Chemical Protective Gloves Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429595 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Chemical Protective Gloves Market Size

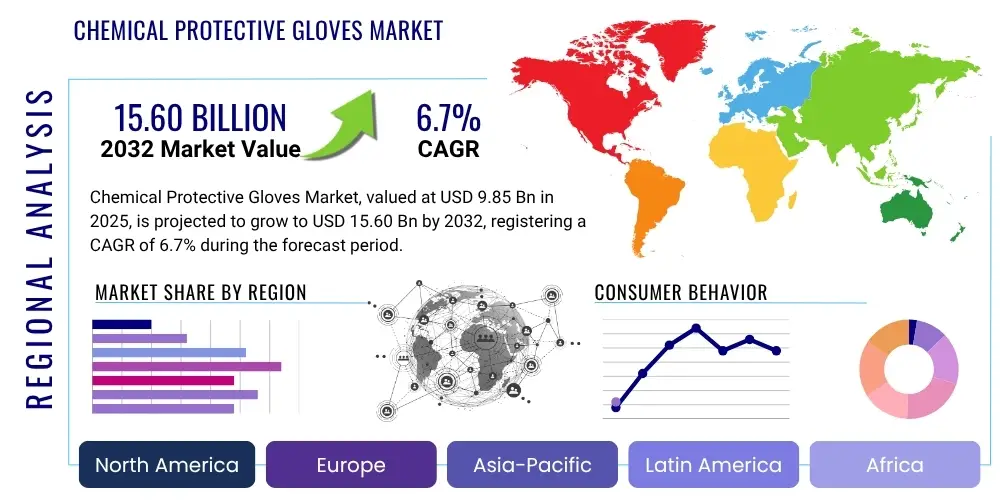

The Chemical Protective Gloves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032. The market is estimated at USD 9.85 Billion in 2025 and is projected to reach USD 15.60 Billion by the end of the forecast period in 2032.

Chemical Protective Gloves Market introduction

The Chemical Protective Gloves Market encompasses the global production and distribution of specialized gloves designed to shield hands from hazardous chemicals, corrosive substances, and other dangerous materials. These gloves are crucial personal protective equipment (PPE) across a multitude of industries, providing an essential barrier against chemical exposure, which can lead to severe injuries, burns, or long-term health issues. The product portfolio includes a wide array of materials, such as nitrile, latex, butyl, neoprene, PVC, and viton, each offering distinct resistance properties against specific chemical classes, temperatures, and physical hazards. The selection of the appropriate glove type is critical and depends heavily on the specific chemicals being handled, the duration of exposure, and the required dexterity for tasks.

Major applications of chemical protective gloves span across sectors like chemical manufacturing, pharmaceuticals, oil and gas, automotive, healthcare, food processing, and research laboratories. In these environments, workers are routinely exposed to acids, alkalis, solvents, and other aggressive compounds, necessitating robust and reliable hand protection. The primary benefits of these gloves include enhanced worker safety, compliance with stringent occupational health regulations, prevention of chemical burns and dermatitis, and reduced downtime due to workplace accidents. They also contribute significantly to maintaining sterile environments in sensitive industries, preventing contamination of products and processes. The market is primarily driven by escalating industrial safety standards, increasing awareness regarding worker well-being, expansion of chemical and pharmaceutical industries, and a rising demand for specialized protective equipment in emerging economies.

Furthermore, continuous innovation in material science and manufacturing processes is leading to the development of gloves with improved chemical resistance, tactile sensitivity, comfort, and durability. This evolution ensures that protective solutions keep pace with the increasing complexity of industrial chemicals and the diverse operational demands of various end-user sectors. Factors such as the growth in infrastructure development, rising manufacturing activities, and heightened focus on regulatory enforcement regarding occupational safety worldwide are further propelling market expansion. The market is also experiencing demand for sustainable and environmentally friendly glove options, pushing manufacturers towards greener production methods and biodegradable materials where feasible.

Chemical Protective Gloves Market Executive Summary

The Chemical Protective Gloves Market is characterized by robust growth, propelled by stringent global occupational safety regulations and the expanding footprint of chemical intensive industries. Key business trends indicate a strong focus on product innovation, with manufacturers developing multi-layered gloves offering superior protection against a broader spectrum of chemicals, alongside improved ergonomic designs for enhanced wearer comfort and dexterity. Strategic collaborations, mergers, and acquisitions are common as companies seek to consolidate market share, expand product portfolios, and penetrate new geographical regions. There is a discernible shift towards sustainable manufacturing practices and the development of eco-friendly materials, addressing growing environmental concerns and consumer demand for responsible sourcing. Digitalization is influencing supply chain management, improving efficiency and responsiveness to market fluctuations, while advanced analytics aid in predicting demand patterns.

Regionally, Asia Pacific is emerging as a significant growth engine, driven by rapid industrialization, burgeoning manufacturing sectors in countries like China and India, and increasing adoption of international safety standards. North America and Europe, while mature markets, continue to demonstrate steady demand, primarily owing to strict regulatory frameworks, high levels of industrial automation, and continuous investments in research and development for advanced protective solutions. Latin America, the Middle East, and Africa are showing promising growth potential, fueled by expanding industrial bases and increasing awareness about workplace safety. Government initiatives and public health campaigns are also playing a pivotal role in augmenting the demand for chemical protective gloves in these developing regions.

Segmentation trends highlight the dominance of nitrile and neoprene gloves due to their versatility, durability, and broad chemical resistance, making them suitable for a wide range of applications. The chemical and pharmaceutical industries remain the largest end-user segments, with consistent demand for high-performance gloves. However, the food processing, automotive, and healthcare sectors are also exhibiting significant uptake, driven by their respective safety protocols and hygiene requirements. The reusable segment is gaining traction over disposable options in certain industrial settings, prompted by cost-effectiveness over the long term and reduced environmental impact. Technological advancements are also allowing for the production of thinner yet equally protective gloves, addressing concerns around tactile sensitivity and wearer fatigue, thereby enhancing overall compliance in demanding work environments.

AI Impact Analysis on Chemical Protective Gloves Market

User questions regarding AI's impact on the Chemical Protective Gloves Market primarily revolve around how artificial intelligence can enhance safety, optimize manufacturing, and improve product performance. Key themes include the potential for AI-driven quality control, smart material development, predictive maintenance for glove longevity, and personalized glove recommendations based on specific chemical exposure data and user biometrics. Users express interest in whether AI can lead to more efficient supply chains, reduce waste, and develop "smart gloves" with integrated sensors for real-time hazard detection or physiological monitoring. There is also curiosity about AI's role in compliance and training, automating risk assessment, and ensuring workers select and use the most appropriate protection. Overall, expectations are high for AI to usher in a new era of proactive safety and customized, high-performance protective solutions, addressing concerns about current limitations in glove selection, monitoring, and material innovation.

- AI can revolutionize quality control in manufacturing by identifying defects in gloves with greater precision and speed than manual inspection, reducing the incidence of faulty products reaching end-users.

- Predictive analytics powered by AI can optimize inventory management and supply chain logistics, forecasting demand more accurately and ensuring timely delivery of specialized gloves to various industries.

- AI-driven material science can accelerate the discovery and development of novel polymers and composites with enhanced chemical resistance, durability, and comfort, leading to next-generation protective gloves.

- Integration of AI into smart glove technology could enable real-time detection of chemical permeation, temperature changes, or even physiological stress of the wearer, providing immediate alerts for enhanced safety.

- AI algorithms can analyze vast datasets of chemical hazards and workplace conditions to provide highly customized glove recommendations, improving the efficacy of PPE selection for specific tasks.

- Training and compliance can be enhanced through AI-powered simulation and virtual reality platforms, offering interactive scenarios for workers to learn proper glove usage and maintenance.

- Automated visual inspection systems using AI cameras can ensure consistent quality during production, minimizing human error and upholding rigorous safety standards.

- AI can optimize manufacturing processes by analyzing production data, identifying bottlenecks, and suggesting improvements to reduce waste and energy consumption, leading to more sustainable operations.

DRO & Impact Forces Of Chemical Protective Gloves Market

The Chemical Protective Gloves Market is significantly influenced by a complex interplay of Drivers, Restraints, and Opportunities, which collectively shape its growth trajectory and competitive landscape. A primary driver is the stringent and continuously evolving occupational safety regulations mandated by governmental bodies and international organizations worldwide. These regulations compel industries handling hazardous chemicals to implement robust personal protective equipment (PPE) protocols, directly increasing the demand for certified chemical protective gloves. The rapid expansion of chemical manufacturing, pharmaceutical production, oil and gas, and automotive industries, particularly in emerging economies, further fuels this demand as more workers are exposed to chemical risks. Growing awareness among employers and employees about the importance of workplace safety and the adverse health effects of chemical exposure also acts as a crucial driver, leading to higher adoption rates of quality protective gear. Innovations in material science, leading to the development of gloves with enhanced chemical resistance, dexterity, and comfort, also stimulate market growth by offering superior protection and user satisfaction.

However, the market faces several restraints. The volatile prices of raw materials, such as nitrile, latex, and petroleum-derived polymers, can impact manufacturing costs and, consequently, the final product prices, potentially hindering market expansion, especially for price-sensitive buyers. The challenge of proper disposal and recyclability of used chemical protective gloves, many of which are single-use and contaminated with hazardous substances, poses an environmental concern and increases operational costs for end-users. Additionally, the availability of low-quality, counterfeit products in the market, particularly in less regulated regions, poses a risk to worker safety and creates price competition for legitimate manufacturers. The lack of standardized testing methods across all regions for chemical permeation and degradation can also create confusion and hinder informed purchasing decisions, affecting market trust and growth.

Despite these restraints, significant opportunities exist for market players. The increasing demand for specialized gloves tailored for niche applications, such as ultra-cold environments, high-temperature chemical handling, or specific chemical mixtures, presents avenues for product diversification and premiumization. The growing focus on sustainability and green manufacturing practices encourages innovation in biodegradable and recyclable glove materials, aligning with corporate social responsibility goals and attracting environmentally conscious customers. Furthermore, the untapped potential in developing regions, where industrialization is on the rise and safety standards are gradually being implemented, offers substantial growth prospects. Strategic collaborations between glove manufacturers and chemical companies to develop highly specific protective solutions, along with leveraging advanced manufacturing technologies like automation and AI for improved production efficiency and quality, represent promising avenues for market expansion. The integration of smart technologies into gloves for real-time monitoring of chemical exposure or glove integrity is another emerging opportunity poised to redefine the market.

Segmentation Analysis

The Chemical Protective Gloves Market is comprehensively segmented across various parameters, including material type, application, end-user industry, and reusability, to provide a detailed understanding of its dynamics. This segmentation helps identify key growth areas, consumer preferences, and technological shifts within the market. Each segment responds differently to market drivers and restraints, offering unique opportunities and challenges for manufacturers and suppliers. Understanding these segments is crucial for strategic planning, product development, and targeted marketing efforts, enabling companies to cater to the diverse and evolving needs of industries requiring chemical hand protection. The market's complexity necessitates a granular view of these categories to effectively analyze competitive landscapes and future growth trajectories.

- By Material Type

- Nitrile Gloves: High puncture resistance, chemical resistance to many solvents and oils, commonly used in healthcare, automotive, and chemical industries.

- Latex Gloves: Excellent elasticity, tactile sensitivity, often used in medical and laboratory settings, but prone to latex allergies.

- Butyl Rubber Gloves: Superior resistance to ketones, esters, and strong acids; ideal for highly corrosive chemical handling.

- Neoprene Gloves: Good resistance to acids, caustics, alcohols, and some organic solvents, offering flexibility and comfort.

- PVC (Polyvinyl Chloride) Gloves: Cost-effective, good abrasion resistance, suitable for mild chemical protection.

- Viton Gloves: Highest resistance to chlorinated and aromatic solvents, specific to highly aggressive chemicals.

- Others: Include PVA, natural rubber, and multi-layer composites designed for specific chemical cocktails.

- By Application

- Chemical Manufacturing: Protection against a wide range of industrial chemicals, acids, and alkalis.

- Pharmaceutical & Biotechnology: Sterile handling, protection against laboratory reagents and drug compounds.

- Oil & Gas: Resistance to hydrocarbons, solvents, and crude oil in drilling and refining operations.

- Automotive: Protection from oils, greases, brake fluids, and industrial cleaners during manufacturing and maintenance.

- Healthcare: Used in hospitals and clinics for handling disinfectants and pharmaceuticals, often disposable.

- Food Processing: Protection from cleaning agents and food-grade chemicals, emphasizing hygiene and safety.

- Laboratories: General chemical handling in research and academic settings.

- Others: Including electronics, mining, agriculture, and construction industries.

- By Reusability

- Disposable Gloves: Single-use, typically thinner, used in environments requiring high hygiene or quick changes.

- Reusable Gloves: Thicker, more durable, designed for repeated use after decontamination, common in heavy industrial settings.

Value Chain Analysis For Chemical Protective Gloves Market

The value chain for the Chemical Protective Gloves Market is a multifaceted network encompassing several critical stages, from raw material sourcing to the final delivery and end-use of the product. Upstream analysis begins with the procurement of essential raw materials, which include various polymers such as nitrile butadiene rubber (NBR), natural latex, neoprene, butyl rubber, PVC, and specialized additives. Key suppliers in this segment are chemical companies and petrochemical firms that provide these base materials. The quality and cost of these raw materials significantly influence the final product characteristics and pricing. This stage is crucial as the performance of the gloves directly depends on the chemical properties and consistency of these foundational components. Relationships with multiple reliable raw material suppliers are vital to ensure supply chain resilience and mitigate risks associated with price fluctuations or material shortages.

The core of the value chain is the manufacturing process, where raw materials are transformed into finished chemical protective gloves. This involves processes such as compounding, dipping, molding, curing, washing, and packaging. Manufacturers, ranging from large multinational corporations to specialized regional players, invest heavily in R&D to develop gloves with improved chemical resistance, tactile sensitivity, ergonomic design, and durability. Automation and advanced manufacturing technologies play an increasing role in optimizing production efficiency and maintaining consistent quality. Downstream analysis focuses on how these manufactured gloves reach the end-users. The distribution channel is diverse, primarily involving direct sales to large industrial clients, indirect sales through wholesalers, distributors, and safety equipment retailers. E-commerce platforms are also gaining prominence, offering a wider reach and convenience for smaller businesses and individual purchasers. Value-added services such as technical support, product training, and waste management solutions are often integrated into the downstream activities to enhance customer experience.

Direct distribution typically involves large manufacturers selling directly to major industrial consumers such as chemical plants, pharmaceutical companies, or automotive factories. This allows for closer customer relationships, better understanding of specific needs, and often includes customized product offerings or bulk purchasing agreements. Indirect distribution leverages a network of specialized safety product distributors who have expertise in serving a broad customer base, including smaller businesses, laboratories, and individual tradespeople. These distributors often maintain inventories, provide local delivery services, and offer a range of complementary PPE products, making them a crucial link in reaching diverse market segments. Both direct and indirect channels are critical for market penetration and ensuring widespread availability of chemical protective gloves across various industries and geographical regions, with channel selection often depending on market maturity, customer size, and regional infrastructure.

Chemical Protective Gloves Market Potential Customers

Potential customers for the Chemical Protective Gloves Market encompass a vast array of industries and professional settings where exposure to hazardous chemicals is a routine or potential risk. These end-users prioritize worker safety, regulatory compliance, and the prevention of chemical-related injuries or contamination. The primary buyers are organizations and institutions that operate in environments where chemicals are manufactured, processed, utilized, or stored, necessitating a reliable barrier of protection for their workforce. This broad customer base is characterized by varying requirements in terms of glove material, chemical resistance profile, dexterity, and reusability, reflecting the diverse nature of chemical hazards and operational tasks across different sectors. Understanding these distinct customer needs is paramount for manufacturers to tailor their product offerings and marketing strategies effectively.

Key segments of end-users include the chemical manufacturing industry, where employees handle corrosive acids, strong alkalis, and organic solvents daily during production and handling. The pharmaceutical and biotechnology sectors are also significant consumers, requiring gloves for laboratory research, drug synthesis, and sterile manufacturing processes where chemical purity and contamination prevention are critical. The oil and gas industry, from exploration and drilling to refining and transportation, uses these gloves to protect against hydrocarbons, solvents, and fuel additives. Additionally, the automotive sector utilizes them during manufacturing processes involving paints, solvents, and degreasers, while the food processing industry requires them for handling cleaning agents and various food additives, with an emphasis on hygiene and compliance with food safety standards. Healthcare facilities, including hospitals and laboratories, also represent a substantial customer base, needing protection against disinfectants, medical chemicals, and biological hazards. Other important segments include agriculture for pesticide handling, electronics manufacturing for precision work with chemicals, and emergency services personnel responding to hazardous material incidents.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 9.85 Billion |

| Market Forecast in 2032 | USD 15.60 Billion |

| Growth Rate | 6.7% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Ansell Limited, Kimberly-Clark Corporation, Lakeland Industries Inc., Honeywell International Inc., 3M Company, DuPont de Nemours Inc., Top Glove Corporation Bhd, Hartalega Holdings Berhad, Kossan Rubber Industries Bhd, Supermax Corporation Berhad, SHIELD Scientific, MSA Safety Inc., Uvex Safety Group, SHOWA Group, Riverstone Holdings Limited, ATG Gloves, Sempermed USA Inc., Superior Glove Works Ltd., Dynarex Corporation, Cardinal Health Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chemical Protective Gloves Market Key Technology Landscape

The Chemical Protective Gloves Market is continuously evolving through significant technological advancements aimed at enhancing protection, comfort, and sustainability. A key area of innovation lies in material science, with manufacturers developing advanced polymer blends and multi-layer glove constructions that offer superior resistance to a broader spectrum of chemicals, including aggressive acids, bases, and organic solvents. This involves optimizing polymer chain structures and incorporating novel additives to improve permeation resistance and degradation performance without compromising tactile sensitivity or flexibility. Nanotechnology is also being explored to create ultra-thin barrier layers and surface coatings that provide enhanced chemical repellency and antimicrobial properties, leading to more effective and hygienic gloves. These material innovations are crucial for addressing the increasing complexity and variety of chemical hazards faced across various industrial settings, while also meeting the demand for lighter and more comfortable PPE.

Furthermore, manufacturing processes are benefiting from automation and precision engineering. Robotic dipping and molding techniques ensure greater consistency in glove thickness and material distribution, minimizing weak spots and enhancing overall product reliability. Ergonomic design is another critical technological focus, utilizing advanced computational modeling to create gloves that fit more naturally, reduce hand fatigue, and improve dexterity, thereby encouraging higher rates of worker compliance and productivity. Innovations also extend to the development of smart gloves, which incorporate embedded sensors or conductive materials to detect chemical permeation in real-time, monitor glove integrity, or even track physiological data of the wearer. While still in nascent stages, these intelligent solutions promise to revolutionize proactive safety measures by providing immediate alerts and data for risk assessment, moving beyond passive protection to active hazard mitigation.

Beyond the product itself, technological advancements are impacting the entire lifecycle of chemical protective gloves. Traceability technologies, such as RFID or QR codes, are being integrated to manage inventory, track usage, and facilitate proper disposal, particularly for reusable gloves or those used with highly toxic substances. Sustainable manufacturing practices are gaining traction, driven by demand for eco-friendly products and reduced environmental impact. This includes the development of biodegradable polymers, recycling programs for certain glove types, and energy-efficient production processes. These technological shifts are not only addressing immediate safety needs but are also aligning with broader industry trends towards smart manufacturing, environmental stewardship, and data-driven decision-making in occupational health and safety. The ongoing research into next-generation materials and integrated smart features is poised to redefine the capabilities and expectations for chemical protective gloves in the coming years.

Regional Highlights

- North America: A mature market characterized by stringent occupational safety regulations (OSHA, ANSI standards) and high industrial automation. The presence of robust chemical, pharmaceutical, and automotive industries drives consistent demand. Focus on premium, high-performance gloves and continuous innovation in materials and smart technologies. The United States and Canada are key contributors due to extensive manufacturing bases and a strong emphasis on worker safety.

- Europe: Similar to North America, Europe boasts strict regulatory frameworks (REACH, EN standards) and a strong emphasis on worker health and safety. Countries like Germany, France, and the UK are major consumers due to their advanced chemical, automotive, and healthcare sectors. High demand for specialized gloves meeting specific chemical resistance standards and growing interest in sustainable and eco-friendly products.

- Asia Pacific (APAC): The fastest-growing region, propelled by rapid industrialization and manufacturing expansion in countries such as China, India, Japan, and South Korea. Increasing awareness of workplace safety, coupled with evolving regulatory landscapes, is boosting demand. Significant investment in infrastructure and a booming chemicals and pharmaceuticals sector contribute to high consumption, with a balance between cost-effectiveness and performance.

- Latin America: An emerging market experiencing steady growth due to expanding industrial activities in countries like Brazil, Mexico, and Argentina. Growing awareness of occupational safety standards and increasing foreign investment in manufacturing and chemical industries are driving demand. While price sensitivity is a factor, the emphasis on quality and compliance is gradually increasing.

- Middle East and Africa (MEA): This region shows significant potential, particularly in the Gulf Cooperation Council (GCC) countries, driven by robust oil and gas, petrochemical, and construction industries. Investments in industrial diversification and the adoption of international safety practices are contributing to market expansion. South Africa also represents a key market within the African continent due to its developed industrial base.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chemical Protective Gloves Market.- Ansell Limited

- Kimberly-Clark Corporation

- Lakeland Industries Inc.

- Honeywell International Inc.

- 3M Company

- DuPont de Nemours Inc.

- Top Glove Corporation Bhd

- Hartalega Holdings Berhad

- Kossan Rubber Industries Bhd

- Supermax Corporation Berhad

- SHIELD Scientific

- MSA Safety Inc.

- Uvex Safety Group

- SHOWA Group

- Riverstone Holdings Limited

- ATG Gloves

- Sempermed USA Inc.

- Superior Glove Works Ltd.

- Dynarex Corporation

- Cardinal Health Inc.

Frequently Asked Questions

What is the projected growth rate for the Chemical Protective Gloves Market?

The Chemical Protective Gloves Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.7% between 2025 and 2032, driven by increasing industrial safety demands and technological advancements.

Which industries are the primary end-users of chemical protective gloves?

The primary end-users include the chemical manufacturing, pharmaceutical & biotechnology, oil & gas, automotive, healthcare, and food processing industries, all requiring specialized hand protection against hazardous substances.

What are the key drivers for the Chemical Protective Gloves Market?

Key drivers include stringent occupational safety regulations, the rapid expansion of chemical-intensive industries globally, heightened worker safety awareness, and continuous innovation in glove materials and design for enhanced protection and comfort.

How is AI expected to impact the Chemical Protective Gloves Market?

AI is expected to impact the market by enhancing quality control, accelerating smart material development, optimizing supply chain management, and enabling smart gloves with real-time chemical detection capabilities for improved safety and efficiency.

What are the main types of materials used in chemical protective gloves?

Common materials include nitrile, latex, butyl rubber, neoprene, PVC, and Viton, each offering specific chemical resistance properties tailored for different industrial applications and chemical hazards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager