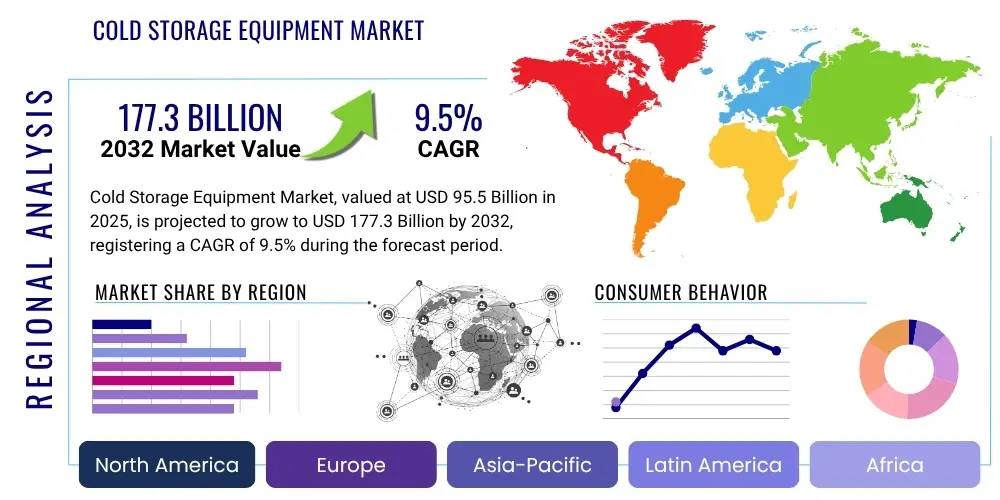

Cold Storage Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428571 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Cold Storage Equipment Market Size

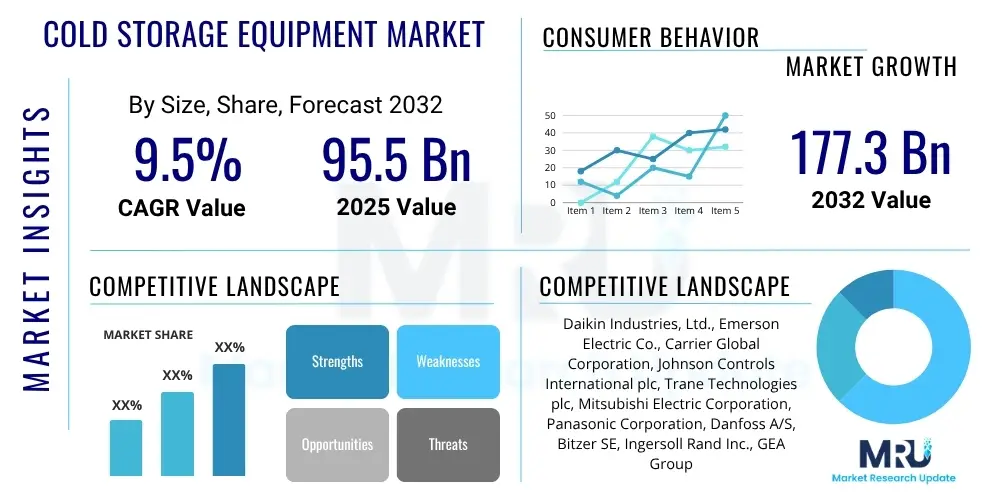

The Cold Storage Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032. The market is estimated at USD 95.5 billion in 2025 and is projected to reach USD 177.3 billion by the end of the forecast period in 2032.

Cold Storage Equipment Market introduction

The Cold Storage Equipment Market encompasses a wide array of specialized machinery and infrastructure designed to maintain products at specific low temperatures, essential for preserving their quality, safety, and extending shelf life. This market includes refrigeration units, insulated panels, temperature control systems, monitoring devices, and various material handling equipment utilized in controlled low-temperature environments. Products range from industrial chillers and freezers to smaller commercial refrigeration units, all playing a critical role in global supply chains. These solutions are vital across numerous sectors where precise temperature management is non-negotiable for product integrity.

Major applications of cold storage equipment span diverse industries, including food and beverages, pharmaceuticals, chemicals, and floriculture, supporting everything from fresh produce and processed foods to vaccines and sensitive chemical compounds. The primary benefits derived from these systems include minimized spoilage, enhanced product safety, regulatory compliance, and expanded market reach for perishable goods. The market is propelled by a confluence of factors such as increasing global trade in temperature-sensitive products, stringent food safety regulations, the expanding pharmaceutical sector, growth in organized retail, and the burgeoning demand for processed and frozen foods, all necessitating robust cold chain infrastructure and reliable equipment.

Cold Storage Equipment Market Executive Summary

The Cold Storage Equipment Market is experiencing robust growth driven by evolving consumer preferences for perishable goods, the expansion of pharmaceutical industries, and increasing globalization of food supply chains. Key business trends include a shift towards energy-efficient and environmentally friendly refrigeration technologies, the integration of automation and IoT for enhanced monitoring and management, and a focus on modular and customizable cold storage solutions to meet diverse industrial needs. Companies are investing in research and development to offer advanced compressors, insulation materials, and smart control systems that improve operational efficiency and reduce carbon footprint, aligning with global sustainability goals.

Regionally, Asia Pacific is anticipated to demonstrate the most significant growth due to rapid urbanization, increasing disposable incomes, and the expansion of the food processing and pharmaceutical sectors, particularly in countries like China and India. North America and Europe continue to be mature markets, focusing on technological upgrades, regulatory compliance, and optimizing existing infrastructure. Emerging economies in Latin America, the Middle East, and Africa are witnessing substantial investments in developing cold chain logistics to reduce post-harvest losses and support healthcare initiatives. Each region presents unique challenges and opportunities, influencing market strategies and equipment adoption.

Segmentation trends indicate a strong demand for industrial-scale refrigeration systems, particularly in warehouses and distribution centers, alongside a steady uptake of commercial refrigeration in retail and foodservice. The market for cold storage equipment is further segmented by temperature range, with both chilled and frozen categories showing consistent expansion, driven by specific product requirements. The integration of advanced refrigerants with lower global warming potential (GWP) is a notable trend across all segments, responding to environmental regulations and corporate sustainability mandates. This comprehensive overview highlights the dynamic nature of the market and its continuous adaptation to technological advancements and global demands.

AI Impact Analysis on Cold Storage Equipment Market

Users frequently inquire about how Artificial intelligence will transform the efficiency, cost-effectiveness, and reliability of cold storage operations. Common questions revolve around AI's ability to predict equipment failures, optimize energy consumption, manage inventory, and enhance overall operational transparency. There is a strong expectation that AI will lead to significant cost reductions through predictive maintenance and optimized energy use, coupled with concerns regarding data privacy, implementation costs, and the technical expertise required to integrate and manage AI systems effectively. The key themes highlight a desire for automation, smarter decision-making, and proactive problem-solving within complex cold chain logistics, tempered by practical considerations of adoption.

- AI-powered Predictive Maintenance: Proactively identifies potential equipment failures, reducing downtime and maintenance costs.

- Energy Optimization: AI algorithms analyze usage patterns and external factors to fine-tune refrigeration cycles, significantly lowering energy consumption.

- Demand Forecasting and Inventory Management: Enhances accuracy in predicting storage needs, minimizing waste and optimizing stock levels.

- Automated Quality Control: AI-driven sensors and cameras monitor product conditions, identifying potential spoilage or damage early.

- Route Optimization for Cold Chain Logistics: Improves efficiency of refrigerated transport, reducing fuel costs and delivery times.

- Enhanced Security and Monitoring: AI integrated with surveillance systems can detect anomalies and improve facility security.

- Data Analysis for Operational Insights: Provides deep insights into performance, allowing for continuous process improvement and strategic planning.

DRO & Impact Forces Of Cold Storage Equipment Market

The Cold Storage Equipment Market is primarily driven by the escalating demand for temperature-sensitive products across various sectors, including food and pharmaceuticals, necessitating robust cold chain infrastructure. Strict government regulations concerning food safety and pharmaceutical product integrity further compel businesses to invest in advanced cold storage solutions. Alongside these, opportunities arise from the rapid growth of e-commerce and organized retail, which require extensive cold chain networks for efficient last-mile delivery. However, the market faces significant restraints such as high initial investment costs for setting up and maintaining cold storage facilities, alongside the substantial energy consumption associated with refrigeration, which contributes to operational expenses and environmental concerns.

Impact forces on the market include technological advancements, particularly in energy-efficient refrigeration systems and smart monitoring solutions, which offer long-term operational savings and improved product safety. The increasing consumer awareness regarding food quality and safety standards also plays a crucial role, pushing manufacturers and logistics providers to upgrade their cold storage capabilities. Geopolitical factors, global trade policies, and economic stability can influence investment in new infrastructure and cross-border movement of temperature-controlled goods. The confluence of these drivers, restraints, and broader impact forces shapes the strategic decisions of market players and influences the overall trajectory of the cold storage equipment industry, pushing towards more sustainable and integrated solutions.

Segmentation Analysis

The Cold Storage Equipment Market is comprehensively segmented to provide a detailed understanding of its diverse components and applications. These segmentations are crucial for analyzing market dynamics, identifying specific growth opportunities, and understanding the varying demands across different industries and geographical regions. The market can be broadly categorized based on the type of equipment, the temperature range maintained, the specific application areas, and the end-user industries utilizing these critical cold chain solutions. Each segment exhibits unique characteristics and growth drivers, influencing investment patterns and technological developments within the sector.

- By Equipment Type

- Refrigeration Systems (Compressors, Condensers, Evaporators)

- Storage Equipment (Racks, Pallets)

- Insulated Panels

- Temperature Control Systems

- Monitoring and Control Devices (Sensors, Data Loggers)

- Freezers (Blast Freezers, Tunnel Freezers)

- Chillers

- Others (Doors, Valves, Controls)

- By Temperature Range

- Chilled (0°C to 15°C)

- Frozen (Below 0°C)

- Deep Frozen (Below -18°C)

- By Application

- Food and Beverages (Meat, Dairy, Fruits, Vegetables, Seafood, Processed Foods, Confectionery)

- Pharmaceuticals (Vaccines, Drugs, APIs)

- Chemicals

- Horticulture and Floriculture

- Healthcare (Blood Banks, Organ Storage)

- Biotechnology and Life Sciences

- Logistics and Distribution

- Others

- By End-User

- Food Processing Units

- Organized Retail and Supermarkets

- Warehouses and Distribution Centers

- Pharmaceutical and Biotech Companies

- Hospitals and Clinics

- Hotels and Restaurants

- Chemical Industry

- Research Institutions

Value Chain Analysis For Cold Storage Equipment Market

The value chain for the Cold Storage Equipment Market initiates with upstream activities, primarily involving the sourcing and manufacturing of raw materials and key components. This includes the production of metals like steel and aluminum for structural components, insulation materials such as polyurethane and polystyrene, and specialized parts like compressors, condensers, and evaporators which are integral to refrigeration systems. Key suppliers in this stage are manufacturers of advanced refrigeration technology, insulation producers, and component fabricators, who play a crucial role in determining the quality and efficiency of the final equipment. Innovation in these upstream segments, especially concerning energy efficiency and sustainable materials, directly impacts the downstream product offerings.

Moving downstream, the value chain encompasses the manufacturing and assembly of the complete cold storage equipment, which involves integrating various components into functional units like cold rooms, blast freezers, and refrigerated transport units. Following manufacturing, distribution channels become critical. These channels are typically a mix of direct and indirect approaches. Direct sales often occur for large industrial projects where manufacturers engage directly with end-users for custom solutions, installation, and after-sales service. Indirect channels involve distributors, wholesalers, and specialized contractors who supply equipment to smaller businesses, retailers, and specific application sectors. The effectiveness of these distribution networks is paramount for market penetration and timely delivery, especially given the global nature of demand.

The final stages of the value chain involve installation, commissioning, and comprehensive after-sales support, including maintenance, repairs, and upgrades. Service providers and specialized technicians are key players here, ensuring optimal performance and longevity of the equipment. Furthermore, the integration of digital solutions like IoT-enabled monitoring and control systems, as well as AI-driven predictive maintenance platforms, adds significant value by enhancing operational efficiency and reducing downtime. The interconnectedness of these stages, from raw material sourcing to end-user support, highlights the complex ecosystem that underpins the Cold Storage Equipment Market, where collaboration and efficiency across each link are vital for sustained growth and market competitiveness.

Cold Storage Equipment Market Potential Customers

Potential customers for Cold Storage Equipment span a wide and diverse range of industries and businesses that rely on precise temperature control for product preservation and safety. At the forefront are entities within the food and beverage industry, including food processing plants, meat and seafood packaging facilities, dairy product manufacturers, fruit and vegetable growers and distributors, and confectionery companies. These end-users require cold storage for raw ingredients, work-in-progress, and finished goods to prevent spoilage and maintain quality standards, which are essential for public health and economic viability. The growing global demand for fresh, frozen, and processed foods directly translates into a continuous need for advanced cold storage solutions across this vast sector.

Beyond food, the pharmaceutical and healthcare sectors represent another critical segment of potential customers. This includes pharmaceutical manufacturers, vaccine producers, hospitals, blood banks, research laboratories, and biotech firms, all of whom necessitate ultra-low temperature storage for sensitive drugs, vaccines, biological samples, and life-saving medical supplies. The stringent regulatory requirements and the high value of these products make reliable and accurately controlled cold storage equipment indispensable. The expansion of global health initiatives and the development of new temperature-sensitive medicines further drive demand from these specialized customers. Additionally, the chemical industry, particularly for specialty chemicals, polymers, and hazardous materials requiring controlled environments, also forms a significant customer base, alongside floriculture and horticulture industries that need cold storage to extend the shelf life of flowers, plants, and seeds during transit and display.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 95.5 Billion |

| Market Forecast in 2032 | USD 177.3 Billion |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Daikin Industries, Ltd., Emerson Electric Co., Carrier Global Corporation, Johnson Controls International plc, Trane Technologies plc, Mitsubishi Electric Corporation, Panasonic Corporation, Danfoss A/S, Bitzer SE, Ingersoll Rand Inc., GEA Group Aktiengesellschaft, Viessmann Group, Epta S.p.A., Lennox International Inc., Hussmann Corporation, Foster Refrigerator, Sanyo Electric Co. Ltd., K rber AG, AHT Cooling Systems GmbH, Dover Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cold Storage Equipment Market Key Technology Landscape

The Cold Storage Equipment Market is undergoing significant technological evolution, driven by the need for enhanced energy efficiency, improved temperature precision, and sustainable operations. A primary focus is on advanced refrigeration technologies, including variable frequency drive (VFD) compressors that optimize energy consumption by adjusting cooling capacity based on real-time demand, rather than operating at a constant, less efficient maximum. Furthermore, transcritical CO2 refrigeration systems are gaining traction as environmentally friendly alternatives to traditional hydrofluorocarbon (HFC) refrigerants, offering lower global warming potential (GWP) and compliance with evolving environmental regulations. These systems are particularly effective for large-scale industrial applications and demonstrate strong performance in various climatic conditions, marking a pivotal shift towards greener refrigeration solutions across the industry.

Another crucial technological advancement involves the integration of smart technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), into cold storage infrastructure. IoT sensors enable real-time monitoring of temperature, humidity, and equipment performance, allowing for proactive adjustments and preventing potential spoilage. This connectivity extends to predictive maintenance platforms, which use AI algorithms to analyze data from sensors and historical performance, forecasting potential equipment failures before they occur. Such predictive capabilities significantly reduce downtime, extend equipment lifespan, and optimize maintenance schedules, translating into substantial operational savings. The adoption of automation in cold storage warehouses, including automated storage and retrieval systems (AS/RS) and robotic material handling, also enhances efficiency, reduces labor costs, and improves safety within these challenging environments.

Moreover, improvements in insulation materials and cold room designs are contributing to the market's technological landscape. Advanced insulated panels with superior thermal properties minimize heat leakage, thereby reducing the energy required to maintain desired temperatures. Modular cold room designs offer flexibility and scalability, allowing businesses to expand or reconfigure their storage spaces as needs evolve. The development of advanced control systems provides precise temperature management and allows for remote monitoring and control, critical for maintaining specific environmental conditions for sensitive goods like pharmaceuticals. These technological innovations collectively aim to create more efficient, sustainable, and reliable cold chain solutions, addressing the complex demands of modern logistics and product preservation.

Regional Highlights

- North America: A mature market characterized by stringent food safety regulations, significant investment in advanced cold chain logistics, and a strong presence of pharmaceutical and processed food industries. Emphasis on energy-efficient and smart cold storage solutions.

- Europe: Driven by strict environmental regulations pushing for natural refrigerants, high demand for organic and fresh produce, and a well-established pharmaceutical sector. Focus on sustainability, automation, and optimizing existing infrastructure.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid urbanization, increasing disposable incomes, expanding food processing and retail sectors, and government initiatives to develop cold chain infrastructure, particularly in China, India, and Southeast Asian countries.

- Latin America: Emerging market with increasing investment in cold chain development to reduce post-harvest losses in agriculture and support growth in the food and beverage industry. Potential for new infrastructure development.

- Middle East and Africa (MEA): Growing demand for cold storage due to increasing food imports, expansion of organized retail, and development of healthcare infrastructure. Climatic challenges necessitate robust and efficient refrigeration technologies.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cold Storage Equipment Market.- Daikin Industries, Ltd.

- Emerson Electric Co.

- Carrier Global Corporation

- Johnson Controls International plc

- Trane Technologies plc

- Mitsubishi Electric Corporation

- Panasonic Corporation

- Danfoss A/S

- Bitzer SE

- Ingersoll Rand Inc.

- GEA Group Aktiengesellschaft

- Viessmann Group

- Epta S.p.A.

- Lennox International Inc.

- Hussmann Corporation

- Foster Refrigerator

- Sanyo Electric Co. Ltd.

- K rber AG

- AHT Cooling Systems GmbH

- Dover Corporation

Frequently Asked Questions

What is the projected growth rate for the Cold Storage Equipment Market?

The Cold Storage Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2025 and 2032, driven by rising demand for perishable goods and advancements in cold chain technology.

Which industries are the primary end-users of cold storage equipment?

The primary end-users include the food and beverage industry, pharmaceuticals, chemicals, horticulture, and healthcare, all requiring precise temperature control for product preservation and safety.

How does AI impact the Cold Storage Equipment Market?

AI significantly impacts the market through predictive maintenance, energy optimization, improved inventory management, and enhanced real-time monitoring, leading to greater efficiency and cost savings.

What are the key drivers for the growth of the Cold Storage Equipment Market?

Key drivers include increasing global demand for perishable goods, stringent food safety regulations, growth in the pharmaceutical sector, and the expansion of organized retail and e-commerce.

What are the main technological trends in cold storage equipment?

Major technological trends involve the adoption of energy-efficient compressors, natural refrigerants like CO2, IoT-enabled monitoring systems, AI for predictive analytics, and automation in warehouse operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager