Cleanroom Technology Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428843 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Cleanroom Technology Market Size

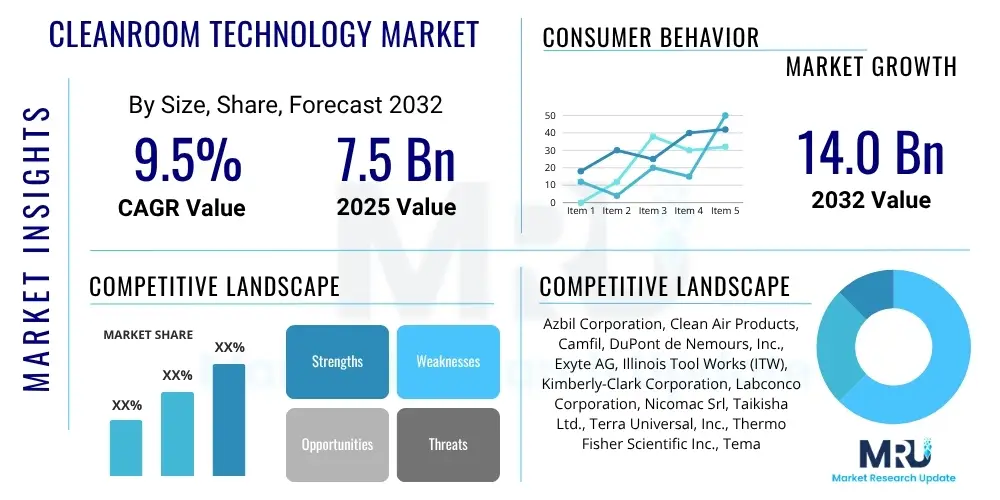

The Cleanroom Technology Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 7.5 billion in 2025 and is projected to reach USD 14.0 billion by the end of the forecast period in 2032.

Cleanroom Technology Market introduction

The Cleanroom Technology Market encompasses the design, construction, and operation of meticulously controlled environments engineered to maintain extremely low levels of pollutants such as dust, airborne microbes, aerosol particles, and chemical vapors. These specialized spaces are absolutely critical for manufacturing and research processes where even microscopic contamination can compromise product integrity, functionality, or safety. The sophisticated systems employed in cleanrooms precisely regulate parameters like air pressure, temperature, humidity, and airflow patterns to prevent particulate ingress and proliferation. This technological domain is foundational for a wide array of high-tech and sterile industries, enabling the production of sensitive components and sterile products under stringent quality control.

The product offerings within this market are extensive, ranging from the core infrastructure to ongoing operational consumables. Key components include advanced Heating, Ventilation, and Air Conditioning (HVAC) systems, high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters, and various forms of cleanroom construction such as modular, hardwall, and softwall designs that offer flexibility and specific environmental control levels. Furthermore, the market includes a comprehensive suite of consumables vital for maintaining cleanliness, such as sterile garments, gloves, masks, wipes, and specialized cleaning agents. Major applications span critical sectors including pharmaceuticals and biotechnology for sterile drug manufacturing, semiconductor and electronics for microchip fabrication, medical devices for aseptic assembly, and aerospace for sensitive component integration, where precision and purity are non-negotiable requirements for operational success and product performance.

The benefits derived from adopting cleanroom technology are profound and multifaceted, primarily centered on ensuring superior product quality, drastically minimizing the risk of contamination, and facilitating strict adherence to an ever-evolving landscape of global regulatory standards like ISO 14644 and various Good Manufacturing Practices (GMP). These advantages collectively lead to enhanced operational efficiency, reduced product recalls, and increased consumer trust. The market's growth is predominantly driven by several interconnected factors: the accelerating global demand from the pharmaceutical and biotechnology industries for sterile production environments, the continuous advancements and miniaturization within the electronics sector necessitating ultra-clean manufacturing conditions, and a pervasive, heightened focus on product safety and quality across all industrial domains. Additionally, significant technological advancements in energy-efficient filtration systems, modular cleanroom designs, and integrated monitoring solutions further fuel market expansion, making cleanroom technology an indispensable component of modern industrial infrastructure.

Cleanroom Technology Market Executive Summary

The Cleanroom Technology Market is currently experiencing robust and sustained growth, primarily propelled by burgeoning demands from the life sciences and high-tech manufacturing sectors globally. Analysis of prevailing business trends reveals a significant pivot towards modular and flexible cleanroom solutions, which are increasingly favored for their adaptability, cost-effectiveness, and rapid deployment capabilities, addressing the dynamic needs of modern industrial expansion. A concurrent trend involves the deeper integration of advanced automation and sophisticated digital monitoring systems, which are revolutionizing cleanroom operations by enhancing efficiency, minimizing human error, and ensuring impeccable data integrity for compliance with stringent regulatory frameworks. These technological advancements are not only improving operational metrics but also driving a paradigm shift towards predictive and proactive contamination control strategies, moving beyond traditional reactive approaches.

Regionally, the market exhibits distinct growth trajectories and maturity levels. Asia Pacific stands out as the most rapidly expanding region, driven by massive investments in manufacturing infrastructure, escalating healthcare expenditures, and proactive governmental initiatives aimed at fostering indigenous pharmaceutical and semiconductor industries, particularly in economic powerhouses like China, India, and South Korea. Conversely, North America and Europe, while representing more mature markets, continue to command substantial market shares. This enduring dominance is sustained by their well-established research and development capabilities in pharmaceuticals and biotechnology, continuous innovation in cleanroom design and environmental control technologies, and an unwavering commitment to maintaining stringent quality and regulatory standards. These regions consistently drive the adoption of cutting-edge solutions and facility upgrades, ensuring their continued leadership in advanced manufacturing and scientific research.

Segment-wise, the market for cleanroom consumables, encompassing specialized garments, gloves, wipes, and cleaning agents, alongside essential cleanroom equipment such as HVAC systems and filtration units, continues to account for the largest proportion of market revenue due to their constant replenishment and integral role in daily operations. However, the cleanroom services segment, which includes crucial aspects like design and consulting, installation, commissioning, validation, and ongoing maintenance, is witnessing an accelerating demand. This surge is attributed to the increasing complexity of regulatory requirements and the need for specialized expertise to ensure optimal performance and compliance throughout the cleanroom lifecycle. Furthermore, an overarching industry trend towards sustainable cleanroom design and operation is gaining significant momentum, reflecting a broader corporate commitment to environmental stewardship, energy conservation, and the adoption of eco-friendly materials and practices across all cleanroom market segments.

AI Impact Analysis on Cleanroom Technology Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Cleanroom Technology Market often center on its potential to revolutionize operational efficiency, enhance contamination control, and improve regulatory compliance through advanced analytical capabilities. Users are keen to understand how AI can facilitate real-time environmental monitoring, enable predictive maintenance of critical cleanroom infrastructure like HVAC systems and filters, and optimize complex cleanroom processes to reduce human intervention and associated contamination risks. There's significant interest in AI's role in processing vast datasets generated by cleanroom sensors to identify subtle anomalies, predict equipment failures before they occur, and streamline auditing processes. Concerns frequently raised include the initial investment costs associated with AI implementation, data security and privacy within highly regulated environments, and the critical need for a workforce equipped with the skills to effectively manage and leverage AI-driven systems. Users anticipate that AI will fundamentally transform cleanroom management from reactive problem-solving to proactive, intelligent decision-making, delivering substantial benefits in terms of cost reduction, energy savings, and elevated product quality.

- AI-powered predictive maintenance for HVAC systems, fan filter units, and other critical equipment, significantly reducing unplanned downtime and operational costs by forecasting potential failures.

- Real-time environmental monitoring and anomaly detection using AI algorithms to analyze sensor data, instantly identifying deviations in particulate counts, temperature, humidity, or pressure, thereby preventing contamination events.

- Automated robotic systems and cobots, guided by AI, for material handling, sterile assembly tasks, and automated cleaning within cleanrooms, minimizing human presence and associated contamination risks while enhancing precision and consistency.

- Optimization of cleanroom design and airflow patterns through AI-driven computational fluid dynamics (CFD) simulations, allowing for more efficient and effective contamination control strategies during the planning phase.

- Enhanced data analytics for regulatory compliance and auditing, where AI processes large volumes of environmental data, equipment logs, and operational records to ensure complete traceability and streamline compliance reporting, improving audit readiness.

- Energy efficiency optimization through AI-driven control systems that intelligently manage lighting, temperature, humidity, and airflow based on real-time conditions and operational schedules, leading to substantial energy savings.

- Supply chain optimization for cleanroom consumables, leveraging AI to predict usage patterns and manage inventory levels, ensuring timely replenishment and reducing waste while preventing stockouts of critical supplies.

DRO & Impact Forces Of Cleanroom Technology Market

The Cleanroom Technology Market is significantly propelled by a robust set of driving forces that underscore its indispensable role across a multitude of modern, sensitive industries. A paramount driver is the exponential growth and continuous innovation within the global pharmaceutical and biotechnology sectors, which demand meticulously controlled, sterile environments for the entire spectrum of activities, from drug discovery and development to vaccine production, sterile compounding, and advanced therapeutic manufacturing. These industries are under intense regulatory scrutiny, necessitating cleanroom facilities to ensure product efficacy, safety, and patient well-being. Concurrently, the relentless expansion and technological advancements within the electronics and semiconductor industries, particularly the drive towards miniaturization and higher integration density of components, critically rely on ultra-clean conditions to prevent even microscopic particulate contamination that can lead to catastrophic defects and significant financial losses in microchip and display fabrication.

However, the market also faces considerable restraints that can temper its growth trajectory and present significant challenges for stakeholders. A primary impediment is the substantial initial capital investment required for the design, construction, and outfitting of a compliant cleanroom facility. This high upfront cost can act as a significant barrier to entry for new companies and can strain the budgets of smaller enterprises, limiting broader market penetration and adoption. Furthermore, the ongoing operational and maintenance expenses associated with running cleanroom environments are remarkably high, including the considerable energy consumption by sophisticated HVAC and filtration systems that must operate continuously, the regular replacement of high-grade consumables, and the specialized training and certification required for personnel. Moreover, a persistent global shortage of skilled professionals proficient in cleanroom operation, maintenance, and rigorous validation processes exacerbates these challenges, complicating facility management and compliance with evolving international standards.

Despite these inherent challenges, numerous compelling opportunities exist within the Cleanroom Technology Market that promise future growth and innovation. The increasing adoption of modular and portable cleanroom solutions represents a significant opportunity, offering superior flexibility, faster deployment times, and enhanced cost-effectiveness compared to traditional stick-built cleanrooms. These adaptable solutions cater to diverse project sizes and industries, enabling rapid scale-up or temporary cleanroom needs. Emerging economies, particularly in the Asia Pacific region, present vast untapped potential as industrialization accelerates, healthcare infrastructure expands, and local manufacturing capabilities mature, creating burgeoning demand for controlled environments. Furthermore, the continuous integration of advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and advanced automation for real-time environmental monitoring, predictive maintenance, and optimized process control offers significant avenues for technological advancement, improved operational efficiency, and enhanced data-driven decision-making. The growing focus on sustainable cleanroom design and operation, emphasizing energy recovery, waste reduction, and eco-friendly materials, also opens new market niches and aligns with global environmental objectives, driving demand for greener and more efficient solutions.

Segmentation Analysis

The Cleanroom Technology Market is meticulously segmented to provide a comprehensive and granular understanding of its diverse components, technological variations, and application landscape. This detailed segmentation is instrumental for market participants to identify specific growth drivers, understand evolving customer needs, and formulate targeted strategies across different verticals. The market's divisions are typically delineated by product type, construction type, and end-use industry, each category revealing unique dynamics and investment opportunities. Analyzing these segments provides critical insights into the varying operational requirements and stringent standards demanded by different sectors, from the ultra-precise conditions in semiconductor manufacturing to the critical sterility in pharmaceutical production, thereby offering a holistic view of the market's current state and its future trajectory.

- By Product Type:

- Equipment

- HVAC Systems: Critical for air quality, temperature, and humidity control.

- Filters (HEPA, ULPA): Essential for trapping airborne particles.

- Air Showers and Tunnels: Designed to remove surface contamination from personnel and materials entering a cleanroom.

- Laminar Flow Hoods and Bio-Safety Cabinets: Provide localized ultra-clean or sterile environments for specific tasks.

- Pass-Throughs: Allow transfer of materials between different cleanliness zones without compromising integrity.

- Contamination Monitoring Equipment: Devices for real-time monitoring of particulate counts, microbial levels, and other environmental parameters.

- Consumables

- Safety Apparel (Gloves, Garments, Masks, Shoe Covers): Designed to prevent human-generated contamination.

- Wipes: Lint-free and pre-saturated options for cleaning surfaces.

- Cleaning Agents: Specialized solutions for maintaining sterile surfaces.

- Disinfectants: Used for microbial control and sanitization.

- Stationery: Low-particulate paper, pens, and binders for use within controlled environments.

- Services

- Design and Consulting: Expert guidance for optimal cleanroom layout and specifications.

- Installation and Commissioning: Professional setup and verification of cleanroom systems.

- Testing, Certification, and Validation: Ensures compliance with international standards like ISO 14644 and GMP.

- Maintenance and Upgradation: Routine servicing and modernization of cleanroom infrastructure.

- Training: Educating personnel on cleanroom protocols and best practices.

- Equipment

- By Construction Type:

- Standard/Conventional Cleanrooms: Traditionally built, permanent structures.

- Modular Cleanrooms: Pre-fabricated, flexible, and scalable cleanroom solutions.

- Softwall Cleanrooms: Economical, flexible enclosures with soft walls, suitable for smaller areas.

- Hardwall Cleanrooms: Feature rigid walls, offering greater durability and environmental control than softwall.

- Hybrid Cleanrooms: Combine features of different construction types to optimize cost and performance.

- By End-Use Industry:

- Pharmaceuticals and Biotechnology: For sterile drug manufacturing, vaccine production, and cell & gene therapy.

- Medical Devices: Aseptic assembly of implants, diagnostic equipment, and surgical instruments.

- Semiconductors and Electronics: Fabrication of microchips, integrated circuits, and displays.

- Life Sciences (Research Labs): Controlled environments for sensitive biological and chemical research.

- Hospitals and Healthcare: Operating theaters, sterile compounding pharmacies, and isolation rooms.

- Automotive: Manufacturing of sensitive electronic components, sensors, and battery production.

- Aerospace and Defense: Assembly of precision optics, satellite components, and sensitive instrumentation.

- Food and Beverage: Aseptic packaging and processing of high-value or perishable food products.

- Optics: Manufacturing and assembly of lenses, mirrors, and precision optical instruments.

- Others (Nanotechnology, Cosmetics, etc.): Specialized applications requiring ultra-clean environments for novel material development and quality control.

Value Chain Analysis For Cleanroom Technology Market

The value chain of the Cleanroom Technology Market is a sophisticated and interconnected network of activities that spans from the initial procurement of raw materials and specialized components to the final deployment, ongoing operation, and maintenance of controlled environments for end-users. The upstream segment of this chain is comprised of a diverse array of suppliers providing critical inputs such as high-performance filtration media for HEPA and ULPA filters, advanced materials for sophisticated HVAC systems, specialized construction materials like cleanroom-grade panels, sealants, and modular wall systems. Additionally, fabric manufacturers supply the technical textiles required for cleanroom garments and wipes, which are designed to be low-linting and particle-free. These upstream providers play a foundational role, as the quality, reliability, and innovative properties of their materials directly influence the overall performance, integrity, and compliance capabilities of the complete cleanroom solution. Strategic sourcing and strong relationships with these suppliers are paramount for maintaining consistent product quality, controlling costs, and fostering innovation throughout the entire cleanroom ecosystem.

Moving downstream from the raw material suppliers, the core processes involve the intricate stages of design, engineering, manufacturing, and integration. Specialized cleanroom technology providers and system integrators undertake the crucial task of designing bespoke or modular cleanroom solutions, precisely tailored to meet specific industry standards, regulatory requirements, and client operational needs. This phase demands extensive technical expertise in areas such as airflow dynamics, pressure differential management, temperature and humidity control, and contamination risk assessment. Post-manufacturing, these sophisticated systems and components undergo rigorous installation, commissioning, and comprehensive validation by highly skilled service providers or dedicated in-house teams. These critical downstream activities extend beyond initial setup to include essential ongoing services such as routine maintenance, calibration of monitoring equipment, and periodic recertification. These services are indispensable for ensuring the sustained operational efficiency, continuous compliance, and long-term integrity of the cleanroom facility, making the expertise of system integrators in project management and regulatory validation a cornerstone of successful cleanroom deployment.

The distribution channels employed within the Cleanroom Technology Market are multifaceted and strategically aligned to optimize market reach and ensure effective customer engagement. For large-scale, highly customized cleanroom projects, particularly those for major pharmaceutical corporations, semiconductor fabrication plants, or advanced research institutions, a direct sales model is predominantly utilized. This approach facilitates deep client engagement, allows for the development of highly tailored solutions, and ensures comprehensive project management from concept through to operational handover. Conversely, for standardized cleanroom equipment, consumables, and smaller-scale cleanroom setups, indirect channels involving an expansive network of specialized distributors, resellers, and increasingly, online marketplaces, play a crucial role. These intermediaries are vital for broadening market access, providing localized sales and technical support, and efficiently managing logistics for a wider, more diverse customer base, including small and medium-sized enterprises (SMEs) and specialized research institutions. The strategic selection and meticulous management of these diverse distribution channels are absolutely critical for achieving widespread market penetration, ensuring customer satisfaction, and sustaining robust business growth in this highly specialized and technologically driven industry.

Cleanroom Technology Market Potential Customers

The potential customer base for Cleanroom Technology is incredibly diverse, primarily encompassing industries where precision, sterility, and stringent contamination control are not merely desirable but absolutely non-negotiable for product integrity, operational success, and regulatory adherence. The largest and most consistent segments of end-users reside within the pharmaceutical and biotechnology sectors, including major drug manufacturers, vaccine producers, contract manufacturing organizations (CMOs), and advanced biotech research firms. These entities are perpetual buyers of cleanroom solutions for sterile drug compounding, biopharmaceutical manufacturing, cell and gene therapy development, and quality control laboratories, where preventing microbial and particulate contamination is paramount for ensuring patient safety and therapeutic efficacy. Similarly, medical device manufacturers represent another substantial customer segment, heavily relying on cleanrooms for the aseptic assembly of sensitive diagnostic equipment, implants, surgical instruments, and wearable medical devices to ensure they are free from particulate matter and microbial contaminants before deployment, safeguarding patient health and device performance.

Beyond the life sciences, the semiconductor and electronics industries constitute a consistently significant and technologically demanding customer base for cleanroom technology. Manufacturers of microprocessors, integrated circuits, memory chips, advanced display technologies, and nanotechnology components absolutely require ultra-clean environments, often classified as ISO Class 1 or 2, to prevent even microscopic particles from causing critical defects that could lead to functional failures and substantial financial losses in advanced electronic devices. The aerospace and defense industries also represent critical customers, utilizing cleanrooms for the precise assembly of sensitive optical components, satellite parts, inertial navigation systems, and advanced weaponry, where environmental control is paramount for achieving the extreme reliability and performance required in unforgiving operational conditions. Emerging customer segments include rapidly developing areas of the automotive industry, particularly for electric vehicle battery manufacturing and the assembly of highly sensitive electronic components, where dust-free environments are crucial for quality and longevity. Additionally, the food and beverage industry increasingly adopts cleanroom principles for aseptic packaging and processing of high-value or perishable specialty foods to extend shelf life and ensure consumer safety, while academic and industrial research and development laboratories across various scientific disciplines consistently procure cleanroom technology for groundbreaking experiments and product innovation under controlled conditions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 7.5 billion |

| Market Forecast in 2032 | USD 14.0 billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Azbil Corporation, Clean Air Products, Camfil, DuPont de Nemours, Inc., Exyte AG, Illinois Tool Works (ITW), Kimberly-Clark Corporation, Labconco Corporation, Nicomac Srl, Taikisha Ltd., Terra Universal, Inc., Thermo Fisher Scientific Inc., Tema Sinergie S.p.A., Flow Sciences, Inc., Air Techniques International (ATI), Connect 2 Cleanrooms Ltd., Clean Room Construction Ltd., Micronova Manufacturing Inc., Kwang Tai Engineering Pte Ltd., Mecart |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cleanroom Technology Market Key Technology Landscape

The Cleanroom Technology Market is characterized by a rapidly evolving and highly dynamic technological landscape, driven by a continuous imperative for enhanced contamination control, superior operational efficiency, and unwavering adherence to increasingly stringent regulatory compliance standards across diverse industries. At the core of this landscape are highly sophisticated Heating, Ventilation, and Air Conditioning (HVAC) systems, which are meticulously engineered to maintain precise control over air pressure differentials, temperature, and humidity levels. These advanced systems are intrinsically linked with high-efficiency particulate air (HEPA) and ultra-low particulate air (ULPA) filters, which are absolutely crucial for trapping microscopic airborne particles and ensuring that the specified cleanliness levels, often defined by international standards such as ISO 14644, are consistently met. Innovations in filter media, including advanced composite materials and pleated designs, along with the development of energy-efficient fan filter units (FFUs) utilizing EC motors, are continuously boosting filtration performance while significantly reducing the substantial energy consumption that constitutes a major operational cost in cleanroom environments.

Beyond the fundamental air management systems, the technological landscape is increasingly shaped by advancements in construction methodologies and cutting-edge environmental monitoring solutions. Modular cleanroom construction has gained considerable traction in recent years, offering unparalleled flexibility, significantly faster deployment times, and easier scalability or reconfiguration compared to traditional, time-consuming stick-built cleanrooms. These modular sys

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager