Commercial Flexible Metal Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427716 | Date : Oct, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Commercial Flexible Metal Conduit Market Size

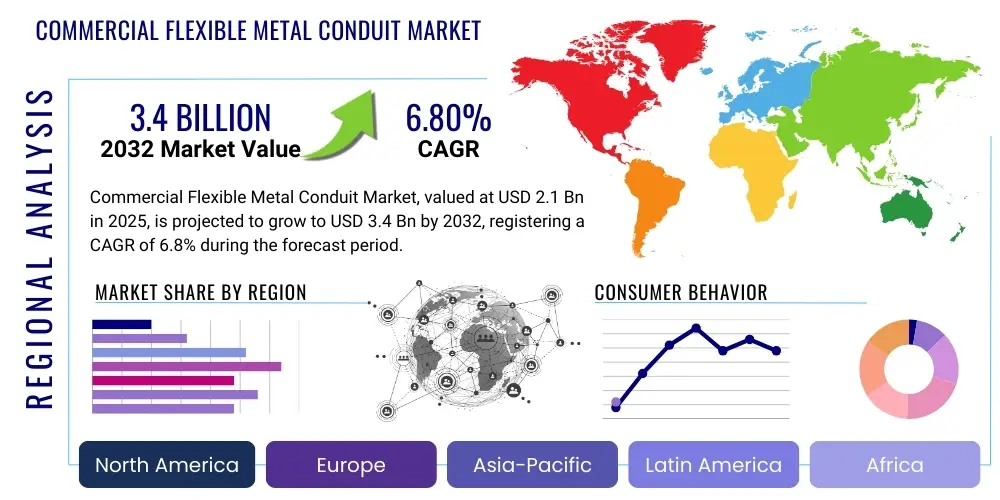

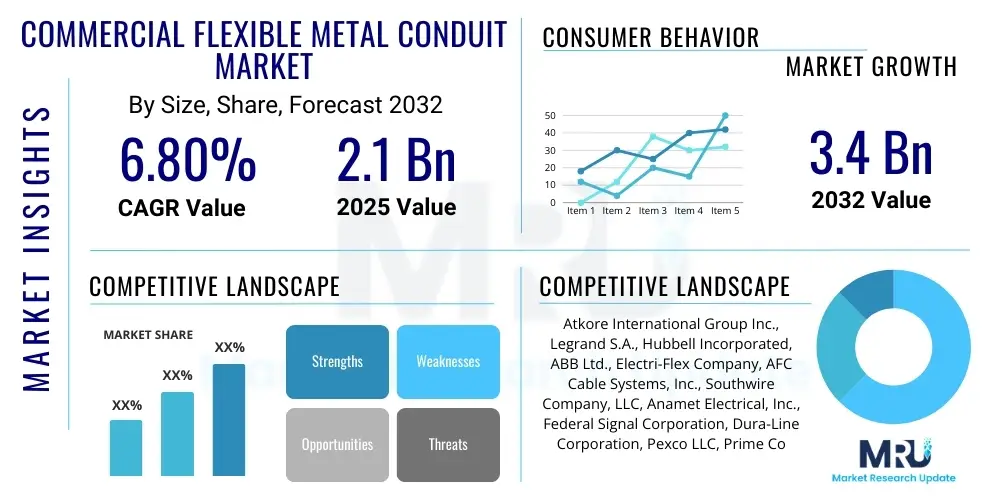

The Commercial Flexible Metal Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 2.1 Billion in 2025 and is projected to reach USD 3.4 Billion by the end of the forecast period in 2032.

Commercial Flexible Metal Conduit Market introduction

The Commercial Flexible Metal Conduit (FMC) Market encompasses a diverse range of products designed to protect electrical wiring in various commercial and industrial settings, providing both mechanical safeguard and a secure raceway for conductors. These conduits are essential components in modern infrastructure, ensuring the integrity and longevity of electrical systems across a multitude of applications. Products typically include flexible metallic conduit (FMC), liquid-tight flexible metallic conduit (LFMC), and explosion-proof flexible metallic conduit, each tailored to specific environmental and operational demands, offering features like corrosion resistance, high flexibility, and EMI shielding. Major applications span commercial buildings, data centers, industrial manufacturing facilities, and critical infrastructure projects where wiring protection is paramount for safety and operational continuity.

The inherent benefits of flexible metal conduits, such as ease of installation, adaptability to complex architectural designs, and robust protection against physical damage, moisture, and electromagnetic interference, contribute significantly to their widespread adoption. These advantages are particularly crucial in environments requiring frequent wiring modifications or where vibration and movement are present. Key driving factors propelling market expansion include the rapid pace of urbanization and global infrastructure development, stringent safety regulations mandating robust electrical installations, and the increasing demand for secure and reliable electrical systems in an increasingly digitized world.

Furthermore, the growth of smart building technologies and the expansion of renewable energy projects contribute to the rising demand for flexible metal conduits. As commercial and industrial sectors prioritize energy efficiency and operational resilience, the role of high-quality electrical infrastructure components like FMC becomes increasingly vital. The continuous evolution of building codes and safety standards globally also reinforces the necessity for advanced conduit solutions, ensuring that electrical installations meet the highest levels of performance and protection.

Commercial Flexible Metal Conduit Market Executive Summary

The Commercial Flexible Metal Conduit (FMC) market is experiencing dynamic shifts, driven by robust business trends focusing on innovation, sustainability, and strategic partnerships to enhance product offerings and market reach. Companies are increasingly investing in research and development to introduce conduits with improved material properties, enhanced flexibility, and specialized coatings that meet evolving industry demands, such as those for fire safety and electromagnetic compatibility. Mergers and acquisitions are also playing a significant role, allowing key players to consolidate market share, expand geographical presence, and diversify their product portfolios, leading to a more competitive and integrated market landscape.

Regional trends indicate strong growth in emerging economies, particularly across the Asia Pacific region, fueled by rapid urbanization, extensive infrastructure projects, and the proliferation of new commercial and industrial facilities. North America and Europe, while representing mature markets, continue to demonstrate steady demand, largely driven by renovation projects, stringent regulatory compliance, and a focus on upgrading existing infrastructure to meet modern safety and efficiency standards. Latin America and the Middle East & Africa are also showing promising growth, supported by investments in commercial development and industrial expansion.

Segment trends highlight a growing preference for liquid-tight flexible metallic conduits (LFMC) due to their superior protection against moisture and corrosive environments, making them ideal for outdoor installations, industrial machinery, and HVAC systems. There is also an increasing demand for conduits engineered with higher temperature ratings and enhanced fire resistance, catering to specialized applications in data centers and critical infrastructure where uninterrupted operation and safety are paramount. The market is also seeing innovation in terms of material composition, with a focus on lighter, more durable, and environmentally friendly options to address sustainability concerns and ease installation challenges.

AI Impact Analysis on Commercial Flexible Metal Conduit Market

The integration of Artificial Intelligence (AI) is poised to significantly transform various facets of the Commercial Flexible Metal Conduit market, addressing common user questions related to manufacturing efficiency, design optimization, predictive maintenance, and smart building integration. Users are keen to understand how AI can streamline production processes, reduce waste, and enhance product quality, moving towards a more automated and data-driven manufacturing environment. There is also a strong interest in AIs potential to revolutionize the design and installation phases of electrical systems, offering solutions for complex routing and material selection, and ensuring compliance with evolving standards. Furthermore, expectations are high regarding AIs role in creating more resilient and intelligent electrical infrastructures through predictive analytics for maintenance and enhanced system monitoring within smart buildings.

- AI-driven optimization of manufacturing processes, leading to increased production efficiency and reduced material waste.

- Enhanced quality control through AI-powered visual inspection systems, identifying defects with higher precision and speed.

- Predictive maintenance for manufacturing equipment, minimizing downtime and extending the lifespan of machinery used in conduit production.

- AI algorithms for optimizing conduit routing and sizing in complex building designs, improving material utilization and installation efficiency.

- Integration of AI in smart building management systems, allowing for real-time monitoring of electrical circuits and predictive insights into conduit performance.

- Improved supply chain management through AI-driven demand forecasting, optimizing inventory levels and reducing logistics costs for conduit manufacturers and distributors.

- Development of smart conduits with embedded sensors, leveraging AI for environmental monitoring, fault detection, and structural integrity assessment.

- AI-assisted material innovation, accelerating the development of conduits with superior properties such as enhanced fire resistance or corrosion protection.

- Personalized product recommendations and faster customer support through AI-powered platforms for buyers and contractors.

DRO & Impact Forces Of Commercial Flexible Metal Conduit Market

The Commercial Flexible Metal Conduit (FMC) market is profoundly shaped by a confluence of drivers, restraints, opportunities, and external impact forces that dictate its growth trajectory and competitive landscape. Key drivers include the relentless pace of global urbanization and the resultant surge in commercial and residential construction activities, particularly in developing economies. Additionally, the increasing emphasis on modernizing existing infrastructure, coupled with stringent electrical safety standards and building codes implemented worldwide, necessitates the use of robust and compliant wiring protection solutions like flexible metal conduits. The growing adoption of smart building technologies and the expansion of renewable energy projects also contribute significantly to the demand for high-performance conduit systems, driving innovation and market expansion across various application segments.

However, the market also faces considerable restraints that temper its growth. The volatility of raw material prices, particularly for steel and aluminum, poses a significant challenge, impacting manufacturing costs and profitability. Intense competition from alternative conduit materials, such as various types of plastic or rigid metal conduits, requires continuous innovation and value proposition differentiation for FMC products. Furthermore, the complexity of regional regulations and differing installation practices can create market fragmentation and necessitate localized product adaptations, increasing operational complexities for manufacturers and distributors alike.

Despite these challenges, substantial opportunities exist within the Commercial Flexible Metal Conduit market. Developing economies, with their burgeoning infrastructure development and rapid industrialization, present lucrative avenues for market penetration and expansion. The global push towards smart city initiatives and the increasing investment in sustainable and energy-efficient building solutions create new demand for technologically advanced flexible conduits that can accommodate sophisticated wiring systems. Furthermore, the retrofitting and renovation of aging buildings, particularly in mature markets, offer continuous demand for modern and compliant electrical protection solutions. Impact forces such as technological advancements in material science, fluctuating global economic cycles affecting construction spending, and evolving regulatory landscapes, constantly reshape market dynamics, compelling stakeholders to remain agile and adaptable to maintain a competitive edge and capitalize on emerging trends.

Segmentation Analysis

The Commercial Flexible Metal Conduit market is comprehensively analyzed through various segmentation categories, providing a granular view of its diverse landscape and enabling a deeper understanding of market dynamics, consumer preferences, and growth opportunities. These segmentations are crucial for identifying specific market niches, tailoring product development strategies, and optimizing sales and marketing efforts to address the distinct needs of different end-users and applications. By dissecting the market based on product type, material, diameter, and application, stakeholders can gain valuable insights into the prevalent trends and potential areas for innovation and expansion.

- By Type: This segment differentiates conduits based on their specific features and environmental suitability, including Flexible Metallic Conduit (FMC), Liquid-tight Flexible Metallic Conduit (LFMC), Explosion-proof Flexible Metallic Conduit (EFMC), and other specialized types designed for particular applications.

- By Material: Segmentation by material focuses on the primary composition of the conduit, influencing its durability, flexibility, corrosion resistance, and cost. Common materials include Galvanized Steel, Aluminum, Stainless Steel, and sometimes hybrid compositions with polymer coatings.

- By Diameter/Size: This category segments the market based on the internal and external diameters of the conduits, which are critical for accommodating different wire gauges and cable capacities, ranging from small-diameter conduits for control wiring to large-diameter conduits for main power feeds.

- By Application: This segmentation is pivotal, categorizing demand based on the end-use sectors where flexible metal conduits are deployed. Key applications include Commercial Buildings (offices, retail, hospitality), Industrial Facilities (manufacturing plants, chemical processing), Data Centers, Infrastructure (transportation, utilities, public works), and Healthcare Facilities.

- By End-User: This segment identifies the primary purchasers and installers of flexible metal conduits, such as Electrical Contractors, Original Equipment Manufacturers (OEMs), Facility Managers, and Industrial Maintenance & Repair Operations (MRO).

Commercial Flexible Metal Conduit Market Value Chain Analysis

The value chain for the Commercial Flexible Metal Conduit market is an intricate network spanning from raw material procurement to end-user application, highlighting the various stages where value is added and costs are incurred. The upstream segment of the value chain is dominated by the sourcing of foundational materials such as galvanized steel, aluminum, and various polymers used for coatings and insulation. Key suppliers in this phase provide the necessary metals, often as strips or coils, which are then processed by conduit manufacturers. The quality and cost of these raw materials significantly influence the final products performance and market competitiveness, making strong supplier relationships crucial for consistency and cost control.

The manufacturing stage involves the conversion of raw materials into finished flexible metal conduits through specialized processes like helically winding metal strips, forming interlocked or square-locked structures, and applying protective coatings. This stage is characterized by significant capital investment in machinery, adherence to strict quality control standards, and continuous innovation in manufacturing techniques to enhance product features such as flexibility, durability, and resistance to environmental factors. Post-manufacturing, products are typically packaged and prepared for distribution, often undergoing certifications to meet regional and international safety and performance standards.

Downstream activities primarily involve the distribution and sales channels, which bridge the gap between manufacturers and end-users. Distribution channels are varied, including direct sales to large construction projects or industrial clients, and more commonly, indirect sales through a network of electrical wholesalers, distributors, and specialized electrical supply houses. These intermediaries play a vital role in inventory management, localized delivery, and providing technical support to contractors and installers. The end-users of flexible metal conduits are diverse, encompassing electrical contractors, construction companies, industrial facilities, data centers, and various commercial enterprises. Effective downstream engagement, including strong customer service and technical support, is crucial for fostering customer loyalty and securing repeat business in a competitive market.

Commercial Flexible Metal Conduit Market Potential Customers

The potential customer base for the Commercial Flexible Metal Conduit market is broad and diverse, encompassing a wide array of entities that require robust and flexible electrical wiring protection solutions across various sectors. These end-users, or buyers of the product, are primarily driven by the need for compliant, durable, and adaptable electrical infrastructure to ensure safety, operational efficiency, and longevity of their facilities. Understanding these customer segments is critical for manufacturers and distributors to tailor their product offerings, marketing strategies, and distribution channels effectively.

A significant segment of potential customers includes **Electrical Contractors and Installation Companies**. These professionals are directly responsible for designing, installing, and maintaining electrical systems in new constructions, renovations, and upgrades across commercial, industrial, and institutional buildings. Their purchasing decisions are often influenced by ease of installation, product reliability, compliance with local codes, and cost-effectiveness. The flexibility of metal conduits significantly reduces labor time and complexity in routing wires through intricate spaces, making them a preferred choice for these users.

**Commercial Building Developers and Construction Firms** represent another major customer group. They procure conduits for large-scale projects such as office complexes, retail centers, hotels, educational institutions, and healthcare facilities. Their focus is on ensuring the long-term integrity and safety of the electrical infrastructure as mandated by building codes and investor expectations. Similarly, **Industrial Manufacturers and Plant Operators** are key buyers, utilizing flexible metal conduits in manufacturing facilities, processing plants, and heavy industry where machinery vibration, harsh environmental conditions, and the need for frequent equipment relocation necessitate durable and liquid-tight conduit solutions. Additionally, **Data Center Operators** require high-performance conduits to protect critical networking and power cabling, ensuring uninterrupted operation and compliance with stringent fire safety and electromagnetic interference (EMI) regulations. Lastly, **Government Agencies and Public Works Departments** also constitute a substantial customer base, acquiring conduits for infrastructure projects such as transportation hubs, utilities, and public service buildings, prioritizing long-term durability and adherence to public safety standards.

Commercial Flexible Metal Conduit Market Key Technology Landscape

The Commercial Flexible Metal Conduit market is continuously evolving through advancements in material science, manufacturing processes, and integration with smart building technologies, collectively shaping its key technology landscape. Innovations are primarily focused on enhancing the performance, durability, and ease of installation of conduits while addressing emerging industry demands for greater safety and efficiency. This technological progression allows for the development of conduits that can withstand more extreme environmental conditions, offer superior protection, and integrate seamlessly into complex modern electrical systems, thereby meeting the stringent requirements of diverse commercial and industrial applications.

One critical area of technological advancement involves **advanced material composition and coatings**. Manufacturers are increasingly utilizing specialized alloys of galvanized steel and aluminum that offer improved corrosion resistance, greater flexibility without compromising strength, and lighter weight for easier handling. Furthermore, sophisticated polymer coatings, such as PVC or LSZH (Low Smoke Zero Halogen) materials, are being developed to provide enhanced liquid-tight properties, fire retardancy, and reduced smoke emission in case of fire, catering to safety-critical environments like data centers and healthcare facilities. These material innovations contribute to the longevity and reliability of the conduit system, minimizing maintenance and replacement costs over its operational lifespan.

Another significant aspect of the technology landscape is the **refinement of manufacturing processes** to produce more consistent, high-quality, and cost-effective conduits. Precision winding techniques ensure uniform interlocked structures, enhancing the mechanical strength and flexibility of the conduits. Automated production lines improve efficiency and reduce manufacturing defects, leading to higher product reliability. Furthermore, the integration of **smart features and embedded technologies** is gaining traction. This includes the development of conduits with integrated sensors capable of monitoring temperature, humidity, and even detecting electrical faults or cable damage within the raceway. These smart conduits facilitate predictive maintenance, improve system diagnostics, and contribute to the overall intelligence and resilience of building electrical infrastructure, aligning with the broader trend towards smart buildings and IoT integration. Such technological strides are crucial for maintaining the competitiveness and relevance of flexible metal conduits in an increasingly demanding market.

Regional Highlights

- North America: This region represents a mature market characterized by stringent safety standards and a strong emphasis on upgrading existing infrastructure. Growth is driven by renovation projects, the expansion of data centers, and the adoption of advanced building codes in the United States and Canada. Demand for liquid-tight and EMI-shielding conduits is particularly high.

- Europe: Europe is another mature market with robust regulatory frameworks focusing on environmental sustainability and fire safety. Countries like Germany, the UK, and France are investing in smart city initiatives and renewable energy infrastructure, driving demand for high-performance and eco-friendly flexible metal conduits. Compliance with CE marking and specific national standards is a key market driver.

- Asia Pacific: The Asia Pacific region is projected to be the fastest-growing market due to rapid urbanization, industrialization, and massive infrastructure development projects, especially in China, India, and Southeast Asian countries. The burgeoning construction sector, coupled with increasing foreign direct investments in manufacturing and commercial real estate, fuels the demand for all types of flexible metal conduits.

- Latin America: This region exhibits steady growth, primarily influenced by ongoing urbanization, industrial development, and government investments in public infrastructure projects. Countries like Brazil, Mexico, and Argentina are key contributors, with demand driven by commercial building construction and the expansion of industrial facilities.

- Middle East & Africa: The market in the Middle East & Africa is experiencing significant expansion, propelled by large-scale commercial and industrial construction projects, particularly in the GCC countries (e.g., UAE, Saudi Arabia) and South Africa. Investments in oil & gas, hospitality, and smart city developments are creating substantial opportunities for flexible metal conduits that can withstand harsh environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Flexible Metal Conduit Market.- Atkore International Group Inc.

- Legrand S.A.

- Hubbell Incorporated

- ABB Ltd. (Thomas & Betts)

- Electri-Flex Company

- AFC Cable Systems, Inc.

- Southwire Company, LLC

- Anamet Electrical, Inc.

- Federal Signal Corporation

- Dura-Line Corporation (Orbia)

- Pexco LLC

- Prime Conduit Inc.

- Cantex Inc.

- Wheatland Tube Company

- Flex-Tube, Inc.

- Sealcon, Inc.

- Calbrite, Inc.

- Gibson Stainless & Specialty, Inc.

- Flex-Cable, Inc.

- Universal Tube & Rollform Equipment Corporation

Frequently Asked Questions

What is flexible metal conduit primarily used for in commercial settings?

Flexible metal conduit (FMC) is primarily used in commercial settings to protect electrical wiring from physical damage, moisture, and electromagnetic interference (EMI). Its flexibility allows for easy routing around obstacles and connections to vibrating equipment, making it ideal for commercial buildings, industrial machinery, and data centers.

What are the main types of flexible metal conduit available?

The main types include Flexible Metallic Conduit (FMC), Liquid-tight Flexible Metallic Conduit (LFMC), and Explosion-proof Flexible Metallic Conduit. FMC provides basic mechanical protection, LFMC offers superior moisture resistance for wet locations, and explosion-proof types are designed for hazardous environments where flammable gases or dust may be present.

What are the key benefits of using flexible metal conduit over rigid alternatives?

Key benefits include enhanced flexibility for easier installation in complex spaces, superior protection against physical impact and abrasion, resistance to vibration, and effective shielding against electromagnetic interference. These attributes contribute to reduced installation time, improved system reliability, and long-term durability compared to rigid conduits.

How do safety regulations and building codes impact the FMC market?

Safety regulations and building codes significantly impact the FMC market by mandating specific performance standards for electrical wiring protection. Compliance with these codes, such as the National Electrical Code (NEC) in the US, drives demand for certified and high-quality flexible metal conduits that meet requirements for fire safety, environmental protection, and mechanical strength, ensuring safe electrical installations.

What technological innovations are shaping the future of flexible metal conduits?

Technological innovations include the use of advanced materials for enhanced corrosion resistance and lighter weight, specialized coatings for improved fire retardancy and liquid-tight properties, and the integration of smart features like embedded sensors for real-time monitoring and fault detection. These advancements aim to improve performance, ease of installation, and system intelligence within modern electrical infrastructures.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager