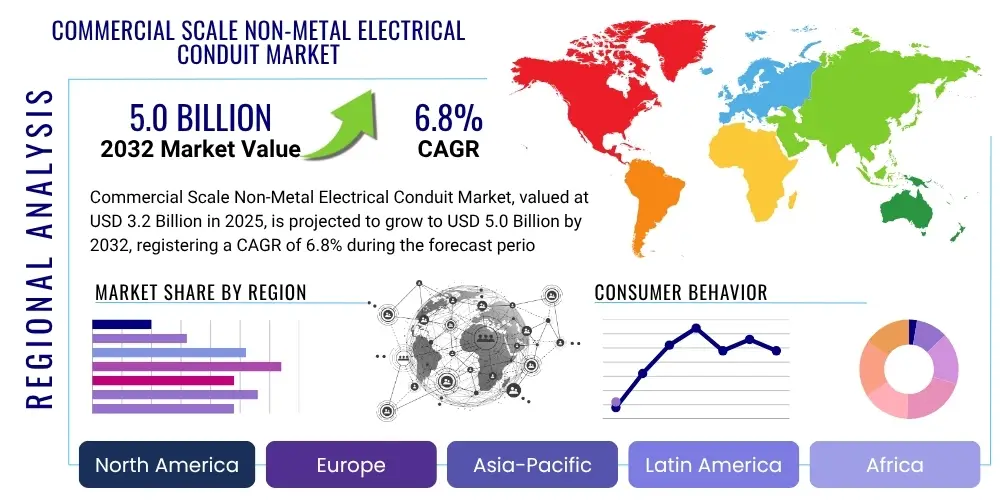

Commercial Scale Non-Metal Electrical Conduit Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429038 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Commercial Scale Non-Metal Electrical Conduit Market Size

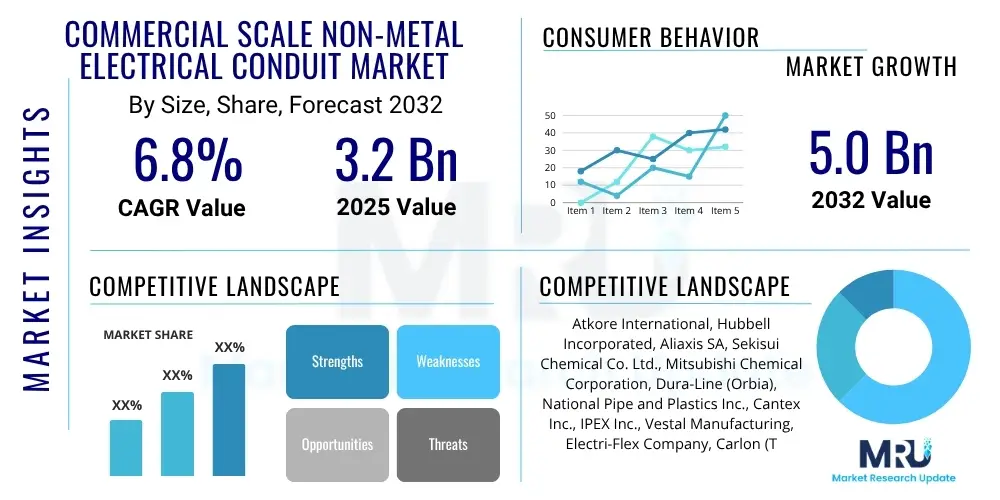

The Commercial Scale Non-Metal Electrical Conduit Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $3.2 Billion in 2025 and is projected to reach $5.0 Billion by the end of the forecast period in 2032.

Commercial Scale Non-Metal Electrical Conduit Market introduction

The Commercial Scale Non-Metal Electrical Conduit Market encompasses the production and distribution of non-metallic systems designed to house and protect electrical wires and cables within commercial and industrial environments. These conduits, primarily made from materials such as PVC, HDPE, fiberglass, and various composites, serve a critical function in ensuring the safety, organization, and longevity of electrical installations. Unlike their metallic counterparts, non-metal conduits offer distinct advantages including superior corrosion resistance, lighter weight, flexibility, and often lower installation costs, making them increasingly preferred in a variety of modern construction and infrastructure projects.

Products within this market range from rigid conduits, suitable for exposed or direct burial applications, to flexible conduits used in tight spaces or where vibrations are a concern. Major applications span across commercial buildings like offices, retail spaces, and hospitals, industrial facilities such as manufacturing plants and data centers, and critical infrastructure projects including transportation hubs and utility networks. The primary benefits driving their adoption include excellent dielectric properties, resistance to chemicals, moisture, and UV radiation, and inherent non-conductivity, which enhances electrical safety. These characteristics are particularly valuable in environments where traditional metal conduits might degrade or pose additional risks due to environmental factors.

Key driving factors for the growth of this market include the global surge in commercial and industrial construction activities, increasingly stringent electrical safety regulations mandating robust wiring protection, and the continuous material science advancements leading to more durable and efficient non-metallic solutions. Furthermore, the rising emphasis on sustainable construction practices and the ease of installation associated with lightweight non-metal conduits contribute significantly to their market expansion. The versatility and adaptability of these products to diverse environmental conditions further solidify their position as an indispensable component of modern electrical systems.

Commercial Scale Non-Metal Electrical Conduit Market Executive Summary

The Commercial Scale Non-Metal Electrical Conduit Market is experiencing robust growth, primarily fueled by a global uptick in infrastructure development and commercial construction, coupled with an increasing preference for materials offering enhanced safety and operational efficiencies. Business trends indicate a strong shift towards modular construction techniques and prefabrication, where non-metal conduits offer considerable advantages due to their ease of handling, cutting, and installation. There is also a notable emphasis on developing conduits with improved fire-retardant properties and higher temperature resistance to meet evolving safety standards and application demands across various industries.

Regional trends highlight significant expansion in emerging economies, particularly across Asia Pacific and Latin America, driven by rapid urbanization and large-scale industrialization projects. North America and Europe, while mature markets, continue to demonstrate stable growth, propelled by renovation activities, smart building integration, and investments in renewable energy infrastructure where non-metal conduits are extensively utilized. The Middle East and Africa also present growing opportunities, especially in commercial and residential developments, where non-corrosive and lightweight electrical solutions are highly valued due to challenging environmental conditions.

Segmentation trends reveal polyvinyl chloride (PVC) conduits maintaining a dominant market share due to their cost-effectiveness and widespread adoption, while high-density polyethylene (HDPE) conduits are gaining traction, especially in underground and data communication applications, owing to their superior strength and flexibility. Fiberglass conduits are seeing increased demand in specialized industrial settings requiring high chemical resistance and structural integrity. The demand for flexible non-metal conduits is also rising in applications that require intricate wiring paths and quick installations, reflecting a broader industry trend towards adaptability and reduced labor costs.

AI Impact Analysis on Commercial Scale Non-Metal Electrical Conduit Market

Common user questions regarding AI's impact on the Commercial Scale Non-Metal Electrical Conduit Market often revolve around how artificial intelligence could optimize manufacturing processes, enhance supply chain efficiencies, and potentially influence product design and smart building integration. Users are concerned with whether AI could lead to more sustainable production methods, improve quality control, or predict market demand more accurately. They also inquire about the potential for AI to facilitate the adoption of "smart" conduits that can monitor their own integrity or integrate seamlessly into intelligent building management systems, raising expectations for advanced fault detection and maintenance capabilities.

- AI can optimize manufacturing processes through predictive maintenance of extrusion machines, reducing downtime and waste.

- Demand forecasting and inventory management can be significantly enhanced by AI, leading to more efficient supply chains and reduced warehousing costs.

- AI-powered design tools could accelerate the development of innovative conduit materials and geometries, improving performance and specialized application suitability.

- Integration of AI in smart building systems could enable conduits with embedded sensors for real-time monitoring of electrical load, temperature, and structural integrity.

- AI analytics can identify market trends and customer preferences, guiding product development and marketing strategies for conduit manufacturers.

- Automated quality control systems leveraging AI can detect defects in conduit production with greater accuracy and speed than manual inspections.

- AI can facilitate sustainable practices by optimizing material usage and energy consumption during manufacturing.

DRO & Impact Forces Of Commercial Scale Non-Metal Electrical Conduit Market

The Commercial Scale Non-Metal Electrical Conduit Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaped by broader economic and technological shifts. Key drivers include the consistent growth in commercial and residential construction globally, particularly in developing nations, alongside substantial investments in infrastructure projects such as transportation networks and data centers. The inherent advantages of non-metal conduits, such as their resistance to corrosion, lightweight properties, and ease of installation compared to metal alternatives, further accelerate their adoption. Additionally, the increasing emphasis on electrical safety regulations and the demand for materials that offer superior insulation and fire resistance are paramount in driving market expansion, as non-metallic options often meet these requirements more effectively.

However, the market also faces considerable restraints. Volatility in the prices of raw materials, primarily petrochemical derivatives like PVC and HDPE, poses a significant challenge to manufacturers' profitability and pricing strategies. Intense competition from traditional metallic conduits, especially in specific high-temperature or impact-resistant applications where metal still holds an edge, continues to exist. Furthermore, a lack of awareness or established preferences for metallic systems in some regions can hinder the broader adoption of non-metal conduits. The market must also contend with limitations in certain extreme environmental conditions where non-metal conduits may not offer the same performance as specialized metal alloys.

Opportunities for growth are abundant, particularly in the burgeoning smart cities and renewable energy sectors, where non-metal conduits are ideal for protecting complex wiring in solar farms, wind turbines, and intelligent urban infrastructure. The ongoing trend towards sustainable and green building practices creates avenues for innovative bio-based or recycled non-metal conduit materials. Expanding into specialized applications requiring chemical resistance, UV stability, or anti-microbial properties also represents significant growth potential. The impact forces within the market are characterized by a moderate bargaining power of buyers due to the availability of numerous suppliers and product choices, while the bargaining power of suppliers is influenced by raw material price fluctuations. The threat of substitutes, largely from metal conduits, remains, though the threat of new entrants is moderate given the capital intensity and regulatory hurdles. Competitive rivalry among existing players is high, fostering continuous product innovation and differentiation.

Segmentation Analysis

The Commercial Scale Non-Metal Electrical Conduit Market is broadly segmented based on various attributes including type, material, application, and end-use, each offering distinct characteristics and catering to specific market demands. This comprehensive segmentation provides a detailed understanding of market dynamics, revealing key areas of growth and competitive landscapes. Analyzing these segments helps stakeholders identify lucrative opportunities, tailor product development, and refine market entry strategies. The dominance of certain material types in specific applications, coupled with the increasing demand for specialized conduits, underscores the intricate nature of the market.

- By Type

- Rigid Non-Metal Conduits

- Flexible Non-Metal Conduits

- By Material

- Polyvinyl Chloride (PVC)

- High-Density Polyethylene (HDPE)

- Fiberglass

- Polypropylene (PP)

- Other Polymers (e.g., Nylon, Polyamide)

- By Application

- Commercial Buildings (Offices, Retail, Hospitality, Healthcare)

- Industrial Facilities (Manufacturing Plants, Chemical Plants)

- Infrastructure (Roads, Bridges, Tunnels, Utilities, Telecommunications)

- Data Centers

- Renewable Energy (Solar, Wind)

- Residential (High-Rise Apartments, Multi-Family Units)

- By End-Use

- Construction

- Telecommunications

- Manufacturing

- Energy & Utilities

- Healthcare

Value Chain Analysis For Commercial Scale Non-Metal Electrical Conduit Market

The value chain for the Commercial Scale Non-Metal Electrical Conduit Market commences with the upstream activities involving the sourcing and processing of raw materials. This stage is dominated by chemical and polymer manufacturers who supply crucial inputs such as PVC resins, HDPE granules, fiberglass rovings, and various additives like flame retardants, UV stabilizers, and plasticizers. The quality and cost of these raw materials significantly influence the final product's performance and market price. Strong relationships with reliable suppliers are critical here to ensure consistent quality and mitigate supply chain risks, especially given the volatility of petrochemical prices.

Moving downstream, the raw materials are transformed into finished non-metal conduits through various manufacturing processes, primarily extrusion for rigid and flexible conduits, and molding for fittings and specialized components. Manufacturers invest heavily in research and development to innovate materials, improve product performance (e.g., enhanced fire resistance, greater flexibility), and optimize production efficiencies. Following manufacturing, products are distributed through a multi-faceted network. Direct sales channels are often employed for large-scale industrial projects or key accounts, allowing manufacturers to maintain direct control over pricing and customer relationships. However, a significant portion of products reaches end-users through indirect channels.

Indirect distribution typically involves wholesalers, distributors, and electrical supply houses that serve as intermediaries between manufacturers and a vast network of electrical contractors, builders, and smaller industrial clients. These distributors play a crucial role in providing logistical support, managing inventory, and offering localized customer service. They often stock a wide range of conduit types and sizes, ensuring product availability and facilitating timely delivery to diverse project sites. End-users, who are primarily electrical contractors, commercial developers, industrial plant operators, and telecommunication companies, purchase these conduits for installation in their respective projects. The effectiveness of both direct and indirect distribution channels is paramount for market penetration and customer reach, requiring strategic partnerships and efficient logistical operations to maintain competitiveness and responsiveness to market demands.

Commercial Scale Non-Metal Electrical Conduit Market Potential Customers

The potential customers and end-users of commercial scale non-metal electrical conduits are diverse, spanning a wide array of industries and sectors involved in construction, infrastructure development, and industrial operations. At the forefront are electrical contractors and engineering firms, who are the primary specifiers and installers of these products in new constructions, renovations, and maintenance projects. Their purchasing decisions are heavily influenced by product performance, ease of installation, compliance with local codes, and overall cost-effectiveness, making them critical stakeholders in the market's demand cycle.

Commercial builders and property developers constitute another significant customer segment. They typically purchase conduits for large-scale projects such as office complexes, retail centers, hospitals, educational institutions, and hospitality establishments. Their focus lies on long-term durability, safety standards, and the ability of conduit systems to integrate efficiently within modern building designs and smart infrastructure. Industrial plant operators, particularly in sectors like manufacturing, chemical processing, oil and gas, and food and beverage, also represent a substantial end-user group, where non-metal conduits are valued for their resistance to corrosive environments, chemicals, and varying temperatures, ensuring reliable operation of critical electrical systems.

Furthermore, telecommunication companies and data center operators are increasingly relying on non-metal conduits, especially HDPE, for protecting vast networks of fiber optic and copper cabling, both underground and within facilities, due to their superior protection against moisture, rodents, and physical damage. Government agencies and municipal bodies involved in public infrastructure projects like roads, bridges, tunnels, and utility distribution also represent a stable demand source, prioritizing durability, safety, and adherence to public works standards. The broad applicability and distinct advantages of non-metal conduits across these varied end-use segments underpin the market's consistent growth and resilience.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $3.2 Billion |

| Market Forecast in 2032 | $5.0 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atkore International, Hubbell Incorporated, Aliaxis SA, Sekisui Chemical Co. Ltd., Mitsubishi Chemical Corporation, Dura-Line (Orbia), National Pipe and Plastics Inc., Cantex Inc., IPEX Inc., Vestal Manufacturing, Electri-Flex Company, Carlon (Thomas & Betts, ABB), United Flexible, Legrand, HellermannTyton, Fränkische Rohrwerke, Pipelife (Wienerberger), JM Eagle, Georg Fischer AG, Warren Pipe & Supply |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Scale Non-Metal Electrical Conduit Market Key Technology Landscape

The Commercial Scale Non-Metal Electrical Conduit Market is continuously evolving with advancements in material science and manufacturing processes aimed at enhancing product performance, safety, and environmental sustainability. A key technological focus is on developing improved polymer formulations that offer superior flame retardancy, reduced smoke emission, and enhanced resistance to extreme temperatures, chemicals, and UV degradation. Innovations in nanocomposites and other advanced additives are enabling the creation of conduits that are lighter yet more durable, capable of withstanding harsher operating conditions and extending their service life in demanding commercial and industrial environments.

Manufacturing technologies are also undergoing significant transformation, with an emphasis on automation and precision. Advanced extrusion and co-extrusion techniques allow for the production of multi-layered conduits that combine different material properties, such as a robust outer layer for impact protection and an inner layer for smoother cable pulling. The integration of Industry 4.0 principles, including IoT sensors and data analytics in production lines, facilitates real-time quality control, predictive maintenance of machinery, and optimization of resource utilization, leading to higher efficiency and reduced waste. This also allows for greater customization to meet specific project requirements, such as unique color codes or specialized diameters.

Furthermore, the market is witnessing the emergence of "smart" conduit systems, although still nascent, which incorporate embedded sensors or integrated pathways for monitoring environmental conditions, cable integrity, or even enabling data transfer. This aligns with the broader trend of smart building technologies and intelligent infrastructure, where electrical conduits could potentially play a more active role in facility management and fault detection. Innovations in installation technologies, such as improved joining methods, specialized cutting tools, and conduit bending equipment, are also contributing to faster and more cost-effective deployment, further enhancing the appeal and competitive advantage of non-metal electrical conduits in the commercial and industrial construction sectors.

Regional Highlights

- North America: A mature market characterized by stringent building codes and safety regulations, driving demand for high-quality, compliant non-metal conduits. Significant investments in data centers, commercial infrastructure upgrades, and renewable energy projects contribute to steady growth.

- Europe: Emphasizes sustainability and energy efficiency, leading to the adoption of advanced non-metal conduits with enhanced fire safety and environmental profiles. Renovation and modernization of existing commercial and industrial buildings are key market drivers.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid urbanization, extensive commercial and industrial construction, and massive infrastructure development projects, particularly in China, India, and Southeast Asian countries. Increasing foreign investment and manufacturing expansion further bolster demand.

- Latin America: An emerging market with growing investments in residential, commercial, and public infrastructure projects. Demand is rising due to economic development and increasing awareness of the benefits of non-metal conduits over traditional materials.

- Middle East and Africa (MEA): Marked by substantial construction activities in commercial, residential, and oil & gas sectors. The need for corrosion-resistant and durable electrical protection in challenging environmental conditions drives the adoption of non-metal conduits.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Scale Non-Metal Electrical Conduit Market.- Atkore International

- Hubbell Incorporated

- Aliaxis SA

- Sekisui Chemical Co. Ltd.

- Mitsubishi Chemical Corporation

- Dura-Line (Orbia)

- National Pipe and Plastics Inc.

- Cantex Inc.

- IPEX Inc.

- Vestal Manufacturing

- Electri-Flex Company

- Carlon (Thomas & Betts, ABB)

- United Flexible

- Legrand

- HellermannTyton

- Fränkische Rohrwerke

- Pipelife (Wienerberger)

- JM Eagle

- Georg Fischer AG

- Warren Pipe & Supply

Frequently Asked Questions

What are the primary benefits of using non-metal electrical conduits in commercial settings?

Non-metal electrical conduits offer superior corrosion resistance, making them ideal for harsh environments, are lighter in weight facilitating easier and faster installation, possess excellent electrical insulation properties enhancing safety, and often provide better cost-effectiveness over their lifecycle due to lower maintenance requirements.

Which materials are most commonly used for commercial non-metal electrical conduits?

The most common materials are Polyvinyl Chloride (PVC) for its versatility and cost-efficiency, High-Density Polyethylene (HDPE) for its flexibility and suitability for underground applications, and Fiberglass for its strength and resistance to chemicals and high temperatures in industrial settings.

What are the key applications driving the growth of the non-metal conduit market?

Key applications include commercial building construction (offices, retail, healthcare), industrial facilities (manufacturing, processing plants), critical infrastructure (transportation, utilities), and data centers, where their protective qualities and material advantages are highly valued.

How do regulatory standards impact the commercial non-metal electrical conduit market?

Stringent regulatory standards for electrical safety, fire protection, and environmental compliance directly influence product development and adoption. Manufacturers must ensure their conduits meet specific codes (e.g., UL, NEC, CE) to be viable in commercial projects, often leading to innovation in fire-retardant and low-smoke materials.

What are the main challenges faced by the non-metal electrical conduit market?

The primary challenges include volatility in raw material prices (polymers), competition from established metallic conduit systems in certain applications, and the need for continuous innovation to meet evolving performance requirements, especially for extreme temperature or high-impact resistance scenarios.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager