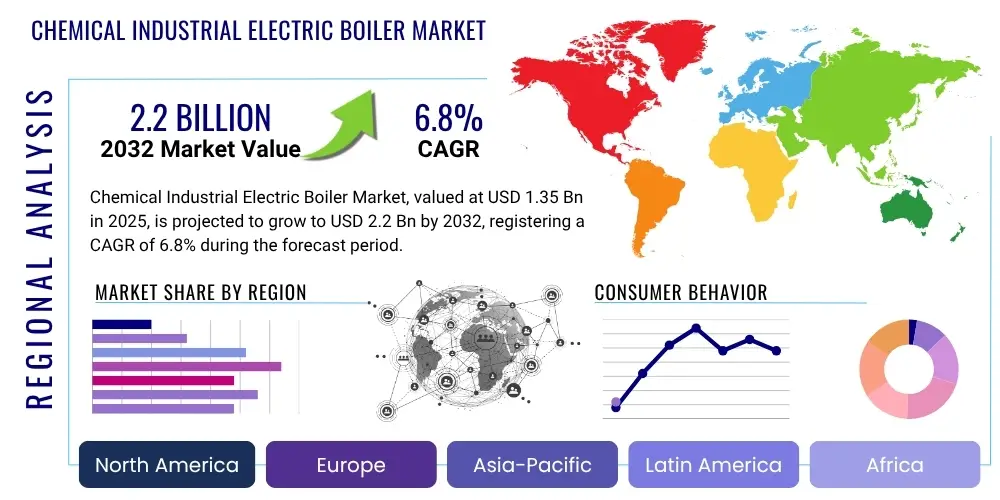

Chemical Industrial Electric Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429572 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Chemical Industrial Electric Boiler Market Size

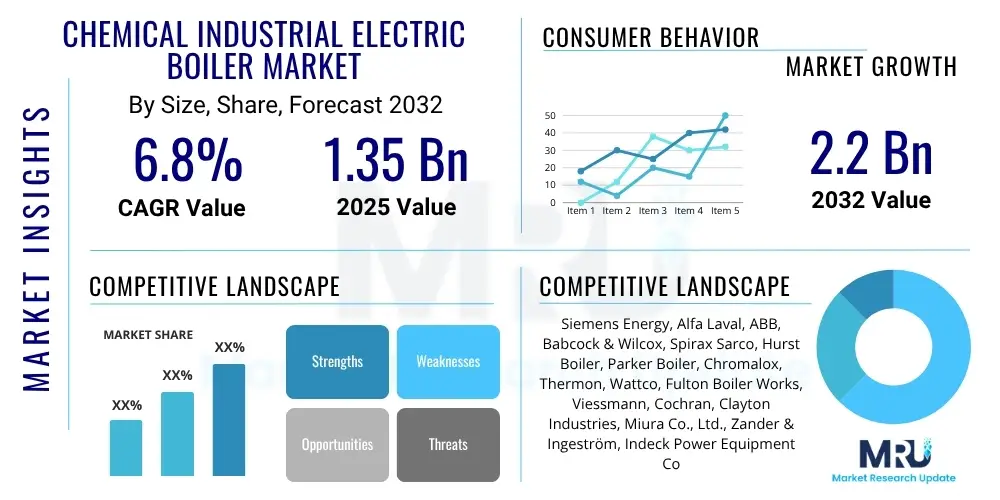

The Chemical Industrial Electric Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.35 Billion in 2025 and is projected to reach USD 2.2 Billion by the end of the forecast period in 2032.

Chemical Industrial Electric Boiler Market introduction

The Chemical Industrial Electric Boiler Market encompasses the design, manufacturing, installation, and maintenance of boilers that utilize electricity to generate steam or hot water for various processes within the chemical industry. These boilers offer an increasingly attractive alternative to traditional fossil-fuel-fired systems, driven by global mandates for decarbonization and enhanced operational efficiency. Their primary function is to provide consistent and controllable heat or steam essential for chemical reactions, distillation, sterilization, and other critical processes, ensuring product quality and safety.

Product descriptions include electrode boilers, which use the electrical conductivity of water to generate heat, and resistance boilers, which employ heating elements. Major applications span petrochemicals, specialty chemicals, pharmaceuticals, and pulp & paper, where precise temperature control and clean steam are paramount. Key benefits include zero direct emissions at the point of use, higher energy conversion efficiency, lower maintenance requirements, and improved safety features due to the absence of combustion. The market is predominantly driven by stringent environmental regulations, the rising cost volatility of fossil fuels, and a growing corporate commitment to sustainable manufacturing practices, making electric boilers a crucial component in the future of industrial heating.

Chemical Industrial Electric Boiler Market Executive Summary

The Chemical Industrial Electric Boiler Market is undergoing significant transformation, characterized by strong business trends focusing on sustainability, operational efficiency, and technological integration. The shift towards electrification in industrial processes is a dominant force, with companies increasingly investing in solutions that reduce their carbon footprint and align with global climate objectives. This trend is amplified by advancements in smart control systems and predictive maintenance technologies, which enhance boiler performance and reliability, optimizing energy consumption and extending asset lifespans. Furthermore, the market is witnessing an emphasis on modular and scalable boiler designs, allowing for greater flexibility in deployment and easier integration into existing infrastructure.

Regionally, the market exhibits varied dynamics, with Europe leading in adoption due to robust environmental policies and incentives for green industrial technologies. The Asia Pacific region is poised for substantial growth, driven by rapid industrial expansion, increasing demand for chemical products, and growing awareness of environmental impacts, alongside supportive government initiatives. North America is focused on upgrading aging infrastructure and enhancing energy independence through electrification. Segment-wise, high-capacity electric boilers for large-scale chemical processes and specialized resistance boilers for precise temperature control in sensitive applications are experiencing notable growth, reflecting the diverse and evolving needs of the chemical industry. The integration of renewable energy sources, such as solar and wind, to power these electric boilers further underscores the market's trajectory towards a cleaner, more efficient industrial future.

AI Impact Analysis on Chemical Industrial Electric Boiler Market

User inquiries about AI's impact on the Chemical Industrial Electric Boiler Market frequently revolve around how artificial intelligence can enhance operational efficiency, ensure reliability, and reduce energy consumption. Users are keen to understand the practical applications of AI in real-time monitoring, predictive maintenance, and optimized control strategies, alongside potential benefits in safety and environmental compliance. Concerns often include the complexity of implementation, data security, and the return on investment for integrating AI into existing boiler systems. The core expectation is that AI will provide smarter, more autonomous boiler management, leading to significant cost savings and improved process outcomes, addressing the challenges of fluctuating energy costs and stringent operational demands.

- AI enables advanced predictive maintenance, forecasting equipment failures before they occur, minimizing downtime and maintenance costs.

- Optimized energy management systems leverage AI to analyze energy consumption patterns and adjust boiler operation for peak efficiency, reducing electricity usage.

- AI-driven control systems offer real-time adjustment of boiler parameters, ensuring precise temperature and pressure control for sensitive chemical processes.

- Enhanced safety protocols are implemented through AI monitoring of operational anomalies, triggering alerts and automatic shutdowns to prevent hazardous situations.

- Remote diagnostics and troubleshooting capabilities are significantly improved with AI, allowing for expert system support and rapid issue resolution.

DRO & Impact Forces Of Chemical Industrial Electric Boiler Market

The Chemical Industrial Electric Boiler Market is significantly shaped by a confluence of drivers, restraints, and opportunities, underpinned by potent impact forces. Key drivers include the global push for decarbonization and net-zero emissions, compelling industries to adopt cleaner heating alternatives. Stricter environmental regulations, particularly in developed economies, coupled with incentives for green technologies, further accelerate adoption. The inherent energy efficiency of electric boilers, often exceeding 98%, contributes to lower operational costs over the long term, making them financially attractive despite higher initial capital outlays. Moreover, technological advancements in control systems and heating elements enhance reliability and operational precision, catering to the exacting demands of chemical processes. The volatility of fossil fuel prices also drives a strategic shift towards electric options, offering greater stability in energy costs.

However, significant restraints temper this growth. The high upfront investment required for electric boilers, particularly for large capacities, can be a barrier for some companies. Limitations in existing electrical grid infrastructure in certain industrial zones may pose challenges to widespread adoption, necessitating substantial upgrades. The perception of electric boilers having lower steam generation capacity compared to large-scale fossil fuel boilers, though often a misconception for specific applications, can also hinder uptake. Furthermore, the energy source for electricity generation itself still impacts the overall carbon footprint, if it relies heavily on fossil fuels, which some stakeholders may view as a limitation. Addressing these challenges requires strategic policy support, financial incentives, and continued technological innovation to overcome market inertia and infrastructure constraints.

Opportunities for market expansion are considerable, particularly with the increasing integration of renewable energy sources into the grid, which makes electric boilers a truly green solution. The potential for electric boilers to integrate with smart grid technologies offers demand-side management benefits, optimizing energy consumption during off-peak hours and reducing strain on the grid. Emerging markets, characterized by new industrialization and developing infrastructure, present fertile ground for initial adoption of cleaner technologies. Furthermore, advancements in modular and compact designs are making electric boilers more versatile and easier to install in diverse industrial settings, including retrofits. The rising demand for green hydrogen production, which heavily relies on clean energy inputs, also presents a substantial opportunity for electric boilers as a preferred heating method, driving innovation and expansion across various chemical sectors.

Segmentation Analysis

The Chemical Industrial Electric Boiler Market is meticulously segmented across various dimensions to provide a granular understanding of its structure and growth dynamics. These segmentations are crucial for identifying specific market niches, understanding customer preferences, and tailoring product development strategies. The primary categories for segmentation include boiler type, capacity, application, and end-use industry, each revealing distinct market trends and competitive landscapes. This layered analysis allows stakeholders to assess market potential with precision, facilitating targeted investments and strategic planning across the value chain. The versatility of electric boilers allows them to serve a broad spectrum of industrial needs, from small-scale laboratory operations to large-scale chemical production facilities.

- By Type

- Electrode Boilers: Utilize the electrical resistance of water to generate heat, suitable for high-capacity applications.

- Resistance Boilers: Employ heating elements to transfer heat to water, often preferred for smaller capacities and precise control.

- By Capacity

- Small Capacity (0-5 MW): Typically used for auxiliary heating or smaller chemical processes.

- Medium Capacity (5-20 MW): Suited for mid-sized industrial plants and diversified applications.

- Large Capacity (20+ MW): Employed in extensive chemical manufacturing facilities requiring substantial steam or hot water.

- By Application

- Process Heating: Essential for maintaining specific temperatures during chemical reactions and synthesis.

- Steam Generation: Provides steam for various processes including distillation, sterilization, and humidification.

- Chemical Reaction Control: Offers precise temperature control vital for sensitive chemical processes.

- Space Heating: Used for heating industrial facilities and ancillary buildings.

- By End-Use Industry

- Petrochemicals: For crude oil refining and derivative production processes.

- Specialty Chemicals: For manufacturing high-value chemicals with specific properties.

- Pharmaceuticals: Requires clean steam for sterilization and precise temperature control for drug synthesis.

- Pulp and Paper: Used in various stages of pulp digestion and paper drying.

- Food and Beverage: For pasteurization, sterilization, and general process heating.

- Textiles: Used in dyeing and finishing processes.

- Other Chemical Processes: Includes various other industrial applications requiring heat or steam.

Value Chain Analysis For Chemical Industrial Electric Boiler Market

The value chain for the Chemical Industrial Electric Boiler Market is an intricate network spanning from raw material extraction to post-sales services, highlighting the various stages involved in bringing the product to the end-user. Upstream activities commence with the procurement of essential raw materials such as specialized steel alloys for boiler shells, high-performance heating elements (for resistance boilers), and advanced electrode materials (for electrode boilers). This also includes insulation materials, sophisticated control components like Programmable Logic Controllers (PLCs), sensors, and wiring. Manufacturers often rely on a global supply chain for these specialized components, focusing on quality and cost-effectiveness. The manufacturing stage then involves assembly, welding, quality control, and rigorous testing to ensure adherence to safety and performance standards, followed by packaging and logistics for distribution.

Downstream activities in the value chain primarily involve the installation, commissioning, operation, and maintenance of the electric boilers at the end-user facilities. This phase often includes engineering, procurement, and construction (EPC) firms that handle large-scale project integration, as well as specialized contractors for boiler installation and pipework. Post-sales support, including routine maintenance, spare parts supply, troubleshooting, and upgrade services, forms a critical part of the downstream segment, ensuring long-term operational efficiency and customer satisfaction. The efficiency and reliability of these services directly impact the reputation and market share of boiler manufacturers. The chemical industry, with its complex processes, often requires highly specialized integration and ongoing support.

Distribution channels for chemical industrial electric boilers typically involve both direct and indirect approaches. Direct sales are common for large industrial clients and complex, custom-engineered solutions, where manufacturers interact directly with end-users or their consulting engineers. This allows for personalized service, technical consultation, and negotiation. Indirect channels involve a network of regional distributors, value-added resellers, and system integrators who serve a broader customer base, including small and medium-sized enterprises (SMEs). These intermediaries often provide local support, warehousing, and installation services, extending the manufacturer's reach into diverse geographical markets. Partnerships with EPC firms are also crucial, as these companies often specify and procure boilers as part of larger industrial plant construction projects. The choice of distribution channel heavily depends on the target customer segment, project complexity, and geographical coverage requirements.

Chemical Industrial Electric Boiler Market Potential Customers

Potential customers for Chemical Industrial Electric Boilers encompass a broad spectrum of industrial entities that rely heavily on process heating, steam generation, and precise temperature control for their operations. These end-users are primarily engaged in manufacturing processes that require substantial thermal energy inputs, often with strict environmental and safety compliance mandates. The core market includes companies seeking to modernize their energy infrastructure, reduce operational costs associated with fluctuating fossil fuel prices, and align with global sustainability goals. Industries such as petrochemicals, specialty chemicals, pharmaceuticals, and pulp and paper represent significant demand drivers due to their high energy intensity and regulatory pressures.

Specific buyers within these industries range from large multinational corporations operating multiple production facilities to smaller, specialized chemical plants. Pharmaceutical manufacturers, for instance, are key customers due to their need for clean, consistent steam for sterilization and precise temperature management in drug synthesis, where electric boilers offer advantages in purity and control. Similarly, food and beverage processing plants require reliable steam for pasteurization and cooking, often under hygienic conditions that electric boilers can easily meet. The growing trend of green hydrogen production also positions these facilities as emerging potential customers, as electric boilers can efficiently integrate with renewable power sources to provide the necessary heat for hydrogen generation processes. Essentially, any industrial facility within the chemical value chain that uses heat or steam for critical processes and is committed to environmental stewardship and operational efficiency stands as a potential customer.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.35 Billion |

| Market Forecast in 2032 | USD 2.2 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens Energy, Alfa Laval, ABB, Babcock & Wilcox, Spirax Sarco, Hurst Boiler, Parker Boiler, Chromalox, Thermon, Wattco, Fulton Boiler Works, Viessmann, Cochran, Clayton Industries, Miura Co., Ltd., Zander & Ingeström, Indeck Power Equipment Co., Cleaver-Brooks, Bosch Industriekessel, Danfoss |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Industrial Electric Boiler Market Key Technology Landscape

The technological landscape of the Chemical Industrial Electric Boiler Market is characterized by continuous innovation aimed at enhancing efficiency, control, and integration capabilities. Advanced control systems, including sophisticated Programmable Logic Controllers (PLCs) and Supervisory Control and Data Acquisition (SCADA) systems, are central to modern electric boilers. These systems enable precise monitoring and control of temperature, pressure, and flow rates, which are critical for sensitive chemical processes, ensuring optimal performance and safety. The integration of Internet of Things (IoT) sensors and connectivity allows for real-time data acquisition, remote monitoring, and predictive analytics, moving towards a more proactive maintenance strategy and away from traditional reactive approaches.

Furthermore, energy management systems are increasingly being deployed, leveraging data analytics to optimize electricity consumption, particularly in conjunction with variable electricity tariffs or renewable energy sources. This includes demand-side management features that can adjust boiler operation based on grid conditions or energy price fluctuations. Material science advancements contribute to the development of more durable and efficient heating elements or electrodes, extending boiler lifespan and reducing maintenance frequency. Modular design and skid-mounted solutions are also gaining traction, simplifying installation, reducing footprint, and allowing for easier scalability and customization to specific industrial requirements. These technological innovations collectively drive higher operational reliability, lower total cost of ownership, and a reduced environmental footprint, making electric boilers increasingly competitive in the industrial heating sector.

Regional Highlights

- North America: This region is characterized by significant investment in upgrading aging industrial infrastructure and a strong push for energy efficiency. Regulations and incentives supporting cleaner manufacturing processes, coupled with the availability of reliable electrical grids, drive the adoption of electric boilers in the chemical sector.

- Europe: Europe leads the market due to stringent environmental policies, ambitious decarbonization targets, and robust government subsidies for green industrial technologies. Countries like Germany, the UK, and Scandinavia are at the forefront of adopting electric boilers to meet sustainability mandates and reduce greenhouse gas emissions.

- Asia Pacific (APAC): The APAC region is experiencing rapid industrialization and expansion of its chemical sector, making it a high-growth market. Increased awareness of environmental concerns, coupled with government support for electrification and sustainable manufacturing, fuels the demand for electric boilers, particularly in China, India, and Southeast Asian nations.

- Latin America: This region shows growing potential driven by increasing industrialization, particularly in countries like Brazil and Mexico. Investments in new industrial facilities and a focus on modernizing existing plants are creating opportunities for electric boiler adoption as industries seek more efficient and environmentally friendly heating solutions.

- Middle East and Africa (MEA): The MEA region is witnessing diversification of its industrial base and a rising emphasis on sustainable energy initiatives. While fossil fuel reliance remains high, increasing governmental and corporate commitments to climate goals are fostering a nascent but growing market for electric industrial boilers, especially in the chemical and petrochemical sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Industrial Electric Boiler Market.- Siemens Energy

- Alfa Laval

- ABB

- Babcock & Wilcox

- Spirax Sarco

- Hurst Boiler

- Parker Boiler

- Chromalox

- Thermon

- Wattco

- Fulton Boiler Works

- Viessmann

- Cochran

- Clayton Industries

- Miura Co., Ltd.

- Zander & Ingeström

- Indeck Power Equipment Co.

- Cleaver-Brooks

- Bosch Industriekessel

- Danfoss

Frequently Asked Questions

What are the main advantages of electric boilers in chemical industrial settings?

Electric boilers offer significant benefits including zero direct emissions, high energy efficiency (typically over 98%), precise temperature and pressure control, reduced maintenance needs, and enhanced safety due to the absence of combustion and fuel storage requirements. They also integrate well with renewable energy sources.

How do electric boilers contribute to decarbonization efforts?

By eliminating on-site combustion of fossil fuels, electric boilers directly reduce Scope 1 emissions. When powered by renewable electricity, they provide a truly carbon-neutral heating solution, significantly aiding industries in achieving their net-zero targets and complying with environmental regulations.

What are the primary types of electric boilers used in industry?

The two main types are electrode boilers and resistance boilers. Electrode boilers use the electrical conductivity of water to generate heat and are often preferred for high-capacity applications. Resistance boilers utilize heating elements and are commonly chosen for smaller capacities and applications requiring precise temperature control.

What are the key challenges for the adoption of electric industrial boilers?

Major challenges include the high initial capital investment compared to traditional boilers, potential limitations of existing electrical grid infrastructure in some industrial areas, and concerns regarding the source of electricity generation if it relies heavily on fossil fuels, impacting overall decarbonization efforts.

How does AI enhance the performance of chemical industrial electric boilers?

AI significantly boosts performance through predictive maintenance, optimizing operational efficiency, and ensuring precise control. It analyzes data from sensors to forecast potential failures, intelligently adjusts boiler parameters for energy savings, and enhances safety by detecting anomalies in real-time, leading to more reliable and cost-effective operation.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager