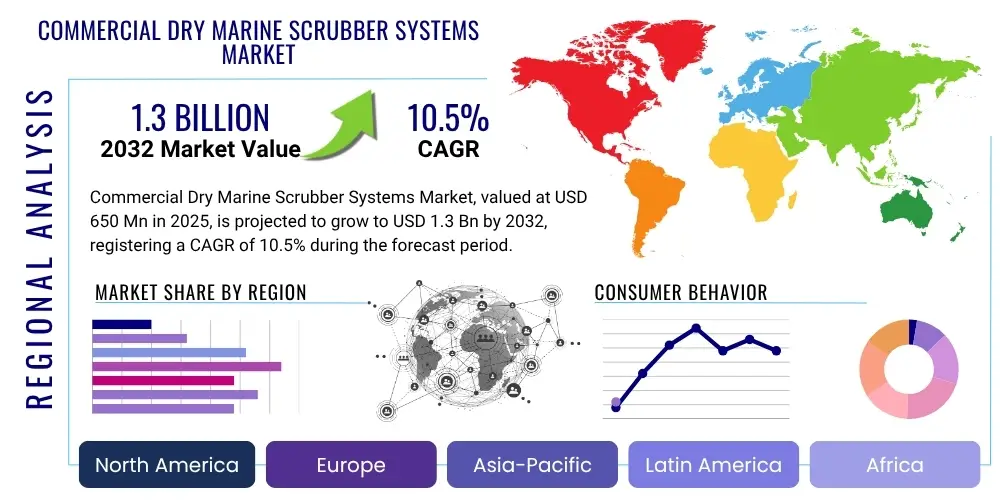

Commercial Dry Marine Scrubber Systems Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430904 | Date : Nov, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Commercial Dry Marine Scrubber Systems Market Size

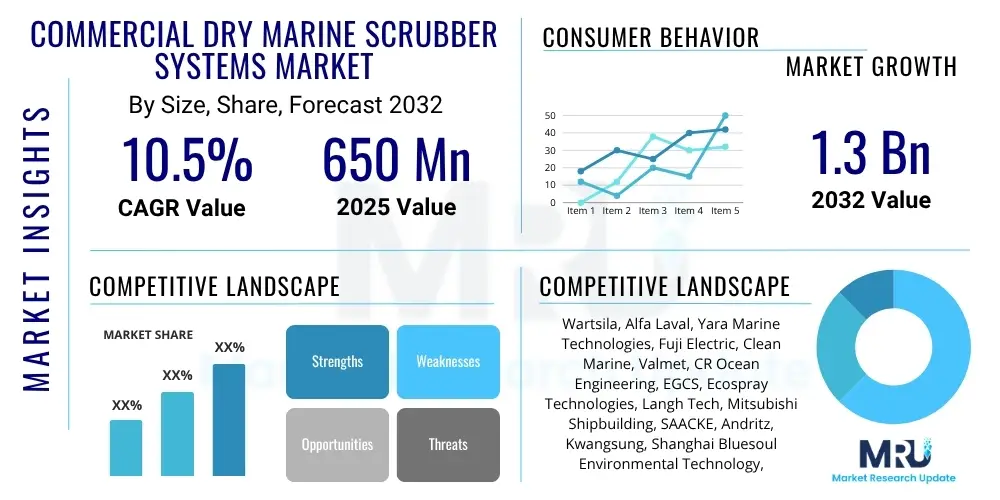

The Commercial Dry Marine Scrubber Systems Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2025 and 2032. The market is estimated at USD 650 Million in 2025 and is projected to reach USD 1.3 Billion by the end of the forecast period in 2032.

Commercial Dry Marine Scrubber Systems Market introduction

The Commercial Dry Marine Scrubber Systems Market encompasses technologies designed to remove sulfur oxides (SOx) from the exhaust gases of marine vessels. These systems are crucial for compliance with stringent international maritime regulations, particularly the IMO 2020 sulfur cap, which limits sulfur content in marine fuel to 0.50% m/m globally. Unlike wet scrubbers that use water to wash exhaust gases, dry scrubbers utilize a dry absorbent material, typically calcium hydroxide, to neutralize SOx, producing a dry waste product that can be safely discharged ashore, thus avoiding wastewater discharge concerns in sensitive aquatic environments.

The core product in this market is the dry marine scrubber unit, characterized by its compact design and the absence of wash water treatment requirements. Major applications span a wide range of commercial vessels, including large container ships, bulk carriers, oil tankers, cruise liners, and ferries, especially those operating in Emission Control Areas (ECAs) or environmentally sensitive regions. The primary benefits include enabling vessels to continue using cheaper high-sulfur fuel oil while achieving regulatory compliance, reducing operational costs, and minimizing the environmental footprint by eliminating scrubber wash water discharge.

Driving factors for market growth include the ongoing enforcement of global and regional sulfur emission regulations, increasing public and governmental pressure for sustainable shipping practices, and the continuous expansion of global maritime trade. Additionally, technological advancements in absorbent materials and system designs are enhancing efficiency and reducing the footprint of dry scrubber installations, making them more attractive to a broader segment of the shipping industry.

Commercial Dry Marine Scrubber Systems Market Executive Summary

The Commercial Dry Marine Scrubber Systems Market is experiencing robust growth driven by a global push for cleaner shipping and strict environmental regulations. Business trends indicate a strong focus on retrofitting existing fleets to comply with IMO 2020 and future emission mandates, alongside increasing installations on newbuild vessels. Manufacturers are investing in R&D to develop more efficient, compact, and automated dry scrubber solutions, often incorporating advanced absorbent materials and waste handling technologies to reduce operational complexities and improve performance. Strategic partnerships between scrubber manufacturers, shipyards, and engineering firms are becoming common to streamline installation and after-sales support.

Regional trends highlight Asia Pacific as a dominant market, largely due to its significant shipbuilding capacity and the high volume of maritime traffic through key trade routes. European countries, with their stringent environmental policies and numerous Emission Control Areas, also represent a substantial market for dry scrubber adoption. North America is another key region, particularly with its established ECAs and a growing emphasis on port and coastal air quality. Emerging markets in Latin America and the Middle East and Africa are showing increasing potential as their maritime sectors expand and environmental regulations mature.

Segment trends suggest a strong demand for dry scrubbers in the cargo and tanker vessel categories, where fuel consumption is high and the economic benefits of using cheaper high-sulfur fuel are substantial. The cruise and ferry sectors also show consistent demand, driven by their operation in densely populated coastal areas and the need to maintain a positive environmental image. Furthermore, there is a growing interest in systems with enhanced automation and lower maintenance requirements, reflecting a broader industry trend towards smart and autonomous vessel operations.

AI Impact Analysis on Commercial Dry Marine Scrubber Systems Market

The integration of Artificial Intelligence (AI) in the Commercial Dry Marine Scrubber Systems market is poised to revolutionize operational efficiency, maintenance strategies, and regulatory compliance. Common user questions often revolve around how AI can optimize scrubber performance, reduce operating costs, enable predictive maintenance, and simplify complex data analysis for environmental reporting. Stakeholders are keen to understand AI's capability to enhance decision-making regarding absorbent consumption, waste management, and real-time emission monitoring, addressing key concerns about operational expenditures and the potential for system downtime. The overarching expectation is that AI will transform scrubbers from passive compliance devices into intelligent, self-optimizing systems that contribute significantly to sustainable and cost-effective maritime operations.

- AI-powered predictive maintenance reduces downtime and extends equipment lifespan by analyzing sensor data to anticipate failures.

- Real-time optimization of scrubber operations, adjusting parameters for maximum SOx removal efficiency based on engine load, fuel type, and environmental conditions.

- Enhanced data analytics for precise emissions monitoring and automated reporting, ensuring seamless compliance with international and regional regulations.

- Integration with vessel management systems for holistic operational insights, improving fuel efficiency and overall vessel performance.

- Autonomous control capabilities for absorbent dosing and waste handling, minimizing human intervention and operational errors.

- Supply chain optimization for absorbent materials and waste disposal services, leveraging AI for demand forecasting and logistics management.

DRO & Impact Forces Of Commercial Dry Marine Scrubber Systems Market

The Commercial Dry Marine Scrubber Systems Market is profoundly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the stringent global environmental regulations, notably the IMO 2020 sulfur cap and the increasing number of Emission Control Areas (ECAs), which mandate significant reductions in sulfur oxide emissions from marine vessels. This regulatory pressure compels shipowners to invest in compliant solutions, with dry scrubbers offering a viable alternative to costly low-sulfur fuels. Additionally, the growing awareness of environmental sustainability and corporate social responsibility within the maritime industry is fueling demand for eco-friendly technologies. The economic advantage of continuing to use cheaper high-sulfur fuel oil, combined with the avoidance of wash water discharge issues associated with wet scrubbers, further propels market expansion.

However, several restraints challenge market growth. The high upfront capital expenditure for purchasing and installing dry scrubber systems can be a significant barrier, particularly for smaller shipping companies or older vessels with limited remaining service life. The operational complexity of managing absorbent materials, including storage, handling, and disposal of solid waste, adds to operational costs and logistical challenges. Furthermore, the limited space available on some existing vessels for scrubber installation, alongside competition from alternative compliance methods such such as LNG propulsion or the use of very low sulfur fuel oil (VLSFO), can temper adoption rates. The technological maturity and compact nature of competing wet and hybrid scrubber systems also present a competitive challenge.

Despite these challenges, substantial opportunities exist within the market. The vast global fleet of existing vessels requiring retrofitting represents a significant market segment. As new environmental regulations emerge or existing ECAs expand, the demand for dry scrubbers is expected to rise. Technological advancements focused on developing more compact, energy-efficient, and fully automated dry scrubber systems, coupled with innovations in absorbent materials that offer higher capacity and easier disposal, will open new avenues for growth. Moreover, the increasing focus on the circular economy and waste valorization could lead to opportunities for the recycling or reuse of spent absorbent materials, enhancing the sustainability profile of dry scrubbers and potentially reducing their long-term operational costs.

Segmentation Analysis

The Commercial Dry Marine Scrubber Systems Market can be comprehensively segmented based on various factors to provide a detailed understanding of its dynamics. Key segmentation approaches include vessel type, which differentiates demand based on the specific operational profiles and regulatory requirements of various maritime vessels, and capacity, reflecting the power output and exhaust gas volume handled by the scrubber systems. These segmentations are crucial for identifying specific market niches, understanding user requirements, and tailoring product development and marketing strategies to effectively serve diverse customer needs within the global shipping industry.

- By Vessel Type

- Container Ships

- Bulk Carriers

- Oil Tankers

- Chemical Tankers

- Cruise Ships

- Ferries

- RoRo Vessels

- General Cargo Vessels

- Offshore Support Vessels

- Others (e.g., naval, research vessels)

- By Capacity

- Small Capacity (Up to 10 MW)

- Medium Capacity (10 MW to 30 MW)

- Large Capacity (Above 30 MW)

- By Application

- Newbuild Vessels

- Retrofit Installations

- By End User

- Shipping Companies

- Ship Owners

- Government/Public Sector

Value Chain Analysis For Commercial Dry Marine Scrubber Systems Market

The value chain for Commercial Dry Marine Scrubber Systems encompasses a series of interconnected stages, beginning with upstream activities related to raw material procurement and component manufacturing. Upstream analysis involves suppliers of specialized metals for fabrication, composite materials for structural components, and chemical manufacturers providing the absorbent materials, primarily calcium hydroxide or other alkali compounds, that are critical to the dry scrubbing process. Additionally, suppliers of fans, pumps, control systems, sensors, and automation hardware contribute significantly to the core components of the scrubber unit. The quality and availability of these upstream inputs directly impact the final product's performance and cost-effectiveness.

Downstream activities involve the distribution, installation, and after-sales support of the scrubber systems. Once manufactured, dry scrubbers are typically delivered to shipyards, either for installation on newbuild vessels or for retrofitting onto existing fleets during scheduled dry-dockings. Shipping companies and vessel owners are the ultimate end-users, integrating these systems into their operational infrastructure to ensure regulatory compliance and optimize fuel consumption. The downstream segment also includes a robust network of maintenance and service providers who offer spare parts, technical support, performance monitoring, and waste disposal services for the spent absorbent material, ensuring the long-term operational efficiency and environmental integrity of the installed systems.

Distribution channels for dry marine scrubber systems primarily involve direct sales from manufacturers to large shipping companies or shipyards. Manufacturers often establish direct relationships with major players in the maritime industry, offering customized solutions and comprehensive project management from design to commissioning. Indirect distribution occurs through engineering, procurement, and construction (EPC) contractors who manage large-scale shipbuilding or retrofitting projects, or through specialized marine equipment distributors and agents who provide regional sales and technical support. This blend of direct and indirect channels ensures broad market reach while catering to the specific procurement preferences and technical requirements of different customer segments.

Commercial Dry Marine Scrubber Systems Market Potential Customers

The Commercial Dry Marine Scrubber Systems Market primarily targets a diverse range of stakeholders within the global maritime industry who are subject to stringent sulfur emission regulations. These potential customers are primarily vessel owners and operators seeking efficient and compliant solutions to reduce their environmental footprint and maintain economic viability amidst evolving environmental legislation. The need to comply with the IMO 2020 sulfur cap and regional Emission Control Areas (ECAs) is the fundamental driver for their interest in these systems, enabling them to continue using less expensive high-sulfur fuel oil while mitigating harmful emissions.

Key end-users include large shipping companies operating fleets of container ships, bulk carriers, oil tankers, and chemical tankers, which represent a significant portion of global maritime trade and face substantial fuel costs. Cruise ship operators and ferry companies are also prime candidates, especially due to their operations in coastal areas and their public image sensitivity to environmental stewardship. Additionally, owners of RoRo vessels, general cargo ships, and offshore support vessels constitute a substantial segment seeking tailored scrubber solutions to meet their specific operational demands and regulatory obligations. Government entities involved in naval fleets or coast guard operations, which often prioritize environmental compliance and long-term operational efficiency, also represent potential buyers.

Beyond direct vessel owners and operators, potential customers also extend to shipyards, marine engineering firms, and specialized retrofit companies that require access to reliable scrubber technology for their newbuild projects or vessel modification services. These entities often act as intermediaries, procuring scrubber systems on behalf of their clients and integrating them into complex vessel designs. The decision to adopt dry scrubbers is often influenced by a careful balance of capital expenditure, operational costs, fuel price differentials, vessel trading routes, and environmental impact considerations.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 650 Million |

| Market Forecast in 2032 | USD 1.3 Billion |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wartsila, Alfa Laval, Yara Marine Technologies, Fuji Electric, Clean Marine, Valmet, CR Ocean Engineering, EGCS, Ecospray Technologies, Langh Tech, Mitsubishi Shipbuilding, SAACKE, Andritz, Kwangsung, Shanghai Bluesoul Environmental Technology, Headway Technology, AEC Maritime, VDL AEC Maritime, Damen Green Solutions, OceanClean |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Dry Marine Scrubber Systems Market Key Technology Landscape

The Commercial Dry Marine Scrubber Systems Market is characterized by a rapidly evolving technological landscape focused on maximizing sulfur removal efficiency, minimizing operational footprint, and enhancing waste management. The core technology revolves around specialized absorbent materials, predominantly calcium hydroxide-based compounds, which react chemically with sulfur oxides in the exhaust gas to form a solid byproduct. Innovations in these absorbent materials aim to improve reactivity, reduce consumption rates, and ensure the resultant waste is inert and manageable for disposal. Research is ongoing into developing more advanced and regenerative absorbent technologies that could further reduce operational costs and environmental impact.

Beyond the absorbent chemistry, the market's technology landscape includes sophisticated material handling systems designed to efficiently store, convey, and inject the dry absorbent into the exhaust stream. These systems often incorporate pneumatic or mechanical conveying technologies to ensure precise dosing and even distribution within the scrubber unit. Post-reaction, advanced filtration systems, such as bag filters or electrostatic precipitators, are crucial for capturing the solid reaction byproducts, preventing their release into the atmosphere. The efficiency of these filtration units directly impacts the overall SOx removal rate and particulate matter emissions, which are increasingly under regulatory scrutiny.

Furthermore, the integration of advanced automation and control systems is a pivotal technological trend. These systems utilize sensors to monitor exhaust gas parameters (SOx, CO2, O2), absorbent levels, and system performance in real-time. Programmable Logic Controllers (PLCs) and Distributed Control Systems (DCS) manage the injection rate of absorbents, optimize fan speeds, and control waste collection processes, often with remote monitoring capabilities. The increasing adoption of digital twin technology and AI-driven analytics is further enhancing the predictive maintenance capabilities and overall operational intelligence of dry scrubber systems, leading to improved reliability and reduced manual intervention.

Regional Highlights

- North America: This region exhibits a strong demand for dry marine scrubber systems, primarily driven by the existence of strict Emission Control Areas (ECAs) along its coasts. The robust cruise industry, with its focus on environmental responsibility and public image, is a significant adopter. Canada and the United States lead in implementing and enforcing maritime emission regulations, fostering a market for compliant technologies.

- Europe: Europe is a mature market for marine scrubbers, characterized by highly stringent environmental regulations, particularly within the Baltic Sea and North Sea ECAs. The region boasts a strong maritime sector, including significant shipbuilding and repair activities. European countries are at the forefront of sustainable shipping initiatives, encouraging the adoption of advanced dry scrubber technologies to comply with both regional and global emission limits.

- Asia Pacific (APAC): APAC is projected to be the largest and fastest-growing market, propelled by its dominance in shipbuilding (China, South Korea, Japan), vast maritime trade volumes, and growing awareness of air pollution. The rapid expansion of port infrastructure and the increasing number of regional emission control zones in countries like China are key drivers. Economic growth and rising energy demand also contribute to increased shipping activity, further fueling the need for emission control solutions.

- Latin America: This region represents an emerging market with increasing maritime trade activities and a growing focus on environmental protection. While adoption rates may be slower than in more regulated regions, growing economies and international trade partnerships are gradually leading to greater demand for compliant marine technologies, including dry scrubbers.

- Middle East and Africa (MEA): The MEA region is experiencing growth in its shipping traffic and port developments, particularly in energy-rich nations. As environmental regulations become more pervasive and global shipping lines operate through these regions, the demand for emission reduction technologies is expected to rise. The strategic location for global trade routes also makes compliance with international standards critical for vessels traversing the area.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Dry Marine Scrubber Systems Market.- Wartsila

- Alfa Laval

- Yara Marine Technologies

- Fuji Electric

- Clean Marine

- Valmet

- CR Ocean Engineering

- EGCS

- Ecospray Technologies

- Langh Tech

- Mitsubishi Shipbuilding

- SAACKE

- Andritz

- Kwangsung

- Shanghai Bluesoul Environmental Technology

- Headway Technology

- AEC Maritime

- VDL AEC Maritime

- Damen Green Solutions

- OceanClean

Frequently Asked Questions

What are Commercial Dry Marine Scrubber Systems?

Commercial Dry Marine Scrubber Systems are exhaust gas cleaning technologies installed on marine vessels to remove sulfur oxides (SOx) from engine exhaust, utilizing a dry absorbent material to ensure compliance with international emission regulations.

How do dry marine scrubbers work?

Dry scrubbers inject a dry alkaline absorbent, typically calcium hydroxide, into the exhaust gas stream. This absorbent reacts with the SOx, converting it into a dry solid byproduct that is then collected by a particulate filter and stored for proper disposal ashore.

What are the main benefits of using dry marine scrubbers?

Key benefits include compliance with IMO 2020 sulfur regulations while continuing to use cheaper high-sulfur fuel oil (HFO), eliminating the discharge of wash water into the sea, which is crucial in sensitive areas, and providing a long-term, reliable solution for emission reduction.

What challenges are associated with dry marine scrubbers?

Challenges include the high initial capital investment, the need for onboard storage of absorbent material and solid waste, the logistical complexity of waste disposal at ports, and the space requirements for installation, particularly on older vessels.

How do dry scrubbers compare to wet and hybrid scrubber systems?

Unlike wet scrubbers, dry systems do not produce wash water discharge, making them ideal for environmentally sensitive areas. They operate without a water treatment plant, simplifying some aspects, but require robust systems for absorbent handling and solid waste management, distinguishing them from wet and hybrid options that use seawater or freshwater.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager