Centrifugal Blower Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427596 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Centrifugal Blower Market Size

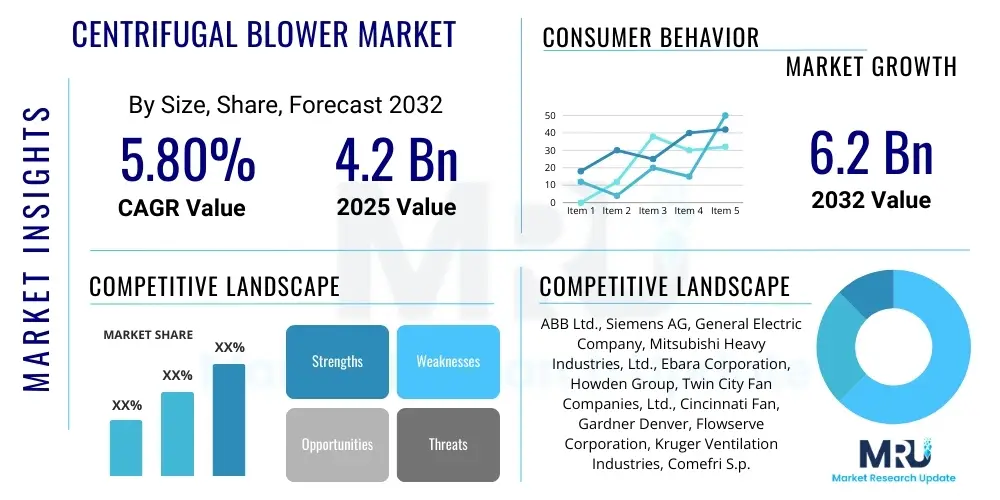

The Centrifugal Blower Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.2 Billion in 2025 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2032.

Centrifugal Blower Market introduction

The Centrifugal Blower Market encompasses a diverse range of industrial equipment designed to move air or gas by increasing its velocity and pressure using centrifugal force. These devices are critical components in numerous industrial processes, facilitating air circulation, ventilation, drying, cooling, and material conveying. Centrifugal blowers are characterized by their impeller design, which draws air into the center and propels it outwards, converting kinetic energy into static pressure. Their robust construction and ability to handle various air volumes and pressures make them indispensable across a wide array of applications, contributing significantly to operational efficiency and environmental control within industrial settings. The markets expansion is fundamentally driven by the escalating demand for energy-efficient ventilation and air movement solutions, coupled with stringent environmental regulations necessitating improved air quality control.

Major applications for centrifugal blowers span industries such as manufacturing, chemical processing, wastewater treatment, power generation, mining, and food and beverage production. In manufacturing, they are used for process ventilation, fume extraction, and dust collection systems, ensuring a safe and clean working environment. Chemical plants utilize them for gas boosting, material drying, and conveying processes, often handling corrosive or high-temperature gases. Wastewater treatment facilities employ blowers for aeration in biological treatment processes, which is crucial for nutrient removal and effluent quality. Furthermore, the burgeoning demand for industrial automation and smart manufacturing practices is significantly contributing to the markets growth, as modern facilities seek integrated solutions for optimizing air management systems.

The primary benefits of centrifugal blowers include their high efficiency, reliability, and versatility across a broad spectrum of operating conditions. They offer precise control over airflow and pressure, which is vital for maintaining optimal process parameters. The driving factors behind market growth are multifaceted, including rapid industrialization and urbanization, particularly in emerging economies, leading to increased infrastructure development and manufacturing activities. Growing awareness of industrial air quality and worker safety standards is also pushing demand for advanced ventilation systems. Technological advancements, such as the integration of variable frequency drives (VFDs) and smart controls, further enhance energy efficiency and operational flexibility, making modern centrifugal blowers more appealing to industries aiming to reduce energy consumption and improve overall productivity. The emphasis on sustainable industrial practices and the need for robust air handling in demanding environments will continue to fuel innovation and market expansion.

Centrifugal Blower Market Executive Summary

The Centrifugal Blower Market is currently experiencing dynamic shifts driven by global economic developments, technological advancements, and evolving regulatory landscapes. Business trends indicate a strong emphasis on energy efficiency and sustainability, compelling manufacturers to innovate with more advanced motor technologies, aerodynamic impeller designs, and integrated control systems. There is a growing demand for customized blower solutions tailored to specific industrial processes, moving away from generic off-the-shelf products. Companies are also focusing on expanding their service offerings, including predictive maintenance and remote monitoring, to provide greater value to end-users and ensure operational continuity. Mergers and acquisitions remain a strategic tool for market consolidation and technology acquisition, allowing leading players to enhance their product portfolios and geographical reach, while smaller, specialized firms often focus on niche applications and innovative solutions to compete effectively.

Regional trends highlight significant growth in the Asia Pacific region, primarily fueled by rapid industrialization, burgeoning manufacturing sectors, and substantial infrastructure investments in countries like China, India, and Southeast Asian nations. This region is witnessing a surge in demand from sectors such as automotive, electronics, and construction. North America and Europe, while mature markets, are characterized by a strong focus on upgrading existing facilities with energy-efficient and intelligent blower systems, driven by strict environmental regulations and high operational cost consciousness. Investments in advanced manufacturing and process automation are key drivers in these regions. The Middle East and Africa are also showing promising growth, particularly in oil and gas, petrochemicals, and construction, where large-scale projects necessitate robust air handling solutions, although political and economic instabilities can pose periodic challenges.

Segmentation trends reveal increasing demand for high-pressure and high-volume blowers, especially in heavy industries and power generation. The market is witnessing a shift towards direct-drive systems over belt-driven ones due to their superior efficiency and lower maintenance requirements. From an end-user perspective, the wastewater treatment sector continues to be a significant consumer, driven by global efforts to improve water quality and sanitation infrastructure. The chemical and petrochemical industries also represent a substantial segment, requiring specialized blowers capable of handling corrosive and explosive atmospheres. Additionally, the proliferation of data centers and cleanroom facilities is fostering a specialized demand for blowers designed for precise temperature control and air purification, further diversifying market opportunities. These segment-specific demands encourage specialized product development and market penetration strategies.

AI Impact Analysis on Centrifugal Blower Market

The integration of Artificial Intelligence (AI) is poised to significantly transform the Centrifugal Blower Market by enhancing operational efficiency, predictive maintenance capabilities, and overall system intelligence. Users are keenly interested in how AI can optimize blower performance, reduce energy consumption, and minimize downtime. Key themes revolve around the potential for AI to move beyond traditional control systems, enabling real-time adaptive adjustments based on environmental conditions and process requirements. Concerns often include the initial investment cost, data security, and the need for skilled personnel to manage complex AI-driven systems. However, the overarching expectation is that AI will unlock new levels of efficiency and reliability, making blowers smarter and more autonomous, thereby providing substantial long-term operational savings and improved process control for industrial applications.

- AI-driven predictive maintenance forecasts potential equipment failures, significantly reducing unplanned downtime and maintenance costs.

- Optimized operational control uses machine learning algorithms to adjust blower speed and pressure in real-time, matching process demands precisely and minimizing energy consumption.

- Enhanced energy management through AI analytics identifies patterns and inefficiencies, leading to substantial reductions in electricity usage for industrial facilities.

- Automated fault detection and diagnostics swiftly pinpoint issues, allowing for quicker troubleshooting and resolution, thereby improving system reliability.

- Intelligent design and simulation tools leverage AI to optimize impeller geometry and housing designs, leading to more aerodynamically efficient and quieter blowers.

- Integration with broader Industrial Internet of Things (IIoT) ecosystems creates interconnected smart factories, enabling centralized monitoring and control of air management systems.

- Adaptive performance tuning allows blowers to dynamically adapt to varying air density, temperature, and humidity, maintaining consistent performance under fluctuating conditions.

DRO & Impact Forces Of Centrifugal Blower Market

The Centrifugal Blower Market is shaped by a confluence of driving factors, restraints, and opportunities, all influenced by various impact forces. A primary driver is the accelerating pace of industrialization across developing nations, particularly in Asia Pacific, leading to increased demand for infrastructure and manufacturing capabilities that inherently require robust air handling solutions. Concurrently, stringent environmental regulations globally, aimed at reducing air pollution and ensuring worker safety, mandate the installation and upgrade of efficient ventilation and exhaust systems in factories, mines, and processing plants. Furthermore, the growing focus on energy efficiency and sustainability pushes industries to adopt advanced blower technologies, such as those integrated with Variable Frequency Drives (VFDs) and smart controls, which offer significant operational cost savings by optimizing energy consumption. The continuous need for process automation and optimization in industries like chemicals, food and beverage, and wastewater treatment further fuels market growth.

Despite these strong drivers, the market faces several restraints. High initial capital investment required for advanced centrifugal blower systems can be a deterrent for small and medium-sized enterprises (SMEs), especially in regions with limited financial resources. The fluctuating prices of raw materials, such as steel and aluminum, directly impact manufacturing costs and, consequently, the final product prices, potentially hindering market expansion. Additionally, the availability of alternative air movement technologies, like axial flow fans or positive displacement blowers for specific applications, provides competitive pressure. The complexity of installing and maintaining sophisticated blower systems, coupled with a shortage of skilled technicians, can also impede broader adoption, particularly in emerging markets where technical expertise might be scarce. Economic downturns and geopolitical uncertainties can further dampen industrial investments, affecting the demand for new equipment.

Opportunities within the centrifugal blower market are abundant and promising. The ongoing digital transformation in manufacturing, characterized by Industry 4.0 initiatives and the adoption of the Industrial Internet of Things (IIoT), presents avenues for developing smart blowers with integrated sensors for real-time monitoring, predictive maintenance, and remote diagnostics. This trend caters to the demand for intelligent, self-optimizing industrial equipment. The expansion of specialized industries such as data centers, cleanrooms, and electric vehicle battery manufacturing facilities creates unique requirements for high-precision air handling, opening new niche markets for advanced blower designs. Moreover, the increasing global emphasis on sustainable wastewater treatment and renewable energy projects (e.g., biogas production) will continue to drive demand for aeration and gas handling blowers. Manufacturers focusing on modular designs, customization, and comprehensive after-sales service can capitalize on these emerging opportunities, fostering long-term growth and market differentiation amidst evolving industrial landscapes.

Segmentation Analysis

The Centrifugal Blower Market is intricately segmented based on various parameters, allowing for a detailed understanding of its diverse applications and technological nuances. These segmentations are critical for market participants to identify specific demand patterns, tailor product offerings, and devise effective market entry and growth strategies. The comprehensive analysis of these segments highlights the varying requirements across industries and applications, from compact, low-pressure units to robust, high-volume blowers designed for heavy industrial use. Understanding these distinctions is fundamental to capturing specialized market niches and addressing the unique operational challenges faced by different end-user sectors, enabling precise product development and targeted marketing efforts within this dynamic industrial equipment landscape.

- By Type: Forward-Curved, Backward-Curved, Radial Blades, Airfoil, Pressure Blower, Volume Blower.

- By Drive Type: Direct Drive, Belt Drive.

- By Capacity/Pressure: Low Pressure, Medium Pressure, High Pressure.

- By End-User Industry: Chemical & Petrochemical, Wastewater Treatment, Power Generation, Mining & Metallurgy, Food & Beverage, Manufacturing, HVAC, Automotive, Others.

- By Application: Ventilation, Drying, Cooling, Fume & Dust Exhaust, Aeration, Material Conveying, Combustion Air, Boosting.

- By Material: Carbon Steel, Stainless Steel, Aluminum, Fiber Reinforced Plastic (FRP).

- By Sales Channel: Original Equipment Manufacturers (OEMs), Aftermarket.

Centrifugal Blower Market Value Chain Analysis

The value chain for the Centrifugal Blower Market encompasses a series of interconnected activities, beginning from raw material procurement to end-user deployment and after-sales service. This intricate network involves various stakeholders, each adding value at different stages. Upstream activities primarily involve the sourcing and processing of essential raw materials such as steel, aluminum, copper, and specialized composites required for the manufacturing of impellers, housings, motors, and other critical components. Suppliers of these materials and components play a crucial role in ensuring quality, cost-effectiveness, and timely delivery, which directly impacts the overall production efficiency and final product quality of centrifugal blowers. Strategic relationships with reliable material suppliers are paramount for manufacturers to maintain competitive pricing and consistent production schedules.

Midstream activities revolve around the design, manufacturing, and assembly of centrifugal blowers. This stage involves engineering teams for product innovation, R&D for performance optimization, and sophisticated manufacturing processes including casting, welding, machining, and precision assembly. Manufacturers invest heavily in advanced production technologies and quality control measures to ensure that blowers meet stringent performance, efficiency, and safety standards. This also includes the integration of advanced features such as Variable Frequency Drives (VFDs), intelligent sensors, and control systems, which add significant value by enhancing the blowers operational flexibility and energy efficiency. The manufacturing phase is where the core value of the product is realized through skilled labor, specialized machinery, and adherence to industry best practices.

Downstream activities focus on bringing the finished products to the end-users and providing ongoing support. This involves diverse distribution channels, including direct sales to large industrial clients, partnerships with distributors and agents, and increasingly, online platforms for standard products. Direct sales allow for closer client relationships and custom solutions for complex industrial projects. Indirect channels, through a network of distributors, enable wider market reach, especially for regional and smaller clients. After-sales services, such as installation support, maintenance, repairs, and spare parts supply, constitute a significant part of the downstream value proposition, ensuring product longevity and customer satisfaction. The efficiency of these distribution and service networks is crucial for market penetration and building long-term customer loyalty, directly impacting the overall market competitiveness and profitability for centrifugal blower manufacturers.

Centrifugal Blower Market Potential Customers

Potential customers for the Centrifugal Blower Market are broadly diversified across a spectrum of industrial and commercial sectors, each with unique operational requirements and performance expectations. These end-users typically require blowers for critical processes involving air or gas movement, ventilation, and pressure generation. Heavy industries such as chemical and petrochemical, power generation, and mining and metallurgy represent substantial segments due to their continuous need for large-scale ventilation, material conveying, gas boosting, and combustion air supply. In these sectors, reliability, durability, and the ability to operate in harsh environments are paramount, often driving demand for custom-engineered, high-capacity, and explosion-proof centrifugal blowers designed for specific hazardous or corrosive applications.

Another significant group of potential customers includes environmental services and public utilities, particularly the wastewater treatment sector. Municipal and industrial wastewater treatment plants are heavy consumers of centrifugal blowers for aeration in biological treatment processes, which is essential for breaking down organic matter and ensuring effluent quality. The growing global focus on water quality and sanitation infrastructure development ensures a consistent and expanding demand from this segment. Similarly, the food and beverage industry requires blowers for various applications such as drying, cooling, conveying, and hygienic ventilation in processing plants, where adherence to strict sanitary standards and food safety regulations dictates specific blower designs and materials.

Furthermore, the manufacturing sector, encompassing diverse industries like automotive, electronics, textiles, and general fabrication, utilizes centrifugal blowers for process ventilation, fume extraction, dust collection, and pneumatic conveying systems, crucial for maintaining air quality and ensuring worker safety. HVAC system integrators also represent a key customer segment, especially for large commercial buildings, data centers, and cleanrooms, where precise temperature, humidity, and particulate control are critical. As industries continue to automate and optimize their processes, the demand for energy-efficient, low-noise, and intelligent blower solutions with advanced control capabilities will expand across all these end-user categories, making them prime targets for manufacturers offering innovative and technologically advanced products.

Centrifugal Blower Market Key Technology Landscape

The technological landscape of the Centrifugal Blower Market is continuously evolving, driven by the persistent demand for enhanced efficiency, reduced operational costs, and improved environmental performance. A cornerstone technology is the widespread adoption of Variable Frequency Drives (VFDs), which allow for precise control over motor speed and, consequently, airflow and pressure. VFDs significantly reduce energy consumption by matching blower output exactly to process requirements, eliminating the inefficiencies associated with throttling or damper controls. This technology is crucial for optimizing performance in applications with fluctuating demand, leading to substantial energy savings and lower operating expenses for end-users, thereby enhancing the overall value proposition of modern centrifugal blowers in various industrial settings.

Material science advancements also play a critical role in the key technology landscape. Manufacturers are increasingly utilizing advanced alloys, composite materials, and specialized coatings to improve the durability, corrosion resistance, and lifespan of blower components. For instance, blowers operating in chemical processing plants or wastewater treatment facilities often require impellers and housings made from stainless steel, fiberglass-reinforced plastics (FRP), or other chemically resistant materials to withstand aggressive environments. The development of lighter, stronger, and more resilient materials contributes to the overall robustness of the equipment, reduces maintenance frequency, and allows for operations in more challenging conditions, thereby expanding the application scope and reliability of centrifugal blower systems across diverse industrial sectors.

Moreover, the integration of smart technologies, including the Industrial Internet of Things (IIoT) and advanced sensor networks, is transforming centrifugal blowers into intelligent, connected devices. These technologies enable real-time monitoring of critical operating parameters such as vibration, temperature, pressure, and airflow, allowing for proactive maintenance and predictive analytics. Embedded sensors provide data that can be analyzed using machine learning algorithms to detect anomalies, predict potential failures, and optimize performance autonomously. This shift towards smart, interconnected blower systems enhances reliability, minimizes unplanned downtime, and provides operators with valuable insights for operational improvements. Noise reduction technologies, such as advanced aerodynamic designs, acoustic enclosures, and anti-vibration mounts, are also gaining prominence, addressing environmental concerns and improving workplace conditions, particularly in urban industrial areas.

Regional Highlights

- Asia Pacific: The largest and fastest-growing market, driven by rapid industrialization, extensive manufacturing sector expansion (e.g., China, India), significant infrastructure development, and increasing foreign investments in industrial projects across Southeast Asia.

- North America: A mature market characterized by stringent environmental regulations, a strong focus on energy efficiency upgrades, and the adoption of advanced automation technologies in industries like automotive, aerospace, and wastewater treatment, leading to demand for high-efficiency and smart blowers.

- Europe: Another mature yet innovation-driven market, distinguished by robust R&D, a strong emphasis on sustainability, and the adoption of Industry 4.0 principles, particularly in Germany, the UK, and France, leading to demand for sophisticated, energy-efficient, and low-emission blower systems.

- Middle East & Africa: Emerging market with substantial growth potential, primarily due to large-scale infrastructure projects, expansion in oil and gas, petrochemicals, and construction sectors, and increasing investments in industrial diversification, though political stability and economic factors can influence growth.

- South America: Experiencing moderate growth, fueled by industrial development in countries like Brazil and Argentina, especially in mining, agriculture, and food processing sectors, with a growing emphasis on modernizing industrial facilities and improving operational efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Centrifugal Blower Market.- ABB Ltd.

- Siemens AG

- General Electric Company

- Mitsubishi Heavy Industries, Ltd.

- Ebara Corporation

- Howden Group

- Twin City Fan Companies, Ltd.

- Cincinnati Fan

- Gardner Denver (now part of Ingersoll Rand)

- Flowserve Corporation

- Kruger Ventilation Industries

- Comefri S.p.A.

- Soler & Palau Ventilation Group

- Nidec Corporation

Frequently Asked Questions

What is a centrifugal blower and how does it work?

A centrifugal blower is a mechanical device that moves air or gas by rotating an impeller to increase the airs velocity and pressure. It draws air into the center of the rotating impeller and pushes it outwards, converting kinetic energy into static pressure. This process is essential for ventilation, cooling, drying, and material conveying in industrial applications.

Which industries are the primary users of centrifugal blowers?

Primary industries utilizing centrifugal blowers include chemical and petrochemical, wastewater treatment, power generation, mining and metallurgy, food and beverage, and general manufacturing. These sectors rely on blowers for critical air and gas handling processes, ensuring operational efficiency and environmental compliance.

What technological advancements are impacting the centrifugal blower market?

Key technological advancements include the integration of Variable Frequency Drives (VFDs) for energy efficiency, the use of advanced materials for durability and corrosion resistance, and the adoption of IIoT and AI for real-time monitoring, predictive maintenance, and optimized operational control, leading to smarter and more reliable systems.

How do energy efficiency and sustainability influence the centrifugal blower market?

Energy efficiency and sustainability are major drivers, prompting demand for blowers with VFDs, optimized aerodynamic designs, and smart controls to reduce power consumption and operational costs. Manufacturers are innovating to meet stricter environmental regulations and support industries in achieving their green initiatives.

What are the key factors driving market growth in the Asia Pacific region?

The Asia Pacific regions market growth is primarily driven by rapid industrialization, significant expansion of manufacturing sectors, large-scale infrastructure development projects, and increasing investments in industries across countries like China, India, and Southeast Asian nations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- High-Speed Single-stage Centrifugal Blower Market Statistics 2025 Analysis By Application (.), By Type (30000 CFM), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Centrifugal Blower Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Single Stage, Multi Stage), By Application (Chemical and Petrochemical, Steel plant, Mining, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

- High-Speed Single-Stage Centrifugal Blower Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Maglev Centrifugal Air Blower, High-Speed Single-stage Centrifugal Blower, Magnetic Levitation Single Stage High Speed Blower), By Application (Sewage Treatment Plant, Petroleum Chemical Plant, Metallurgy, Gas, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager