Child Resistant Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430296 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Child Resistant Packaging Market Size

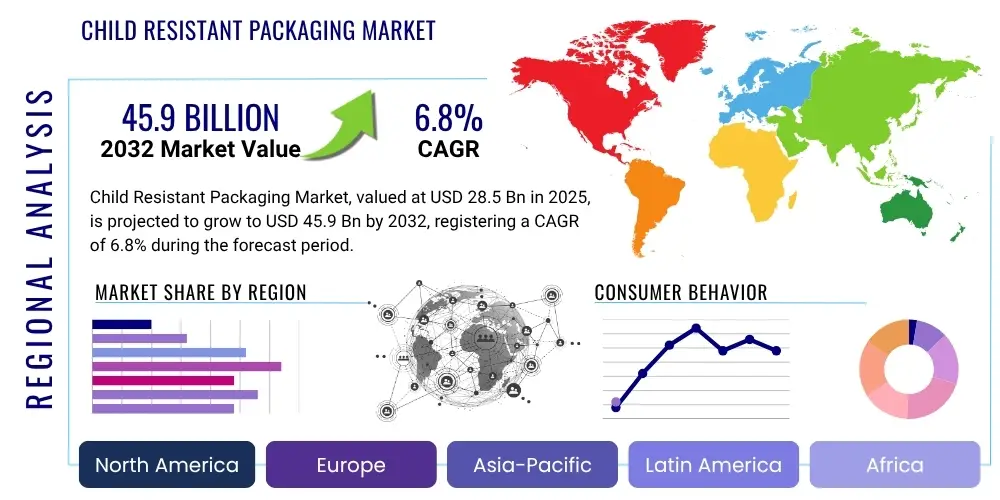

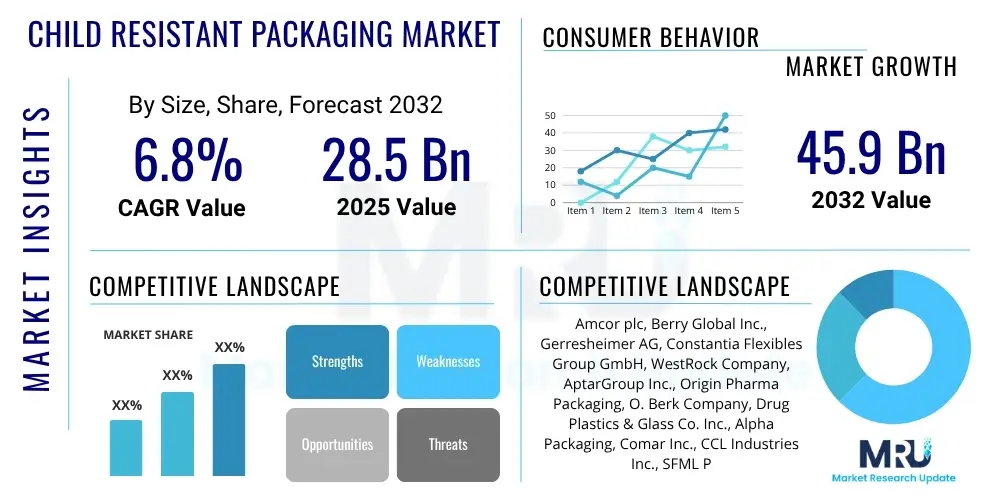

The Child Resistant Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $28.5 billion in 2025 and is projected to reach $45.9 billion by the end of the forecast period in 2032.

Child Resistant Packaging Market introduction

The Child Resistant Packaging (CRP) market is a critical segment of the packaging industry, driven primarily by stringent regulatory requirements and growing public awareness concerning child safety. These specialized packaging solutions are meticulously designed to prevent children under a certain age from gaining access to potentially harmful products, while simultaneously allowing adults to open them without undue difficulty. This dual functionality is achieved through innovative designs that often incorporate specific mechanisms, requiring a sequence of motions or a degree of dexterity that young children typically lack. The market encompasses a vast array of product types and materials, tailored to the unique demands of various end-use sectors, thereby ensuring compliance and enhancing consumer trust.

Major applications of child resistant packaging span across diverse industries, including pharmaceuticals, cannabis products, household chemicals, automotive fluids, and certain cosmetic items. In pharmaceuticals, CRP is indispensable for preventing accidental ingestion of medications by toddlers. Similarly, with the global legalization and regulation of cannabis, child resistant features have become mandatory to protect children from accidental exposure. The benefits of adopting child resistant packaging are multifaceted; paramount among them is the prevention of accidental poisonings and injuries in children, which in turn leads to a significant reduction in healthcare costs and improved public health outcomes. Beyond safety, CRP helps companies meet legal obligations, avoid costly product recalls, mitigate legal liabilities, and build a reputation as a responsible and safety-conscious brand.

The driving factors behind the sustained growth of the Child Resistant Packaging Market are deeply rooted in the escalating global focus on product safety and consumer protection. Increasingly stringent governmental regulations, such as those imposed by the Poison Prevention Packaging Act (PPPA) in the United States and similar directives in Europe and Asia Pacific, mandate the use of CRP for a widening range of products. Furthermore, rising consumer awareness about the dangers of unsupervised access to hazardous substances, coupled with the expansion of industries requiring such packaging, particularly the burgeoning legal cannabis market and the ever-present pharmaceutical sector, continuously fuel demand. Technological advancements enabling more intuitive yet secure designs, alongside the integration of sustainable materials, also serve as significant growth accelerators.

Child Resistant Packaging Market Executive Summary

The Child Resistant Packaging Market is experiencing robust expansion, propelled by an evolving landscape of regulatory frameworks, heightened consumer safety consciousness, and innovation in packaging design. Business trends within this sector are characterized by a strong emphasis on compliance, sustainability, and user-friendliness. Manufacturers are continually investing in research and development to create packaging solutions that not only meet stringent child-resistant standards but also address adult accessibility challenges and environmental concerns. The integration of advanced materials, smart technologies, and customizable designs is shaping the competitive dynamics, with companies striving to offer holistic solutions that balance safety, functionality, and brand aesthetics. Furthermore, there is a growing trend towards flexible packaging formats, driven by their cost-effectiveness and versatility.

Regional trends indicate North America and Europe as dominant forces in the market, primarily due to their mature regulatory environments and well-established pharmaceutical and chemical industries. The rapid legalization and commercialization of cannabis products across various U.S. states and Canadian provinces have significantly bolstered the demand for specialized child resistant packaging solutions in North America. Europe benefits from harmonized safety standards and a strong focus on consumer protection. Asia Pacific is emerging as the fastest-growing region, fueled by increasing disposable incomes, expanding pharmaceutical manufacturing capabilities, and a gradual tightening of product safety regulations, particularly in populous countries like China and India. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as industrialization and regulatory awareness improve.

Segment trends reveal that the pharmaceutical sector remains the largest end-user of child resistant packaging, driven by the critical need to protect children from medication overdose. However, the cannabis industry is rapidly gaining prominence, with mandatory child resistant packaging requirements across all legal cannabis products, including edibles, concentrates, and flower. In terms of materials, plastics, particularly polypropylene (PP) and high-density polyethylene (HDPE), dominate due to their versatility, cost-effectiveness, and ease of molding into complex child-resistant mechanisms. Nevertheless, there is a visible shift towards more sustainable alternatives, such as recycled plastics, bio-plastics, and paper-based solutions, as environmental concerns become a paramount consideration for brands and consumers alike. Closure types, such as push and turn, squeeze and turn, and reclosable zippers, continue to evolve, offering enhanced safety features and improved adult usability, contributing to the overall market dynamism.

AI Impact Analysis on Child Resistant Packaging Market

User inquiries regarding AI's impact on the Child Resistant Packaging Market frequently revolve around how artificial intelligence can enhance design efficiency, improve compliance verification, optimize manufacturing processes, and contribute to more sophisticated safety features. There's significant interest in whether AI can accelerate the development of innovative child resistant mechanisms, predict potential failure points in packaging designs, or even personalize safety instructions for adult users. Common concerns include the cost of AI implementation, data privacy for smart packaging, and the need for human oversight in critical safety applications. Users expect AI to reduce human error, streamline regulatory approval processes, and offer new avenues for creating packaging that is both safe for children and convenient for adults, alongside potential advancements in preventing counterfeiting and improving supply chain visibility.

- AI-driven generative design tools can rapidly prototype and optimize child resistant packaging mechanisms, significantly reducing development cycles and costs.

- Predictive analytics powered by AI can analyze extensive data on packaging failures and user interactions to identify design flaws and enhance safety efficacy before mass production.

- AI-enabled quality control systems utilize computer vision to detect microscopic defects or inconsistencies in manufacturing, ensuring every package meets stringent child resistant standards.

- Smart packaging integrated with AI, such as NFC or QR codes linked to AI platforms, can provide personalized opening instructions for adults, improve traceability, and manage product recalls more effectively.

- AI algorithms can optimize material usage and manufacturing processes, leading to reduced waste, lower production costs, and greater sustainability in child resistant packaging solutions.

- Supply chain optimization using AI can predict demand fluctuations, manage inventory for critical packaging components, and improve logistics, ensuring timely delivery of compliant packaging.

- AI can facilitate regulatory compliance by instantly cross-referencing new designs with updated global child resistant packaging standards and providing automated reports.

DRO & Impact Forces Of Child Resistant Packaging Market

The Child Resistant Packaging (CRP) market is significantly influenced by a complex interplay of drivers, restraints, and opportunities, all shaped by various impact forces. The primary drivers include the escalating global demand for product safety, largely stemming from public health initiatives and increasing consumer awareness regarding accidental poisoning in children. Furthermore, the pervasive and evolving nature of governmental regulations, such as the Poison Prevention Packaging Act (PPPA) in the U.S. and similar mandates worldwide, necessitates the use of CRP for a broader range of products. The rapid expansion of industries handling potentially hazardous substances, particularly the pharmaceutical sector and the burgeoning legal cannabis market, also acts as a powerful catalyst for market growth, driving continuous innovation and adoption of advanced child resistant solutions to ensure compliance and consumer protection.

However, the market faces several notable restraints that temper its growth trajectory. The inherent complexity in designing child resistant features that are simultaneously difficult for children to open yet easy for adults to operate presents a significant engineering challenge, often leading to higher research and development costs. Manufacturing child resistant packaging typically involves specialized machinery and processes, contributing to elevated production expenses compared to standard packaging. Additionally, concerns regarding adult usability, particularly for elderly or physically challenged individuals, sometimes lead to consumer frustration and necessitate careful design considerations to ensure accessibility without compromising child safety. The ongoing challenge of balancing regulatory stringency with practical functionality and cost-effectiveness remains a persistent restraint for market participants.

Despite these challenges, the Child Resistant Packaging Market is rife with compelling opportunities that promise future expansion and innovation. The increasing demand for sustainable packaging solutions opens avenues for developing child resistant packaging from recycled, biodegradable, or bio-based materials, aligning with global environmental objectives and consumer preferences for eco-friendly products. The advent of smart packaging technologies, integrating features like QR codes, NFC tags, or tamper-evident seals with child resistant mechanisms, offers potential for enhanced traceability, brand protection, and improved consumer engagement. Moreover, the growth of emerging markets, coupled with rising awareness and the gradual implementation of stricter safety regulations in developing countries, presents significant untapped potential for CRP manufacturers. Strategic collaborations and investments in advanced manufacturing techniques also offer opportunities for market players to develop more efficient and cost-effective child resistant solutions, catering to a wider array of industrial and consumer needs.

Segmentation Analysis

The Child Resistant Packaging Market is broadly segmented based on several key characteristics, providing a granular view of its diverse landscape. These segments include product type, material, end-use industry, and closure type. Each segment reflects distinct market dynamics, driven by varying regulatory requirements, cost considerations, application-specific needs, and technological advancements. This multi-faceted segmentation helps to understand the market’s structure, identify specific growth opportunities, and track the adoption patterns of child resistant solutions across different sectors and geographies, enabling market players to tailor their offerings effectively.

- By Type:

- Blister Packaging

- Bottles and Jars

- Cartons and Boxes

- Bags and Pouches

- Cans and Tubes

- Other Types (e.g., clamshells, aerosols)

- By Material:

- Plastics (HDPE, PP, PET, PVC, Others)

- Paper and Paperboard

- Metal (Aluminum, Steel)

- Glass

- Other Materials (e.g., Composites)

- By End-Use Industry:

- Pharmaceuticals

- Cannabis Products

- Household Chemicals and Cleaners

- Automotive Products

- Cosmetics and Personal Care

- Nutraceuticals

- Other Consumer Goods

- By Closure Type:

- Push and Turn Closures

- Squeeze and Turn Closures

- Reclosable Zipper Closures

- Snap Closures

- Tear Away/Peel Off Closures

- Blister Packs with Peelable Lidding

- Other Closure Mechanisms

Value Chain Analysis For Child Resistant Packaging Market

The value chain for the Child Resistant Packaging Market is a comprehensive network of activities that spans from raw material sourcing to the end-user consumption, encompassing multiple stages of transformation and distribution. The upstream segment of the value chain involves the procurement of various raw materials, including plastic resins such as HDPE, PP, and PET from petrochemical companies, paper and paperboard from pulp and paper manufacturers, metals like aluminum and steel from primary producers, and glass from specialized suppliers. These raw material providers form the foundational base of the industry, supplying essential components that are crucial for the structural integrity and functionality of child resistant features. Key activities at this stage focus on securing high-quality, consistent, and cost-effective materials, often involving long-term contracts and strategic partnerships to ensure supply stability and adherence to specific material specifications required for child resistant properties. Innovation in this segment also includes the development of sustainable and recycled content materials to meet evolving market demands.

Moving downstream, the value chain progresses through the manufacturing and converting stages, where these raw materials are transformed into finished child resistant packaging products. This involves specialized processes such as injection molding, blow molding, thermoforming, and advanced printing techniques to create the intricate designs and mechanisms characteristic of child resistant features. Packaging manufacturers and converters often possess specialized expertise and machinery to produce compliant solutions, from child resistant closures to complex blister packs and flexible pouches. After manufacturing, the products are distributed to end-use industries. Distribution channels can be direct, where packaging manufacturers sell directly to large pharmaceutical companies, cannabis producers, or chemical manufacturers with significant volume requirements. Alternatively, indirect channels involve working through a network of packaging distributors, brokers, or wholesalers who serve a broader customer base, including smaller businesses or those with specific logistical needs. E-commerce platforms are also emerging as significant indirect channels, especially for standardized child resistant products. This dual approach ensures wide market reach, catering to diverse customer sizes and geographic locations, while navigating regulatory complexities in different regions.

Child Resistant Packaging Market Potential Customers

The primary potential customers and end-users of child resistant packaging solutions are diverse, encompassing a wide array of industries that produce or distribute products posing potential hazards to children. The most significant customer segment is the pharmaceutical industry, including both prescription and over-the-counter (OTC) drug manufacturers, who are legally mandated to package nearly all their oral medications in child resistant containers to prevent accidental poisonings. This segment requires a broad range of solutions, from push-and-turn bottles to peelable blister packs, tailored to specific drug formulations and dosage forms. The rapidly expanding legal cannabis industry also represents a major customer base, with stringent regulations requiring child resistant packaging for all cannabis-infused products, including edibles, concentrates, and flower, driving demand for innovative and secure solutions that also preserve product integrity and appeal.

Beyond pharmaceuticals and cannabis, manufacturers of household chemicals and cleaning products constitute a substantial customer segment. Products such as detergents, disinfectants, drain cleaners, and automotive fluids are highly toxic if ingested by children, making child resistant caps and containers essential for public safety and regulatory compliance. The agricultural sector also utilizes child resistant packaging for pesticides and other hazardous chemicals. Furthermore, certain cosmetic and personal care products, particularly those containing potent ingredients or in attractive formulations that might appeal to children, increasingly adopt child resistant features. This diverse customer landscape underscores the pervasive need for child resistant packaging across multiple sectors, driven by a universal commitment to child safety and adherence to a continually evolving global regulatory environment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $28.5 billion |

| Market Forecast in 2032 | $45.9 billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Amcor plc, Berry Global Inc., Gerresheimer AG, Constantia Flexibles Group GmbH, WestRock Company, AptarGroup Inc., Origin Pharma Packaging, O. Berk Company, Drug Plastics & Glass Co. Inc., Alpha Packaging, Comar Inc., CCL Industries Inc., SFML Plastics, Tekni-Plex Inc., Pretium Packaging LLC, Mold Rite Plastics, Caps & Closures, Global Closure Systems, RPC Group Plc, SGD Pharma |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Child Resistant Packaging Market Key Technology Landscape

The Child Resistant Packaging Market is characterized by a dynamic technology landscape, constantly evolving to meet stricter safety standards, improve user experience, and embrace sustainability. Core technologies primarily involve advanced molding processes such as injection molding, blow molding, and thermoforming, which are crucial for creating the precise and intricate components of child resistant closures and containers. These technologies enable the production of complex geometries that require specific force or multiple steps to open, making them challenging for young children. Furthermore, innovations in material science play a vital role, including the development of multi-layer co-extruded plastics for barrier protection, high-strength polymers for enhanced durability, and an increasing focus on incorporating recycled content (PCR) and bio-based plastics to improve the environmental profile of packaging solutions while maintaining child safety efficacy.

Beyond manufacturing processes and materials, the technology landscape is expanding into digital and smart packaging solutions. Digital printing technologies offer greater flexibility for customized designs, variable data printing, and enhanced brand aesthetics, which can be integrated with child resistant features. The incorporation of smart technologies like RFID (Radio-Frequency Identification) and NFC (Near Field Communication) tags, along with serialized QR codes, allows for enhanced product traceability, anti-counterfeiting measures, and provides opportunities for consumer engagement through interactive features or accessible opening instructions for adults. Advanced testing methodologies, including sophisticated simulation software and precise mechanical testing equipment, are also integral to verifying the child resistant efficacy and adult-friendliness of new designs. These technological advancements collectively drive the market forward by improving safety, efficiency, and sustainability across the child resistant packaging ecosystem.

Regional Highlights

The global Child Resistant Packaging Market exhibits diverse growth patterns and regulatory landscapes across various key regions, each contributing uniquely to the overall market trajectory. North America currently stands as a dominant region, largely driven by the stringent regulatory environment in the United States and Canada. The Poison Prevention Packaging Act (PPPA) in the U.S. mandates child resistant packaging for a wide array of household products, pharmaceuticals, and cannabis items, creating a robust and consistent demand. The rapid legalization of cannabis across numerous U.S. states and Canadian provinces has particularly spurred innovation and demand for specialized child resistant solutions that not only comply with safety regulations but also maintain brand appeal and product integrity, making it a pivotal growth engine for the market.

Europe represents another significant market for child resistant packaging, characterized by a mature regulatory framework and a high degree of consumer awareness regarding product safety. Directives from the European Union, such as those related to chemicals (CLP Regulation) and pharmaceuticals, impose strict requirements for child resistant features on hazardous products. Countries like Germany, France, and the UK are prominent consumers of child resistant packaging, driven by their well-established pharmaceutical and chemical industries. The region is also witnessing a growing emphasis on sustainable packaging, pushing manufacturers to innovate with eco-friendly materials that still meet demanding child safety standards. The harmonization of standards across EU member states ensures consistency in market requirements, facilitating cross-border trade and development.

The Asia Pacific (APAC) region is projected to be the fastest-growing market for child resistant packaging during the forecast period. This growth is attributable to several factors, including rapid industrialization, expanding pharmaceutical manufacturing bases, and increasing disposable incomes leading to higher consumption of consumer goods. While regulatory frameworks in some APAC countries are still evolving, major economies like China and India are progressively adopting stricter product safety standards, mirroring those in Western markets. This creates immense opportunities for child resistant packaging manufacturers to enter and expand within these dynamic markets. Latin America, the Middle East, and Africa (MEA) are emerging markets for child Resistant Packaging. While currently smaller in market share, these regions are experiencing gradual economic development, rising consumer awareness, and the nascent implementation of product safety regulations, signaling long-term growth potential as their industrial sectors mature.

- North America: Dominant market due to strict regulations (e.g., PPPA in the U.S.) and the rapidly expanding legal cannabis industry across the U.S. and Canada. High consumer awareness and significant pharmaceutical sector demand further contribute to its leading position.

- Europe: Strong market driven by comprehensive EU directives concerning chemical and pharmaceutical product safety. Key countries like Germany, France, and the UK show high adoption, with an increasing focus on sustainable and compliant packaging solutions.

- Asia Pacific (APAC): Fastest-growing region, fueled by rapid industrialization, burgeoning pharmaceutical manufacturing, rising disposable incomes, and the gradual adoption of stricter safety regulations in major economies like China and India.

- Latin America: Emerging market with increasing awareness of product safety and a growing pharmaceutical sector. Economic development and improving regulatory enforcement are expected to drive future growth.

- Middle East and Africa (MEA): Nascent market with significant growth potential as industrialization progresses and consumer safety standards gradually improve. Regional governments are beginning to implement more robust product safety regulations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Child Resistant Packaging Market.- Amcor plc

- Berry Global Inc.

- Gerresheimer AG

- Constantia Flexibles Group GmbH

- WestRock Company

- AptarGroup Inc.

- Origin Pharma Packaging

- O. Berk Company

- Drug Plastics & Glass Co. Inc.

- Alpha Packaging

- Comar Inc.

- CCL Industries Inc.

- SFML Plastics

- Tekni-Plex Inc.

- Pretium Packaging LLC

- Mold Rite Plastics

- Caps & Closures

- Global Closure Systems

- RPC Group Plc

- SGD Pharma

Frequently Asked Questions

Analyze common user questions about the Child Resistant Packaging market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of the Child Resistant Packaging Market?

The market is primarily driven by stringent global regulatory mandates, such as the Poison Prevention Packaging Act (PPPA), increasing public and parental awareness of child safety concerning hazardous products, and the continuous expansion of industries requiring secure packaging, particularly pharmaceuticals and the legal cannabis sector.

How do regulatory mandates influence CRP market growth?

Regulatory mandates are a fundamental growth driver, as they legally compel manufacturers across various industries to implement child resistant features for products that could harm children. These evolving regulations expand the scope of products requiring CRP and drive innovation to meet stringent compliance standards globally.

What role do sustainable materials play in child resistant packaging?

Sustainable materials are increasingly crucial in CRP. There's a growing demand for packaging made from recycled plastics (PCR), bio-based polymers, and easily recyclable paperboard. Manufacturers are actively researching and developing solutions that balance child safety efficacy with environmental responsibility, driven by consumer preference and corporate sustainability goals.

What are the key challenges faced by manufacturers in this market?

Manufacturers face challenges in designing packaging that is both child resistant and adult-friendly, which can be complex and costly. Other challenges include adhering to diverse international regulatory standards, managing high manufacturing costs for specialized components, and integrating sustainable materials without compromising safety or functionality.

Which end-use industry is the largest consumer of child resistant packaging?

The pharmaceutical industry remains the largest end-use consumer of child resistant packaging globally. This is primarily due to the critical necessity and strict legal mandates for securely packaging medications to prevent accidental ingestion by children, encompassing a wide range of prescription and over-the-counter drugs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager