Cellular Concrete Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427364 | Date : Oct, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Cellular Concrete Market Size

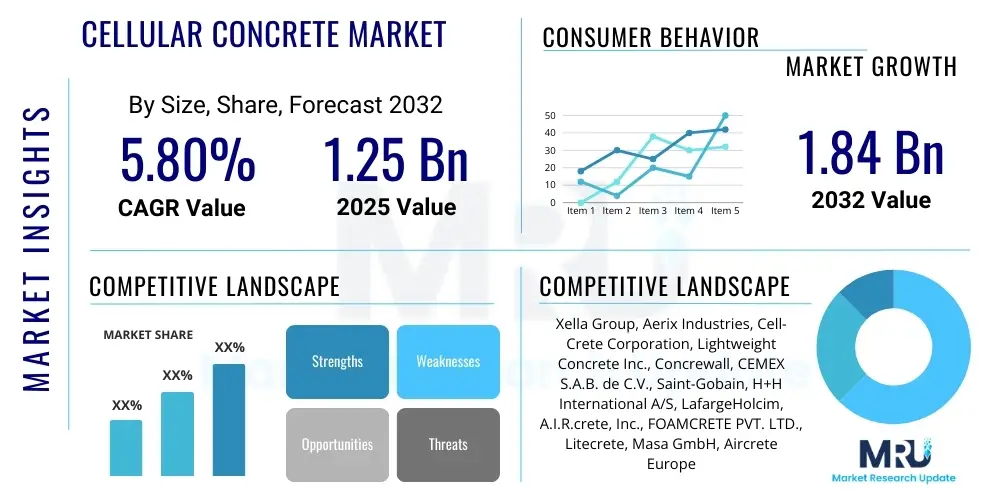

The Cellular Concrete Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 1.25 billion in 2025 and is projected to reach USD 1.84 billion by the end of the forecast period in 2032.

Cellular Concrete Market introduction

The Cellular Concrete Market encompasses the production and application of a versatile, lightweight construction material characterized by a high volume of entrapped air voids within a cementitious mixture, often incorporating fly ash, sand, and other supplementary cementitious materials. This innovative product, also known as Foamed Concrete or Lightweight Aggregate Concrete (LAC), offers a unique combination of properties including excellent thermal and acoustic insulation, fire resistance, and a high strength-to-weight ratio, making it highly desirable across various construction applications. Its primary uses range from non-structural components like wall panels, floor screeds, and roof insulation to void filling, road sub-bases, and geotechnical applications, demonstrating its adaptability in modern infrastructure development and building construction. The inherent benefits of cellular concrete, such as reduced dead loads on structures, energy efficiency in buildings due to superior insulation, and faster construction times owing to its lightweight nature and ease of handling, position it as a preferred material in sustainable building practices. Key driving factors propelling market growth include rapid urbanization, increasing investments in infrastructure development, a growing global emphasis on green building certifications, and stringent energy efficiency regulations mandating better insulation in residential and commercial constructions, alongside the materials increasing adoption in prefabrication and modular construction methodologies. The pursuit of sustainable and cost-effective building solutions continues to elevate the prominence of cellular concrete as a fundamental element in the construction industrys evolution.

Cellular Concrete Market Executive Summary

The Cellular Concrete Market is experiencing robust growth, driven by an escalating global demand for sustainable, lightweight, and energy-efficient building materials, particularly within the burgeoning construction sectors of developing economies. Business trends indicate a strong focus on enhancing production efficiency through advanced mixing technologies, optimizing material compositions for improved performance, and expanding the application scope of cellular concrete beyond traditional uses into specialized geotechnical and infrastructure projects. The increasing adoption of prefabrication and modular construction methods is also significantly contributing to market expansion, as cellular concretes lightweight and insulating properties are ideal for factory-produced components, offering quicker assembly and reduced on-site labor requirements. Regionally, Asia-Pacific remains the dominant force, propelled by unprecedented rates of urbanization and extensive infrastructure development initiatives in countries like China and India, while North America and Europe are witnessing steady growth fueled by renovation projects, the retrofitting of existing structures for energy efficiency, and stringent environmental building codes. Segment-wise, the market is primarily driven by residential and commercial building applications, with significant growth observed in road construction, void filling, and insulation segments, all benefiting from the materials diverse functional advantages and cost-effectiveness over conventional alternatives. This market trajectory suggests a promising future for cellular concrete as a cornerstone of modern, sustainable construction practices worldwide.

AI Impact Analysis on Cellular Concrete Market

The integration of Artificial Intelligence (AI) within the cellular concrete market is poised to revolutionize various aspects of its lifecycle, from raw material sourcing and production to quality control and application, addressing common user questions about efficiency, precision, and sustainability. Stakeholders are keen to understand how AI can optimize mix designs, predicting the optimal ratios of cement, aggregates, water, and foaming agents to achieve desired densities, strengths, and thermal properties with unprecedented accuracy, thereby minimizing material waste and enhancing performance consistency. Furthermore, there is significant interest in AIs potential to streamline complex manufacturing processes, automate monitoring of production lines, and perform real-time adjustments, which can significantly reduce energy consumption and operational costs, a critical concern for manufacturers aiming for competitive advantage and environmental stewardship. Users frequently inquire about AIs role in improving the predictability of material behavior and its impact on the structural integrity and long-term durability of cellular concrete applications.

AIs analytical capabilities extend to predictive maintenance for manufacturing equipment, ensuring uninterrupted production cycles and reducing costly downtimes, while also offering sophisticated quality assurance mechanisms through automated visual inspection systems that can identify imperfections or inconsistencies far more rapidly and reliably than human oversight. Beyond production, AI can also optimize supply chain logistics, forecasting demand more accurately and managing inventory levels to ensure timely delivery of cellular concrete products to construction sites, thereby reducing lead times and improving project timelines. The application of machine learning algorithms to vast datasets of project specifications, environmental conditions, and material performance can lead to the development of highly customized cellular concrete formulations tailored to specific regional climates and structural requirements, further enhancing the materials adaptability and market appeal. Such advancements are crucial for addressing the growing complexity of construction projects and the increasing demand for high-performance, tailored building solutions.

Moreover, AI can play a pivotal role in the research and development of next-generation cellular concrete, exploring novel material composites and production techniques that push the boundaries of current capabilities. By simulating various material interactions and environmental stressors, AI can accelerate the discovery of more sustainable and superior cellular concrete formulations, including those utilizing a higher percentage of recycled content or alternative binders, thereby contributing significantly to the circular economy within the construction sector. This intelligent assistance will not only foster innovation but also empower manufacturers and builders to make more informed decisions, leading to a more efficient, sustainable, and resilient cellular concrete industry that can effectively meet future challenges and capitalize on emerging opportunities.

- AI optimizes mix designs for precise material properties and waste reduction.

- Predictive analytics enhance production efficiency, reducing energy consumption and operational costs.

- Automated quality control systems improve consistency and reliability of cellular concrete products.

- AI-driven logistics enhance supply chain management, improving delivery times and inventory control.

- Machine learning facilitates development of customized, high-performance formulations for diverse applications.

- Accelerated R&D through AI simulations leads to more sustainable and advanced cellular concrete materials.

DRO & Impact Forces Of Cellular Concrete Market

The Cellular Concrete Market is propelled by several significant drivers, including rapid urbanization and industrialization, particularly in emerging economies, leading to a surge in demand for efficient and sustainable construction materials for housing, commercial complexes, and infrastructure projects. The increasing global focus on energy efficiency in buildings, driven by stringent regulatory mandates and a heightened awareness of climate change, further boosts the adoption of cellular concrete due to its superior thermal insulation properties. Moreover, the materials lightweight nature reduces transportation costs, simplifies handling on construction sites, and lessens the structural load on foundations, offering significant economic and logistical advantages that contribute to its market expansion. However, the market faces notable restraints, such as the high initial capital investment required for specialized production equipment, which can deter new entrants and limit growth in regions with less developed industrial infrastructures. A lack of widespread awareness regarding cellular concretes benefits and proper application techniques in some construction communities, alongside the perception of lower strength compared to traditional concrete (despite its high strength-to-weight ratio), also poses challenges to its broader acceptance. Competition from well-established, conventional building materials and other lightweight alternatives further necessitates continuous innovation and market education to overcome these barriers.

Opportunities for growth are abundant, particularly in the realm of sustainable construction practices, where cellular concrete can play a crucial role in achieving green building certifications and reducing the carbon footprint of structures. Expanding applications in prefabrication, modular construction, and repair and rehabilitation of existing infrastructure represent lucrative avenues for market penetration, leveraging the materials versatility and ease of use. Furthermore, continuous research and development into advanced foaming agents, alternative binders, and novel production methods are expected to enhance performance characteristics and reduce production costs, opening up new market segments and applications. The impact forces shaping this market include evolving regulatory frameworks that increasingly favor eco-friendly and energy-efficient building solutions, which act as a powerful catalyst for adoption. Technological advancements in manufacturing processes and material science are continuously improving the quality and expanding the functional range of cellular concrete, making it suitable for more demanding applications. Economic cycles influence construction activity, directly affecting demand for building materials, while environmental concerns and sustainability initiatives continue to exert pressure on the industry to adopt greener alternatives, positioning cellular concrete favorably within the global construction landscape. These dynamics underscore a complex interplay of factors driving both challenges and opportunities within the cellular concrete sector.

Segmentation Analysis

The Cellular Concrete Market is extensively segmented to cater to diverse industry needs, providing a granular view of market dynamics and opportunities across various categories. These segmentations typically include analyses by type, application, end-use industry, and geographic region, allowing for a comprehensive understanding of specific market niches and their growth trajectories. By analyzing these segments, stakeholders can identify key demand drivers, competitive landscapes, and emerging trends within each particular category, enabling more targeted strategic planning and resource allocation. Understanding the market through these detailed segmentations is crucial for manufacturers, suppliers, and construction companies seeking to optimize their product portfolios, tailor marketing strategies, and enhance their market penetration in specific areas. This systematic approach ensures that the unique requirements and preferences of different consumer groups and industrial applications are effectively addressed, driving overall market efficiency and innovation.

- By Type: Autoclaved Aerated Concrete (AAC), Non-Autoclaved Foamed Concrete (NAFC)

- By Application: Building Blocks, Wall Panels, Floor Screeds, Roof Insulation, Void Filling, Road Sub-bases, Geotechnical Applications

- By End-Use Industry: Residential Construction, Commercial Construction, Infrastructure Projects, Industrial Construction

- By Density: Low-Density Cellular Concrete, Medium-Density Cellular Concrete, High-Density Cellular Concrete

- By Raw Material: Cement, Fly Ash, Sand, Foaming Agents, Water, Other Additives

Cellular Concrete Market Value Chain Analysis

The value chain for the Cellular Concrete Market commences with the upstream analysis, involving the sourcing of fundamental raw materials that constitute cellular concrete. This typically includes cement, a primary binding agent, along with supplementary cementitious materials such as fly ash, silica fume, or ground granulated blast-furnace slag, which enhance material properties and promote sustainability. Other critical inputs comprise fine aggregates like sand, water, and crucially, foaming agents that create the characteristic air voids in the mixture, along with various admixtures to control setting times and enhance workability. Key suppliers in this stage are cement manufacturers, industrial waste processors (for fly ash), chemical companies producing foaming agents, and aggregate quarries. The quality and consistent supply of these raw materials are paramount for maintaining the performance characteristics of the final cellular concrete product, highlighting the importance of robust supplier relationships and quality control at this initial stage. Efficiency in sourcing, including proximity to production facilities, significantly impacts overall production costs and market competitiveness, pushing manufacturers towards localized sourcing where feasible to reduce logistics expenses.

Moving downstream, the value chain encompasses the manufacturing processes, distribution channels, and eventual application of cellular concrete. Manufacturers transform raw materials into finished cellular concrete products, which can be produced as pre-cast blocks, panels, or ready-mix solutions for on-site pouring. The choice of production method, whether autoclaved (for AAC) or non-autoclaved (for foamed concrete), dictates specific equipment and energy requirements. Following production, these products are then moved through various distribution channels to reach end-users. Direct distribution often involves large manufacturers selling directly to major construction companies for large-scale projects, allowing for tailored solutions and direct technical support. Indirect distribution utilizes a network of third-party distributors, building material suppliers, and retailers, serving a broader customer base including smaller contractors, individual builders, and renovation projects. This multi-channel approach ensures widespread market penetration and accessibility. Effective logistics and efficient inventory management are critical in the downstream segment to ensure timely delivery and minimize material wastage, ultimately impacting customer satisfaction and project timelines. The final stage involves the application by construction firms, contractors, and specialized installers, where proper handling and installation techniques are vital to fully realize the benefits of cellular concrete in various building and infrastructure projects.

Cellular Concrete Market Potential Customers

Potential customers for cellular concrete are diverse, primarily spanning the entire construction industry due to the materials versatile properties and broad applicability across different project types. The largest segment of end-users includes residential builders and developers who increasingly prioritize lightweight, energy-efficient, and cost-effective solutions for single-family homes, multi-story apartments, and housing complexes. For these customers, cellular concrete offers excellent thermal insulation, reducing heating and cooling costs for occupants, and its ease of handling and faster construction times contribute to project profitability and quicker market entry. The demand for sustainable building materials in residential construction, driven by consumer preference and green building certifications, further strengthens cellular concretes appeal in this segment, as it often incorporates recycled materials like fly ash and reduces overall structural weight, lessening environmental impact.

Beyond residential, commercial developers and institutional contractors constitute another significant customer base, employing cellular concrete for office buildings, retail spaces, hotels, schools, and hospitals. In these applications, cellular concrete is valued for its superior fire resistance, acoustic dampening properties, and ability to contribute to healthier indoor environments, meeting stringent safety and comfort standards. Furthermore, infrastructure development companies and government agencies represent a growing segment, utilizing cellular concrete for road sub-bases, bridge void filling, tunnel backfilling, and other civil engineering projects where its lightweight, load-bearing, and insulating capabilities provide substantial advantages over traditional infill materials, particularly in areas with poor soil conditions. The prefabrication and modular construction sectors are also rapidly emerging as key customers, appreciating cellular concretes suitability for off-site manufacturing of building components, enabling faster assembly, consistent quality, and reduced on-site labor requirements. This broad spectrum of potential customers underscores the materials integral role in the evolving landscape of modern construction, from individual homeowners to large-scale urban planners and engineers.

Cellular Concrete Market Key Technology Landscape

The technology landscape for the Cellular Concrete Market is characterized by continuous innovation aimed at improving material properties, optimizing production processes, and expanding application versatility. A foundational technology revolves around the precise formulation of the concrete mix, including the selection and proportioning of cementitious materials, fine aggregates, water, and specialized chemical admixtures. Advanced foaming agents are crucial; these agents, typically protein-based or synthetic, are responsible for generating stable air voids within the cement slurry, directly influencing the density, strength, and thermal conductivity of the final product. Technological advancements in foaming agent chemistry focus on enhancing foam stability, improving cell structure uniformity, and reducing setting times, leading to more consistent and higher-quality cellular concrete. Furthermore, the use of supplementary cementitious materials such as fly ash, ground granulated blast furnace slag, and silica fume is a key technological trend, not only for their sustainability benefits but also for their role in improving long-term strength, durability, and workability of cellular concrete, thereby allowing for the production of materials with a wider range of tailored properties.

Production technologies are equally pivotal, encompassing specialized mixing equipment and curing methods. Modern cellular concrete production facilities utilize high-shear mixers that ensure thorough blending of ingredients and effective incorporation of foam, leading to a homogenous mix. For Autoclaved Aerated Concrete (AAC), the autoclaving process, which involves high-pressure steam curing, is a critical technology that accelerates the hydration process and imparts superior strength and dimensional stability to the material. In contrast, for Non-Autoclaved Foamed Concrete (NAFC), ambient or low-temperature curing techniques are employed, relying on precise control of chemical reactions and environmental conditions. Automation and process control systems are increasingly being integrated into manufacturing lines to monitor and adjust parameters in real-time, ensuring consistent product quality, reducing labor costs, and improving energy efficiency. Moreover, advancements in digital design tools and Building Information Modeling (BIM) are enabling architects and engineers to more effectively integrate cellular concrete components into structural designs, optimizing material usage and streamlining construction workflows, further underscoring the technologically driven evolution of the cellular concrete market.

Regional Highlights

- Asia-Pacific: This region stands as the largest and fastest-growing market for cellular concrete, primarily driven by rapid urbanization, significant government investments in infrastructure development, and a booming residential and commercial construction sector, particularly in countries like China, India, and Southeast Asian nations. The demand for lightweight and energy-efficient building materials is soaring due to high population density and the need for cost-effective, sustainable construction solutions. Strict environmental regulations and green building initiatives also contribute to the increased adoption of cellular concrete as a preferred construction material, making it a pivotal growth hub for the global market.

- North America: The North American market exhibits steady growth, fueled by increasing renovation and retrofitting activities, a growing emphasis on green building practices, and the adoption of stricter energy efficiency codes for residential and commercial buildings. Countries such as the United States and Canada are seeing a rising demand for cellular concrete in insulation applications, lightweight infill, and the construction of high-performance buildings. Technological advancements in production and application techniques, coupled with increasing awareness of the materials benefits among architects and contractors, further support market expansion.

- Europe: Europe represents a mature but consistently growing market, strongly influenced by stringent environmental regulations, ambitious energy efficiency targets, and a high demand for sustainable construction materials. Countries like Germany, the UK, and Scandinavian nations are at the forefront of adopting cellular concrete for its excellent thermal insulation properties, fire resistance, and contribution to reduced carbon footprints in construction projects. The regions focus on innovative building solutions and the extensive use of prefabrication also create substantial opportunities for cellular concrete manufacturers.

- Latin America: The market in Latin America is in an emerging phase, characterized by growing construction activities, particularly in Brazil, Mexico, and Argentina. Increased urbanization and investments in affordable housing projects are driving the demand for cost-effective and efficient building materials. While the market is still developing, rising awareness about the benefits of cellular concrete and increasing foreign investments in the construction sector are expected to accelerate its growth trajectory in the coming years.

- Middle East & Africa (MEA): The MEA region is experiencing significant growth due to large-scale infrastructure projects, rapid urban development, and a strong focus on sustainable and energy-efficient building solutions in countries like UAE, Saudi Arabia, and Qatar. The extreme climatic conditions in many parts of the region make cellular concretes thermal insulation properties particularly attractive for reducing energy consumption in buildings. Government initiatives to diversify economies and invest in non-oil sectors are further bolstering the construction industry and, consequently, the cellular concrete market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cellular Concrete Market.- Xella Group

- Aerix Industries

- Cell-Crete Corporation

- Lightweight Concrete Inc.

- Concrewall

- CEMEX S.A.B. de C.V.

- Saint-Gobain

- H+H International A/S

- LafargeHolcim

- A.I.R.crete, Inc.

- FOAMCRETE (India) PVT. LTD.

- Litecrete

- Masa GmbH

- Aircrete Europe

- Cellular Lightweight Concrete (India) Pvt. Ltd.

Frequently Asked Questions

What is cellular concrete and how is it made?

Cellular concrete, also known as foamed concrete or lightweight aggregate concrete, is a lightweight, cement-based material characterized by a high volume of entrapped air voids. It is produced by mixing cement, water, and sand (optional) with a pre-formed foam or by introducing a foaming agent into the cementitious slurry, which then sets and hardens to create a material with a cellular structure. The density and strength vary depending on the amount of air incorporated.

What are the primary benefits of using cellular concrete in construction?

The primary benefits of cellular concrete include its lightweight nature, which reduces dead loads and transportation costs; excellent thermal and acoustic insulation properties, leading to energy efficiency and noise reduction; superior fire resistance; and ease of handling and installation, contributing to faster construction times. It is also often made with recycled materials like fly ash, enhancing its sustainability profile.

Where is cellular concrete most commonly applied?

Cellular concrete finds common application in residential and commercial construction for wall panels, building blocks, floor screeds, and roof insulation. It is also extensively used for void filling, trench reinstatement, road sub-bases, and various geotechnical applications due to its lightweight and self-leveling properties, making it versatile for both structural and non-structural uses.

Is cellular concrete a sustainable building material?

Yes, cellular concrete is considered a sustainable building material due to several factors. It often incorporates industrial by-products like fly ash, reducing waste and the demand for virgin materials. Its superior insulation properties contribute to significant energy savings in buildings, lowering their operational carbon footprint. Furthermore, its lightweight nature reduces the environmental impact associated with transportation and allows for more efficient structural designs.

What distinguishes Autoclaved Aerated Concrete (AAC) from Non-Autoclaved Foamed Concrete (NAFC)?

The primary distinction lies in the curing process. AAC undergoes high-pressure steam curing in an autoclave, which significantly enhances its strength, dimensional stability, and creates a distinct, highly porous microstructure. NAFC, conversely, cures at ambient or low temperatures, relying on natural hydration, and typically has lower strength but offers greater flexibility in on-site production and tailored density variations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager