Ceramic Electric Capacitor Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428746 | Date : Oct, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Ceramic Electric Capacitor Market Size

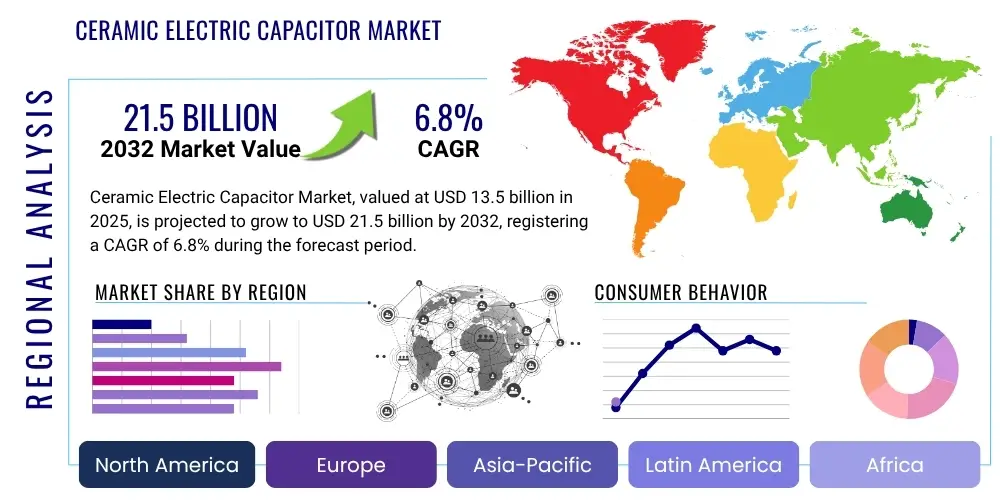

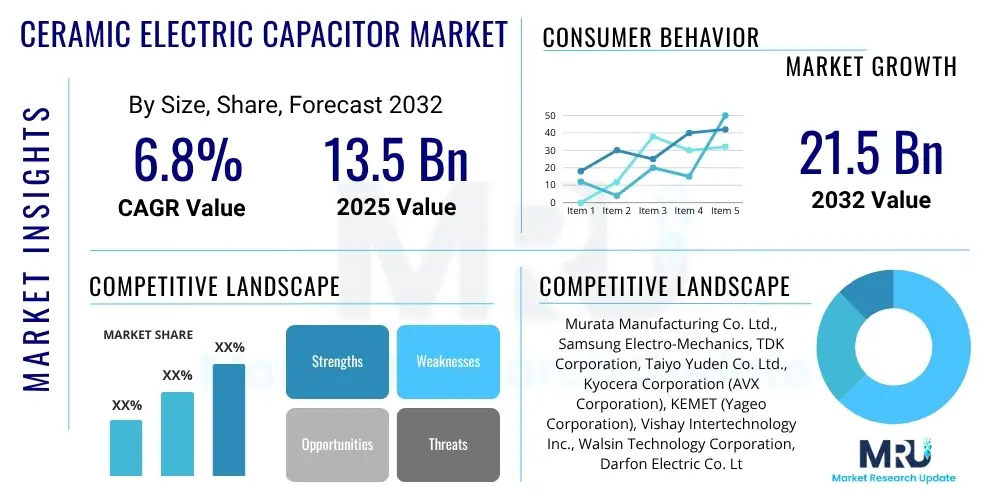

The Ceramic Electric Capacitor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $13.5 billion in 2025 and is projected to reach $21.5 billion by the end of the forecast period in 2032.

Ceramic Electric Capacitor Market introduction

The Ceramic Electric Capacitor Market encompasses a wide array of passive electronic components essential for modern circuitry, primarily utilized for storing electrical energy, filtering signals, and stabilizing voltage. These capacitors leverage ceramic materials as their dielectric, offering advantages such as high capacitance density, excellent frequency characteristics, and superior temperature stability. Products range from multi-layer ceramic capacitors (MLCCs), which dominate the market due to their miniaturization and versatility, to ceramic disc capacitors and feed-through capacitors, each serving specific application needs.

Major applications for ceramic electric capacitors span across diverse industries including consumer electronics, automotive, telecommunications, industrial machinery, and medical devices. Their inherent benefits, such as compact size, high reliability, cost-effectiveness, and ability to operate in demanding environments, make them indispensable. The market's growth is predominantly driven by the pervasive trend of electronic device miniaturization, the escalating demand for electric vehicles (EVs) and hybrid electric vehicles (HEVs), rapid deployment of 5G infrastructure, and the expansion of the Internet of Things (IoT) ecosystem, all of which require advanced, high-performance passive components.

Ceramic Electric Capacitor Market Executive Summary

The Ceramic Electric Capacitor market is experiencing robust growth fueled by several converging business trends. There is a clear emphasis on product miniaturization and the development of high-capacitance, high-voltage, and high-frequency components to meet the stringent demands of advanced electronic systems. Manufacturers are investing heavily in research and development to create new dielectric materials and manufacturing processes that enhance performance, reduce size, and improve cost-efficiency. Additionally, the industry is witnessing strategic consolidations and partnerships aimed at expanding market share and technological capabilities, alongside a growing focus on sustainable manufacturing practices and supply chain resilience amidst geopolitical shifts.

Regionally, Asia Pacific continues to dominate the market, primarily due to the concentration of electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. This region is a major consumer and producer of ceramic capacitors, driven by robust domestic demand and significant export activities in consumer electronics, automotive, and telecommunications sectors. North America and Europe are also experiencing substantial growth, particularly in specialized segments such as automotive electronics, industrial automation, and medical devices, where the demand for high-reliability and high-performance ceramic capacitors is steadily increasing. Emerging economies in Latin America, the Middle East, and Africa present significant growth opportunities as their technological infrastructures develop.

Segmentation trends indicate that Multi-Layer Ceramic Capacitors (MLCCs) remain the largest and fastest-growing segment, largely due to their integral role in almost all electronic devices, from smartphones to advanced automotive systems. Within MLCCs, the demand for ultra-small, high-capacitance, and high-temperature stable components is particularly strong. Application-wise, the automotive electronics segment is witnessing exponential growth driven by the electrification of vehicles and the proliferation of advanced driver-assistance systems (ADAS). Similarly, the telecommunications sector, especially with the global rollout of 5G networks, is a critical growth driver for ceramic capacitors capable of handling high frequencies and power levels.

AI Impact Analysis on Ceramic Electric Capacitor Market

Common user questions regarding AI's impact on the Ceramic Electric Capacitor Market frequently revolve around how artificial intelligence will influence component design, manufacturing efficiency, demand for specific capacitor types in AI hardware, and overall market dynamics. Users are particularly interested in the potential for AI to optimize material selection, streamline production processes, and enhance quality control, while also considering how the proliferation of AI-powered devices will create new demand for specialized, high-performance capacitors that meet the unique power and processing requirements of AI chipsets and systems.

The key themes emerging from this analysis include the expectation that AI will drive innovation in capacitor characteristics, necessitating higher capacitance in smaller footprints, superior thermal management, and enhanced reliability to support complex AI workloads. Concerns often relate to the challenges of scaling manufacturing to meet potentially volatile AI-driven demand and the competitive landscape as manufacturers vie to produce AI-optimized components. Overall, users anticipate that AI will be both a disruptor and an enabler, transforming both the supply-side (manufacturing and design) and demand-side (new applications) of the ceramic electric capacitor market.

- AI-driven demand for high-performance capacitors in AI accelerators, GPUs, and edge AI devices.

- Optimization of capacitor design and material selection using AI algorithms for enhanced performance.

- AI-powered predictive maintenance and quality control in capacitor manufacturing, reducing defects and improving yield.

- Increased need for high-frequency, low-ESR, and miniaturized ceramic capacitors for AI-enabled systems.

- AI contributing to faster product development cycles and customized capacitor solutions for specialized AI applications.

DRO & Impact Forces Of Ceramic Electric Capacitor Market

The Ceramic Electric Capacitor Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and broader impact forces. Key drivers include the relentless push towards miniaturization in electronic devices, requiring smaller yet more powerful components. The burgeoning electric vehicle (EV) market and the ongoing global rollout of 5G telecommunication networks are creating substantial demand for high-voltage, high-frequency, and robust capacitors. Furthermore, the proliferation of IoT devices and advanced industrial automation systems continues to expand the application scope for these essential components. These factors collectively propel market expansion by necessitating higher performance and greater integration density.

However, the market also faces notable restraints. Fluctuations in the prices and availability of raw materials such as ceramic powders, palladium, and silver can impact production costs and lead times, creating supply chain volatility. Intense competition among manufacturers, particularly from Asian players, often leads to price erosion and compressed profit margins. Additionally, the rapid pace of technological innovation, while a driver, can also be a restraint if manufacturers struggle to keep up with evolving standards or face product obsolescence. Geopolitical tensions and trade disputes further complicate global supply chains and market access.

Opportunities for growth are abundant, particularly in the development of advanced dielectric materials that offer superior performance characteristics, such as higher temperature operation and improved capacitance stability. The increasing demand for high-voltage capacitors in power electronics, renewable energy systems, and industrial applications presents a significant avenue for expansion. Moreover, specialized applications in medical devices, aerospace, and defense, which require ultra-high reliability and specific certifications, offer premium market segments. Emerging economies represent untapped markets as their electronic manufacturing capabilities and consumer bases expand, alongside new avenues in energy storage and smart infrastructure. The collective impact forces, including technological advancements, stringent regulatory requirements for electronic waste and material sourcing, economic shifts, and environmental sustainability initiatives, continuously reshape the market landscape, pushing manufacturers towards more efficient, compliant, and environmentally friendly production processes.

Segmentation Analysis

The Ceramic Electric Capacitor market is broadly segmented to provide a detailed understanding of its diverse landscape and to facilitate targeted strategies for manufacturers and stakeholders. These segmentations typically include classifications based on product type, application, end-use industry, and capacitance value, allowing for a granular view of market dynamics. Each segment exhibits unique growth patterns and demand drivers, reflecting the varied technological requirements across different electronic sectors. Analyzing these segments helps identify key areas of innovation, investment, and competitive advantage, enabling market participants to align their product development and market penetration strategies effectively.

The most prominent segmentation involves multi-layer ceramic capacitors (MLCCs) versus other types like ceramic disc capacitors, which fundamentally differ in construction, performance characteristics, and typical applications. Further differentiation occurs within applications, categorizing demand from consumer electronics, automotive, telecommunications, and industrial sectors, each with distinct volume and specification needs. Understanding these segmentations is crucial for forecasting market trends, assessing competitive intensity, and identifying emerging niches within the broad ceramic capacitor market. The market's complexity necessitates such detailed breakdowns to capture the nuances of technological advancements and shifting consumer and industrial demands.

- By Type

- Multi-Layer Ceramic Capacitors (MLCCs)

- Ceramic Disc Capacitors

- Feed-Through Capacitors

- High Voltage Ceramic Capacitors

- Ceramic Chip Capacitors

- By Dielectric Material

- Class 1 (C0G/NP0)

- Class 2 (X7R, X5R, Y5V, Z5U)

- Class 3

- By Application

- Bypass and Decoupling

- Filtering

- Timing

- Frequency Discrimination

- Energy Storage

- Voltage Regulation

- By End-Use Industry

- Consumer Electronics (Smartphones, Laptops, Wearables, TVs)

- Automotive (ADAS, Powertrain, Infotainment, EV/HEV)

- Telecommunications (5G Infrastructure, Base Stations, Networking Equipment)

- Industrial (Automation, Power Supplies, Lighting)

- Medical Devices (Imaging, Implantables, Diagnostic Equipment)

- Aerospace and Defense

- Others (Energy, IoT, Computing)

- By Voltage Range

- Low Voltage

- Medium Voltage

- High Voltage

Value Chain Analysis For Ceramic Electric Capacitor Market

The value chain for the Ceramic Electric Capacitor Market begins with the upstream segment, which involves the sourcing and processing of raw materials. This crucial stage includes suppliers of high-purity ceramic powders (such as barium titanate, strontium titanate), electrode materials (palladium, silver, nickel, copper), and other additives like binders and solvents. These materials undergo stringent quality control and processing to ensure the desired dielectric and conductive properties essential for capacitor performance. The efficiency and cost-effectiveness at this stage directly impact the final product's quality and competitiveness, with technological advancements in material science driving innovation here.

Moving downstream, the processed raw materials are then utilized by capacitor manufacturers, who engage in sophisticated fabrication processes including ceramic slurry preparation, green sheet formation, electrode printing, stacking, lamination, cutting, firing at high temperatures, and terminal plating. This manufacturing stage is highly capital-intensive and requires specialized equipment and expertise. Post-manufacturing, the products enter the distribution channels, which can be direct or indirect. Direct channels involve manufacturers selling directly to large Original Equipment Manufacturers (OEMs) or system integrators, fostering close technical collaboration. Indirect channels typically involve a network of distributors, wholesalers, and retailers who cater to a broader range of smaller and medium-sized enterprises (SMEs) and often provide value-added services like inventory management and technical support.

The final stage of the value chain involves the end-users who integrate ceramic electric capacitors into their finished electronic products. This includes manufacturers of consumer electronics, automotive systems, telecommunications equipment, industrial machinery, and medical devices. The interaction between manufacturers, distributors, and end-users is critical for market feedback, driving product innovation and adaptation to evolving market demands. The complex interplay across this value chain emphasizes the importance of robust supply chain management, quality assurance at every step, and efficient distribution networks to deliver high-quality, reliable, and cost-effective ceramic capacitors to a global customer base.

Ceramic Electric Capacitor Market Potential Customers

The potential customers for ceramic electric capacitors span a vast array of industries and applications, primarily defined by the need for reliable and efficient electronic components to manage power, filter signals, and store charge. These end-users are continually seeking capacitors that offer enhanced performance, smaller form factors, and greater durability to integrate into their increasingly sophisticated products. The primary categories of buyers include large-scale Original Equipment Manufacturers (OEMs) in high-volume industries, as well as specialized manufacturers in niche markets demanding stringent specifications and high reliability.

Key end-user segments driving demand include the consumer electronics sector, encompassing manufacturers of smartphones, laptops, wearable devices, televisions, and home appliances, all of which require millions of tiny, high-performance ceramic capacitors. The automotive industry represents a rapidly expanding customer base, particularly with the widespread adoption of electric and hybrid vehicles, advanced driver-assistance systems (ADAS), and infotainment systems, which demand robust, high-temperature, and high-voltage capacitors. Similarly, the telecommunications sector, driven by 5G network infrastructure deployment and the development of new communication devices, consistently seeks high-frequency and low-ESR capacitors.

Beyond these high-volume sectors, industrial equipment manufacturers, creating automation systems, power supplies, and LED lighting solutions, are significant buyers, valuing durability and stability. The medical device industry, producing everything from diagnostic equipment to implantable devices, represents a premium segment due to its stringent quality and reliability requirements. Aerospace and defense also constitute critical customer segments, demanding components that can withstand extreme environmental conditions and offer unparalleled reliability. The growth across these diverse customer bases underscores the foundational role of ceramic electric capacitors in the global electronic ecosystem, with each segment presenting unique challenges and opportunities for capacitor manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $13.5 billion |

| Market Forecast in 2032 | $21.5 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Murata Manufacturing Co. Ltd., Samsung Electro-Mechanics, TDK Corporation, Taiyo Yuden Co. Ltd., Kyocera Corporation (AVX Corporation), KEMET (Yageo Corporation), Vishay Intertechnology Inc., Walsin Technology Corporation, Darfon Electric Co. Ltd., Holy Stone Enterprise Co. Ltd., Samwha Capacitor Group, Nippon Chemi-Con Corporation, Cornell Dubilier Electronics, Knowles Corporation, CDE (Cornell Dubilier Electronics), Rubycon Corporation, Panasonic Corporation, EPCOS AG (TDK Group), Johanson Dielectrics Inc., Kemet Electronics Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ceramic Electric Capacitor Market Key Technology Landscape

The Ceramic Electric Capacitor Market is characterized by a dynamic and continuously evolving technology landscape, driven by the persistent demand for smaller, more efficient, and higher-performance components. A primary technological focus remains on Multi-Layer Ceramic Capacitors (MLCCs), where advancements in ultra-thin dielectric layer technology are enabling higher capacitance values within increasingly diminutive footprints. This miniaturization is critical for modern electronic devices, which are becoming more compact while integrating greater functionality. Manufacturers are constantly refining processes such as stacking accuracy and electrode printing to achieve these extremely fine geometries and increase volumetric efficiency.

Innovations in dielectric materials represent another core aspect of the technological landscape. The development of advanced ceramic formulations, particularly for Class 2 (X7R, X5R) and Class 1 (C0G/NP0) capacitors, is crucial for achieving superior temperature stability, higher breakdown voltages, and improved capacitance retention under varying conditions. Research is ongoing to develop lead-free and environmentally friendly dielectric materials, aligning with global sustainability initiatives and regulatory compliance. Furthermore, significant progress is being made in base metal electrode (BME) technology, primarily using nickel and copper instead of costly palladium and silver, which not only reduces manufacturing costs but also improves performance characteristics for certain applications.

Beyond material science and fabrication processes, advancements in manufacturing automation and quality control, often leveraging AI and machine learning, are enhancing production yields and reliability. Techniques like advanced sputtering and atomic layer deposition (ALD) are being explored for creating ultra-precise dielectric layers and novel capacitor structures. The emphasis is on developing capacitors that can handle higher frequencies and greater power densities with minimal equivalent series resistance (ESR) and equivalent series inductance (ESL), critical for high-speed data processing, RF applications, and power management in electric vehicles and 5G infrastructure. These technological advancements collectively contribute to the expansion of ceramic capacitors into new and more demanding applications, sustaining market growth and innovation.

Regional Highlights

The Ceramic Electric Capacitor Market exhibits distinct regional dynamics, reflecting varying levels of electronic manufacturing, technological adoption, and economic development across the globe. Asia Pacific stands as the undisputed leader in both production and consumption, primarily driven by its robust electronics manufacturing ecosystem. Countries like China, Japan, South Korea, and Taiwan are global hubs for consumer electronics, automotive electronics, and telecommunication equipment production, leading to immense demand for ceramic capacitors. The region benefits from established supply chains, significant investments in R&D, and a large consumer base, making it a critical market for all major players.

North America and Europe represent mature markets with strong demand for high-reliability and high-performance ceramic capacitors, particularly in the automotive, industrial, medical, and aerospace and defense sectors. In North America, the growth is fueled by innovation in electric vehicles, advanced computing, and IoT devices, alongside substantial government and private investments in technology infrastructure. European countries, notably Germany, are at the forefront of automotive and industrial automation, demanding specialized capacitors that meet stringent quality and performance standards. Both regions are characterized by stringent regulatory environments that influence product development and manufacturing practices, pushing for lead-free and environmentally compliant solutions.

Latin America, the Middle East, and Africa (MEA) are emerging markets that offer substantial growth opportunities. While currently smaller in market size compared to Asia Pacific, these regions are experiencing increasing industrialization, urbanization, and technological penetration. Investments in telecommunications infrastructure, renewable energy projects, and the gradual expansion of local electronics manufacturing are driving the demand for ceramic capacitors. These regions present potential for market expansion as economic development progresses and access to modern electronic technologies becomes more widespread, though they often face challenges related to infrastructure, investment, and supply chain logistics.

- Asia Pacific (APAC): Dominant market share driven by robust consumer electronics, automotive, and telecommunications manufacturing in China, Japan, South Korea, and Taiwan.

- North America: Significant growth due to strong automotive (EVs), industrial, medical, and computing sectors in the United States and Canada.

- Europe: Steady demand from advanced automotive, industrial automation, and renewable energy sectors in Germany, France, and the UK.

- Latin America: Emerging market with growing demand from electronics assembly, telecommunications, and automotive industries, particularly in Brazil and Mexico.

- Middle East and Africa (MEA): Developing market with increasing investments in infrastructure, telecom, and modest electronics manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ceramic Electric Capacitor Market.- Murata Manufacturing Co. Ltd.

- Samsung Electro-Mechanics

- TDK Corporation

- Taiyo Yuden Co. Ltd.

- Kyocera Corporation (AVX Corporation)

- KEMET (Yageo Corporation)

- Vishay Intertechnology Inc.

- Walsin Technology Corporation

- Darfon Electric Co. Ltd.

- Holy Stone Enterprise Co. Ltd.

- Samwha Capacitor Group

- Nippon Chemi-Con Corporation

- Cornell Dubilier Electronics

- Knowles Corporation

- CDE (Cornell Dubilier Electronics)

- Rubycon Corporation

- Panasonic Corporation

- EPCOS AG (TDK Group)

- Johanson Dielectrics Inc.

- Kemet Electronics Corporation

Frequently Asked Questions

What is the projected growth rate for the Ceramic Electric Capacitor Market?

The Ceramic Electric Capacitor Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032.

What are the primary drivers of the Ceramic Electric Capacitor Market?

Key drivers include the miniaturization of electronic devices, rapid growth in electric vehicles (EVs), 5G network deployment, and the expansion of IoT ecosystems.

Which region dominates the Ceramic Electric Capacitor Market?

Asia Pacific currently holds the largest share in the Ceramic Electric Capacitor Market, driven by its extensive electronics manufacturing sector.

What is the most common type of ceramic capacitor?

Multi-Layer Ceramic Capacitors (MLCCs) are the most prevalent type due to their compact size, high capacitance, and versatility across numerous applications.

How does AI impact the Ceramic Electric Capacitor Market?

AI influences the market by driving demand for specialized capacitors in AI hardware, optimizing capacitor design and manufacturing processes, and enhancing quality control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager