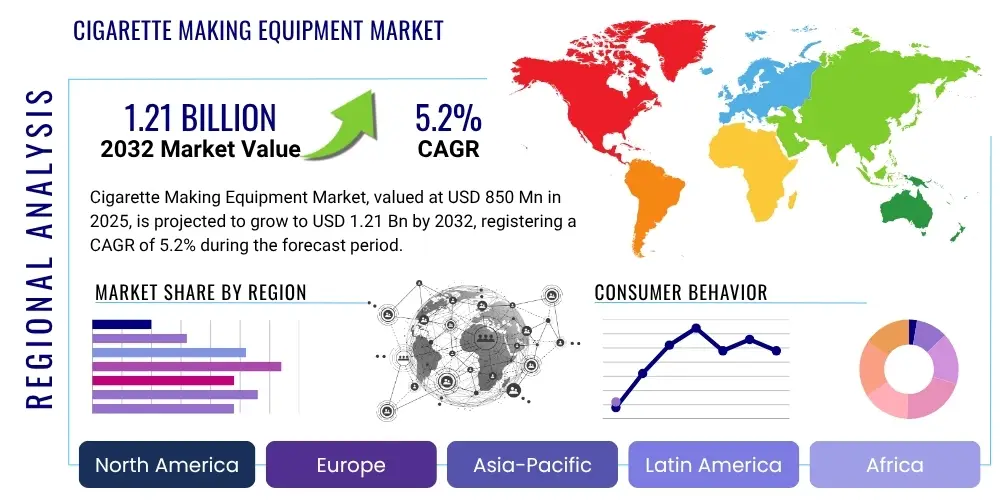

Cigarette Making Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430018 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Cigarette Making Equipment Market Size

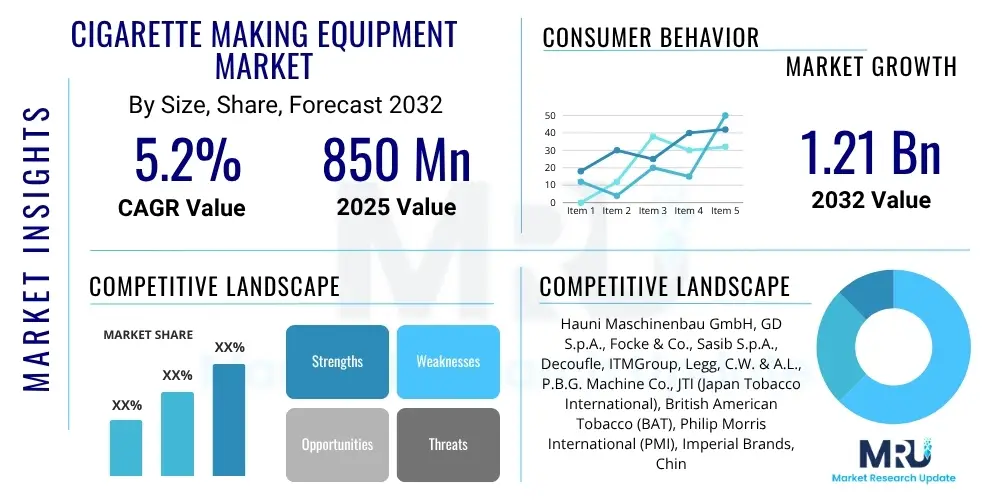

The Cigarette Making Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% between 2025 and 2032. The market is estimated at USD 850 Million in 2025 and is projected to reach USD 1.21 Billion by the end of the forecast period in 2032.

Cigarette Making Equipment Market introduction

The Cigarette Making Equipment Market encompasses machinery and systems utilized in the production of cigarettes, from raw tobacco processing to final packaging. This sophisticated equipment is central to the global tobacco industry, enabling high-volume, precision manufacturing to meet diverse consumer demands. Products range from primary processing machinery like tobacco cutting and drying equipment to secondary processing units such as cigarette makers, filter assemblers, and packing machines, which can incorporate advanced automation and quality control features. The primary application of these machines is within large-scale tobacco manufacturing facilities, where efficiency, speed, and consistency are paramount.

The benefits derived from advanced cigarette making equipment include enhanced production efficiency, superior product quality through precise control over blend consistency and cigarette dimensions, and significant cost reductions via automation and minimized waste. Furthermore, modern equipment offers flexibility for producing various cigarette types, including different lengths, diameters, and filter configurations, allowing manufacturers to adapt to evolving market preferences and regulatory changes, such as the increasing demand for reduced-risk product components or specialized filter technologies. These benefits collectively drive market adoption, ensuring manufacturers can maintain competitiveness in a dynamic global landscape.

Key driving factors for this market include the sustained global demand for tobacco products, particularly in emerging economies, alongside the continuous need for manufacturers to upgrade their existing machinery to improve operational efficiency, reduce labor costs, and adhere to stricter quality and safety standards. Technological advancements in automation, data analytics, and precision engineering also play a crucial role, enabling the development of more sophisticated and adaptable equipment. Moreover, the necessity for producing consistent product quality across vast production volumes further stimulates investment in advanced cigarette manufacturing solutions.

Cigarette Making Equipment Market Executive Summary

The Cigarette Making Equipment Market is experiencing dynamic shifts, primarily driven by the tobacco industry's persistent pursuit of efficiency, automation, and enhanced product quality amidst evolving regulatory landscapes and consumer preferences. Business trends indicate a strong focus on high-speed, modular, and integrated production lines that can quickly adapt to various cigarette formats and filter specifications. Manufacturers are also increasingly investing in equipment that offers greater precision in tobacco blending and stick formation, alongside advanced packaging solutions that contribute to brand differentiation and product integrity. The market is characterized by a blend of consolidation among established players and innovation from specialized technology providers, all striving to deliver solutions that address the dual challenges of cost optimization and product diversification.

Regionally, the market exhibits varied trends. Asia Pacific, particularly countries like China, India, and Indonesia, represents a significant growth hub due to a large consumer base and expanding manufacturing capabilities, leading to substantial investments in new equipment and modernization projects. Europe and North America, while facing stricter regulations and declining traditional cigarette consumption, see demand for advanced, flexible machinery that can produce a wider array of specialty products, including those with harm reduction claims, and for upgrading existing lines for higher efficiency. Latin America, the Middle East, and Africa are also showing moderate growth, driven by localized production expansions and efforts to reduce reliance on imported tobacco products.

Segment-wise, fully automated cigarette making machines continue to dominate due to their unparalleled efficiency and consistency, appealing to large-scale producers. The segment for filter attachment and assembly machines is also witnessing robust growth, propelled by the introduction of innovative filter technologies and an emphasis on healthier or differentiated product offerings. Furthermore, the market for spare parts and maintenance services remains crucial, supporting the longevity and operational reliability of existing equipment. Customization and the integration of smart manufacturing capabilities are emerging as critical segment trends, allowing manufacturers to tailor their production processes precisely to specific market demands and regulatory compliance requirements.

AI Impact Analysis on Cigarette Making Equipment Market

Users frequently inquire about how Artificial Intelligence will revolutionize the Cigarette Making Equipment Market, focusing on potential improvements in operational efficiency, predictive maintenance, quality control, and the personalization of production. Common questions revolve around AI's ability to optimize machine performance, reduce downtime, and enhance the consistency of the final product. There is also significant interest in AI's role in data analytics for production insights and its potential to facilitate more agile manufacturing processes, allowing for quicker adaptation to market changes and regulatory shifts, while simultaneously raising concerns about the investment required and the skilled workforce needed to manage these advanced systems.

- Enhanced Predictive Maintenance: AI algorithms analyze machine performance data to forecast potential failures, optimizing maintenance schedules and minimizing costly downtime.

- Optimized Production Efficiency: AI-driven systems adjust machine parameters in real-time, fine-tuning speed, temperature, and material flow for maximum output and minimal waste.

- Superior Quality Control: Computer vision and machine learning identify defects in tobacco blending, cigarette formation, and filter attachment with unparalleled accuracy, ensuring consistent product quality.

- Personalized Production: AI enables rapid reconfigurations of equipment settings to produce diverse cigarette types or even customized batches, responding to niche market demands.

- Supply Chain Optimization: AI helps manage inventory levels for raw materials and spare parts, improving procurement and reducing storage costs through demand forecasting.

- Energy Consumption Reduction: AI systems monitor and optimize energy usage across the production line, contributing to lower operational costs and environmental impact.

- Workforce Augmentation: AI tools assist operators with complex tasks, troubleshooting, and training, enhancing productivity and reducing human error.

DRO & Impact Forces Of Cigarette Making Equipment Market

The Cigarette Making Equipment Market is influenced by a complex interplay of drivers, restraints, and opportunities. Key drivers include the persistent global demand for tobacco products, particularly in developing economies, coupled with manufacturers' continuous need for advanced machinery to boost production efficiency, ensure product consistency, and manage operational costs. The demand for automation to reduce labor dependency and enhance precision also acts as a significant catalyst. However, the market faces notable restraints such as increasingly stringent anti-tobacco regulations, health awareness campaigns leading to declining consumption in developed markets, and the high capital investment required for acquiring and maintaining sophisticated equipment. The stigma associated with the tobacco industry also affects investment and public perception.

Opportunities within this market are primarily found in technological innovation, including the integration of AI, IoT, and advanced robotics to create smarter, more flexible, and highly efficient manufacturing lines. The rising demand for specialized products, such as next-generation tobacco and nicotine products (e.g., heated tobacco, e-cigarettes), which require unique manufacturing solutions, presents a new avenue for equipment providers. Furthermore, the modernization of aging production facilities in emerging markets and the increasing focus on sustainable manufacturing practices, leading to demand for energy-efficient and waste-reducing machinery, offer considerable growth prospects. These opportunities enable market players to diversify their offerings and adapt to the evolving needs of the tobacco industry.

The impact forces are shaped by these drivers, restraints, and opportunities, creating a dynamic environment. Economic growth in emerging markets directly propels demand for new production capabilities. Conversely, public health initiatives and increasing taxation on tobacco products in mature markets exert downward pressure on traditional cigarette production, shifting focus towards diversification. Technological advancements are an overarching impact force, driving innovation in machine design, operational efficiency, and product quality. Regulatory changes globally continue to significantly influence equipment specifications, requiring adaptable and compliant machinery. The competitive landscape itself is an impact force, pushing manufacturers to continuously innovate and offer superior solutions to gain market share.

Segmentation Analysis

The Cigarette Making Equipment Market is comprehensively segmented based on various attributes to provide a granular view of its structure and dynamics. These segments help in understanding the distinct requirements of different manufacturers and the specialized nature of the machinery involved in the production process. The primary categorizations include equipment type, level of automation, production capacity, and application. Each segment reflects specific technological demands, operational scales, and target markets within the global tobacco manufacturing ecosystem, enabling a detailed analysis of market trends and growth opportunities.

- By Equipment Type:

- Primary Processing Equipment (e.g., tobacco cutting, drying, blending machines)

- Secondary Processing Equipment (e.g., cigarette makers, filter assemblers)

- Packaging Equipment (e.g., packers, wrappers, cartoners)

- Filter Rod Makers

- Ancillary Equipment (e.g., quality control systems, material handling)

- By Automation Level:

- Fully Automatic

- Semi-Automatic

- By Production Capacity:

- Low Capacity (up to 5,000 cigarettes/minute)

- Medium Capacity (5,000 to 10,000 cigarettes/minute)

- High Capacity (over 10,000 cigarettes/minute)

- By Application:

- Traditional Cigarettes

- Kretek Cigarettes

- Cigars & Cigarillos

- Next-Generation Products (e.g., heated tobacco sticks)

Value Chain Analysis For Cigarette Making Equipment Market

The value chain for the Cigarette Making Equipment Market begins with upstream analysis, which involves the sourcing of raw materials and components critical for machine manufacturing. This stage includes suppliers of specialized metals, electronic components, precision engineering parts, and advanced control systems. These suppliers often operate in highly specialized niches, providing high-quality, durable, and precise components essential for the complex machinery. Strong relationships with reliable component providers are crucial for equipment manufacturers to ensure the quality, performance, and longevity of their products, directly impacting production costs and equipment reliability.

Moving downstream, the value chain extends to the direct and indirect distribution channels through which cigarette making equipment reaches its end-users. Direct channels typically involve equipment manufacturers selling directly to large-scale tobacco companies, often including installation, commissioning, and ongoing maintenance services as part of comprehensive contracts. This approach allows for direct communication, customization, and strong client relationships. Indirect channels involve distributors, agents, or regional partners who facilitate sales, provide local support, and sometimes offer after-sales services, particularly for smaller manufacturers or in markets where direct presence is less feasible for the original equipment manufacturer.

The end of the value chain focuses on the end-users, primarily large multinational tobacco corporations and regional cigarette manufacturers, who deploy this equipment in their production facilities. Post-sales services, including spare parts supply, technical support, training, and maintenance contracts, constitute a critical part of the value chain, ensuring the operational efficiency and extended lifespan of the machinery. Effective service and support are paramount for customer satisfaction and repeat business, highlighting the importance of a robust after-sales infrastructure. The overall efficiency and cost-effectiveness of this value chain are vital for both equipment manufacturers and tobacco producers, influencing market competitiveness and product availability.

Cigarette Making Equipment Market Potential Customers

The primary potential customers for Cigarette Making Equipment are enterprises involved in the manufacturing of tobacco products globally. This encompasses a broad spectrum of companies, ranging from multinational tobacco giants with vast production capacities and complex supply chains to smaller, regional manufacturers focused on local markets or specialized products. These end-users consistently seek equipment that offers high efficiency, reliability, precision, and adaptability to meet diverse production demands and regulatory requirements. Their purchasing decisions are heavily influenced by factors such as machine speed, automation level, product quality consistency, energy consumption, and the availability of robust after-sales support and spare parts.

Large-scale multinational tobacco corporations represent a significant segment of potential customers. These entities often require integrated, high-speed production lines capable of manufacturing billions of cigarettes annually across multiple global facilities. They invest in the latest technologies to maintain a competitive edge, achieve economies of scale, and ensure compliance with stringent quality and safety standards. Their needs often include modular systems that can be easily expanded or reconfigured, as well as equipment that supports the production of both traditional cigarettes and emerging next-generation tobacco products, requiring advanced and versatile machinery solutions.

Additionally, small and medium-sized tobacco manufacturers, particularly in emerging markets, constitute another important customer segment. These companies might seek more cost-effective, semi-automatic, or modular equipment that allows them to scale production gradually. They often prioritize equipment that is easy to operate and maintain, with readily available technical support. The ongoing modernization of existing production facilities and the establishment of new ones, particularly in regions experiencing economic growth and stable tobacco consumption, also contribute significantly to the potential customer base. New entrants into the tobacco manufacturing sector or companies diversifying their product portfolio also represent opportunities for equipment providers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 850 Million |

| Market Forecast in 2032 | USD 1.21 Billion |

| Growth Rate | CAGR of 5.2% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hauni Maschinenbau GmbH, GD S.p.A., Focke & Co., Sasib S.p.A., Decoufle, ITMGroup, Legg, C.W. & A.L., P.B.G. Machine Co., JTI (Japan Tobacco International), British American Tobacco (BAT), Philip Morris International (PMI), Imperial Brands, China National Tobacco Corporation (CNTC), KT&G Corporation, Eastern Tobacco Company, Philip Morris Manufacturing & Technology S.à r.l., G.D. Packaging, TABACO, Comas, S.L. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cigarette Making Equipment Market Key Technology Landscape

The Cigarette Making Equipment Market is characterized by a rapidly evolving technological landscape, driven by the imperative for increased efficiency, precision, and flexibility in manufacturing. High-speed automation remains a cornerstone, with modern machines capable of producing tens of thousands of cigarettes per minute, leveraging advanced robotics and sophisticated mechanical engineering to handle delicate tobacco materials and assemble complex filter systems. This automation extends to entire production lines, integrating various stages from tobacco preparation to final packaging, all controlled by centralized digital systems. Manufacturers are constantly pushing the boundaries of machine speed and throughput while maintaining product quality and consistency across extensive production runs.

Moreover, the integration of advanced sensor technology, often coupled with artificial intelligence and machine learning algorithms, is transforming quality control and predictive maintenance. In-line sensors monitor critical parameters such as tobacco moisture content, density, and filter integrity, allowing for real-time adjustments and minimizing defects. AI-driven predictive maintenance systems analyze operational data to identify potential equipment failures before they occur, significantly reducing downtime and extending machine lifespan. This shift towards smart manufacturing, or Industry 4.0 principles, enables greater operational transparency, optimizes resource utilization, and enhances overall plant efficiency, moving beyond reactive maintenance to proactive operational management.

Furthermore, modular design and flexible manufacturing concepts are gaining prominence, allowing manufacturers to quickly adapt production lines to different cigarette formats, filter types, and next-generation tobacco products. This adaptability is crucial in a market influenced by evolving consumer preferences and regulatory changes, demanding quick shifts in product specifications. The adoption of IoT (Internet of Things) for interconnectivity between machines and central control systems, along with advanced data analytics platforms, provides invaluable insights into production performance, waste reduction, and energy consumption. These technological advancements collectively drive the market towards more intelligent, resilient, and responsive manufacturing processes.

Regional Highlights

- North America: Characterized by declining traditional cigarette consumption, leading to a focus on advanced equipment for producing specialized, premium, and next-generation tobacco products. Stringent regulations drive demand for highly compliant and precise machinery. Modernization of existing facilities for efficiency gains is also a key trend.

- Europe: Similar to North America, Europe faces robust anti-tobacco legislation and declining smoking rates. The demand is strong for highly automated, flexible equipment capable of producing reduced-risk products and adhering to strict quality and emissions standards. Innovation in filter technology and sustainable manufacturing processes are significant drivers.

- Asia Pacific (APAC): The largest and fastest-growing market, driven by a substantial consumer base, increasing disposable incomes, and expanding domestic manufacturing capabilities in countries like China, India, and Indonesia. This region sees significant investment in new plant setups and modernization, requiring high-capacity, efficient, and cost-effective cigarette making equipment.

- Latin America: Exhibits moderate growth, fueled by local production expansion and the need to reduce import reliance. Manufacturers seek reliable and robust equipment that offers a balance between cost-effectiveness and efficiency, adapting to varying market demands across different countries within the region.

- Middle East and Africa (MEA): A nascent but growing market, propelled by urbanization, population growth, and increasing local manufacturing investments. Demand is for durable, high-throughput machinery suitable for establishing new production lines and upgrading older ones, often seeking equipment that can handle diverse tobacco blends.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cigarette Making Equipment Market.- Hauni Maschinenbau GmbH

- GD S.p.A.

- Focke & Co.

- Sasib S.p.A.

- Decoufle

- ITMGroup

- Legg, C.W. & A.L.

- P.B.G. Machine Co.

- JTI (Japan Tobacco International)

- British American Tobacco (BAT)

- Philip Morris International (PMI)

- Imperial Brands

- China National Tobacco Corporation (CNTC)

- KT&G Corporation

- Eastern Tobacco Company

- Philip Morris Manufacturing & Technology S.à r.l.

- G.D. Packaging

- TABACO

- Comas, S.L.

- Molins PLC

Frequently Asked Questions

What is the projected growth rate of the Cigarette Making Equipment Market?

The Cigarette Making Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% between 2025 and 2032, driven by efficiency needs and technological advancements.

What are the primary drivers for the Cigarette Making Equipment Market?

Key drivers include persistent global demand for tobacco products, the continuous need for manufacturers to enhance production efficiency, reduce operational costs through automation, and ensure consistent product quality.

How does AI impact the Cigarette Making Equipment Market?

AI significantly impacts the market through enhanced predictive maintenance, optimized production efficiency, superior quality control via computer vision, and the ability to enable personalized and flexible manufacturing processes.

Which regions are key contributors to the Cigarette Making Equipment Market growth?

Asia Pacific is the largest and fastest-growing market, while North America and Europe focus on advanced equipment for specialized products. Latin America and MEA show moderate growth from local production expansion.

What are the main types of equipment covered in this market?

The market primarily covers primary processing equipment (cutting, drying), secondary processing equipment (cigarette makers, filter assemblers), and packaging equipment (packers, wrappers).

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager