacturing of camshaft lifters involves advanced processes like grinding, polishing, and assembly, especially for hydraulic lifters which require complex internal mechanisms. These manufacturers often specialize in specific types of lifters, catering to the diverse needs of engine builders. The finished camshaft lifters are then distributed through various channels to reach the end-users. Direct distribution channels involve sales directly to Original Equipment Manufacturers (OEMs), including major automotive companies, commercial vehicle manufacturers, and producers of marine and industrial engines. These direct relationships are characterized by long-term contracts, rigorous quality control, and co-development efforts to integrate lifters seamlessly into new engine designs.

Indirect distribution channels primarily serve the aftermarket segment. This involves a network of wholesale distributors, retailers, and independent repair shops that stock and sell camshaft lifters for replacement, maintenance, and performance upgrade purposes. The aftermarket is crucial for sustaining product longevity and catering to vehicle repair cycles. Both direct and indirect channels play vital roles in the market, with OEMs driving volume and new technology adoption, while the aftermarket ensures broader availability and supports the extended lifecycle of existing engines. Efficient logistics and robust supply chain management are paramount across all stages to ensure timely delivery and cost optimization, maintaining the delicate balance between quality, performance, and affordability in a highly competitive market.

Camshaft Lifters Market Potential Customers

The primary potential customers for camshaft lifters are diverse, encompassing major participants across the automotive, marine, and industrial sectors. Automotive Original Equipment Manufacturers (OEMs) represent the largest customer base, consistently requiring high volumes of camshaft lifters for the production of new passenger cars and commercial vehicles. These OEMs demand components that meet stringent performance, durability, and emission standards, often seeking customized solutions for their specific engine designs. Their purchasing decisions are heavily influenced by supplier reliability, technological capabilities, and cost-effectiveness.

Beyond the initial manufacturing, the aftermarket segment forms another substantial customer group. This includes a vast network of automotive repair shops, independent mechanics, specialty performance shops, and individual consumers who purchase camshaft lifters for maintenance, replacement, or performance upgrades on existing vehicles. These buyers prioritize product availability, brand reputation, compatibility with various engine models, and a balance between cost and quality. The demand in the aftermarket is influenced by the average age of vehicles on the road, driving patterns, and the prevalence of performance modification culture.

Furthermore, manufacturers of marine engines and various industrial equipment also constitute significant potential customers. Marine applications, such as powerboats, yachts, and commercial vessels, require robust lifters capable of enduring harsh operating conditions and extended periods of use. Industrial customers include manufacturers of generators, heavy machinery, agricultural equipment, and other power-driven systems that utilize internal combustion engines. These sectors emphasize reliability, longevity, and resistance to extreme temperatures and loads. The varying technical specifications and operational demands across these diverse customer segments necessitate a broad range of camshaft lifter products and specialized supplier capabilities to effectively address market needs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 5.9 Billion |

| Market Forecast in 2032 | USD 8.1 Billion |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Eaton Corporation, Schaeffler AG, Federal-Mogul LLC (Tenneco), Johnson Lifters, Delphi Technologies (BorgWarner Inc.), MAHLE GmbH, Crower Cams & Equipment Co., COMP Cams (Comp Performance Group), Melling Engine Parts, Lunati (Comp Performance Group), Morel Lifters, Elgin Industries, WABCO Holdings Inc. (ZF Friedrichshafen AG), Ford Motor Company (Parts Division), General Motors (ACDelco), Chrysler (Mopar), Honda (Parts Division), Toyota (Toyota Parts), Mazda (Mazda Genuine Parts), Subaru (Subaru Genuine Parts) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Camshaft Lifters Market Key Technology Landscape

The Camshaft Lifters Market is continuously evolving with significant technological advancements aimed at improving engine efficiency, reducing emissions, and enhancing overall performance. A prominent technological trend involves the integration of variable valve timing (VVT) and variable valve lift (VVL) systems, which require highly sophisticated lifter designs capable of precise and dynamic actuation. These systems optimize valve operation across varying engine speeds and loads, contributing significantly to better fuel economy and reduced emissions. Lifters designed for VVT/VVL applications often incorporate advanced hydraulic or electro-hydraulic mechanisms that allow for flexible valve control, presenting a complex engineering challenge that drives continuous innovation.

Another crucial aspect of the technology landscape is the development and application of advanced materials and surface coatings. Manufacturers are increasingly utilizing lightweight yet robust materials such as specialized steel alloys, high-strength cast iron, and even advanced composites to reduce the inertia of the valvetrain components. This weight reduction directly translates to higher engine speeds, improved responsiveness, and better fuel efficiency. Furthermore, innovative surface treatments and coatings, including Diamond-Like Carbon (DLC) and various ceramic composites, are applied to lifter surfaces to minimize friction, enhance wear resistance, and extend component lifespan. These coatings play a critical role in reducing energy losses within the valvetrain and improving overall engine durability.

Manufacturing precision also stands as a cornerstone of the key technology landscape. The production of camshaft lifters demands extremely tight tolerances and high-quality finishes to ensure optimal performance and quiet operation. Advanced manufacturing techniques, such as Computer Numerical Control (CNC) machining, automated grinding, and superfinishing processes, are indispensable for achieving the required dimensional accuracy and surface integrity. Furthermore, advancements in Noise, Vibration, and Harshness (NVH) reduction technologies are being integrated into lifter design, contributing to a smoother and quieter engine operation. The adoption of additive manufacturing (3D printing) for prototyping and potentially for specialized, low-volume production of complex lifter geometries is also emerging as a significant technological development, promising greater design flexibility and faster iteration cycles.

Regional Highlights

The global Camshaft Lifters Market exhibits distinct regional dynamics, driven by varying automotive production levels, emission regulations, technological adoption rates, and economic conditions across different geographical areas. Understanding these regional nuances is essential for market players to formulate effective strategies and capitalize on growth opportunities. Each major region contributes uniquely to the market's overall trajectory, influenced by local demand and supply factors.

Asia Pacific continues to be the largest and fastest-growing market for camshaft lifters, primarily propelled by the robust automotive manufacturing industries in countries like China, India, Japan, and South Korea. This region benefits from high vehicle production volumes, increasing disposable incomes leading to greater vehicle ownership, and a burgeoning aftermarket demand. The rapid industrialization and expansion of commercial vehicle fleets further underscore its dominance. European markets present a stable demand, characterized by stringent emission standards and a strong emphasis on advanced engine technologies and premium vehicle segments. Innovation in lightweight materials and high-efficiency valvetrain components is a key driver in this region.

North America maintains a significant share in the market, driven by a well-established automotive industry, a preference for larger engines, and a strong aftermarket for performance upgrades and maintenance. The region also sees steady adoption of advanced lifter technologies for both conventional and hybrid powertrains. Latin America and the Middle East and Africa (MEA) are emerging markets, expected to exhibit consistent growth throughout the forecast period. This growth is fueled by increasing foreign investment in manufacturing, improving infrastructure, and a growing demand for both passenger and commercial vehicles, although these regions often adopt technologies later than their more developed counterparts.

- Asia Pacific: Largest market share, driven by high automotive production in China, India, Japan, and South Korea. Rapid urbanization and increasing disposable income boost demand. Strong aftermarket presence.

- Europe: Stable market with a focus on advanced technology, stringent emission regulations, and premium vehicle segments. High adoption of hydraulic roller lifters.

- North America: Significant market share, characterized by a mature automotive industry, demand for powerful engines, and a thriving aftermarket for performance parts.

- Latin America: Emerging market with steady growth, influenced by increasing vehicle ownership, industrial development, and local manufacturing expansion.

- Middle East and Africa (MEA): Consistent growth prospects due to developing economies, infrastructure projects, and increasing vehicle sales, though adoption of latest technologies might be slower.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Camshaft Lifters Market.- Eaton Corporation

- Schaeffler AG

- Federal-Mogul LLC (Tenneco)

- Johnson Lifters

- Delphi Technologies (BorgWarner Inc.)

- MAHLE GmbH

- Crower Cams & Equipment Co.

- COMP Cams (Comp Performance Group)

- Melling Engine Parts

- Lunati (Comp Performance Group)

- Morel Lifters

- Elgin Industries

- WABCO Holdings Inc. (ZF Friedrichshafen AG)

- Ford Motor Company (Parts Division)

- General Motors (ACDelco)

- Chrysler (Mopar)

- Honda (Parts Division)

- Toyota (Toyota Parts)

- Mazda (Mazda Genuine Parts)

- Subaru (Subaru Genuine Parts)

Frequently Asked Questions

What is a camshaft lifter and its primary function?

A camshaft lifter, also known as a tappet or valve lifter, is a mechanical component in an internal combustion engine's valvetrain. Its primary function is to transfer the rotational motion of the camshaft lobes into linear motion to actuate the engine's intake and exhaust valves, ensuring proper timing for combustion.

What are the main types of camshaft lifters available in the market?

The main types include hydraulic roller lifters, mechanical (flat tappet) lifters, and hydraulic flat tappet lifters. Hydraulic roller lifters are known for superior performance, reduced friction, and lower maintenance, while mechanical lifters offer precise valve control for high-performance applications.

How do camshaft lifters contribute to engine performance and fuel efficiency?

Camshaft lifters contribute by precisely actuating valves to optimize air-fuel mixture intake and exhaust gas expulsion. Advanced designs, especially in conjunction with variable valve timing, reduce friction, improve combustion efficiency, and minimize power loss, leading to enhanced engine performance and better fuel economy.

What factors are driving the growth of the Camshaft Lifters Market?

Key growth drivers include stringent global emission regulations, increasing global vehicle production, the trend towards engine downsizing and turbocharging, and the persistent demand for higher fuel efficiency in modern vehicles. Innovations in materials and manufacturing also play a significant role.

What impact does the rise of electric vehicles have on the Camshaft Lifters Market?

The rise of electric vehicles (EVs) poses a long-term restraint on the Camshaft Lifters Market as EVs do not utilize internal combustion engines. However, hybrid electric vehicles (HEVs) still incorporate internal combustion engines, providing a transitional demand, while the market also focuses on aftermarket and industrial applications for continued relevance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager