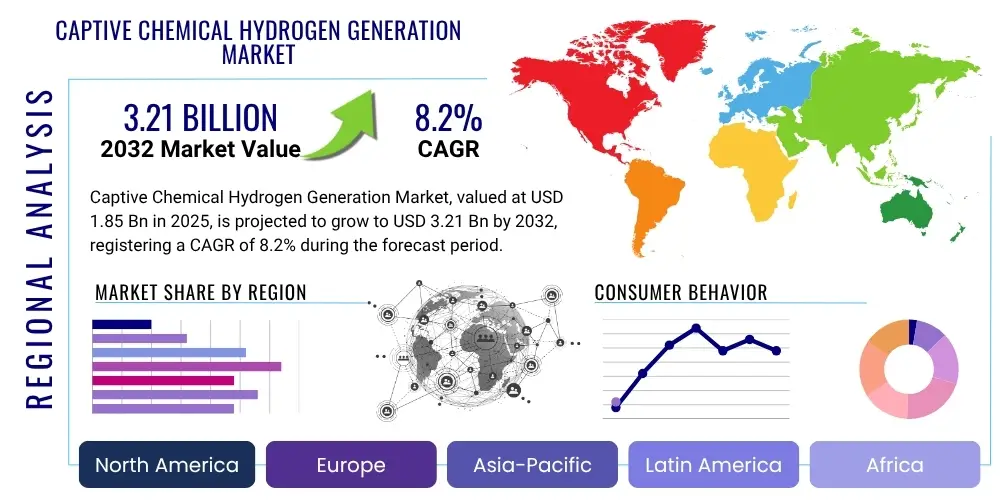

Captive Chemical Hydrogen Generation Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429557 | Date : Nov, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Captive Chemical Hydrogen Generation Market Size

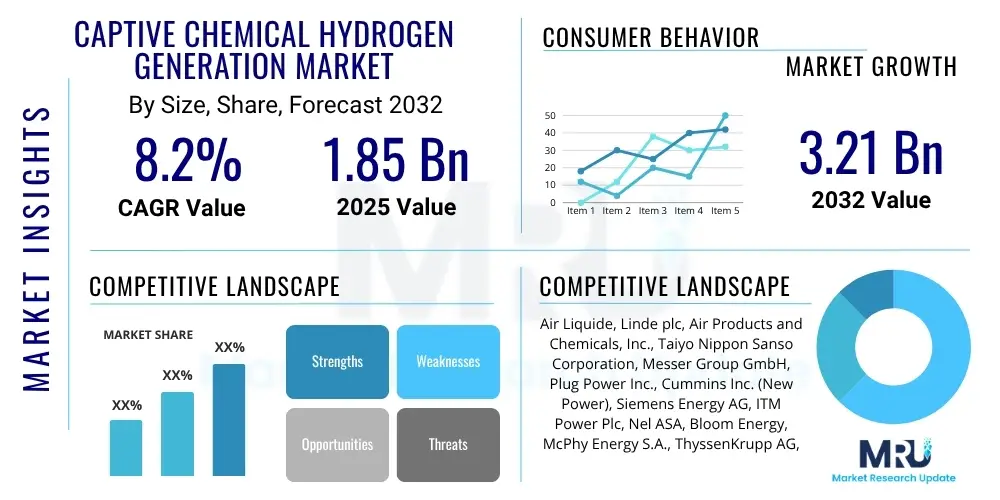

The Captive Chemical Hydrogen Generation Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.2% between 2025 and 2032. The market is estimated at USD 1.85 Billion in 2025 and is projected to reach USD 3.21 Billion by the end of the forecast period in 2032.

Captive Chemical Hydrogen Generation Market introduction

The Captive Chemical Hydrogen Generation Market encompasses the on-site production of hydrogen gas through various chemical processes, directly by end-user industries for their internal consumption. This approach contrasts with sourcing hydrogen from centralized industrial gas suppliers, offering enhanced supply security, reduced transportation costs, and greater control over hydrogen purity and production volumes. The market is primarily driven by industries requiring a consistent and reliable supply of hydrogen for critical processes, where even minor disruptions can lead to significant operational and financial impacts. The emphasis on localized production aligns with broader trends towards supply chain resilience and decentralized energy systems.

Products within this market range from conventional methods like Steam Methane Reforming (SMR) and Auto Thermal Reforming (ATR) to more advanced and environmentally friendly techniques such as water electrolysis, often powered by renewable energy sources to produce green hydrogen. Chemical hydrides, though less prevalent for large-scale captive generation, also represent a niche segment, particularly for portable or specialized applications. The core benefit of captive generation lies in its ability to integrate hydrogen production seamlessly into the existing industrial infrastructure, optimizing operational efficiency and minimizing logistical complexities associated with hydrogen procurement and storage.

Major applications for captive chemical hydrogen generation span across several heavy industries, including petroleum refining, ammonia production for fertilizers, methanol synthesis, and various chemical manufacturing processes. Furthermore, demand is growing from emerging sectors such as fuel cell electric vehicles (FCEVs), electronics manufacturing for semiconductor fabrication, and metallurgy for annealing processes. Key driving factors for this market include the increasing global demand for hydrogen as a feedstock and energy carrier, stringent environmental regulations pushing for cleaner production methods, the pursuit of energy independence, and technological advancements that are improving the efficiency and reducing the cost of on-site hydrogen generation units.

Captive Chemical Hydrogen Generation Market Executive Summary

The Captive Chemical Hydrogen Generation Market is experiencing significant growth, propelled by the global imperative for decarbonization and the increasing adoption of hydrogen as a clean energy vector and industrial feedstock. Business trends indicate a strong move towards modular, scalable on-site generation units, which provide industries with greater operational flexibility and reduced reliance on external supply chains. There is a notable shift in investment towards green hydrogen production methods, particularly electrolysis powered by renewable energy, as companies seek to minimize their carbon footprint and achieve sustainability targets. Automation and digitalization are also becoming central to optimizing these captive plants, enhancing efficiency, and ensuring safety standards.

Regionally, Asia Pacific continues to dominate the market due to its robust industrial growth, especially in chemical, refining, and electronics sectors, alongside significant government initiatives supporting hydrogen infrastructure development in countries like China, India, and Japan. Europe and North America are also witnessing substantial expansion, driven by ambitious decarbonization policies, generous government incentives for green hydrogen projects, and increasing R&D investments aimed at improving hydrogen generation technologies. Latin America and the Middle East and Africa regions are emerging as key players, leveraging abundant renewable energy resources for large-scale green hydrogen production, primarily for export but also for growing domestic industrial demand.

In terms of segments, Steam Methane Reforming (SMR) currently holds the largest market share due to its established infrastructure and cost-effectiveness, particularly for large-scale industrial applications. However, the electrolysis segment is projected to exhibit the highest growth rate, fueled by advancements in electrolyzer technology, falling renewable energy costs, and a strong regulatory push towards sustainable hydrogen. Applications in refining and ammonia production remain primary drivers, while demand from fuel cell technologies, metallurgy, and the burgeoning power-to-X sector is creating new opportunities for on-site hydrogen production. The market is also seeing innovation in smaller-scale, distributed generation solutions catering to diverse industrial needs.

AI Impact Analysis on Captive Chemical Hydrogen Generation Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the efficiency, cost-effectiveness, and safety of captive chemical hydrogen generation. Common questions revolve around AI's role in optimizing complex production processes, predicting equipment failures, managing energy consumption, and enhancing overall plant performance. There is a strong interest in understanding how AI can enable more autonomous operations, integrate seamlessly with renewable energy sources for green hydrogen production, and facilitate real-time decision-making to adapt to fluctuating demand and supply conditions. Users anticipate AI to be a transformative force, driving down operational expenditures and improving the reliability of on-site hydrogen generation facilities, while also addressing environmental concerns through smarter resource management.

- AI-driven process optimization: Enhances efficiency of reformers and electrolyzers by real-time monitoring and adaptive control, minimizing energy and feedstock consumption.

- Predictive maintenance: Utilizes machine learning algorithms to analyze operational data, anticipate equipment failures, and schedule proactive maintenance, reducing downtime and operational costs.

- Energy management: Optimizes integration with renewable energy sources for electrolysis, predicting power availability and coordinating hydrogen production to align with grid demands and electricity prices.

- Safety and risk management: Implements AI-powered sensor networks for early detection of leaks or abnormal conditions, significantly improving safety protocols and emergency response.

- Autonomous operation and control: Facilitates the development of self-regulating hydrogen generation plants, requiring minimal human intervention and enhancing operational consistency.

DRO & Impact Forces Of Captive Chemical Hydrogen Generation Market

The Captive Chemical Hydrogen Generation Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by overarching impact forces. A primary driver is the accelerating global energy transition, which prioritizes hydrogen as a critical component in decarbonizing various industrial sectors and transportation. Industries are increasingly seeking energy independence and supply security, which captive generation offers by mitigating the risks associated with external hydrogen supply disruptions. Furthermore, evolving environmental regulations and corporate sustainability mandates are compelling companies to invest in cleaner hydrogen production methods, particularly green hydrogen generated on-site, to reduce their carbon footprint and achieve emission reduction targets.

Despite these strong drivers, the market faces notable restraints. High capital expenditure (CAPEX) associated with setting up new hydrogen generation plants, especially for advanced electrolysis technologies, remains a significant barrier for many potential adopters. Technical challenges related to hydrogen storage and distribution for certain niche captive applications, particularly small-scale or highly dispersed consumption points, also present difficulties. Additionally, competition from established, large-scale industrial gas suppliers, who can leverage economies of scale and extensive distribution networks, continues to exert pressure on the captive market. The complexity of integrating new hydrogen production units into existing industrial processes requires specialized expertise and can be a deterrent.

Opportunities within this market are substantial and multifaceted. The rapid advancements in electrolyzer technology, coupled with the declining costs of renewable energy, are making green hydrogen production increasingly economically viable and attractive for captive use. The emergence of small-scale, modular hydrogen generation solutions allows for greater flexibility and scalability, catering to a broader range of industrial consumers. Furthermore, new applications in sectors such as power-to-X technologies, synthetic fuels, and advanced materials manufacturing are opening up unexplored avenues for captive hydrogen demand. Strategic partnerships and collaborative research efforts aimed at reducing costs and improving efficiency represent key pathways for market expansion, alongside supportive government policies and funding initiatives.

Segmentation Analysis

The Captive Chemical Hydrogen Generation Market is comprehensively segmented to provide a detailed understanding of its diverse landscape and growth dynamics. These segments differentiate the market based on the primary technologies employed for hydrogen production, the specific end-use applications, the industries that serve as end-users, and the capacity of the generation units. This granular segmentation allows for a precise analysis of market trends, identification of high-growth areas, and strategic positioning for stakeholders across the value chain, reflecting the varied needs and operational scales of industrial hydrogen consumers globally.

- By Technology

- Steam Methane Reforming (SMR)

- Auto Thermal Reforming (ATR)

- Partial Oxidation (POX)

- Electrolysis

- Alkaline Electrolysis

- Proton Exchange Membrane (PEM) Electrolysis

- Solid Oxide Electrolysis Cell (SOEC)

- Chemical Hydrides (e.g., Sodium Borohydride)

- By Application

- Petroleum Refining

- Ammonia Production

- Methanol Production

- Food Processing

- Electronics (Semiconductor Fabrication)

- Metallurgy (Annealing, Reducing Agent)

- Fuel Cells (for backup power, mobility)

- Glass Manufacturing

- Chemical Synthesis

- By End-User Industry

- Chemical and Petrochemical

- Oil and Gas

- Manufacturing (Metals, Glass, Electronics)

- Power Generation

- Automotive (Fuel Cell Vehicle Manufacturing, Refueling)

- Food and Beverage

- Pharmaceuticals

- By Capacity

- Small-Scale (Below 100 Nm3/hr)

- Medium-Scale (100 to 1000 Nm3/hr)

- Large-Scale (Above 1000 Nm3/hr)

Value Chain Analysis For Captive Chemical Hydrogen Generation Market

The value chain for the Captive Chemical Hydrogen Generation Market begins with the upstream activities involving the sourcing of primary raw materials and the manufacturing of essential equipment. Raw materials can include natural gas, water, electricity (especially renewable sources for electrolysis), and various catalysts required for reforming processes. Key upstream players are natural gas suppliers, water treatment companies, renewable energy developers, and manufacturers of specialized components such as reformers, electrolyzer stacks, compressors, purifiers, and control systems. Innovation in these upstream segments directly impacts the overall efficiency and cost-effectiveness of captive hydrogen production, with a growing focus on sustainable sourcing and manufacturing practices to align with green hydrogen initiatives.

The core of the value chain involves the actual hydrogen generation at the end-user's facility, followed by immediate consumption. This middle segment comprises engineering, procurement, and construction (EPC) firms responsible for designing and building captive hydrogen plants, as well as technology providers offering proprietary generation processes. Once hydrogen is produced, it is typically purified to meet specific industrial standards, compressed, and sometimes stored on-site before being fed directly into the end-user's process. Downstream activities are relatively integrated within captive generation, as the hydrogen is consumed directly by the same entity that produced it, minimizing the need for extensive external distribution networks.

Distribution channels in the captive market are primarily direct, where the hydrogen generation unit is owned and operated by the end-user for their own consumption. This direct model is a defining characteristic of captive generation, offering distinct advantages such as eliminating third-party logistics costs and ensuring a dedicated supply. However, indirect channels can also exist, particularly where an industrial gas company designs, builds, and operates an on-site hydrogen plant under a long-term supply contract for a client, essentially providing "hydrogen-as-a-service." This hybrid model combines the benefits of on-site production with the operational expertise of a specialized supplier, offering flexibility to end-users who prefer to outsource the complexities of hydrogen plant management. Both direct ownership and these specialized service models contribute to the market's overall dynamism.

Captive Chemical Hydrogen Generation Market Potential Customers

The Captive Chemical Hydrogen Generation Market caters to a diverse range of industrial end-users and buyers who require a reliable and often high-purity supply of hydrogen for their critical operations. These potential customers are primarily heavy industries where hydrogen serves as an indispensable feedstock, a reducing agent, or an energy source. The inherent benefits of on-site generation, such as enhanced supply security, reduced logistical complexities, and greater control over product specifications, make it an attractive proposition for these industries, particularly those with substantial and consistent hydrogen demand, or those located in areas where grid-supplied hydrogen is less accessible or cost-prohibitive.

Key segments of potential customers include petroleum refineries, which consume massive quantities of hydrogen for hydrotreating and hydrocracking processes to remove impurities and upgrade fuels. Chemical manufacturing plants, especially those producing ammonia for fertilizers, methanol, or other petrochemicals, represent another significant customer base due to their high demand for hydrogen as a reactant. The electronics industry, particularly semiconductor manufacturers, requires extremely high-purity hydrogen for various fabrication steps, making captive generation a preferred option to maintain stringent quality control and prevent contamination.

Beyond these major consumers, other important potential customers include manufacturers in the metallurgy sector using hydrogen for annealing and reducing atmospheres, glass manufacturers needing hydrogen for float glass production, and food processing companies utilizing hydrogen for hydrogenation processes. The emerging market for fuel cell applications, including industrial forklifts, backup power systems, and hydrogen refueling stations co-located with fleet depots, also represents a growing customer segment seeking on-site hydrogen generation to ensure reliable fuel supply. Pharmaceutical companies, with their need for high-purity hydrogen in synthesis, further broaden the customer landscape for captive hydrogen solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.85 Billion |

| Market Forecast in 2032 | USD 3.21 Billion |

| Growth Rate | 8.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Air Liquide, Linde plc, Air Products and Chemicals, Inc., Taiyo Nippon Sanso Corporation, Messer Group GmbH, Plug Power Inc., Cummins Inc. (New Power), Siemens Energy AG, ITM Power Plc, Nel ASA, Bloom Energy, McPhy Energy S.A., ThyssenKrupp AG, De Nora, Proton OnSite (Nel Hydrogen US), Snam S.p.A., Uniper SE, Chiyoda Corporation, Johnson Matthey, Honeywell UOP |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Captive Chemical Hydrogen Generation Market Key Technology Landscape

The Captive Chemical Hydrogen Generation Market is characterized by a dynamic and evolving technology landscape, driven by the dual objectives of increasing efficiency and reducing environmental impact, particularly carbon emissions. Traditional methods like Steam Methane Reforming (SMR) continue to be widely used due to their cost-effectiveness and proven scalability, but ongoing advancements in SMR focus on integrating Carbon Capture, Utilization, and Storage (CCUS) technologies to produce blue hydrogen, thereby mitigating their carbon footprint. Innovations in catalyst development for these reforming processes aim to improve conversion rates and lower operating temperatures, further enhancing efficiency and reducing energy requirements.

A significant technological shift is observed in water electrolysis, which is rapidly gaining prominence for green hydrogen production. Proton Exchange Membrane (PEM) electrolyzers are advancing rapidly, offering high current densities, dynamic response, and compact designs, making them suitable for integration with intermittent renewable energy sources like solar and wind power. Alkaline electrolyzers, while more mature, are also seeing improvements in electrode materials and cell design to enhance efficiency and durability. Solid Oxide Electrolysis Cells (SOECs) are another promising area, capable of operating at high temperatures and leveraging waste heat from industrial processes, potentially achieving higher electrical efficiencies, though they require more complex material science and manufacturing techniques.

Beyond the core generation processes, the technology landscape includes crucial supporting systems that enable efficient captive hydrogen production. This encompasses advanced gas purification technologies to meet specific industry standards, efficient hydrogen compression and on-site storage solutions, and sophisticated plant automation and control systems. Digitalization, including the deployment of IoT sensors, big data analytics, and Artificial Intelligence (AI) for predictive maintenance and process optimization, is becoming integral to modern captive hydrogen plants. Modular and standardized plant designs are also emerging, which can significantly reduce installation times and capital costs, making captive hydrogen generation more accessible to a wider range of industrial users.

Regional Highlights

- North America: This region is witnessing substantial growth, propelled by significant policy support such as the Inflation Reduction Act (IRA) in the United States, which offers lucrative tax credits for clean hydrogen production. Demand primarily stems from the refining sector and an expanding ecosystem for fuel cell applications, including heavy-duty transportation and industrial material handling. Investment in both blue and green hydrogen projects for captive use is accelerating, driven by decarbonization targets and energy security imperatives.

- Europe: Europe is a frontrunner in green hydrogen initiatives, guided by the European Green Deal and national hydrogen strategies across member states. The region is heavily investing in large-scale electrolysis projects, often co-located with renewable energy farms, to produce hydrogen for industrial decarbonization, particularly in chemical and steel industries. Regulatory frameworks and substantial funding programs are fostering a robust market for captive chemical hydrogen generation, emphasizing sustainable and carbon-neutral production methods.

- Asia Pacific (APAC): APAC holds the largest share in the captive chemical hydrogen generation market due to its extensive industrial base, especially in China, India, Japan, and South Korea. Rapid expansion in petrochemicals, ammonia production, and electronics manufacturing drives immense hydrogen demand. While SMR remains dominant, significant investments are pouring into electrolysis projects to support energy transitions and reduce reliance on fossil fuels, with an increasing focus on developing localized, cost-efficient hydrogen supply chains.

- Latin America: This region is emerging as a significant hub for future green hydrogen production, leveraging abundant renewable energy resources like hydro, solar, and wind, particularly in countries such as Chile, Brazil, and Colombia. While current captive demand is lower compared to other regions, there is growing interest from mining, agriculture, and chemical sectors in developing on-site hydrogen production capabilities, supported by nascent government initiatives and international collaborations focused on green hydrogen exports and domestic industrial application.

- Middle East and Africa (MEA): MEA is positioned as a potential global leader in low-cost green hydrogen production, primarily due to its vast solar energy potential and strategic geographical location for export. Countries like Saudi Arabia and UAE are investing billions in mega-scale green hydrogen projects, with a strong focus on both export and integrating hydrogen into their domestic petrochemical and industrial complexes. Captive generation for local industrial consumption is expected to grow as these large-scale projects come online and drive down costs, fostering regional energy diversification.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Captive Chemical Hydrogen Generation Market.- Air Liquide

- Linde plc

- Air Products and Chemicals, Inc.

- Taiyo Nippon Sanso Corporation

- Messer Group GmbH

- Plug Power Inc.

- Cummins Inc. (New Power)

- Siemens Energy AG

- ITM Power Plc

- Nel ASA

- Bloom Energy

- McPhy Energy S.A.

- ThyssenKrupp AG

- De Nora

- Proton OnSite (Nel Hydrogen US)

- Snam S.p.A.

- Uniper SE

- Chiyoda Corporation

- Johnson Matthey

- Honeywell UOP

Frequently Asked Questions

What is captive chemical hydrogen generation?

Captive chemical hydrogen generation refers to the on-site production of hydrogen gas directly by an industrial end-user for their immediate internal consumption, utilizing various chemical processes. This method offers advantages such as enhanced supply security, reduced transportation costs, and greater control over hydrogen purity compared to sourcing from external suppliers.

What are the primary benefits of on-site hydrogen production?

The primary benefits of on-site hydrogen production include ensuring a highly reliable and secure supply, eliminating complex and costly hydrogen transportation logistics, allowing for precise control over hydrogen purity and production volumes tailored to specific industrial needs, and potentially reducing overall operational costs through integrated energy management and reduced reliance on third-party suppliers.

How does AI enhance captive hydrogen generation?

AI significantly enhances captive hydrogen generation by optimizing process efficiency through real-time data analysis and adaptive control, implementing predictive maintenance to reduce downtime, improving energy management by integrating with renewable sources, and bolstering safety protocols through intelligent monitoring. AI contributes to more autonomous, efficient, and reliable hydrogen production operations.

What are the main challenges for the Captive Chemical Hydrogen Generation Market?

The main challenges include the high initial capital expenditure required for setting up new generation plants, particularly for advanced electrolysis technologies. Technical complexities associated with hydrogen storage and distribution for specific applications, regulatory hurdles, and intense competition from established centralized industrial gas suppliers also pose significant restraints on market growth.

Which technologies are driving market growth in captive hydrogen generation?

Market growth in captive hydrogen generation is significantly driven by advancements in water electrolysis technologies, specifically Proton Exchange Membrane (PEM) and Solid Oxide Electrolysis Cells (SOEC), enabling efficient green hydrogen production. Furthermore, enhanced Steam Methane Reforming (SMR) with Carbon Capture, Utilization, and Storage (CCUS) and modular, scalable plant designs are also crucial drivers, responding to demands for cleaner, more flexible, and cost-effective on-site solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager