Collaborative Manufacturing Robots Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428687 | Date : Oct, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Collaborative Manufacturing Robots Market Size

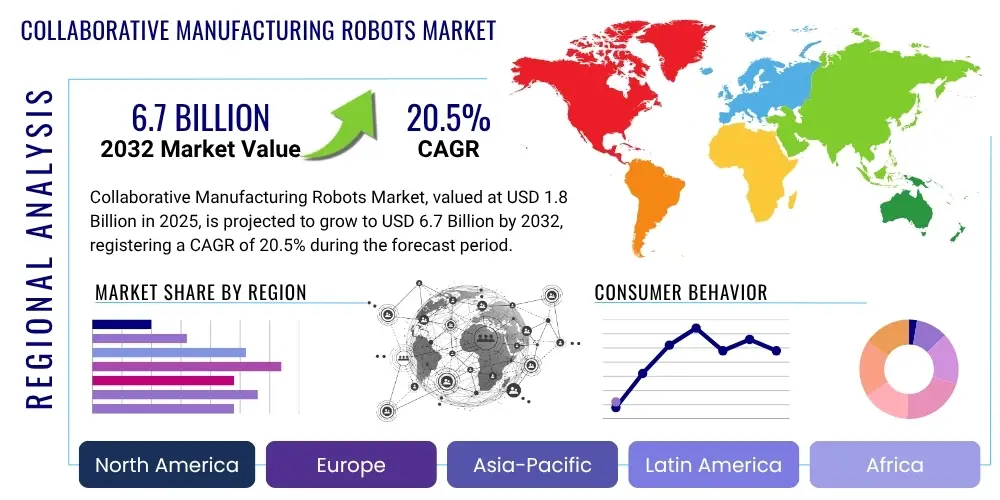

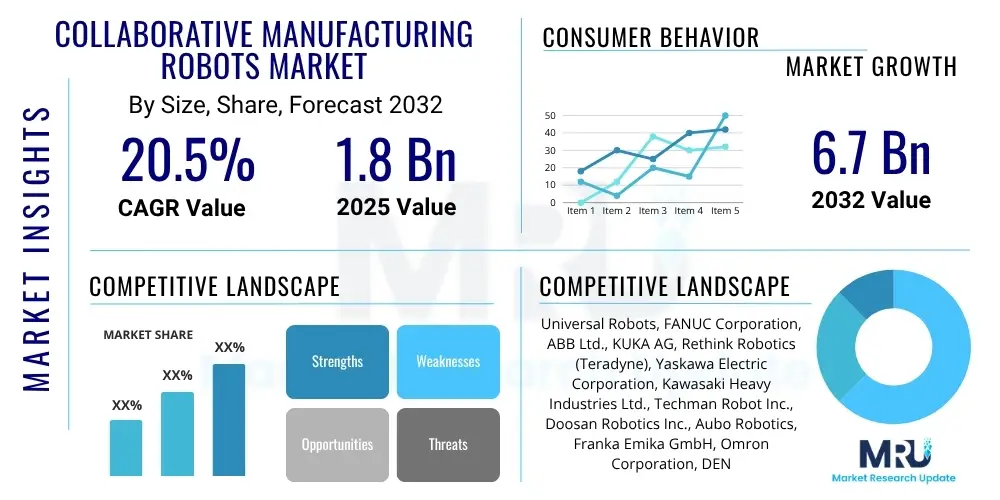

The Collaborative Manufacturing Robots Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 20.5% between 2025 and 2032. The market is estimated at USD 1.8 Billion in 2025 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2032.

Collaborative Manufacturing Robots Market introduction

The Collaborative Manufacturing Robots Market encompasses the development, production, and deployment of robots designed to work safely and interactively alongside humans in shared workspaces without the need for extensive safety caging. These robots, often referred to as cobots, are characterized by their ability to perform tasks with precision and flexibility while maintaining inherent safety features, making them distinct from traditional industrial robots that operate in isolated environments. Cobots are increasingly vital in modern manufacturing as industries seek to enhance productivity, improve worker ergonomics, and adapt to rapidly changing production demands, fostering a new era of human-robot collaboration on the factory floor.

The product description for collaborative manufacturing robots centers on their user-friendliness, adaptability, and safety mechanisms. They are typically lightweight, easy to program through intuitive interfaces or even by demonstration, and equipped with advanced sensors such as force-torque sensors and vision systems that enable them to detect human presence and react appropriately to prevent collisions. Major applications span across various manufacturing processes, including precision assembly, pick and place operations for material handling, quality inspection, machine tending, and packaging. Their flexibility allows them to be redeployed easily for different tasks, making them ideal for high-mix, low-volume production environments.

The benefits of adopting collaborative robots are manifold, including significant improvements in operational efficiency, enhanced worker safety by offloading repetitive or dangerous tasks, and a reduction in operational costs over time through optimized labor allocation and increased throughput. Key driving factors for market growth include a growing emphasis on industrial automation to counter labor shortages and rising labor costs, the need for flexible manufacturing solutions that can quickly adapt to market fluctuations, and increasing awareness of the ergonomic benefits and improved worker satisfaction that results from human-robot collaboration. The integration of cobots also supports the broader Industry 4.0 initiatives focused on smart factories and interconnected production systems.

Collaborative Manufacturing Robots Market Executive Summary

The Collaborative Manufacturing Robots market is experiencing robust expansion, propelled by transformative business trends such as the pervasive adoption of Industry 4.0 philosophies, a heightened focus on human-robot collaboration to augment human capabilities, and significant advancements in artificial intelligence and machine learning that enhance cobot autonomy and flexibility. Businesses are increasingly recognizing the strategic imperative of integrating cobots to address critical challenges like labor scarcity, the demand for mass customization, and the need for adaptable production lines. The shift towards agile manufacturing and the pursuit of operational excellence are pivotal in driving investment into these sophisticated automation solutions, enabling enterprises to maintain competitive advantages in a dynamic global economy. Furthermore, the imperative for improved workplace safety and ergonomic working conditions is consistently influencing adoption rates, particularly in regions with stringent labor regulations, leading to a profound transformation in how manufacturing tasks are conceived and executed.

Regionally, the market exhibits varied growth patterns and drivers. Asia Pacific stands out as a dominant and rapidly expanding market, fueled by vast manufacturing bases, aggressive automation initiatives in countries like China, Japan, and South Korea, and supportive government policies promoting technological upgrades. North America and Europe represent mature markets with high adoption rates, driven by a focus on high-value manufacturing, a shortage of skilled labor, and sustained investment in research and development for advanced robotics. These regions are characterized by a strong emphasis on integrating cobots for complex assembly, precision manufacturing, and customized production. Emerging economies in Latin America and the Middle East and Africa are also showing nascent but promising growth, as industrialization efforts gain momentum and companies seek cost-effective automation solutions to enhance their manufacturing capabilities and compete on a global scale.

Segmentation trends within the Collaborative Manufacturing Robots market highlight the diversification of product offerings and application specializations. Based on payload capacity, there is a strong demand for robots in the 5-10 kg range, suitable for a wide array of assembly and material handling tasks, though higher payload cobots are gaining traction for more demanding applications. Application-wise, pick and place, assembly, and machine tending remain the core areas of deployment, with increasing penetration into packaging, quality inspection, and welding due to technological advancements. The automotive, electronics, and food and beverages industries continue to be primary end-users, but the healthcare and pharmaceutical sectors are emerging as significant growth avenues, leveraging cobots for precision tasks and sterile environments. Component-wise, advancements in hardware, particularly sensors and end-effectors, coupled with sophisticated software and integrated services, are crucial for market differentiation and driving further adoption.

AI Impact Analysis on Collaborative Manufacturing Robots Market

Common user questions regarding the impact of Artificial Intelligence on the Collaborative Manufacturing Robots Market frequently revolve around how AI enhances cobot capabilities, particularly in terms of adaptability, decision-making, and interaction with dynamic environments. Users often inquire about the extent to which AI can simplify programming, improve safety protocols, and enable cobots to perform more complex, non-repetitive tasks traditionally reserved for human workers. Concerns about job displacement are also prominent, alongside questions about the learning curve for integrating AI-powered cobots and the overall return on investment. Furthermore, there is significant interest in how AI contributes to predictive maintenance, real-time analytics, and the seamless integration of cobots into existing smart factory ecosystems.

Based on this analysis, the key themes, concerns, and expectations users have about AI's influence in this domain center on augmented intelligence, operational efficiency, and human-robot synergy. Users anticipate AI to empower cobots with greater autonomy, enabling them to learn from experience, adapt to unforeseen changes in the workspace, and make informed decisions on the fly, thereby moving beyond purely programmed movements. This advanced capability is expected to unlock new application possibilities in highly dynamic and unstructured environments, reducing the need for constant human supervision and extensive reprogramming. However, concerns persist regarding the ethical implications of increasingly intelligent machines, the need for a skilled workforce capable of managing these advanced systems, and ensuring that AI integration truly enhances, rather than complicates, manufacturing processes.

- Enhanced perception and environmental understanding through advanced computer vision and sensor fusion, allowing cobots to identify objects, navigate complex spaces, and detect human presence more accurately.

- Adaptive learning capabilities enabling cobots to learn new tasks from demonstrations or through reinforcement learning, significantly reducing programming time and increasing flexibility.

- Predictive maintenance facilitated by AI algorithms analyzing operational data to forecast equipment failures, minimizing downtime and optimizing maintenance schedules.

- Simplified human-robot interaction through natural language processing and intuitive gestural commands, making cobots more accessible to non-expert users.

- Improved decision-making for dynamic task execution, allowing cobots to autonomously adjust to variations in products, processes, or unforeseen obstacles on the factory floor.

- Optimized task allocation and load balancing within a fleet of robots, leveraging AI to enhance overall production efficiency and throughput.

- Advanced safety protocols and collision avoidance, where AI systems can anticipate human movements and react preemptively to maintain a safe working environment.

- Personalized manufacturing capabilities, as AI-powered cobots can adapt to individual product variations and custom requirements with minimal human intervention.

- Integration with broader industrial IoT and cloud platforms for real-time data analysis, remote monitoring, and continuous improvement of operational parameters.

DRO & Impact Forces Of Collaborative Manufacturing Robots Market

The Collaborative Manufacturing Robots Market is significantly influenced by a confluence of driving forces, restraining factors, and emerging opportunities, all interacting to shape its trajectory. Key drivers include the escalating global demand for industrial automation, primarily fueled by rising labor costs and a persistent shortage of skilled labor in manufacturing sectors worldwide. The inherent safety features of cobots, allowing them to work alongside humans, address stringent workplace safety regulations and improve overall working conditions, acting as a major catalyst for adoption. Furthermore, the imperative for greater manufacturing flexibility, enabling rapid shifts in production lines and facilitating customized product runs, strongly pushes manufacturers towards cobot integration. The increasing affordability of cobot technology, coupled with ease of programming and quicker return on investment compared to traditional industrial robots, also accelerates market expansion. These factors collectively underscore the transformative potential of collaborative robots in modern manufacturing paradigms.

Despite these compelling drivers, the market faces several significant restraints. The initial capital investment for implementing collaborative robot systems, while decreasing, can still be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. A lack of awareness and understanding regarding cobot capabilities and their optimal integration can also slow adoption rates, particularly in regions where industrial automation is less mature. The perception of job displacement due to automation, though often mitigated by upskilling initiatives, can generate resistance from the workforce. Additionally, the complexity involved in programming and integrating cobots for highly specific or intricate tasks, despite advancements in user-friendliness, still requires a degree of specialized expertise, which can be a bottleneck. Ensuring robust cybersecurity for interconnected cobot systems also presents an ongoing challenge for manufacturers.

Opportunities within the Collaborative Manufacturing Robots market are abundant and diverse. The burgeoning demand for automation in emerging economies, alongside the expansion into new application areas beyond traditional manufacturing, such as healthcare, logistics, and retail, presents significant growth avenues. The continuous evolution of AI and machine learning promises to enhance cobot intelligence, making them capable of more complex and adaptive tasks, thereby unlocking new use cases. The increasing focus on human-robot collaboration in various industries creates demand for more sophisticated and intuitive interfaces, fostering innovation. Furthermore, the growing trend of reshoring manufacturing operations in developed countries, aimed at mitigating supply chain risks and enhancing local production, provides fertile ground for cobot adoption to maintain competitiveness. The development of advanced end-effectors and software solutions tailored for specific industry needs also represents a substantial opportunity for market players to differentiate and expand their offerings.

Segmentation Analysis

The Collaborative Manufacturing Robots Market is comprehensively segmented across various dimensions to provide a detailed understanding of its dynamics and growth prospects. These segments typically include payload capacity, application, end-use industry, and component type, each reflecting different facets of demand and technological development within the market. This detailed segmentation helps in analyzing specific market niches, identifying key growth areas, and understanding the distinct needs and preferences of different user groups, thereby informing strategic business decisions for manufacturers, suppliers, and integrators within the collaborative robotics ecosystem. The differentiation across these segments is critical for tailoring product development and marketing strategies to specific industrial requirements and operational contexts.

- By Payload Capacity:

- Up to 5 kg

- 5-10 kg

- 10 kg and above

- By Application:

- Assembly

- Pick and Place

- Material Handling

- Packaging and Palletizing

- Quality Inspection

- Machine Tending

- Welding and Soldering

- Polishing and Deburring

- Dispensing

- Others

- By End-Use Industry:

- Automotive

- Electronics

- Metals and Machinery

- Food and Beverages

- Healthcare and Pharmaceuticals

- Plastics and Rubber

- Aerospace

- Logistics and E-commerce

- Semiconductor

- Others

- By Component:

- Hardware

- Robot Arm

- End Effectors (Grippers, Vacuum, Welding Torches, Force-Torque Sensors)

- Controllers

- Sensors (Vision, Force, Proximity)

- Drive Systems

- Software

- Programming Software

- Simulation Software

- Analytics Software

- Services

- Installation and Commissioning

- Maintenance and Support

- Training

- Consulting

- Hardware

Value Chain Analysis For Collaborative Manufacturing Robots Market

The value chain for the Collaborative Manufacturing Robots Market begins with upstream activities focused on research and development, design, and the procurement of advanced components. This stage involves a complex network of specialized suppliers providing critical technologies such as high-precision motors and actuators, sophisticated sensors (vision, force-torque, proximity), advanced control systems, and high-performance computing units for artificial intelligence integration. These suppliers are crucial for the performance, safety, and intelligence of collaborative robots, driving innovation in areas like human-robot interaction and adaptive task execution. Strategic partnerships with these upstream component providers are essential for robotic manufacturers to maintain a competitive edge and ensure the continuous improvement of their product offerings in terms of functionality, cost-effectiveness, and reliability.

Moving downstream, the value chain encompasses the manufacturing, assembly, and testing of collaborative robots, followed by distribution channels that bring these products to end-users. Distribution can occur through direct sales channels, where manufacturers engage directly with large enterprise customers, offering bespoke solutions and integration support. Alternatively, indirect channels involve a network of third-party distributors, value-added resellers (VARs), and system integrators. These intermediaries play a vital role in reaching a broader customer base, particularly small and medium-sized enterprises (SMEs) who may lack in-house robotics expertise. System integrators are especially critical, as they customize cobot solutions for specific applications, provide installation, programming, and ongoing support, effectively bridging the gap between standard products and diverse industrial requirements.

The direct distribution channel offers manufacturers greater control over customer relationships, branding, and service quality, often preferred for complex, high-value installations requiring extensive customization and support. This allows for direct feedback loops that can inform future product development. Conversely, indirect distribution leverages the existing market reach and expertise of partners, enabling quicker market penetration and reducing the overheads associated with direct sales infrastructure. The choice of distribution strategy depends on target market segments, geographic reach, and the complexity of the solutions offered. Regardless of the channel, comprehensive post-sales services, including maintenance, technical support, and training, are indispensable for ensuring customer satisfaction and maximizing the operational lifespan and efficiency of collaborative robot deployments, thereby enhancing the overall value proposition for end-users.

Collaborative Manufacturing Robots Market Potential Customers

The primary potential customers and end-users of collaborative manufacturing robots span a wide array of industries and enterprise sizes, driven by the universal need for enhanced productivity, improved safety, and increased manufacturing flexibility. Large-scale automotive manufacturers represent a significant customer base, deploying cobots for tasks like assembly, quality control, and component handling where precision and adaptability are paramount. Similarly, the electronics industry, with its demand for intricate assembly of delicate components and high-volume production, heavily invests in cobots for pick and place operations, soldering, and testing. These sectors benefit from the cobots' ability to handle repetitive tasks with consistent accuracy, alleviating human workers from monotonous and ergonomically challenging roles.

Beyond these established industrial giants, the market for collaborative robots is increasingly expanding to small and medium-sized enterprises (SMEs). SMEs are attracted to cobots due to their lower total cost of ownership compared to traditional industrial robots, ease of programming, and quick deployment, which allow them to automate processes without requiring extensive in-house robotics expertise or significant upfront infrastructure investments. Industries such as food and beverages utilize cobots for packaging, palletizing, and processing, ensuring hygiene and efficiency. The healthcare and pharmaceutical sectors are also emerging as key customers, adopting cobots for laboratory automation, sterile handling, and drug dispensing, where precision, repeatability, and contamination control are critical requirements. Furthermore, companies in the metals and machinery, plastics and rubber, and logistics sectors are increasingly leveraging cobots for machine tending, material handling, and quality inspection tasks, demonstrating the broad applicability and growing customer base for these versatile robotic solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.8 Billion |

| Market Forecast in 2032 | USD 6.7 Billion |

| Growth Rate | 20.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Universal Robots, FANUC Corporation, ABB Ltd., KUKA AG, Rethink Robotics (Teradyne), Yaskawa Electric Corporation, Kawasaki Heavy Industries Ltd., Techman Robot Inc., Doosan Robotics Inc., Aubo Robotics, Franka Emika GmbH, Omron Corporation, DENSO WAVE INCORPORATED, Hanwha Corporation, Staubli International AG, Comau S.p.A., Estun Automation, Elite Robot, Jaka Robotics, Nachi-Fujikoshi Corp. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Collaborative Manufacturing Robots Market Key Technology Landscape

The technological landscape of the Collaborative Manufacturing Robots Market is defined by a continuous evolution of innovations aimed at enhancing safety, usability, intelligence, and integration capabilities. At the core are advanced sensor technologies, including sophisticated force-torque sensors embedded in the robot joints and end-effectors, vision systems (2D and 3D cameras), and proximity sensors. These sensors are crucial for enabling cobots to perceive their environment, detect human presence, and react safely to unexpected contact or changes in the workspace, thereby facilitating human-robot collaboration without physical barriers. This sensor fusion allows for dynamic collision detection and avoidance, a cornerstone of cobot safety features, distinguishing them from traditional industrial robots.

Further advancements in the technology landscape include intuitive programming interfaces and artificial intelligence (AI) and machine learning (ML) algorithms. Many cobots feature 'lead-through' or 'teach pendant' programming methods that allow operators to program tasks by physically guiding the robot arm, significantly simplifying the setup process for non-expert users. The integration of AI/ML allows cobots to learn from demonstration, adapt to variations in tasks or workpieces, optimize their movements, and even predict potential issues. This intelligent automation contributes to greater flexibility, reduces reprogramming needs, and enables cobots to handle more complex and unstructured tasks that require cognitive capabilities. Natural language processing and gesture recognition are also emerging technologies designed to make human-cobot interaction even more seamless and intuitive, expanding their applicability in diverse operational settings.

Connectivity and digital integration also play a pivotal role, aligning cobots with Industry 4.0 and the Industrial Internet of Things (IIoT). Cloud connectivity enables remote monitoring, predictive maintenance through data analytics, and over-the-air software updates, ensuring that cobots operate at peak efficiency and benefit from continuous improvements. The development of advanced end-effectors, such as versatile grippers and specialized tools, further expands the range of tasks cobots can perform across different industries. Furthermore, robust cybersecurity measures are becoming increasingly critical to protect interconnected cobot systems from vulnerabilities, ensuring data integrity and operational security within smart factory environments. These combined technological advancements underscore a market driven by innovation, aiming to make automation more accessible, intelligent, and collaborative.

Regional Highlights

- North America: This region demonstrates strong adoption, particularly in the automotive, electronics, and aerospace sectors. Driven by rising labor costs, a skilled labor shortage, and a focus on advanced manufacturing, countries like the United States and Canada are rapidly integrating cobots. Government initiatives supporting automation and robotics research further bolster market growth.

- Europe: A mature market characterized by robust industrialization and stringent safety regulations. Countries such as Germany, Italy, and France are leading the charge, driven by Industry 4.0 initiatives, the need for flexible production, and an emphasis on human-robot collaboration. Investments in research and development and a strong manufacturing base contribute to consistent growth.

- Asia Pacific (APAC): The largest and fastest-growing market globally, fueled by expansive manufacturing industries in countries like China, Japan, South Korea, and India. Rapid industrialization, government support for automation, and the desire to enhance productivity and quality at competitive costs are key drivers. The region is a significant producer and consumer of collaborative robots.

- Latin America: An emerging market with increasing industrialization, particularly in countries like Brazil and Mexico. Growing foreign direct investment in manufacturing and the adoption of modern production techniques are driving initial but steady growth for cobot solutions, especially in automotive and general manufacturing.

- Middle East and Africa (MEA): Currently a nascent market but with significant potential for future growth. Economic diversification efforts in countries like Saudi Arabia and UAE, coupled with investments in industrial infrastructure and smart factories, are creating new opportunities for cobot adoption, primarily in oil and gas, manufacturing, and logistics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Collaborative Manufacturing Robots Market.- Universal Robots

- FANUC Corporation

- ABB Ltd.

- KUKA AG

- Rethink Robotics (Teradyne)

- Yaskawa Electric Corporation

- Kawasaki Heavy Industries Ltd.

- Techman Robot Inc.

- Doosan Robotics Inc.

- Aubo Robotics

- Franka Emika GmbH

- Omron Corporation

- DENSO WAVE INCORPORATED

- Hanwha Corporation

- Staubli International AG

- Comau S.p.A.

- Estun Automation

- Elite Robot

- Jaka Robotics

- Nachi-Fujikoshi Corp.

Frequently Asked Questions

What is a collaborative robot or cobot?

A collaborative robot, or cobot, is a type of robot designed to work safely alongside human workers in a shared workspace without the need for extensive safety guarding, enhancing productivity and worker safety through direct interaction.

How do cobots ensure safety in human-robot collaboration?

Cobots ensure safety through inherent design features like force and speed limitations, advanced sensors (force-torque, vision) for collision detection and avoidance, and emergency stop functions, allowing them to react instantly to human presence.

What are the primary benefits of integrating cobots into manufacturing?

Primary benefits include increased productivity, improved worker safety by automating repetitive or dangerous tasks, enhanced manufacturing flexibility, reduced operational costs, and better utilization of human capital for complex tasks.

Is Artificial Intelligence (AI) a crucial component for collaborative

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager