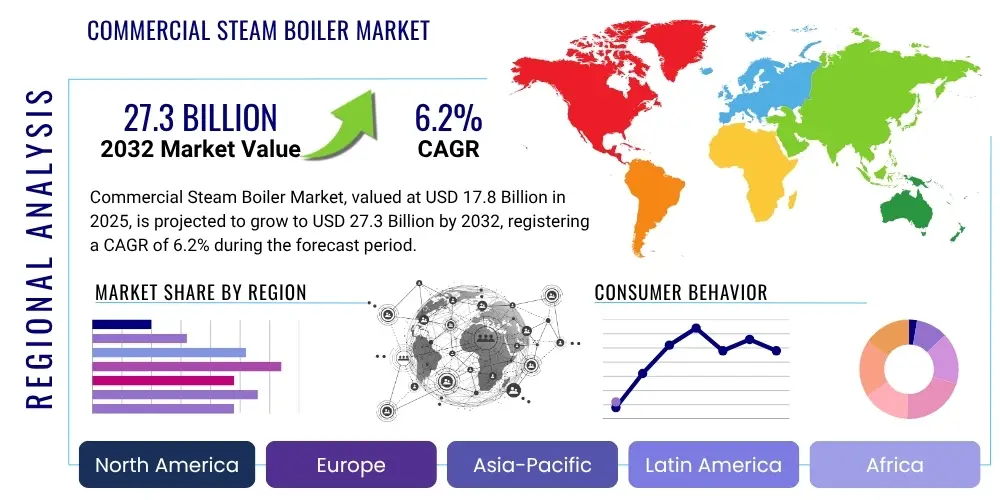

Commercial Steam Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428954 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Commercial Steam Boiler Market Size

The Commercial Steam Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2025 and 2032. The market is estimated at $17.8 Billion in 2025 and is projected to reach $27.3 Billion by the end of the forecast period in 2032.

Commercial Steam Boiler Market introduction

The commercial steam boiler market encompasses the manufacturing, distribution, and maintenance of advanced systems designed to generate steam for a wide array of commercial and industrial applications. These crucial devices operate by heating water to its boiling point, converting it into high-pressure steam which is then utilized for various processes including space heating, water heating, sterilization, power generation, and specialized industrial operations. The market is driven by continuous innovation in boiler design, aiming for enhanced energy efficiency, reduced emissions, and improved operational reliability, responding to both economic pressures and stringent environmental regulations. Products range from compact electric boilers suitable for smaller commercial settings to large, robust fire-tube and water-tube systems powering extensive industrial facilities and district heating networks.

Commercial steam boilers are indispensable across numerous sectors due to their ability to provide consistent and controllable heat energy. Key applications span commercial buildings such as hotels, hospitals, educational institutions, and large office complexes, where they are vital for HVAC systems and domestic hot water. In industrial processes, they are central to manufacturing operations in food and beverage, pharmaceuticals, chemical processing, textiles, and pulp and paper industries, providing steam for drying, cooking, distillation, and sterilization. The fundamental benefits of modern commercial steam boilers include their high thermal efficiency, often exceeding 85-90% for advanced models, their capacity to deliver high-quality steam consistently, and their long operational lifespans with proper maintenance. These systems contribute significantly to operational cost savings and reduced environmental impact when optimized for fuel consumption and emissions.

Several factors are propelling the growth of this market. Rapid industrialization and urbanization in emerging economies are increasing demand for new installations in manufacturing plants and commercial infrastructure. Stricter energy efficiency mandates and carbon emission reduction targets globally are compelling businesses to upgrade to more advanced, eco-friendly boiler systems, including those that can utilize cleaner fuels or hybrid technologies. Furthermore, the burgeoning demand for reliable and continuous steam supply in critical sectors like healthcare for sterilization and food processing for hygiene and safety continues to underpin market expansion. The integration of smart technologies for better control and monitoring is also enhancing the appeal and performance of contemporary commercial steam boiler solutions.

Commercial Steam Boiler Market Executive Summary

The Commercial Steam Boiler Market is experiencing dynamic shifts, influenced by global industrial expansion, a strong focus on energy efficiency, and evolving environmental regulations. Key business trends include the increasing adoption of smart boilers with IoT capabilities for remote monitoring and predictive maintenance, a growing preference for modular boiler systems that offer scalability and flexibility, and a significant investment in research and development for alternative fuel sources, such as biomass and hybrid systems. Companies are also prioritizing customer service and lifecycle support, recognizing the long-term value in maintenance contracts and operational optimization services. Mergers and acquisitions are prevalent as market players seek to consolidate their positions and expand their technological portfolios, particularly in areas like advanced combustion and emissions control.

Regionally, the Asia Pacific (APAC) market is poised for robust growth, driven by rapid industrialization, extensive infrastructure development, and increasing energy demand from developing economies like China and India. North America and Europe, characterized by mature markets, are seeing demand primarily from boiler replacements and upgrades, spurred by stringent emissions standards and incentives for energy-efficient technologies. Latin America and the Middle East and Africa (MEA) are emerging as significant growth frontiers, fueled by investments in manufacturing, commercial construction, and resource processing industries. Localized regulatory frameworks around fuel types, emission limits, and energy performance are shaping regional market dynamics, pushing manufacturers to tailor solutions to specific geographical requirements.

From a segmentation perspective, the market is observing a notable trend towards electric and hybrid boiler systems, especially in regions committed to decarbonization, offering solutions where fossil fuels are being phased out. Natural gas fired boilers continue to dominate due to cost-effectiveness and relatively lower emissions compared to oil and coal, though biomass and hydrogen-ready boilers are gaining traction as sustainable alternatives. The high-capacity segment is growing due to increasing industrial scale, while medium and low-capacity boilers are experiencing consistent demand from commercial buildings and smaller manufacturing units. Applications in industrial processing, particularly food and beverage and pharmaceuticals, remain strong, alongside a steady demand from commercial HVAC applications driven by new constructions and retrofits focusing on sustainable building practices.

AI Impact Analysis on Commercial Steam Boiler Market

User inquiries concerning AI's influence on the Commercial Steam Boiler Market frequently center on enhanced operational efficiency, predictive maintenance capabilities, and intelligent energy management. Users are keen to understand how AI algorithms can optimize boiler performance, reduce downtime, and significantly lower fuel consumption. There is considerable interest in AI's role in improving safety, streamlining regulatory compliance through automated data analysis, and integrating seamlessly with existing building management systems (BMS) and industrial control platforms. Concerns often revolve around the initial investment costs of AI integration, data security, and the necessity for specialized expertise to implement and manage these advanced systems. Expectations are high for AI to transform boiler operations from reactive to proactive, providing real-time insights and autonomous adjustments for optimal performance.

AI's capability to analyze vast datasets from boiler sensors, including temperature, pressure, flow rates, and emissions, allows for unprecedented levels of operational optimization. By identifying subtle patterns and correlations that human operators might miss, AI systems can fine-tune combustion processes, modulate fuel input, and adjust air-to-fuel ratios in real-time to achieve peak efficiency. This optimization not only reduces fuel consumption and operational costs but also minimizes the carbon footprint of commercial steam boiler operations. Furthermore, AI can predict fluctuations in steam demand based on historical data and external factors like weather, enabling boilers to ramp up or down proactively, reducing standby losses and improving overall system responsiveness. This intelligent control contributes directly to both economic and environmental sustainability goals within commercial and industrial settings.

The impact of AI extends significantly into predictive maintenance, a critical area for minimizing costly downtime and extending the lifespan of boiler assets. AI algorithms can detect anomalies in operational data, such as slight changes in vibration patterns, unusual pressure drops, or subtle shifts in exhaust gas composition, indicating potential component failures before they escalate. By analyzing these indicators, AI provides early warnings, allowing maintenance teams to schedule interventions proactively during planned shutdowns rather than reacting to catastrophic breakdowns. This shift from reactive to predictive maintenance strategies translates into substantial savings on emergency repairs, reduced production losses, and improved safety across facilities utilizing commercial steam boilers. The integration of AI also facilitates easier compliance reporting by automatically logging and analyzing operational data against regulatory standards.

- Enhanced Predictive Maintenance: AI analyzes sensor data to forecast equipment failures, minimizing downtime.

- Optimized Fuel Consumption: Real-time adjustments of combustion parameters lead to significant energy savings.

- Improved Operational Efficiency: AI algorithms fine-tune boiler performance for peak output and reduced waste.

- Automated Diagnostics: AI identifies and diagnoses operational issues, speeding up troubleshooting.

- Seamless Integration with BMS: Facilitates holistic control and management within commercial buildings.

- Reduced Emissions: Precision control of combustion helps meet environmental regulations more effectively.

- Enhanced Safety Monitoring: AI systems can detect abnormal conditions that pose safety risks and trigger alerts.

- Intelligent Load Management: AI optimizes boiler output to match real-time steam demand, reducing standby losses.

- Remote Monitoring and Control: AI-powered platforms enable off-site management and performance tracking.

DRO & Impact Forces Of Commercial Steam Boiler Market

The Commercial Steam Boiler Market is influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating pace of industrialization and urbanization across emerging economies, which necessitates extensive infrastructure development and increased manufacturing capabilities, all reliant on robust steam generation for various processes and heating needs. Coupled with this, stringent global environmental regulations and an imperative for energy efficiency are compelling businesses to upgrade or invest in modern, high-efficiency boiler systems that reduce fuel consumption and lower carbon emissions. The consistent demand for steam in critical sectors such as food and beverage processing, pharmaceuticals, and healthcare, where sterilization and precise temperature control are non-negotiable, further fuels market growth. Advances in boiler technology, including condensing designs and improved burner efficiency, also act as significant drivers, offering better performance and lower operating costs.

Despite these strong drivers, the market faces notable restraints. The substantial upfront capital investment required for purchasing and installing commercial steam boilers, especially larger or more advanced models, can be a barrier for smaller enterprises or those with limited budgets. Additionally, the complexities associated with boiler maintenance, including specialized skills and periodic inspections to ensure safety and efficiency, add to the operational expenditure and can deter some potential adopters. Environmental concerns regarding fossil fuel combustion, despite advancements in emissions reduction, contribute to a negative perception, with increasing pressure to shift towards renewable energy sources for heating and power. The ongoing global economic uncertainties and fluctuations in raw material prices, particularly steel and other metals, can impact manufacturing costs and market stability, influencing investment decisions and project timelines.

Opportunities for growth are abundant within this evolving landscape. The development and increasing adoption of hybrid boiler systems, combining conventional fuels with renewable sources like solar thermal or biomass, present a promising avenue for market expansion as companies seek to diversify their energy portfolios and enhance sustainability. The burgeoning retrofit market, driven by the need to replace aging, inefficient boilers with more modern, environmentally compliant units in mature economies, offers substantial growth potential. Furthermore, the integration of IoT, AI, and advanced analytics into boiler systems for predictive maintenance, remote monitoring, and real-time performance optimization represents a significant opportunity for value addition and competitive differentiation. Emerging economies in Asia Pacific and Africa, with their rapid industrial growth and developing infrastructure, represent untapped markets for new boiler installations and technology adoption.

- Drivers: Rapid industrialization, stringent energy efficiency regulations, growing demand from processing industries, infrastructure development, HVAC system requirements.

- Restraints: High initial investment costs, complex maintenance requirements, environmental concerns over fossil fuel usage, volatile raw material prices.

- Opportunities: Development of hybrid boiler systems, retrofit and replacement market in developed regions, integration of IoT and AI for smart operations, expansion in emerging economies.

- Impact Forces: Technological advancements in combustion and controls, shifting regulatory landscapes regarding emissions, global economic stability, geopolitical energy policies, and the availability of skilled labor.

Segmentation Analysis

The Commercial Steam Boiler market is extensively segmented based on various attributes to provide a comprehensive understanding of its structure and dynamics. These segmentations allow for detailed analysis of market trends, consumer preferences, and technological adoption across different applications and geographical regions. Understanding these distinct segments is crucial for manufacturers, suppliers, and investors to identify lucrative opportunities, tailor product offerings, and devise effective market penetration strategies.

- By Type:

- Fire-tube Boilers

- Water-tube Boilers

- Electric Boilers

- Condensing Boilers

- Hybrid Boilers

- Others (e.g., Coil Tube, Cast Iron)

- By Fuel Type:

- Natural Gas Fired

- Oil Fired

- Coal Fired

- Electric

- Biomass Fired

- Hybrid Fuel

- Other (e.g., Hydrogen, Waste Heat)

- By Capacity:

- Less than 10 MMBtu/hr

- 10-50 MMBtu/hr

- More than 50 MMBtu/hr

- By Application:

- HVAC (Heating, Ventilation, and Air Conditioning)

- Power Generation

- Industrial Process Heating (e.g., Manufacturing, Chemical, Food & Beverage)

- Sterilization

- Water Heating

- Other Commercial Applications

- By End-User:

- Manufacturing Industry (e.g., Automotive, Textile, Pulp & Paper)

- Commercial Buildings (e.g., Offices, Hotels, Retail)

- Healthcare (e.g., Hospitals, Clinics)

- Food & Beverage Industry

- Pharmaceuticals

- Chemical & Petrochemical

- Power Plants

- Others (e.g., Laundries, Education)

Value Chain Analysis For Commercial Steam Boiler Market

The value chain for the Commercial Steam Boiler Market encompasses a series of interconnected stages, beginning with the sourcing of raw materials and extending through manufacturing, assembly, distribution, installation, and post-sales services, ultimately reaching the end-users. The upstream segment involves the procurement of essential raw materials such as steel plates and tubes, cast iron, refractory materials, insulation, and various electronic components and controls from specialized suppliers. Key component manufacturers also contribute by supplying burners, pumps, valves, heat exchangers, and automation systems that are integral to the boiler's functionality. Strong relationships with reliable suppliers are critical for ensuring material quality, cost efficiency, and timely delivery, directly impacting the final product's performance and market competitiveness.

In the midstream, the manufacturing process involves precision engineering, welding, fabrication, and assembly of these components into complete boiler units. This stage is heavily reliant on skilled labor, advanced manufacturing technologies, and adherence to strict quality control standards and safety regulations. After manufacturing, the products move to the downstream segment, which includes logistics, distribution, and sales. Distribution channels are varied, encompassing direct sales by manufacturers to large industrial clients, sales through a network of authorized distributors and dealers, and engagement with engineering, procurement, and construction (EPC) contractors for integrated project solutions. The choice of distribution channel often depends on the scale of the project, the geographical reach, and the complexity of the boiler system being sold.

Post-sales activities form a crucial part of the value chain, encompassing installation, commissioning, maintenance services, spare parts supply, and technical support. These services are vital for ensuring the long-term operational efficiency, safety, and reliability of the boilers, thereby enhancing customer satisfaction and fostering repeat business. Direct sales often involve the manufacturer providing comprehensive installation and ongoing service contracts, particularly for complex industrial boilers. Indirect channels rely on certified third-party installers and service providers who have been trained and authorized by the manufacturers. Effective management of this entire value chain, from upstream material sourcing to downstream customer support, is paramount for companies to maintain competitive advantages, optimize costs, and build strong brand reputation in the commercial steam boiler market.

Commercial Steam Boiler Market Potential Customers

The commercial steam boiler market serves a diverse array of potential customers, spanning multiple industries and sectors that have a fundamental requirement for reliable steam generation. These end-users and buyers are typically organizations that need steam for process heating, sterilization, humidification, power generation, or space heating applications. The customer base is broad, ranging from large-scale manufacturing facilities that require vast quantities of high-pressure steam for their production lines to commercial buildings such as hotels, hospitals, and educational institutions that depend on steam for HVAC systems and domestic hot water. Identifying and understanding the specific needs, regulatory environment, and operational challenges of each customer segment is crucial for manufacturers to tailor their product offerings and marketing strategies effectively.

Key segments of potential customers include the manufacturing sector, encompassing diverse industries such as textiles, pulp and paper, automotive, and general manufacturing. These industries often utilize steam for drying, curing, distillation, and various chemical processes, making reliable and efficient boiler systems indispensable for their operations. The food and beverage industry represents another significant customer base, where steam is critical for cooking, pasteurization, sterilization of equipment, and cleaning processes to ensure product safety and quality. Similarly, the pharmaceutical industry relies heavily on high-purity steam for sterilization of equipment, cleanroom humidification, and various synthesis processes, demanding boilers that meet stringent regulatory standards for cleanliness and reliability.

Beyond traditional industrial users, the commercial and institutional sectors form a substantial portion of the market. Hospitals and healthcare facilities require steam for sterilization of medical instruments, laundry services, and space heating, often prioritizing extreme reliability and rapid response times. Hotels, resorts, and large residential complexes use commercial boilers for heating, hot water, and sometimes for laundry operations. Educational institutions, government buildings, and district heating networks also represent significant buyers, driven by the need for efficient and cost-effective heating solutions for large spaces. The increasing focus on energy efficiency and sustainability across all these sectors is leading customers to seek out advanced boiler technologies that offer lower operating costs and reduced environmental impact.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $17.8 Billion |

| Market Forecast in 2032 | $27.3 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Bosch Thermotechnology, Cleaver-Brooks, Miura Co Ltd, Fulton Boiler Works, Viessmann Group, Cochran Ltd, Hurst Boiler & Welding Co Inc, Weil-McLain, Thermax Limited, Aalborg Boilers (Alfa Laval), Clayton Industries, Babcock & Wilcox Enterprises Inc, Boiler & Combustion System Solutions (BCSS), GETABEC, Vapor Power International, Parker Boiler, Atlantic Boilers, Siemens Energy, Mitsubishi Hitachi Power Systems, John Cockerill. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Steam Boiler Market Key Technology Landscape

The commercial steam boiler market is characterized by a rapidly evolving technology landscape focused on enhancing efficiency, reducing environmental impact, and improving operational intelligence. A prominent technological advancement is the widespread adoption of condensing boiler technology, which recaptures latent heat from exhaust gases that would otherwise be lost. By preheating incoming feedwater with this recovered heat, condensing boilers achieve significantly higher thermal efficiencies, often exceeding 90%, leading to substantial fuel savings and reduced emissions. This technology is becoming standard, particularly in regions with stringent energy efficiency mandates, pushing manufacturers to continuously refine heat exchanger designs and materials for maximum heat transfer and corrosion resistance.

Another pivotal technological trend is the integration of digital solutions, including the Internet of Things (IoT), advanced control systems, and artificial intelligence (AI), into boiler operations. IoT sensors embedded within boilers collect vast amounts of real-time data on parameters such as temperature, pressure, fuel consumption, and emissions. This data is then processed by sophisticated control algorithms and AI-powered analytics to optimize combustion, predict maintenance needs, and enable remote monitoring and diagnostics. Smart boiler systems can autonomously adjust operating parameters to match demand, identify potential faults before they lead to downtime, and provide detailed performance reports, thereby maximizing uptime and operational efficiency while minimizing human intervention.

Furthermore, advancements in burner technology are crucial for optimizing fuel combustion and reducing harmful emissions. Low NOx (nitrogen oxide) burners, for instance, are designed to reduce the formation of nitrogen oxides during combustion, helping facilities comply with increasingly strict air quality regulations. The development of multi-fuel and hybrid burner systems allows boilers to switch between different fuel sources, offering greater operational flexibility and the ability to utilize cleaner or more cost-effective fuels as they become available, including hydrogen or bio-derived fuels. Material science innovations are also contributing to lighter, more durable, and more corrosion-resistant boiler components, improving longevity and reducing maintenance frequency. These technological innovations collectively aim to make commercial steam boilers more sustainable, efficient, and intelligent.

Regional Highlights

Regional dynamics play a crucial role in shaping the Commercial Steam Boiler Market, with each major geographical area presenting unique drivers, challenges, and opportunities based on economic development, industrial activity, and regulatory environments. North America, for instance, is a mature market characterized by a strong emphasis on boiler replacement and upgrades. Stringent environmental regulations, particularly concerning NOx and CO2 emissions, coupled with incentives for energy-efficient equipment, drive demand for advanced condensing and low-emission boiler technologies. The presence of a vast installed base of aging infrastructure ensures a steady retrofit market, while the robust manufacturing sector and commercial building construction contribute to consistent demand for new installations, particularly in high-growth states.

Europe mirrors many trends seen in North America, with a strong focus on decarbonization and achieving net-zero emissions targets. European policies, such as the EU Emissions Trading System and various national energy efficiency directives, are accelerating the transition away from fossil fuel-fired boilers towards electric, biomass, and potentially hydrogen-ready systems. Germany, the UK, and France are leading this transition, investing heavily in renewable energy integration and district heating networks that rely on efficient steam generation. While new construction drives some demand, the primary growth driver remains the modernization of existing heating infrastructure and industrial facilities to comply with stricter environmental standards and improve energy performance.

The Asia Pacific (APAC) region stands out as the fastest-growing market, propelled by rapid industrialization, urbanization, and a burgeoning manufacturing sector across countries like China, India, and Southeast Asia. The escalating demand for energy in these developing economies, coupled with significant investments in infrastructure and commercial real estate, necessitates a substantial increase in boiler installations for industrial processes, power generation, and commercial heating. While cost-effectiveness remains a key consideration, there is also a growing awareness and adoption of more energy-efficient and environmentally compliant boiler technologies as regional regulations begin to tighten and industries seek to enhance their global competitiveness.

- North America: Focus on replacement and upgrades, stringent environmental regulations, robust manufacturing and commercial sectors. Dominant in smart and high-efficiency systems.

- Europe: Driven by decarbonization goals, energy efficiency directives, and a shift towards electric and biomass boilers. Significant retrofit market and investment in district heating.

- Asia Pacific (APAC): Rapid industrialization, urbanization, and manufacturing growth driving new installations. Balancing cost-effectiveness with increasing demand for efficient solutions in China and India.

- Latin America: Growing industrial base and infrastructure development, particularly in Brazil and Mexico. Demand for reliable steam solutions in resource processing and food & beverage.

- Middle East and Africa (MEA): Investments in industrialization, particularly oil and gas, petrochemicals, and general manufacturing. Demand for robust

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager