Chlorinated Methane Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430684 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Chlorinated Methane Market Size

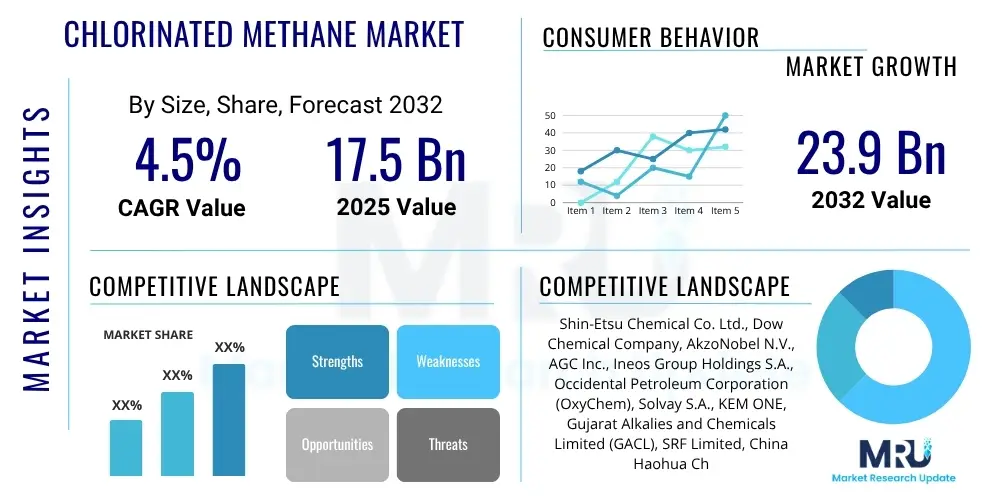

The Chlorinated Methane Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% between 2025 and 2032. The market is estimated at USD 17.5 Billion in 2025 and is projected to reach USD 23.9 Billion by the end of the forecast period in 2032.

Chlorinated Methane Market introduction

The Chlorinated Methane market encompasses a group of organic compounds derived from methane where one or more hydrogen atoms are replaced by chlorine atoms. Key products include methyl chloride (chloromethane), methylene chloride (dichloromethane), chloroform (trichloromethane), and carbon tetrachloride (tetrachloromethane), each possessing unique chemical properties that make them indispensable across various industrial applications. These compounds serve as crucial building blocks and solvents in a wide array of manufacturing processes, contributing significantly to modern industrial economies.

Chlorinated methanes find extensive applications in sectors such as refrigerants, aerosol propellants, chemical intermediates, solvents for plastics and resins, degreasing agents, and pharmaceutical manufacturing. For instance, methylene chloride is widely used as a solvent in paint strippers and in the production of pharmaceuticals, while methyl chloride is critical in the synthesis of silicones and as an intermediate for herbicides. The versatility of these compounds, coupled with their effective solvent properties and reactivity, underpins their sustained demand across diverse end-use industries. Despite growing environmental and health scrutiny, their unique performance characteristics often make them difficult to replace entirely in certain specialized applications.

The market is primarily driven by robust growth in downstream industries such as construction, automotive, pharmaceuticals, and chemicals, particularly in emerging economies. The rising demand for silicones, refrigerants, and agrochemicals further propels market expansion. Additionally, the increasing focus on advanced manufacturing processes that rely on these chemical intermediates contributes to their continued consumption. However, the market faces challenges due to stringent environmental regulations concerning ozone depletion and toxicity, pushing manufacturers towards developing safer production methods and exploring sustainable alternatives.

Chlorinated Methane Market Executive Summary

The Chlorinated Methane Market is experiencing dynamic shifts, characterized by evolving business trends, significant regional disparities in demand and regulatory frameworks, and varied growth trajectories across its key segments. Overall, the market is poised for steady growth, driven by its critical role as an industrial solvent and chemical intermediate, particularly in rapidly industrializing regions. However, the industry is navigating increasing scrutiny over environmental impact and human health concerns, necessitating strategic adaptations from key players.

Key business trends reveal a strong emphasis on operational efficiency, feedstock optimization, and the development of more environmentally friendly production processes to mitigate regulatory pressures. Companies are investing in R&D to enhance process safety and reduce emissions, while also exploring alternative chemistries where feasible. Consolidation among smaller players and strategic partnerships aimed at improving supply chain resilience and market reach are also notable. Furthermore, the push towards a circular economy model encourages innovations in recycling and responsible disposal of chlorinated methane byproducts, aligning with global sustainability goals.

Regional trends indicate that the Asia Pacific (APAC) region is expected to lead market growth, primarily due to rapid industrialization, burgeoning chemical and pharmaceutical sectors, and robust infrastructure development in countries like China and India. North America and Europe, while mature markets, are experiencing growth driven by specialized applications and stringent regulatory compliance, often leading to higher demand for premium-grade or sustainably produced chlorinated methanes. In terms of segments, methylene chloride continues to dominate due to its wide application in pharmaceuticals and foam blowing agents, while methyl chloride sees steady demand from the silicone industry. Carbon tetrachloride, facing severe regulatory restrictions due to its ozone-depleting potential, is predominantly used for feedstock purposes in closed systems, witnessing a gradual decline in open applications.

AI Impact Analysis on Chlorinated Methane Market

Common user questions regarding AI's impact on the Chlorinated Methane Market often revolve around how artificial intelligence can address the industry's significant challenges, such as optimizing production efficiency, enhancing safety protocols, improving environmental compliance, and accelerating the development of sustainable alternatives. Users are keen to understand if AI can predict market fluctuations, optimize supply chain logistics, or even contribute to discovering novel, less hazardous chemical synthesis routes. There is also interest in AI's potential to monitor emissions and ensure regulatory adherence more effectively, thereby transforming the traditionally conservative chemical manufacturing processes.

AI's analytical capabilities can revolutionize the production of chlorinated methanes by optimizing reaction conditions, predicting equipment failures, and minimizing waste generation. Machine learning algorithms can process vast amounts of data from sensors in chemical plants, leading to predictive maintenance, improved yield rates, and reduced energy consumption. This optimization directly translates into cost savings and enhanced operational efficiency, which are critical for an industry facing tight margins and intense competition. Furthermore, AI can aid in real-time monitoring of process parameters, ensuring consistent product quality and preventing deviations that could lead to safety hazards or environmental breaches.

Beyond operational improvements, AI holds promise in addressing the environmental and health concerns associated with chlorinated methanes. AI-driven predictive modeling can simulate the environmental impact of various production scenarios, helping manufacturers identify and implement cleaner processes. Moreover, AI can accelerate the research and development of greener alternatives or more efficient capture technologies for emissions, thereby improving the industry's sustainability profile. The ability of AI to rapidly analyze complex chemical data and identify patterns can significantly reduce the time and cost associated with developing new, safer chemicals and optimizing existing ones, marking a paradigm shift in chemical innovation.

- AI-driven process optimization for enhanced yield and reduced energy consumption.

- Predictive maintenance of equipment, minimizing downtime and improving operational safety.

- Advanced analytics for real-time quality control and anomaly detection in production.

- Supply chain optimization through demand forecasting and logistics management.

- AI-assisted R&D for discovering new catalysts and greener synthesis routes.

- Enhanced environmental monitoring and emission tracking to ensure regulatory compliance.

- Improved risk assessment and safety management through data-driven insights.

DRO & Impact Forces Of Chlorinated Methane Market

The Chlorinated Methane market operates under a complex interplay of drivers, restraints, and opportunities, heavily influenced by various impact forces that shape its growth trajectory. The demand for chlorinated methanes is primarily fueled by their extensive use as industrial solvents and essential chemical intermediates across numerous end-use sectors. However, the market faces significant headwinds from increasingly stringent environmental and health regulations, which constrain production and usage, particularly for products with high ozone-depleting potential or toxic profiles.

The primary drivers include the expanding pharmaceutical industry, where methylene chloride is critical for extraction and purification processes, and the growing demand for silicones, which rely heavily on methyl chloride. The surge in construction and automotive industries, particularly in developing nations, also contributes to the demand for chlorinated methane-derived products like refrigerants and blowing agents. Conversely, strict governmental regulations such as the Montreal Protocol and various national chemical safety acts impose significant restraints, pushing industries to seek out or develop alternative substances. Concerns over occupational exposure risks and long-term environmental persistence further limit market expansion.

Opportunities for market growth lie in the development of more sustainable production technologies, such as greener chlorination processes or those utilizing renewable feedstocks, which could potentially bypass some regulatory hurdles. Furthermore, emerging applications in specialized fields requiring their unique solvent properties, where no viable alternatives exist, present niche growth avenues. Impact forces such as raw material price volatility, global economic fluctuations affecting industrial output, and geopolitical factors influencing trade policies also play a significant role in shaping the market landscape. Technological advancements in chemical synthesis and purification methods are continuously influencing the efficiency and environmental footprint of chlorinated methane production, while public perception and advocacy groups exert pressure for safer chemical management.

Segmentation Analysis

The Chlorinated Methane market is segmented to provide a granular understanding of its diverse applications and product types, reflecting the varied needs of end-use industries across different geographical regions. This segmentation helps in identifying key growth areas, understanding competitive landscapes, and formulating targeted market strategies. The market is primarily categorized based on product type, application, and end-use industry, each exhibiting unique market dynamics and growth potentials.

- By Product Type:

- Methyl Chloride (Chloromethane)

- Methylene Chloride (Dichloromethane)

- Chloroform (Trichloromethane)

- Carbon Tetrachloride (Tetrachloromethane)

- Others

- By Application:

- Refrigerants

- Solvents

- Chemical Intermediates

- Foaming Agents

- Adhesives

- Aerosol Propellants

- Pharmaceuticals

- Agriculture

- Others

- By End-Use Industry:

- Chemicals

- Pharmaceuticals

- Automotive

- Building & Construction

- Electronics

- Agriculture

- Aerospace

- Others

Value Chain Analysis For Chlorinated Methane Market

The value chain for the Chlorinated Methane Market begins with the upstream sourcing of crucial raw materials, primarily methanol and chlorine, which are typically derived from natural gas, coal, or electrolysis. Key suppliers in this segment focus on cost-effective production and reliable supply to ensure stability for downstream manufacturers. The efficiency of raw material procurement, including transportation and storage, significantly impacts the final cost and competitive positioning of chlorinated methane producers. This initial stage requires substantial capital investment in infrastructure and energy resources.

Moving downstream, the raw materials undergo various chemical processes, predominantly catalytic chlorination of methane, to produce methyl chloride, which is then further chlorinated to produce methylene chloride, chloroform, and carbon tetrachloride. Manufacturers within this stage are critical, as they transform basic chemicals into high-value chlorinated methanes using advanced chemical engineering techniques and strict quality control measures. These manufacturers also bear the responsibility for managing byproducts, waste streams, and ensuring compliance with stringent environmental and safety regulations. Their ability to innovate in production processes, optimize yields, and manage energy consumption is paramount.

The distribution channel plays a vital role in connecting manufacturers with a diverse range of end-users. This involves a complex network of logistics providers, distributors, and agents. Direct sales often occur for large industrial clients with specific bulk requirements, while indirect channels through chemical distributors serve a broader base of smaller to medium-sized enterprises. Efficient distribution, warehousing, and adherence to hazardous materials transportation regulations are crucial to ensuring timely delivery and minimizing risks. End-users, including pharmaceutical companies, manufacturers of refrigerants, solvents, and agrochemicals, then integrate these chlorinated methanes into their respective production processes, forming the final link in the value chain. The overall efficiency and sustainability of the entire chain are increasingly under scrutiny due to environmental and health concerns associated with these compounds.

Chlorinated Methane Market Potential Customers

Potential customers for chlorinated methane products span a wide array of industrial sectors, driven by the unique properties and versatility these chemicals offer as solvents, intermediates, and propellants. These end-users are typically large-scale industrial consumers requiring bulk quantities for continuous manufacturing processes. The demand profile varies significantly based on the specific type of chlorinated methane and its intended application, highlighting the diverse customer base that the market serves globally.

The pharmaceutical industry represents a significant customer segment, particularly for methylene chloride and chloroform, which are utilized as reaction solvents, extraction agents, and purifiers in the synthesis of various drugs and active pharmaceutical ingredients. Similarly, the chemical manufacturing sector relies on methyl chloride for the production of silicones, which have applications ranging from sealants and lubricants to medical devices and electronics. Other chemical companies also use chlorinated methanes as intermediates for the synthesis of fluorocarbons, herbicides, and other specialized chemicals.

Furthermore, the automotive and construction industries are indirect but substantial consumers, as they utilize products like refrigerants (derived from chlorinated methanes) in air conditioning systems and foam blowing agents in insulation materials. Solvent applications in paint strippers, degreasers, and adhesive manufacturing also target a broad industrial client base. While environmental regulations have reduced some traditional uses, specialized industrial applications continue to rely on chlorinated methanes due to their cost-effectiveness and performance, making manufacturers of these downstream products core potential customers for the market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 17.5 Billion |

| Market Forecast in 2032 | USD 23.9 Billion |

| Growth Rate | 4.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Shin-Etsu Chemical Co. Ltd., Dow Chemical Company, AkzoNobel N.V., AGC Inc., Ineos Group Holdings S.A., Occidental Petroleum Corporation (OxyChem), Solvay S.A., KEM ONE, Gujarat Alkalies and Chemicals Limited (GACL), SRF Limited, China Haohua Chemical Group Co. Ltd., Juhua Group Corporation, Tokuyama Corporation, Reliance Industries Limited, PVR Group, Chemours Company, BASF SE, Linde AG, Arkema S.A., SABIC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chlorinated Methane Market Key Technology Landscape

The technology landscape for the Chlorinated Methane market is dominated by established chemical synthesis processes, primarily the direct chlorination of methane or methanol, which have been refined over decades to achieve high yields and efficiency. The most common industrial method involves the reaction of methane with chlorine at high temperatures, producing a mixture of all four chlorinated methanes. Subsequent separation and purification technologies, such as distillation and fractional distillation, are critical to isolate the desired product and ensure high purity levels required for various end-use applications. Continuous advancements in catalyst design and reactor technology aim to optimize selectivity towards specific chlorinated methanes, minimizing byproduct formation and increasing overall process efficiency.

In addition to traditional synthesis, alternative processes and improvements focus on sustainability and environmental impact reduction. This includes research into oxychlorination routes that utilize hydrogen chloride (HCl) instead of chlorine, potentially reducing the reliance on elemental chlorine and making use of an industrial byproduct. Furthermore, there is an increasing emphasis on developing processes that minimize energy consumption and greenhouse gas emissions. Technologies for managing and recycling unreacted feedstocks and byproducts are also crucial to enhancing the overall environmental performance and cost-effectiveness of chlorinated methane production facilities.

The industry is also witnessing technological evolution in terms of process control and automation. Advanced sensor technologies, coupled with sophisticated control systems, enable real-time monitoring and adjustment of reaction conditions, improving safety, consistency, and operational efficiency. Furthermore, R&D efforts are exploring novel catalytic systems that can facilitate more selective and milder chlorination reactions, potentially leading to lower capital and operating costs while also reducing the environmental footprint. The integration of advanced computational chemistry and process simulation tools is also becoming more prevalent, aiding in the design and optimization of next-generation chlorinated methane production facilities.

Regional Highlights

The global Chlorinated Methane market exhibits distinct regional dynamics influenced by industrial development, regulatory frameworks, and end-user demand patterns. Asia Pacific (APAC) currently stands as the largest and fastest-growing region, driven by rapid industrialization, urbanization, and a burgeoning chemical manufacturing base, particularly in countries like China and India. The robust growth in pharmaceutical, automotive, and construction sectors in these economies fuels the demand for chlorinated methanes as solvents and intermediates. Favorable government policies supporting manufacturing and less stringent environmental regulations compared to Western counterparts, though evolving, have also contributed to the region's dominance.

North America and Europe represent mature markets with established chemical industries. Growth in these regions is largely propelled by specialized applications and the need for high-purity products for pharmaceutical and electronic industries, coupled with a strong emphasis on sustainability and regulatory compliance. Strict environmental regulations and health concerns have led to a decline in certain applications, but demand for essential uses, particularly as chemical intermediates for silicones and fluoropolymers, remains significant. Manufacturers in these regions are investing in advanced technologies to improve process efficiency and reduce emissions, adhering to stringent environmental standards like REACH in Europe and EPA regulations in North America.

Latin America and the Middle East and Africa (MEA) regions are emerging markets for chlorinated methanes, characterized by increasing industrialization and diversification of their economies. Countries in Latin America, such as Brazil and Mexico, are witnessing growth in their chemical and automotive industries, driving modest demand. The MEA region, with its expanding petrochemical infrastructure and growing manufacturing sectors, is also showing potential for increased consumption, particularly in applications related to construction and agriculture. However, these regions often face challenges related to technological advancements, investment in infrastructure, and evolving regulatory landscapes, which influence their market development trajectory.

- Asia Pacific (APAC): Dominates the market due to rapid industrial growth in China and India, strong chemical and pharmaceutical sectors, and increasing demand from construction and automotive industries.

- North America: Mature market driven by specialized applications, high-purity product demand, and stringent environmental regulations fostering innovation in cleaner production.

- Europe: Stable market with a focus on regulatory compliance, sustainability, and demand from advanced manufacturing and pharmaceutical industries.

- Latin America: Emerging market with growing demand from chemical, automotive, and agricultural sectors, driven by industrial expansion.

- Middle East and Africa (MEA): Developing market with increasing investments in petrochemicals and manufacturing, contributing to gradual demand growth for chlorinated methanes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chlorinated Methane Market.- Shin-Etsu Chemical Co. Ltd.

- Dow Chemical Company

- AkzoNobel N.V.

- AGC Inc.

- Ineos Group Holdings S.A.

- Occidental Petroleum Corporation (OxyChem)

- Solvay S.A.

- KEM ONE

- Gujarat Alkalies and Chemicals Limited (GACL)

- SRF Limited

- China Haohua Chemical Group Co. Ltd.

- Juhua Group Corporation

- Tokuyama Corporation

- Reliance Industries Limited

- PVR Group

- Chemours Company

- BASF SE

- Linde AG

- Arkema S.A.

- SABIC

Frequently Asked Questions

Analyze common user questions about the Chlorinated Methane market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of chlorinated methane and their main uses?

The primary types are methyl chloride, methylene chloride, chloroform, and carbon tetrachloride. They are extensively used as solvents, chemical intermediates for silicones, refrigerants, and in pharmaceutical manufacturing.

How do environmental regulations impact the Chlorinated Methane Market?

Environmental regulations, particularly concerning ozone depletion and toxicity, significantly restrict the production and use of certain chlorinated methanes, driving demand for alternatives and cleaner production technologies.

Which region currently leads the global Chlorinated Methane Market?

The Asia Pacific (APAC) region currently leads the global Chlorinated Methane Market, primarily due to rapid industrial growth and a strong manufacturing base in countries like China and India.

What are the key drivers for the growth of the Chlorinated Methane Market?

Key drivers include the increasing demand from the pharmaceutical industry, the expanding silicone manufacturing sector, and growth in the construction and automotive industries, particularly in emerging economies.

What technological advancements are impacting chlorinated methane production?

Technological advancements include optimized catalytic processes for higher selectivity, greener chlorination routes, improved process control and automation, and R&D into sustainable alternatives and emission reduction strategies.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager