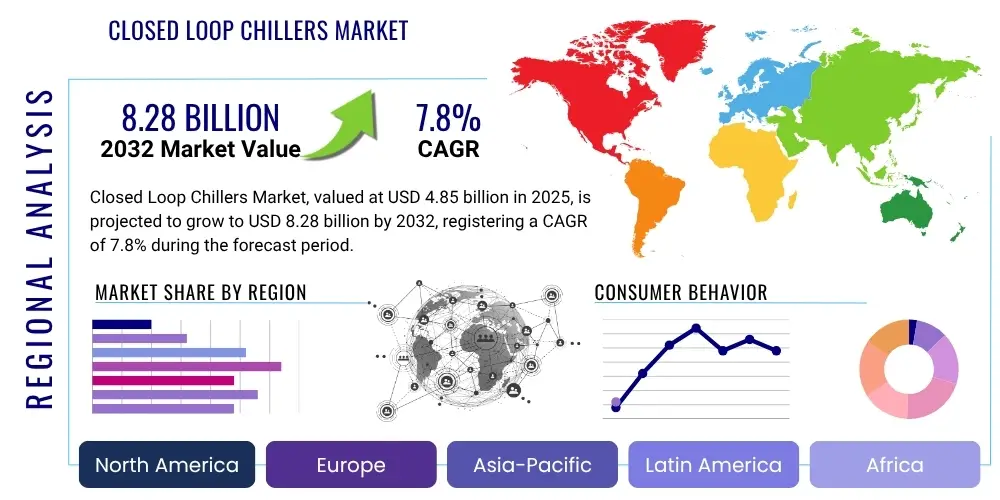

Closed Loop Chillers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429003 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Closed Loop Chillers Market Size

The Closed Loop Chillers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2025 and 2032. The market is estimated at $4.85 billion in 2025 and is projected to reach $8.28 billion by the end of the forecast period in 2032.

Closed Loop Chillers Market introduction

The Closed Loop Chillers Market encompasses systems designed to remove heat from a process or equipment by circulating a coolant through a sealed circuit, without exposing the coolant to ambient air. These systems are crucial for maintaining precise temperature control, preventing contamination, and ensuring efficient operation across various industries. The product range includes air-cooled and water-cooled variants, differentiated by their method of heat rejection.

Major applications for closed loop chillers span industrial process cooling, where they are vital for manufacturing operations involving plastics, metals, and chemicals; data centers, for managing the significant heat generated by servers; medical and pharmaceutical facilities, ensuring the integrity of sensitive equipment and processes; and laboratories, for precise environmental control in research and development. Their core benefit lies in their ability to deliver consistent, clean, and reliable cooling, minimizing water consumption and reducing operational costs compared to open-loop systems.

Key driving factors for the market include rapid industrialization, particularly in emerging economies, the surging demand from the burgeoning data center industry due to digital transformation, increasingly stringent regulatory requirements for process temperature control and water conservation, and a growing emphasis on energy efficiency and sustainability in industrial operations.

Closed Loop Chillers Market Executive Summary

The Closed Loop Chillers Market is characterized by a strong emphasis on energy efficiency, automation, and the adoption of eco-friendly refrigerants. Business trends indicate a shift towards modular and customizable chiller solutions that can be integrated seamlessly into smart factory ecosystems, along with a rising demand for predictive maintenance services powered by IoT. Companies are investing in research and development to enhance system performance, reduce noise levels, and offer compact designs suitable for diverse applications. The competitive landscape is dynamic, with both established players and new entrants vying for market share through technological innovation and strategic partnerships.

Regionally, Asia Pacific is anticipated to exhibit the highest growth rate, fueled by robust industrial expansion, significant investments in manufacturing, and the proliferation of data centers, particularly in countries like China and India. North America and Europe represent mature markets, driven by the need for upgrading existing infrastructure, stringent environmental regulations promoting energy-efficient solutions, and continued technological advancements in specialized industries such as medical and semiconductor manufacturing. Latin America and the Middle East and Africa are also showing promising growth, albeit from a smaller base, as industrial and commercial infrastructure develops.

In terms of segments, industrial process cooling continues to dominate the market due to its wide range of applications, from injection molding to chemical processing. However, the data center segment is experiencing rapid growth, propelled by the increasing demand for cloud computing and edge computing capabilities. The medical and pharmaceutical segments are also expanding significantly, driven by the need for precise temperature control in drug manufacturing, diagnostic equipment, and laboratory settings, highlighting the market's diversification beyond traditional industrial uses.

AI Impact Analysis on Closed Loop Chillers Market

User inquiries regarding AI's influence on the Closed Loop Chillers Market frequently center on how artificial intelligence can optimize chiller performance, enable predictive maintenance, and contribute to significant energy savings. There is a strong interest in understanding AI's role in smart factory integration, how it enhances system reliability, and its potential to address the complexities of energy management in large-scale cooling operations. Users often seek concrete examples of AI applications that translate into tangible benefits such as reduced operational costs, extended equipment lifespan, and improved environmental sustainability.

AI's impact on the Closed Loop Chillers Market is poised to be transformative, moving beyond simple automation to intelligent, adaptive control systems. By leveraging machine learning algorithms to analyze vast quantities of operational data, AI can precisely predict cooling loads, identify potential equipment failures before they occur, and dynamically adjust chiller parameters for optimal energy consumption. This capability not only enhances operational efficiency but also significantly reduces downtime and maintenance costs, addressing critical pain points for end-users.

- Enhanced Predictive Maintenance: AI algorithms analyze sensor data to forecast potential failures, enabling proactive servicing and minimizing unexpected downtime.

- Optimized Energy Consumption: Machine learning models adjust chiller settings in real-time based on environmental conditions and cooling demand, leading to substantial energy savings.

- Improved System Efficiency: AI-driven controls fine-tune operations, ensuring chillers run at peak performance and maximizing coefficient of performance (COP).

- Intelligent Fault Detection and Diagnosis: AI can quickly pinpoint anomalies and diagnose issues, streamlining troubleshooting and repair processes.

- Automated Load Management: AI dynamically balances cooling loads across multiple chillers, ensuring efficient operation and extending equipment lifespan.

- Seamless Integration with Building Management Systems (BMS): AI facilitates smarter communication and control within broader HVAC and facility management infrastructures.

DRO & Impact Forces Of Closed Loop Chillers Market

The Closed Loop Chillers Market is significantly influenced by a confluence of drivers, restraints, and opportunities that shape its growth trajectory and competitive landscape. Key drivers include the ongoing global industrialization, particularly the expansion of manufacturing capabilities in emerging economies, and the exponential growth of data centers worldwide, which demand highly reliable and efficient cooling solutions. Additionally, increasing environmental regulations mandating precise temperature control and advocating for energy-efficient industrial processes are pushing industries towards advanced closed loop systems. The growing adoption in specialized sectors like medical, pharmaceutical, and biotechnology further solidifies market expansion.

However, several restraints pose challenges to market growth. The high initial capital investment required for closed loop chiller systems can be a deterrent for small and medium-sized enterprises. Furthermore, the complexity involved in the installation, commissioning, and specialized maintenance of these advanced systems often necessitates skilled personnel, adding to operational costs. The presence of alternative cooling technologies, though often less efficient for specific applications, can also limit market penetration in certain segments. Environmental concerns related to certain refrigerants and their potential global warming impact also represent a restraint, pushing for innovation in greener alternatives.

Opportunities for market players lie in the development and integration of IoT and AI for enhanced predictive maintenance, remote monitoring, and optimal system performance, offering significant value to end-users. The rising demand for customized chiller solutions tailored to specific niche applications, coupled with the ongoing research and development into eco-friendly and low-GWP (Global Warming Potential) refrigerants, presents avenues for innovation and market differentiation. Expansion into rapidly industrializing regions and addressing the evolving needs of advanced manufacturing processes also represent substantial growth opportunities.

Segmentation Analysis

The Closed Loop Chillers Market is comprehensively segmented by various criteria to provide a detailed understanding of its dynamics and target customer groups. These segments allow for a granular analysis of market trends, technological preferences, and application-specific demands, enabling stakeholders to identify lucrative opportunities and tailor their strategies effectively. The primary segmentation categories include type of chiller, key components, refrigerant type, diverse applications, and the end-use industries that primarily benefit from these cooling solutions.

- By Type:

- Air-Cooled

- Water-Cooled

- By Component:

- Compressors

- Condensers

- Evaporators

- Expansion Valves

- Pumps

- Controls

- Heat Exchangers

- By Refrigerant Type:

- HFCs (Hydrofluorocarbons)

- HFOs (Hydrofluoroolefins)

- Natural Refrigerants (CO2, Ammonia, Propane)

- By Application:

- Industrial Process Cooling

- Data Centers

- Medical and Pharmaceutical

- Laboratories

- Plastics and Rubber Processing

- Food and Beverage

- Printing and Packaging

- Metal Finishing

- HVAC Systems

- By End-Use Industry:

- Manufacturing (Automotive, Electronics, Heavy Industry)

- IT and Telecommunications

- Healthcare (Hospitals, Clinics, Research Facilities)

- Chemicals and Petrochemicals

- Energy (Power Generation, Renewables)

- Food and Beverage Processing

- Building and Construction

Value Chain Analysis For Closed Loop Chillers Market

The value chain for the Closed Loop Chillers Market begins with upstream activities involving the sourcing and manufacturing of critical raw materials and components. This segment includes suppliers of metals such as copper and aluminum for coils, refrigerants, compressors, condensers, evaporators, pumps, and sophisticated control systems. Key players in this stage focus on quality, cost-effectiveness, and ensuring a stable supply chain, as the performance and reliability of the final chiller product are heavily dependent on these foundational elements. Innovations in component design and material science directly impact the efficiency and sustainability of the entire system.

Moving downstream, the value chain encompasses the assembly and manufacturing of the chiller units, followed by their distribution, installation, and after-sales services. Manufacturers either sell directly to large industrial clients and data center operators or utilize a network of distributors, wholesalers, and Original Equipment Manufacturers (OEMs) who integrate chillers into larger systems. The distribution channels can be direct, involving manufacturer sales teams, or indirect, through specialized resellers and contractors. After-sales support, including maintenance, repairs, and parts supply, forms a critical part of the downstream segment, contributing significantly to customer satisfaction and long-term value.

Both direct and indirect distribution channels play vital roles. Direct sales allow for closer client relationships and custom solutions for complex industrial projects, ensuring specific technical requirements are met. Indirect channels provide broader market reach, particularly for standardized products and smaller installations, leveraging the established networks of distributors and system integrators. The efficiency and effectiveness of these channels are paramount for market penetration and ensuring timely delivery and service to a diverse customer base, from large industrial plants to specialized laboratories.

Closed Loop Chillers Market Potential Customers

The Closed Loop Chillers Market serves a diverse range of end-users who require precise and reliable temperature control for their operations. These end-users are typically characterized by processes or equipment that generate significant heat and demand consistent cooling to maintain optimal performance, prevent damage, or ensure product quality. Manufacturing facilities across various sectors constitute a major segment, where chillers are integral to processes such as plastic injection molding, metal fabrication, laser cutting, and chemical reaction control. The consistent cooling provided by closed loop systems ensures the integrity of production lines and the quality of finished goods.

Another rapidly expanding customer base includes data centers and IT infrastructure providers. With the continuous growth of cloud computing, artificial intelligence, and big data analytics, the heat generated by servers and networking equipment has escalated, making efficient and reliable cooling an absolute necessity to prevent overheating and ensure uninterrupted operation. Closed loop chillers offer the critical advantage of isolated coolant circuits, protecting sensitive electronics from contamination and ensuring stable thermal environments crucial for data integrity and system uptime.

Furthermore, the medical, pharmaceutical, and laboratory sectors are significant potential customers. Hospitals and research facilities rely on closed loop chillers for cooling MRI machines, medical lasers, laboratory equipment like electron microscopes, and maintaining precise temperatures for drug manufacturing and storage. In these applications, the cleanliness, stability, and reliability of closed loop cooling are paramount to meet stringent regulatory requirements and ensure the accuracy of scientific processes and the safety of patient care.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $4.85 billion |

| Market Forecast in 2032 | $8.28 billion |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daikin Industries Ltd., Carrier Global Corporation, Johnson Controls International Plc, Trane Technologies Plc, Mitsubishi Electric Corporation, Emerson Electric Co., Parker Hannifin Corporation, KKT chillers GmbH, FASCHING L + R GmbH (AETA CHILLERS), Dimplex Thermal Solutions (Glen Dimplex Deutschland GmbH), OptiTemp, Inc., Fluidex Systems, Hubbell Incorporated (Harmonizer), Smardt Chiller Group Inc., Mayekawa Mfg. Co. Ltd., SMC Corporation, Kaeser Kompressoren SE, GEA Group AG, Frigel Firenze S.p.A., SPX Cooling Technologies |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Closed Loop Chillers Market Key Technology Landscape

The Closed Loop Chillers Market is characterized by continuous technological evolution aimed at enhancing efficiency, reliability, and environmental sustainability. A prominent trend is the widespread adoption of variable speed drive (VSD) compressors, which allow chillers to precisely match cooling loads, significantly reducing energy consumption compared to traditional fixed-speed compressors. This technology not only lowers operational costs but also extends the lifespan of the equipment by minimizing wear and tear. Furthermore, advancements in heat exchanger designs, such as microchannel condensers, improve heat transfer efficiency within more compact footprints, making chillers more suitable for space-constrained applications.

Another critical area of innovation lies in the development and integration of advanced control systems and digital technologies. IoT connectivity is becoming standard, enabling remote monitoring, diagnostics, and predictive maintenance. This allows operators to track performance in real-time, anticipate potential failures, and optimize settings for peak efficiency, often leveraging cloud-based analytics. The integration of artificial intelligence and machine learning algorithms further refines these control capabilities, allowing chillers to adapt autonomously to changing environmental conditions and cooling demands, thereby maximizing energy savings and minimizing human intervention.

The market also sees significant developments in refrigerant technology, driven by stringent environmental regulations aimed at phasing out high global warming potential (GWP) refrigerants. There is a growing shift towards low-GWP alternatives, including hydrofluoroolefins (HFOs) and natural refrigerants like CO2, ammonia, and propane. Manufacturers are investing in redesigning systems to safely and efficiently utilize these new refrigerants, contributing to the overall sustainability efforts of the industry. These technological advancements collectively contribute to more intelligent, environmentally friendly, and economically viable closed loop cooling solutions.

Regional Highlights

- North America: This region represents a mature market for closed loop chillers, driven by the strong presence of data centers, advanced manufacturing industries, and a robust healthcare sector. Emphasis is placed on energy efficiency, smart technologies, and retrofitting existing infrastructure with more sustainable solutions. The U.S. and Canada are leading adopters of advanced chiller technologies due to stringent environmental regulations and a focus on operational cost reduction.

- Europe: The European market is characterized by strict environmental policies, such as the F-Gas regulation, which drives demand for chillers utilizing low-GWP refrigerants and highly energy-efficient designs. Countries like Germany, France, and the UK are key markets, with significant adoption in the automotive, chemical, and pharmaceutical industries, as well as a growing focus on sustainable building solutions and district cooling networks.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, propelled by rapid industrialization, massive investments in infrastructure development, and the explosive growth of the digital economy leading to a proliferation of data centers. China, India, Japan, and South Korea are at the forefront of this expansion, with increasing demand from manufacturing (electronics, plastics), food and beverage, and pharmaceutical sectors, alongside a growing awareness of energy conservation.

- Latin America: This region is an emerging market for closed loop chillers, driven by increasing foreign direct investment in manufacturing, growth in the food and beverage industry, and nascent data center development. Countries like Brazil, Mexico, and Argentina are gradually adopting modern cooling solutions to improve industrial efficiency and meet rising operational demands, albeit with a focus on cost-effective and reliable systems.

- Middle East and Africa (MEA): The MEA market is witnessing steady growth, primarily fueled by significant investments in industrial infrastructure, particularly in the oil and gas, petrochemical, and construction sectors in the Gulf Cooperation Council (GCC) countries. The demand for reliable cooling solutions in extreme climatic conditions, coupled with expanding commercial and residential developments requiring centralized cooling, is a key driver. Africa's industrialization efforts also contribute to the market's expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Closed Loop Chillers Market.- Daikin Industries Ltd.

- Carrier Global Corporation

- Johnson Controls International Plc

- Trane Technologies Plc

- Mitsubishi Electric Corporation

- Emerson Electric Co.

- Parker Hannifin Corporation

- KKT chillers GmbH

- FASCHING L + R GmbH (AETA CHILLERS)

- Dimplex Thermal Solutions (Glen Dimplex Deutschland GmbH)

- OptiTemp, Inc.

- Fluidex Systems

- Hubbell Incorporated (Harmonizer)

- Smardt Chiller Group Inc.

- Mayekawa Mfg. Co. Ltd.

- SMC Corporation

- Kaeser Kompressoren SE

- GEA Group AG

- Frigel Firenze S.p.A.

- SPX Cooling Technologies

Frequently Asked Questions

What is a closed loop chiller and how does it differ from an open loop system?

A closed loop chiller circulates a coolant through a sealed system without exposure to ambient air or contaminants, ensuring consistent temperature and system cleanliness. In contrast, open loop systems expose the coolant to the atmosphere, making them susceptible to evaporation and contamination, thus requiring more maintenance and potentially less precise temperature control.

What are the primary benefits of using a closed loop chiller in industrial applications?

The primary benefits include enhanced energy efficiency due to precise temperature control, reduced water consumption because the coolant is recirculated, prevention of contamination in sensitive processes, extended equipment lifespan by avoiding corrosion and scaling, and lower overall operational costs compared to less efficient cooling methods.

Which industries are the largest consumers of closed loop chillers?

The largest consumers of closed loop chillers are typically industries requiring precise temperature management and contamination control. This includes industrial process cooling (e.g., plastics, metals, chemicals), data centers, medical and pharmaceutical facilities, and various laboratory applications.

How do environmental regulations impact the Closed Loop Chillers Market?

Environmental regulations, such as those targeting fluorinated greenhouse gases (F-gases), significantly impact the market by driving the demand for chillers that utilize low global warming potential (GWP) or natural refrigerants. This pushes manufacturers to innovate in system design and refrigerant alternatives, promoting sustainable cooling solutions.

What role does AI play in modern closed loop chiller systems?

AI plays a crucial role in modern closed loop chiller systems by enabling predictive maintenance, optimizing energy consumption through real-time load management, enhancing overall system efficiency, and providing intelligent fault detection. This leads to reduced downtime, lower operational costs, and improved reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager