Cold Planer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428265 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Cold Planer Market Size

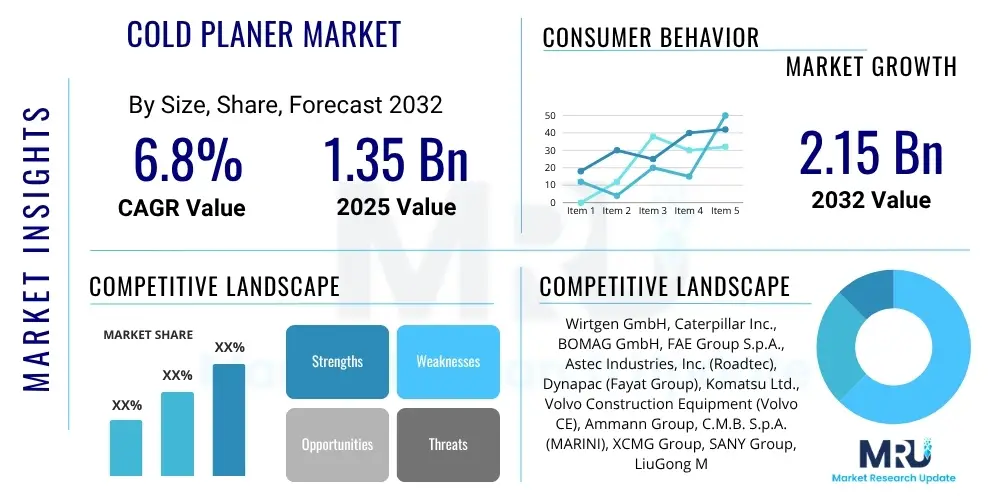

The Cold Planer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.35 Billion in 2025 and is projected to reach USD 2.15 Billion by the end of the forecast period in 2032.

Cold Planer Market introduction

The Cold Planer Market encompasses the global sales and distribution of heavy construction equipment specifically designed for the removal of asphalt and concrete surfaces. These machines, also known as pavement milling machines or road planers, are critical for road maintenance, rehabilitation, and new construction projects. Their primary function involves precisely grinding and removing layers of pavement to a specified depth, creating a uniform surface for subsequent repairs or overlays. This process is essential for correcting pavement distresses such as ruts, cracks, and bumps, ultimately extending the lifespan of road infrastructure and improving ride quality. The versatility of cold planers allows them to be utilized in various applications, from large-scale highway projects to smaller municipal roads, airport runways, and parking lots, making them indispensable assets in the construction and infrastructure development sector worldwide.

The core product in this market is the cold planer itself, which typically consists of a powerful engine, a rotating cutting drum equipped with tungsten carbide teeth, and a sophisticated control system that ensures precise depth and slope accuracy. These machines are available in various sizes and configurations, including compact models for urban environments and large, high-capacity units for major highway rehabilitation. The significant benefits derived from using cold planers include enhanced operational efficiency, reduced material waste through recycling of milled pavement, and the ability to maintain traffic flow by quickly clearing work zones. Furthermore, the precision offered by modern cold planers minimizes the need for extensive structural repairs, contributing to cost-effectiveness and sustainability in road construction and maintenance. The ability to reclaim and reuse milled materials also aligns with growing environmental sustainability goals, providing a circular economy approach to road infrastructure management.

The market is significantly driven by a confluence of factors, prominently including increasing global investment in infrastructure development and rehabilitation, particularly in emerging economies. The aging road networks in developed countries necessitate constant repair and upgrade, further fueling demand. Rapid urbanization and the corresponding expansion of transportation networks also contribute to market growth, as new roads are built and existing ones are expanded or improved to accommodate rising traffic volumes. Additionally, technological advancements in cold planer design, such as improved fuel efficiency, enhanced operator comfort, and integrated telematics for fleet management, are accelerating the adoption of newer models. These advancements not only improve productivity but also address environmental concerns through reduced emissions and more efficient material handling. The shift towards preventive maintenance strategies over reactive repairs further solidifies the demand for cold planers, emphasizing long-term infrastructure health.

Cold Planer Market Executive Summary

The Cold Planer Market is experiencing robust growth, propelled by global infrastructure spending and the imperative for road maintenance and rehabilitation. Business trends indicate a strong emphasis on technological innovation, with manufacturers integrating advanced features such as automation, telematics, and improved operator interfaces to enhance efficiency and productivity. There is a discernible shift towards more sustainable and fuel-efficient models, driven by stringent environmental regulations and rising operational costs. The market is also witnessing a trend of consolidation among key players, alongside a burgeoning rental market that allows smaller contractors to access high-value equipment without significant upfront capital investment. Supply chain resilience, following recent global disruptions, is a major focus for manufacturers, ensuring consistent delivery of machines and spare parts.

From a regional perspective, the Asia Pacific region is poised for significant growth, primarily due to rapid urbanization, massive infrastructure projects in countries like China and India, and increasing government allocations for road development. North America and Europe, while mature markets, continue to exhibit steady demand, driven by the ongoing need to repair and upgrade aging road networks and a strong focus on adopting advanced, eco-friendly technologies. Latin America and the Middle East & Africa regions are also contributing to market expansion, fueled by investments in transportation infrastructure linked to economic development and resource extraction projects. Each region presents unique challenges and opportunities, influenced by local economic conditions, regulatory frameworks, and the pace of infrastructure development. The diversified regional growth ensures a balanced global market expansion profile, mitigating risks associated with over-reliance on any single geographical area.

Segmentation trends within the Cold Planer Market highlight an increasing demand for specialized equipment tailored to specific applications. For instance, compact and versatile cold planers are gaining traction in urban areas for precise milling in confined spaces, while larger, high-capacity machines remain dominant for extensive highway projects. There is also a growing preference for tracked cold planers over wheeled ones in certain applications due to better traction and stability on uneven surfaces. Furthermore, the market is seeing a demand for machines with enhanced dust suppression systems and lower noise emissions, reflecting greater environmental consciousness and urban planning requirements. The integration of advanced control systems and data analytics capabilities is becoming a standard expectation across all segments, enabling operators to achieve higher precision and efficiency, thereby optimizing project timelines and costs. This evolution in product offerings is critical for meeting the diverse and evolving needs of construction professionals globally.

AI Impact Analysis on Cold Planer Market

User inquiries about AI's influence on the Cold Planer Market frequently revolve around how artificial intelligence can enhance operational efficiency, safety, and precision. Common questions include the potential for autonomous operation, the role of AI in predictive maintenance, how AI can optimize milling parameters in real-time, and its contribution to data-driven project management. Users are particularly interested in understanding if AI can mitigate the current shortage of skilled operators, improve fuel efficiency, and reduce overall project costs. There is a clear expectation that AI will lead to smarter, more adaptive machines that can self-diagnose issues and provide actionable insights for decision-making, transforming traditional pavement milling processes into highly optimized and sustainable operations.

- AI-driven predictive maintenance: Algorithms analyze machine data to forecast potential failures, optimizing maintenance schedules and reducing downtime.

- Autonomous operation capabilities: AI facilitates self-steering and navigation, allowing cold planers to operate independently or with minimal human intervention, especially in repetitive tasks.

- Real-time milling optimization: AI systems process sensor data to adjust cutting depth, speed, and pressure dynamically, ensuring optimal material removal and surface quality.

- Operator assist systems: AI provides real-time feedback and guidance to operators, enhancing precision, consistency, and reducing the learning curve for new personnel.

- Enhanced safety protocols: AI-powered collision avoidance and proximity detection systems improve workplace safety on construction sites.

- Data analytics for project management: AI integrates operational data with project plans, offering insights for better resource allocation, scheduling, and overall project efficiency.

- Improved fuel efficiency: AI algorithms optimize engine performance and hydraulic systems based on current operating conditions, reducing fuel consumption and emissions.

- Automated quality control: AI vision systems can detect surface irregularities post-milling, ensuring conformity to specifications and minimizing rework.

- Integration with BIM and digital twins: AI facilitates the seamless flow of data between cold planers and broader digital construction models for comprehensive project oversight.

- Adaptive learning for diverse materials: AI can learn from different asphalt and concrete compositions to adapt milling strategies for optimal results across varying surface conditions.

DRO & Impact Forces Of Cold Planer Market

The Cold Planer Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all contributing to its overall growth trajectory and impact forces. A primary driver is the accelerating global infrastructure development, particularly the expansion and renovation of road networks. Governments worldwide are allocating substantial budgets towards enhancing transportation infrastructure, which directly translates into increased demand for road construction and rehabilitation equipment, including cold planers. The urgent need for maintenance and repair of aging pavements in developed economies also acts as a consistent demand generator. Furthermore, rapid urbanization necessitates new road construction and expansion projects, especially in emerging markets, further bolstering market growth. Technological advancements in cold planer design, offering improved efficiency, precision, and sustainability, also serve as a crucial driver, encouraging equipment upgrades and new purchases.

Conversely, several restraints temper the market's full potential. The high initial capital investment required for purchasing cold planers can be a significant barrier for smaller contractors or those in regions with limited financial resources. This often leads to a preference for renting equipment, which, while beneficial for the rental market, can suppress direct sales. A persistent shortage of skilled operators and maintenance technicians capable of handling advanced cold planing equipment poses operational challenges, affecting productivity and equipment uptime. Additionally, the cyclical nature of the construction industry, heavily dependent on economic conditions and government spending, introduces market volatility. Environmental regulations pertaining to noise emissions, dust control, and fuel efficiency also impose additional costs on manufacturers for compliance and on operators for adherence, which can impact profitability and equipment design.

Despite these restraints, substantial opportunities exist for market expansion and innovation. The growing trend of adopting sustainable construction practices, including the recycling of milled asphalt pavement (RAP), presents a significant opportunity for cold planer manufacturers to highlight the environmental benefits of their equipment. Expanding rental equipment markets offer a pathway for greater penetration and accessibility, particularly in developing regions. Furthermore, the integration of advanced technologies such as telematics, automation, and AI for predictive maintenance and autonomous operation creates avenues for product differentiation and value addition. Emerging markets, with their burgeoning infrastructure needs and relatively nascent road networks, offer considerable long-term growth prospects. The increasing focus on smart city initiatives, which prioritize efficient and integrated urban infrastructure, also presents new applications and demands for sophisticated cold planing solutions, pushing innovation in precision and low-impact operations. These opportunities, coupled with ongoing infrastructure demands, are expected to shape the market's future trajectory.

Segmentation Analysis

The Cold Planer Market is extensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation allows for targeted market strategies and a granular analysis of demand patterns across various categories. The primary methods of segmentation include classification by product type, application, capacity, sales channel, and geographical region, each offering unique insights into the market structure and consumer preferences.

- By Product Type:

- Wheeled Cold Planers: Characterized by greater mobility and speed for transport between job sites, often favored for smaller or urban projects.

- Tracked Cold Planers: Provide superior traction and stability, especially on uneven terrain, preferred for large-scale highway and heavy-duty applications.

- By Application:

- Road Construction: New road building, expansion, and major highway projects.

- Road Rehabilitation & Maintenance: Repairing existing roads, highways, and bridges.

- Airport Runways: Milling and resurfacing of airport pavements.

- Parking Lots & Urban Areas: Smaller scale milling for commercial properties and city streets.

- Bridge Decks: Specialized applications for bridge deck rehabilitation.

- By Capacity (Cutting Width):

- Small (less than 1 meter): Compact machines for urban and confined spaces.

- Medium (1 to 2 meters): Versatile machines for a wide range of municipal and medium-sized projects.

- Large (more than 2 meters): High-capacity machines for extensive highway and airport projects.

- By Sales Channel:

- Direct Sales: Manufacturers selling directly to large contractors or government bodies.

- Dealer & Distributor Sales: Sales through authorized third-party networks, providing local support and services.

- Rental Sales: Equipment leased to contractors for specific project durations, catering to varying project needs and capital constraints.

- By Regional Outlook:

- North America: United States, Canada, Mexico

- Europe: Germany, United Kingdom, France, Italy, Spain, Russia, Rest of Europe

- Asia Pacific: China, India, Japan, South Korea, ASEAN Countries, Rest of Asia Pacific

- Latin America: Brazil, Argentina, Colombia, Rest of Latin America

- Middle East & Africa: GCC Countries, South Africa, Rest of Middle East & Africa

Value Chain Analysis For Cold Planer Market

The value chain for the Cold Planer Market is a complex network involving various stakeholders, from raw material suppliers to end-users, each contributing to the production, distribution, and consumption of these specialized machines. The process begins with upstream analysis, which focuses on the sourcing of critical components and raw materials. Key inputs include high-grade steel for the machine chassis and cutting drums, advanced engines (diesel, and increasingly, hybrid or electric powertrains) from specialized manufacturers, sophisticated hydraulic systems, electronic control units, and wear parts like tungsten carbide cutting teeth. Relationships with these upstream suppliers are crucial for ensuring the quality, reliability, and cost-effectiveness of the final product. Strong partnerships and supply chain resilience are paramount, especially given global commodity price fluctuations and potential disruptions in component availability. Manufacturers often engage in strategic sourcing to secure components that meet strict performance and environmental standards, particularly regarding engine emissions and fuel efficiency.

Moving further along the value chain, the manufacturing stage involves the assembly, testing, and quality control of cold planers. This stage is capital-intensive and requires significant investment in advanced production facilities, skilled labor, and R&D for continuous product innovation. Manufacturers often differentiate themselves through proprietary cutting drum designs, advanced control systems, and integrated technologies such as telematics and automation. Once manufactured, the machines move through distribution channels to reach the end-users. The distribution network is a critical component, encompassing both direct sales and indirect channels. Direct sales typically involve major national or multinational construction firms and government agencies, where manufacturers can offer tailored solutions and direct support. Indirect sales, primarily through extensive dealer and distributor networks, are vital for reaching a broader base of regional contractors and providing localized sales, service, and spare parts support. These dealers often act as crucial intermediaries, offering financing options, training, and maintenance services, thereby adding significant value to the customer experience.

The downstream analysis of the value chain focuses on the ultimate end-users and the services associated with equipment operation and maintenance. The primary downstream consumers are road construction and maintenance contractors, public works departments, airport authorities, and private developers engaged in infrastructure projects. Rental companies also form a significant part of the downstream market, purchasing machines from manufacturers to lease out to contractors who prefer operational flexibility over capital expenditure. Post-sale services, including maintenance, repairs, spare parts supply, and operator training, are critical for maximizing equipment uptime and ensuring customer satisfaction. The efficiency of these downstream services directly impacts the perceived value and brand loyalty of cold planer manufacturers. The circular economy aspect is also gaining prominence, with the recycling of milled asphalt and concrete materials creating a feedback loop for sustainable practices, further integrating the cold planer into broader infrastructure management ecosystems. This comprehensive value chain ensures that cold planers are not just sold, but are effectively supported throughout their operational life cycle.

Cold Planer Market Potential Customers

The Cold Planer Market serves a diverse range of potential customers, each with specific operational needs and purchasing criteria. Primarily, the core customer base comprises large and small-scale road construction and maintenance contractors. These entities are engaged in a wide array of projects, from major highway rehabilitation to urban street repair and new road construction. For larger contractors, the focus is often on high-capacity, technologically advanced machines that can handle extensive projects efficiently, offering precision and reliability under demanding conditions. Smaller contractors, on the other hand, might prioritize versatile, compact models that are easier to maneuver in confined urban spaces and offer a favorable balance between performance and investment cost. Both segments value equipment durability, fuel efficiency, and ease of maintenance, as these factors directly impact project profitability and operational uptime. The recurring need for road infrastructure upkeep ensures a consistent demand from this contractor segment.

Government public works departments and municipal authorities represent another significant customer segment. These governmental bodies are responsible for maintaining public infrastructure, including roads, bridges, and sometimes airport runways. Their purchasing decisions are often influenced by long-term cost-effectiveness, adherence to environmental regulations, and the ability of the equipment to support sustainable practices, such as cold recycling. They frequently procure cold planers for their own crews or specify their use in contracts awarded to private companies. Airport authorities also constitute a specialized customer group, requiring cold planers for the precision milling and resurfacing of runways and taxiways, where surface smoothness and structural integrity are paramount for aircraft safety. These applications often demand highly accurate and reliable machines that can operate within strict timeframes to minimize disruption to air traffic. The public sector's continuous investment in maintaining and upgrading critical infrastructure ensures a stable and significant portion of the cold planer market demand.

Furthermore, rental equipment companies form a crucial indirect customer segment that influences the market. These companies purchase cold planers directly from manufacturers to then lease them to contractors, offering flexibility and reducing the capital expenditure burden for end-users. This model is particularly attractive for contractors with fluctuating project volumes or those seeking to try new equipment without a long-term commitment. The growth of the rental market indicates a trend towards operational efficiency and asset utilization, making rental companies key purchasers who then serve as intermediaries to a broad spectrum of end-users. Private developers, involved in large-scale commercial or residential projects requiring new access roads and parking facilities, also represent a segment of potential customers, often purchasing or renting cold planers for specific project requirements. The diverse needs of these customer groups collectively drive innovation and product development in the cold planer industry, pushing manufacturers to offer a wide range of machines with varying capacities, features, and technological capabilities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.35 Billion |

| Market Forecast in 2032 | USD 2.15 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wirtgen GmbH, Caterpillar Inc., BOMAG GmbH, FAE Group S.p.A., Astec Industries, Inc. (Roadtec), Dynapac (Fayat Group), Komatsu Ltd., Volvo Construction Equipment (Volvo CE), Ammann Group, C.M.B. S.p.A. (MARINI), XCMG Group, SANY Group, LiuGong Machinery Co. Ltd., John Deere, Terex Corporation, GEHL (Manitou Group), Case Construction Equipment, GOMACO Corporation, Atlas Copco, Hyundai Construction Equipment |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cold Planer Market Key Technology Landscape

The Cold Planer Market is continuously evolving with significant technological advancements aimed at enhancing efficiency, precision, and environmental performance. A cornerstone of this evolution is the integration of advanced control systems, which utilize sophisticated sensors and software to ensure highly accurate milling depths and precise slope control. Modern cold planers feature automatic leveling systems, often incorporating GPS and 3D machine control technologies, enabling operators to achieve exact specifications with minimal manual intervention. This precision is critical for seamless pavement overlays and for optimizing material removal, thereby reducing waste and project costs. Furthermore, telematics systems have become standard, allowing for real-time monitoring of machine performance, location, fuel consumption, and operational parameters, which significantly aids in fleet management, predictive maintenance, and operational planning. These systems provide valuable data insights, helping contractors optimize their workflow and improve overall productivity across multiple job sites.

Another crucial aspect of the technology landscape is the development of more powerful and fuel-efficient engines that comply with increasingly stringent emission standards, such as EPA Tier 4 Final and EU Stage V. Manufacturers are investing heavily in advanced engine technologies, including selective catalytic reduction (SCR) and diesel particulate filters (DPF), to minimize environmental impact while maintaining high performance. Beyond engine efficiency, innovations in cutting drum design and cutting tool materials are enhancing milling performance and extending wear life. For instance, optimized tooth patterns and harder tungsten carbide inserts improve cutting efficiency, reduce vibrations, and prolong the intervals between tool changes. Dust suppression systems, incorporating high-pressure water sprays and vacuum extraction units, are also becoming more prevalent, improving air quality on job sites and enhancing worker safety, particularly in urban environments where dust can be a significant concern for public health and environmental compliance.

The future technology landscape for cold planers is increasingly leaning towards automation and artificial intelligence (AI). Semi-autonomous and fully autonomous capabilities are being explored, particularly for repetitive tasks, which could address the ongoing challenge of skilled labor shortages and further enhance operational consistency. AI is also being leveraged for predictive maintenance, analyzing machine data to anticipate component failures and schedule maintenance proactively, thereby minimizing costly downtime. Operator comfort and ergonomics are also receiving significant attention, with advancements in cabin design, noise reduction, and intuitive control interfaces. Moreover, the integration of cold planers into broader digital construction ecosystems, utilizing Building Information Modeling (BIM) and digital twin technologies, promises to revolutionize project planning, execution, and lifecycle management. These integrated solutions will allow for seamless data exchange and real-time project adjustments, ultimately leading to more efficient, sustainable, and safer road construction practices. The convergence of these technological innovations is transforming cold planers into highly intelligent and indispensable tools for modern infrastructure development.

Regional Highlights

- North America: This region represents a mature yet dynamic market, driven by extensive infrastructure rehabilitation projects and significant government investment in maintaining existing road networks. The focus here is on adopting technologically advanced cold planers, particularly those with telematics, automation features, and stringent emission compliance. There's a robust demand for versatile machines capable of handling both large-scale highway reconstruction and urban street repairs. The presence of major construction equipment manufacturers and a well-established rental market further fuels demand.

- Europe: Similar to North America, Europe is characterized by a strong emphasis on maintaining and upgrading aging infrastructure. Stringent environmental regulations and a focus on sustainability drive demand for fuel-efficient, low-emission cold planers with advanced dust suppression systems. Innovation in cold recycling technologies is also a key driver, promoting the use of cold planers that facilitate material reuse. Countries like Germany, France, and the UK are at the forefront of adopting cutting-edge milling technologies.

- Asia Pacific (APAC): This region is projected to be the fastest-growing market, primarily due to rapid urbanization, burgeoning population growth, and massive investments in new infrastructure development, particularly in China and India. The expansion of national highway networks, development of smart cities, and increased government spending on transportation infrastructure are key market drivers. While there's demand for advanced machines, cost-effectiveness and durability are significant purchasing factors for many developing economies within the region.

- Latin America: The market in Latin America is driven by ongoing infrastructure projects, particularly in countries like Brazil, Argentina, and Colombia. Investments in mining, agriculture, and energy sectors often necessitate the development and maintenance of robust road networks, contributing to the demand for cold planers. Economic stability and government policies favoring infrastructure development play a crucial role in shaping market growth here.

- Middle East & Africa (MEA): This region is experiencing growth fueled by significant investments in large-scale infrastructure projects, including new cities, transportation hubs, and energy-related developments. The expansion of road networks to support economic diversification away from oil in some countries, coupled with the need to upgrade existing infrastructure, drives demand. Projects related to tourism and trade also contribute to the market.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cold Planer Market.- Wirtgen GmbH

- Caterpillar Inc.

- BOMAG GmbH

- FAE Group S.p.A.

- Astec Industries, Inc. (Roadtec)

- Dynapac (Fayat Group)

- Komatsu Ltd.

- Volvo Construction Equipment (Volvo CE)

- Ammann Group

- C.M.B. S.p.A. (MARINI)

- XCMG Group

- SANY Group

- LiuGong Machinery Co. Ltd.

- John Deere

- Terex Corporation

- GEHL (Manitou Group)

- Case Construction Equipment

- GOMACO Corporation

- Atlas Copco

- Hyundai Construction Equipment

Frequently Asked Questions

What is a cold planer and its primary function?

A cold planer, also known as a pavement milling machine or road planer, is heavy construction equipment designed to remove layers of asphalt or concrete pavement from roads, bridges, and other surfaces. Its primary function is to grind and remove existing pavement to a specified depth, creating a uniform surface for rehabilitation or new overlay applications.

How do wheeled and tracked cold planers differ in application?

Wheeled cold planers offer greater mobility and higher travel speeds between job sites, making them suitable for urban projects or smaller, intermittent tasks. Tracked cold planers provide superior traction and stability, especially on uneven or soft terrain, making them preferred for large-scale highway rehabilitation and heavy-duty, long-duration milling operations requiring consistent performance.

What are the main benefits of using cold planers in road construction?

The main benefits include enhanced operational efficiency and precision in pavement removal, cost savings through the recycling of milled material (Reclaimed Asphalt Pavement or RAP), reduced need for extensive structural repairs, and minimal disruption to traffic flow due to faster project completion times. They also improve the quality and lifespan of rehabilitated road surfaces.

How is technology impacting the cold planer market?

Technology is significantly impacting the market through the integration of advanced control systems (GPS, 3D machine control), telematics for fleet management and diagnostics, and automation features for enhanced precision and efficiency. AI is also emerging for predictive maintenance and potential autonomous operation, contributing to smarter, more sustainable, and safer machines.

What factors are driving the growth of the Cold Planer Market?

Key drivers include increasing global investment in infrastructure development and road rehabilitation, the urgent need to maintain and upgrade aging road networks in developed countries, rapid urbanization leading to new road construction, and continuous technological advancements improving equipment efficiency, precision, and environmental performance.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager