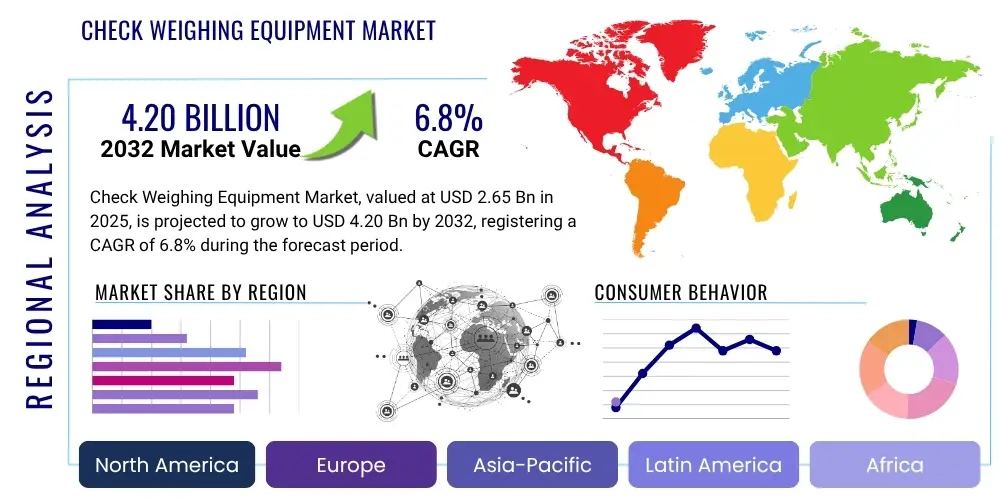

Check Weighing Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429790 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Check Weighing Equipment Market Size

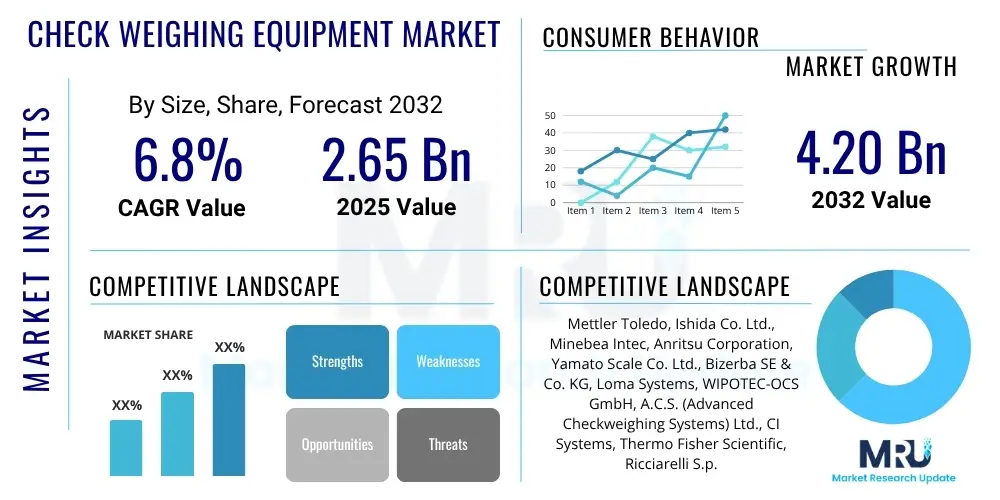

The Check Weighing Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $2.65 Billion in 2025 and is projected to reach $4.20 Billion by the end of the forecast period in 2032.

Check Weighing Equipment Market introduction

The Check Weighing Equipment Market encompasses specialized industrial systems designed to verify the weight of products during production or packaging processes, ensuring they fall within predefined tolerance limits. These sophisticated devices are crucial for maintaining product quality, complying with regulatory standards, and minimizing waste across various industries. They typically integrate with existing production lines, providing real-time weight measurements and enabling automatic rejection of non-conforming items.

Check weighing equipment plays a pivotal role in sectors such as food and beverage, pharmaceuticals, chemicals, and logistics, where precise weight control is paramount. The primary benefits include enhanced operational efficiency through automation, reduced material giveaway, improved customer satisfaction by ensuring consistent product quantity, and strict adherence to legal weight requirements. The market's growth is predominantly driven by increasing automation demands in manufacturing, stringent quality control regulations, and a growing emphasis on minimizing production costs and optimizing supply chain operations. As industries continue to strive for higher levels of precision and speed, the demand for advanced check weighing solutions capable of handling diverse product types and production speeds is steadily rising.

Check Weighing Equipment Market Executive Summary

The Check Weighing Equipment Market is experiencing robust growth, primarily fueled by the accelerating adoption of automation in manufacturing processes and the increasing global emphasis on stringent quality control and regulatory compliance. Business trends indicate a strong move towards integrated solutions, where check weighers are seamlessly incorporated into broader production lines, often linked with other inspection systems like metal detectors and X-ray scanners. This integration aims to enhance overall efficiency, reduce manual intervention, and provide comprehensive product integrity checks, thereby driving significant investment from manufacturers seeking to modernize their operations and achieve Industry 4.0 objectives.

Regionally, the Asia Pacific market is poised for significant expansion, attributed to rapid industrialization, burgeoning manufacturing sectors, and increasing consumer awareness regarding product quality in countries like China and India. North America and Europe, while mature markets, continue to demonstrate steady demand, driven by technological advancements, the need for replacing aging equipment, and strict adherence to established regulatory frameworks. Segment-wise, dynamic check weighers are leading the market due to their ability to process products at high speeds, making them ideal for high-volume production environments. The food and beverage and pharmaceutical industries remain the largest end-user segments, propelled by the critical need for precise portion control, allergen management, and adherence to health and safety standards. Manufacturers are focusing on developing more versatile, hygienic, and intelligent check weighing systems to cater to these diverse and evolving industrial requirements.

AI Impact Analysis on Check Weighing Equipment Market

Common user inquiries regarding AI's influence on check weighing equipment frequently revolve around enhanced accuracy, predictive maintenance capabilities, seamless integration with smart factory ecosystems, and the potential for real-time, autonomous decision-making. Users are keen to understand how AI can move check weighers beyond simple weight verification to intelligent anomaly detection, process optimization, and proactive fault prevention. There is a strong expectation that AI will significantly improve the operational intelligence and adaptability of these systems, making them more efficient, reliable, and integral to advanced manufacturing environments. The overarching themes include leveraging data for prescriptive insights, minimizing downtime, and achieving unprecedented levels of precision in quality assurance processes.

- Enhanced precision and stability through AI-driven algorithms for noise reduction and vibration compensation.

- Predictive maintenance capabilities, allowing for proactive servicing and minimizing unexpected downtime.

- Real-time data analysis and feedback loops for continuous process optimization and improved production line efficiency.

- Integration with broader IoT and Industry 4.0 platforms, enabling intelligent factory automation and communication.

- Automated calibration and self-learning capabilities to adapt to varying product characteristics and environmental conditions.

- Improved anomaly detection, identifying subtle deviations that might indicate equipment malfunction or product quality issues.

- Personalized settings and adaptive weighing parameters based on historical performance and current production demands.

DRO & Impact Forces Of Check Weighing Equipment Market

The Check Weighing Equipment Market is propelled by several key drivers, primarily the escalating global demand for stringent quality control in manufacturing, especially within the food and beverage and pharmaceutical sectors, where product consistency and safety are non-negotiable. Regulatory mandates from bodies like the FDA and various national metrology agencies necessitate accurate weight verification, pushing industries to adopt advanced check weighing solutions. Furthermore, the growing trend of industrial automation and the push towards Industry 4.0 adoption are significantly boosting demand, as manufacturers seek to enhance operational efficiency, reduce labor costs, and streamline production processes through integrated, automated systems.

However, the market also faces notable restraints. The initial high capital investment required for purchasing and implementing sophisticated check weighing equipment can be a significant barrier for small and medium-sized enterprises (SMEs). The complexity of integrating these advanced systems with existing legacy production lines often requires specialized technical expertise and can lead to operational challenges, delaying adoption. Additionally, the need for regular calibration and maintenance, along with the requirement for skilled operators to manage and troubleshoot these intricate machines, adds to the operational costs and complexity for end-users.

Despite these challenges, substantial opportunities exist, particularly in emerging economies where industrialization is accelerating and quality standards are progressively tightening. The increasing focus on customized solutions and the development of highly specialized check weighers for niche applications present avenues for market expansion. Moreover, the continuous evolution and integration of advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and machine learning into check weighing systems offer opportunities for enhanced functionality, predictive capabilities, and smarter decision-making, promising to revolutionize the market landscape. These technological advancements are set to provide more adaptable, efficient, and user-friendly solutions, opening doors to new applications and broader market penetration.

- Drivers:

- Increasing demand for automation and efficiency in manufacturing.

- Stringent quality control regulations and compliance requirements across industries.

- Growing focus on reducing product giveaway and material waste.

- Rise in consumer demand for consistent product quality and accurate packaging.

- Technological advancements in sensor technology and data analytics.

- Restraints:

- High initial investment and operational costs associated with advanced equipment.

- Complexity of integrating check weighing systems with existing production lines.

- Requirement for skilled personnel for operation, maintenance, and calibration.

- Sensitivity to environmental factors like vibration and temperature fluctuations.

- Opportunities:

- Expansion into emerging markets with growing industrialization.

- Development of highly specialized and customized check weighing solutions.

- Integration with Artificial Intelligence, IoT, and machine learning for enhanced capabilities.

- Increasing adoption of remote monitoring and predictive maintenance services.

- Demand for hygienic and washdown-safe equipment in food and pharmaceutical industries.

- Impact Forces:

- Bargaining power of buyers: Moderate to high due to product standardization and choice.

- Bargaining power of suppliers: Moderate, influenced by technology and specialization of components.

- Threat of new entrants: Low to moderate due to high capital requirements and R&D investment.

- Threat of substitutes: Low, as check weighers offer unique, legally mandated functionality.

- Competitive rivalry: High, with established players and continuous innovation.

Segmentation Analysis

The Check Weighing Equipment Market is segmented across various parameters, providing a comprehensive view of its intricate structure and diverse application landscape. These segmentations are crucial for understanding market dynamics, identifying specific growth opportunities, and tailoring solutions to meet distinct industry requirements. The primary segmentation categories typically include classification by type of machine, the end-user industry, the application of the equipment, and the underlying technology employed. Each segment reveals unique demand patterns, technological preferences, and growth trajectories, reflecting the specialized needs of different operational environments and production scales.

Understanding these segments allows market participants to strategically position their products and services, focusing on areas with the highest growth potential or unmet needs. For instance, the distinction between static and dynamic check weighers highlights the difference in production speed requirements, while the various end-user industries underscore the diverse regulatory and hygienic standards that influence equipment design and functionality. The ongoing evolution within these segments, driven by technological advancements and shifting industry demands, continually reshapes the market landscape, fostering innovation and competitive differentiation among key players.

- By Type:

- Static Check Weighers

- Dynamic Check Weighers

- By End-User Industry:

- Food and Beverage

- Bakery and Confectionery

- Meat, Poultry, and Seafood

- Dairy Products

- Snacks and Convenience Foods

- Beverages

- Other Food Products

- Pharmaceutical

- Tablets and Capsules

- Powders and Granules

- Medical Devices

- Syrups and Liquids

- Chemical and Petroleum

- Cosmetics and Personal Care

- Automotive

- Logistics and Packaging

- Other Industries

- Food and Beverage

- By Application:

- Package Inspection

- Production Line Weighing

- Quality Control

- Missing Part Detection

- Filling Control

- Sorting and Classification

- By Technology:

- Load Cell Technology

- Electromagnetic Force Restoration (EMFR) Technology

- Strain Gauge Technology

Value Chain Analysis For Check Weighing Equipment Market

The value chain for the Check Weighing Equipment Market begins with the upstream analysis, which involves the sourcing of critical raw materials and components. This stage includes suppliers of precision sensors, load cells, electronic components such as microcontrollers and circuit boards, mechanical parts like conveyor belts and frames, and specialized software modules for data processing and control. Key suppliers in this segment are often highly specialized, providing advanced technological components that directly impact the accuracy and reliability of the final check weighing system. Relationships with these upstream suppliers are vital for maintaining product quality, managing costs, and ensuring a consistent supply of advanced components.

Moving downstream, the value chain encompasses manufacturing, assembly, and rigorous testing of the check weighing equipment. Following production, the distribution channel plays a crucial role in bringing these products to the end-users. Distribution can occur through direct sales channels, where manufacturers engage directly with large enterprise clients or specialized system integrators for complex projects. Alternatively, indirect channels involve a network of distributors, wholesalers, and value-added resellers who provide regional market access, localized support, and integration services, particularly to smaller and medium-sized businesses. These indirect channels often offer broader market penetration and specialized expertise in regional compliance and service.

The downstream activities further extend to installation, commissioning, training, and extensive after-sales services, including maintenance, calibration, and software updates. End-users, encompassing a wide array of industries such as food and beverage, pharmaceuticals, and logistics, are the final recipients of these solutions. The efficiency and effectiveness of this entire value chain are heavily reliant on seamless coordination between all stakeholders, from component manufacturers to installation teams, ensuring that the check weighing equipment delivers consistent performance and meets the stringent quality and regulatory demands of modern manufacturing environments.

Check Weighing Equipment Market Potential Customers

The primary potential customers for check weighing equipment span a diverse array of industrial sectors, each requiring precise weight verification for product quality, regulatory compliance, and operational efficiency. Manufacturers in the food and beverage industry represent a significant customer base, encompassing companies involved in processing meats, dairy, baked goods, snacks, beverages, and confectionery. These entities utilize check weighers to ensure accurate portion control, prevent product giveaway, maintain package integrity, and comply with strict food safety regulations and labeling requirements, crucial for consumer trust and market reputation.

Another critical segment comprises pharmaceutical and medical device manufacturers. In this highly regulated industry, check weighing equipment is indispensable for ensuring the precise dosage of medications, verifying the completeness of pharmaceutical kits, and controlling the weight of medical instruments. Adherence to Good Manufacturing Practices (GMP) and other regulatory standards necessitates meticulous weight accuracy to guarantee patient safety and product efficacy. Beyond these, chemical and petrochemical companies, cosmetics and personal care product manufacturers, and logistics and packaging firms also form substantial customer groups, using check weighers for quality assurance, inventory management, and optimizing shipping weights. The diverse applications across these industries underscore the broad utility and indispensable nature of check weighing technology in modern manufacturing and supply chain operations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $2.65 Billion |

| Market Forecast in 2032 | $4.20 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mettler Toledo, Ishida Co. Ltd., Minebea Intec, Anritsu Corporation, Yamato Scale Co. Ltd., Bizerba SE & Co. KG, Loma Systems, WIPOTEC-OCS GmbH, A.C.S. (Advanced Checkweighing Systems) Ltd., CI Systems, Thermo Fisher Scientific, Ricciarelli S.p.A., Optima Packaging Group GmbH, OMRON Corporation, GEA Group Aktiengesellschaft, Sesotec GmbH, Multivac, Heat and Control, Avery Weigh-Tronix, Cardinal Scale Manufacturing Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Check Weighing Equipment Market Key Technology Landscape

The technological landscape of the Check Weighing Equipment Market is characterized by a continuous evolution towards greater precision, speed, and integration, fundamentally driven by advancements in sensor technology and digital processing. At the core of these systems are highly sensitive load cells, predominantly utilizing strain gauge technology or more advanced electromagnetic force restoration (EMFR) principles. EMFR technology offers superior accuracy and speed, making it ideal for high-precision applications in the pharmaceutical sector, while robust load cell designs cater to demanding industrial environments, such as those found in food processing. The accuracy and repeatability of these sensors are paramount, directly influencing the performance and reliability of the check weighing system.

Beyond the fundamental weighing mechanisms, modern check weighers heavily incorporate sophisticated software and control systems. Human Machine Interfaces (HMIs) with intuitive touchscreens allow for easy operation, data input, and recipe management. Furthermore, the integration of advanced data analytics capabilities enables real-time monitoring of production performance, statistical process control, and comprehensive reporting, which is crucial for quality assurance and regulatory compliance. Many contemporary systems are also designed with IoT connectivity, allowing them to communicate seamlessly with other factory equipment, enterprise resource planning (ERP) systems, and cloud-based platforms, facilitating remote monitoring, predictive maintenance, and overall factory automation initiatives under the Industry 4.0 paradigm.

The market is also seeing an increased adoption of modular designs, making systems more adaptable to different product types and production line configurations. Hygienic design principles are particularly vital for the food and pharmaceutical industries, leading to the development of equipment that is easy to clean, washdown-safe, and resistant to corrosive agents. Looking ahead, the embedding of artificial intelligence and machine learning algorithms promises to further enhance check weigher capabilities, enabling self-calibration, adaptive weighing, and more intelligent anomaly detection, pushing the boundaries of what these essential quality control devices can achieve in diverse industrial settings.

Regional Highlights

- North America: This region represents a mature yet robust market for check weighing equipment, driven by strict regulatory standards in the food, pharmaceutical, and manufacturing industries. The adoption of advanced automation technologies and the continuous need for upgrading existing infrastructure contribute to steady demand. High capital expenditure capabilities and a focus on operational efficiency further support market growth.

- Europe: Similar to North America, Europe is a well-established market characterized by stringent quality control regulations and high standards for product safety, particularly in Germany, France, and the UK. The region is a hub for technological innovation, with a strong emphasis on precision engineering and the integration of check weighers into smart factory concepts.

- Asia Pacific (APAC): The APAC region is projected to be the fastest-growing market, fueled by rapid industrialization, expanding manufacturing bases, and increasing disposable incomes leading to higher demand for packaged and processed goods. Countries like China, India, Japan, and South Korea are investing heavily in manufacturing automation, quality control systems, and expanding production capacities, making this a lucrative market.

- Latin America: This region is experiencing steady growth in the check weighing equipment market, primarily driven by increasing foreign investments in manufacturing sectors, particularly in Brazil and Mexico. Rising consumer awareness regarding product quality and safety, coupled with evolving regulatory frameworks, contributes to the demand for modern check weighing solutions.

- Middle East and Africa (MEA): The MEA market for check weighing equipment is in its nascent stage but shows promising growth. Investments in infrastructure development, diversification of economies away from oil, and an increasing focus on developing local manufacturing capabilities, especially in food processing and pharmaceuticals, are expected to boost market adoption over the forecast period.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Check Weighing Equipment Market.- Mettler Toledo

- Ishida Co. Ltd.

- Minebea Intec

- Anritsu Corporation

- Yamato Scale Co. Ltd.

- Bizerba SE & Co. KG

- Loma Systems

- WIPOTEC-OCS GmbH

- A.C.S. (Advanced Checkweighing Systems) Ltd.

- CI Systems

- Thermo Fisher Scientific

- Ricciarelli S.p.A.

- Optima Packaging Group GmbH

- OMRON Corporation

- GEA Group Aktiengesellschaft

- Sesotec GmbH

- Multivac

- Heat and Control

- Avery Weigh-Tronix

- Cardinal Scale Manufacturing Company

Frequently Asked Questions

What is a check weighing equipment and its primary function?

Check weighing equipment is an industrial system designed to precisely measure the weight of individual products during the manufacturing or packaging process, ensuring they fall within a predefined weight tolerance. Its primary function is to maintain product quality, ensure regulatory compliance, and prevent underweight or overweight items from reaching consumers, thereby minimizing waste and optimizing production efficiency.

Which industries are the largest adopters of check weighing equipment?

The food and beverage and pharmaceutical industries are the largest adopters of check weighing equipment. These sectors require extremely precise weight verification for portion control, dosage accuracy, allergen management, and strict adherence to health and safety regulations, making check weighers indispensable for their operations and product integrity.

How do dynamic check weighers differ from static check weighers?

Dynamic check weighers measure product weight while items are in motion on a conveyor belt, enabling high-speed, continuous production. Static check weighers, conversely, require products to be placed manually or temporarily stopped on the weighing platform for measurement, making them suitable for lower volume production or batch weighing processes.

What are the key benefits of integrating check weighing equipment into a production line?

Key benefits include enhanced product quality and consistency, significant reduction in product giveaway and material waste, assured compliance with legal weight regulations, improved operational efficiency through automation, and protection of brand reputation by delivering accurately weighed products to consumers.

What future technological trends are expected to impact the check weighing equipment market?

Future technological trends include greater integration of Artificial Intelligence (AI) for predictive maintenance and advanced anomaly detection, enhanced IoT connectivity for real-time data analytics and remote monitoring, development of self-calibrating systems, and increased demand for highly hygienic and modular designs to meet evolving industry standards and customization needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager