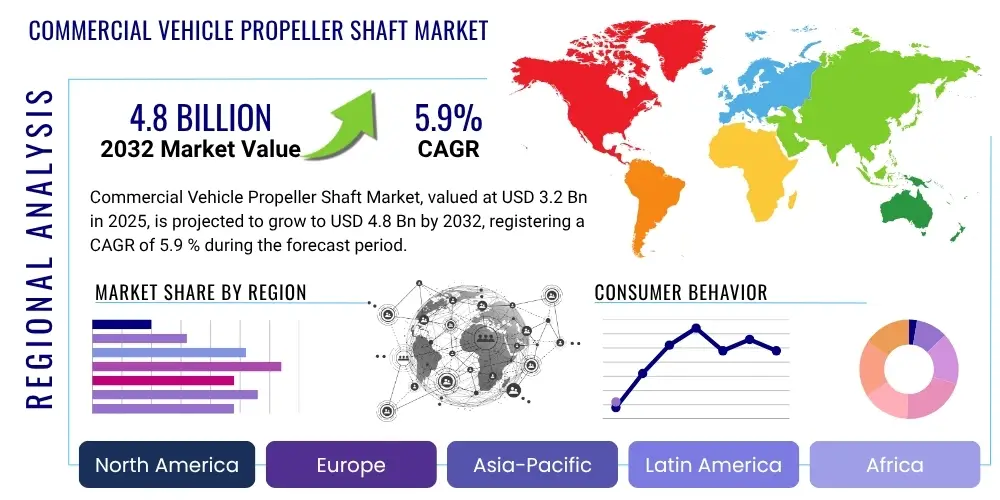

Commercial Vehicle Propeller Shaft Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427969 | Date : Oct, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Commercial Vehicle Propeller Shaft Market Size

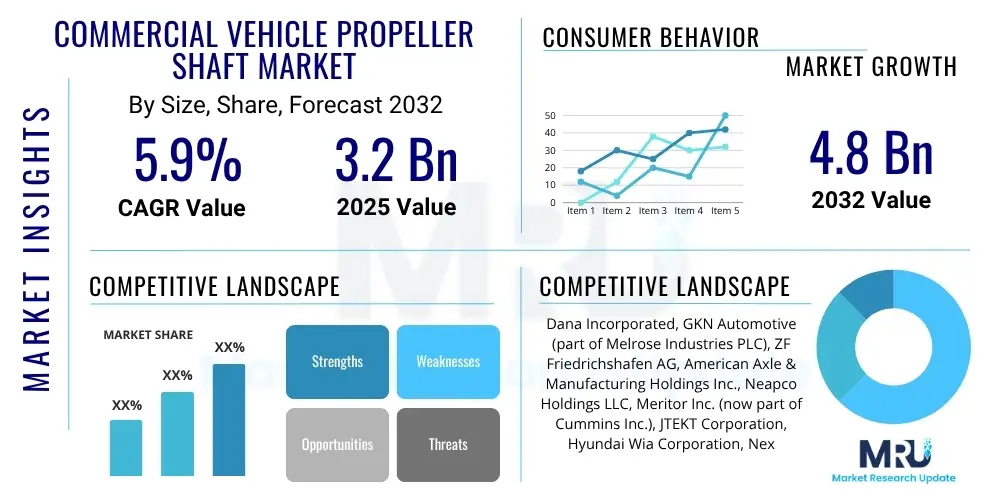

The Commercial Vehicle Propeller Shaft Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.9% between 2025 and 2032. The market is estimated at USD 3.2 billion in 2025 and is projected to reach USD 4.8 billion by the end of the forecast period in 2032.

Commercial Vehicle Propeller Shaft Market introduction

The Commercial Vehicle Propeller Shaft Market encompasses the global industry involved in the design, manufacturing, and distribution of propeller shafts for various types of commercial vehicles. A propeller shaft, also known as a drive shaft, is a mechanical component used for transmitting torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. This critical component plays a pivotal role in vehicles with a front-engine, rear-wheel-drive (FR) configuration or all-wheel-drive (AWD) systems, effectively transferring power from the transmission to the differential, which in turn powers the wheels. Its robust construction ensures reliable power delivery across diverse operating conditions, from heavy-duty hauling to long-distance transportation.

Product descriptions within this market highlight innovations in material science and engineering, focusing on durability, reduced weight, and improved efficiency. Modern propeller shafts are engineered to withstand extreme torsional loads, vibrations, and environmental factors, often incorporating advanced alloys, composites, and specialized coatings to enhance their service life and performance. Major applications span a broad spectrum of commercial vehicles, including heavy-duty trucks, medium-duty trucks, light commercial vehicles (LCVs), buses, and various off-highway equipment such as construction machinery and agricultural vehicles. The continuous evolution of vehicle design and power output necessitates equally sophisticated propeller shaft solutions capable of meeting stringent performance criteria.

The benefits derived from high-quality propeller shafts are manifold, including efficient power transmission, enhanced vehicle stability, reduced noise, vibration, and harshness (NVH) levels, and overall operational reliability. Driving factors for market growth are primarily linked to the robust expansion of the logistics and transportation sectors globally, increasing demand for commercial vehicles due to booming e-commerce activities, significant infrastructure development projects, and the ongoing modernization of existing commercial vehicle fleets. Furthermore, advancements in manufacturing techniques and materials that promise lighter, stronger, and more fuel-efficient propeller shafts also contribute significantly to market acceleration.

Commercial Vehicle Propeller Shaft Market Executive Summary

The Commercial Vehicle Propeller Shaft Market is experiencing dynamic shifts driven by several overarching business trends, reflecting a global push towards efficiency, sustainability, and technological integration. Key among these is the increasing adoption of lightweight materials such as aluminum and carbon fiber composites, aimed at reducing overall vehicle weight, improving fuel efficiency, and lowering emissions. Electrification of commercial vehicles, while presenting a long-term challenge, also introduces new design requirements for propeller shafts, including specialized configurations for electric drivetrains. Furthermore, modular design approaches and predictive maintenance capabilities, often supported by integrated sensors, are gaining traction, allowing for greater customization, easier servicing, and prolonged component lifespan.

Regionally, the market exhibits varied growth trajectories and maturity levels. The Asia Pacific region stands out as the primary growth engine, fueled by rapid industrialization, extensive infrastructure development projects, and a burgeoning logistics sector, particularly in economies like China and India. North America and Europe represent mature markets characterized by stringent regulatory environments, a strong emphasis on fleet modernization, and a growing demand for advanced, high-performance components that enhance operational safety and efficiency. Emerging markets in Latin America, the Middle East, and Africa are showing promising growth, driven by increasing trade activities, urbanization, and government investments in transport infrastructure, albeit with a focus on cost-effective and durable solutions.

Segmentation trends reveal a persistent demand for steel propeller shafts due to their cost-effectiveness and proven robustness, particularly in heavy-duty applications. However, the market for aluminum and composite shafts is steadily expanding, driven by the need for weight reduction in medium and light commercial vehicles. By vehicle type, heavy-duty trucks continue to dominate the market share, followed by medium-duty trucks and buses, reflecting the critical role these vehicles play in global logistics and public transportation. The aftermarket segment also holds significant value, driven by the need for replacement parts and maintenance, underscoring the long operational lifespan of commercial vehicles and the importance of reliable component supply chains.

AI Impact Analysis on Commercial Vehicle Propeller Shaft Market

Common user questions regarding AI's impact on the Commercial Vehicle Propeller Shaft Market often revolve around how artificial intelligence can enhance component reliability, optimize design processes, improve manufacturing efficiency, and contribute to the evolution of autonomous commercial vehicles. Users are keen to understand if AI can predict failures, thereby extending maintenance intervals, or if it can lead to entirely new propeller shaft technologies. There's also significant interest in AI's role in the broader supply chain and how it might enable greater customization and responsiveness to market demands. The overarching theme is the expectation that AI will bring about a paradigm shift, moving from reactive maintenance and traditional design to proactive, data-driven approaches that improve performance and reduce operational costs across the entire lifecycle of commercial vehicles.

Based on this analysis, AI is poised to fundamentally transform various aspects of the Commercial Vehicle Propeller Shaft Market. It is expected to usher in a new era of predictive analytics for maintenance, allowing fleet operators and manufacturers to foresee potential failures before they occur, thereby minimizing downtime and extending the operational life of vehicles. In the realm of design and engineering, AI-powered generative design tools can rapidly explore thousands of design permutations, optimizing for weight, strength, and material usage, leading to more efficient and resilient propeller shaft designs tailored to specific vehicle requirements. Furthermore, AI integration into manufacturing processes promises greater automation, precision, and quality control, reducing defects and waste, while also streamlining production schedules.

The influence of AI extends beyond individual component optimization, impacting the broader ecosystem of commercial vehicle manufacturing and operation. AI algorithms can analyze vast datasets from vehicle telematics, road conditions, and driver behavior to inform design improvements and personalized maintenance schedules for propeller shafts. As commercial vehicles increasingly incorporate autonomous driving features, AI will play a crucial role in managing the complex interplay of power transmission systems with autonomous control, ensuring seamless and safe operation. This comprehensive integration of AI across the value chain positions it as a critical enabler for future innovations and efficiencies in the commercial vehicle propeller shaft domain.

- Enhanced predictive maintenance through real-time data analysis, reducing unscheduled downtime.

- AI-driven generative design for optimal weight, strength, and material efficiency in propeller shafts.

- Automated quality control and inspection in manufacturing processes, minimizing defects.

- Optimization of supply chain logistics for raw materials and finished products, improving responsiveness.

- Integration with autonomous vehicle systems for adaptive power transmission management.

DRO & Impact Forces Of Commercial Vehicle Propeller Shaft Market

The Commercial Vehicle Propeller Shaft Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities (DRO), alongside various Impact Forces that influence its growth trajectory and competitive landscape. Key drivers propelling market expansion include the significant growth of the global logistics and transportation industry, fueled by the booming e-commerce sector and increasing international trade volumes. Extensive infrastructure development projects in emerging economies, alongside government initiatives promoting industrialization and urbanization, inherently increase the demand for commercial vehicles, consequently boosting the need for robust propeller shafts. Moreover, the continuous modernization and expansion of commercial vehicle fleets globally, driven by stringent emission regulations and a desire for more fuel-efficient and higher-performing vehicles, necessitate advanced and durable propeller shaft solutions.

Conversely, several restraints impede the market's full potential. The high manufacturing cost associated with advanced materials like carbon fiber composites and specialized engineering for noise, vibration, and harshness (NVH) reduction can elevate the overall price of propeller shafts, impacting cost-sensitive segments. Volatility in raw material prices, particularly for steel and aluminum, directly affects production costs and profit margins for manufacturers. Furthermore, the increasing adoption of electric vehicles (EVs) in the commercial sector presents a long-term challenge, as electric powertrains often require different or even fewer propeller shaft configurations, potentially reducing demand for traditional designs. Stiff competition from established players and the emergence of alternative power transmission technologies also pose significant competitive pressures.

Despite these restraints, substantial opportunities exist for market participants. The development and integration of lightweight and high-strength materials, such as advanced composites, for propeller shafts represent a significant avenue for innovation, enabling fuel efficiency improvements and compliance with stricter emission standards. The expanding aftermarket segment, driven by the extensive operational lifespan of commercial vehicles and the need for reliable replacement parts, offers consistent revenue streams. Moreover, the increasing demand for customized propeller shaft solutions for specialized commercial vehicles, such as those used in mining, construction, and agriculture, provides niche market growth opportunities. The impact forces within the market, including the bargaining power of buyers (large OEMs dictating terms) and suppliers (material costs), the threat of new entrants (high capital investment), the threat of substitutes (electric drivetrains), and intense competitive rivalry, necessitate continuous innovation and strategic differentiation for market players to maintain their competitive edge and foster sustainable growth.

Segmentation Analysis

The Commercial Vehicle Propeller Shaft Market is comprehensively segmented to provide a detailed understanding of its diverse components and dynamics. This segmentation helps in analyzing market trends, identifying key growth areas, and understanding the varied needs of different commercial vehicle applications and end-users. The market can be broadly categorized based on various parameters such as vehicle type, material used, design configuration, and the end-use segment, each exhibiting distinct demand patterns and technological requirements.

- By Vehicle Type

- Heavy-Duty Trucks

- Medium-Duty Trucks

- Light Commercial Vehicles (LCVs)

- Buses

- Off-Highway Vehicles (Construction Equipment, Agricultural Vehicles)

- By Material

- Steel

- Aluminum

- Carbon Fiber Composites

- By Design

- Single-Piece Propeller Shaft

- Multi-Piece Propeller Shaft

- By End-Use

- Original Equipment Manufacturer (OEM)

- Aftermarket

- By Sales Channel

- Direct Sales

- Indirect Sales (Distributors, Retailers)

Value Chain Analysis For Commercial Vehicle Propeller Shaft Market

The value chain for the Commercial Vehicle Propeller Shaft Market encompasses a series of interconnected activities, starting from raw material sourcing to the final delivery and aftermarket services. Upstream analysis focuses on the procurement and processing of fundamental raw materials and sub-components. This stage involves suppliers of high-grade steel, various aluminum alloys, and advanced composite materials such as carbon fibers and resins. These raw material providers form the foundational layer of the value chain, supplying critical inputs that determine the ultimate strength, weight, and durability of the propeller shafts. Additionally, suppliers of specialized components like universal joints, constant velocity (CV) joints, bearings, and rubber components for damping also play a crucial role in the upstream segment, ensuring the availability of specialized parts necessary for shaft assembly.

Moving downstream, the value chain progresses through the manufacturing and assembly phases. Propeller shaft manufacturers engage in processes such as forging, machining, welding, balancing, and dynamic testing to produce finished shafts that meet stringent OEM specifications and industry standards. This stage often involves significant R&D investment to innovate in material science, design optimization, and manufacturing efficiency. Following production, the finished propeller shafts are supplied to various commercial vehicle original equipment manufacturers (OEMs), including major truck, bus, and off-highway vehicle producers. These OEMs integrate the propeller shafts into their vehicle assembly lines, making them a critical component of the overall drivetrain system. The relationship between propeller shaft manufacturers and OEMs is often characterized by long-term contracts and collaborative design efforts to ensure optimal compatibility and performance.

The distribution channel for commercial vehicle propeller shafts primarily involves direct sales to OEMs for new vehicle production. However, a substantial portion of the market relies on an indirect distribution network for the aftermarket segment. This includes independent distributors, wholesalers, and authorized service centers that supply replacement propeller shafts for vehicle maintenance and repair. Direct channels facilitate close collaboration and customized solutions for OEMs, enabling seamless integration into their production cycles. Indirect channels, on the other hand, cater to the diverse needs of fleet operators, independent garages, and individual vehicle owners seeking reliable and readily available replacement parts, thereby extending the lifecycle of commercial vehicles and ensuring continuous operational efficiency across the global commercial vehicle fleet.

Commercial Vehicle Propeller Shaft Market Potential Customers

The Commercial Vehicle Propeller Shaft Market serves a broad and diverse range of potential customers, primarily comprising entities involved in the manufacturing, operation, and maintenance of commercial vehicles across various industries. At the forefront are the major Original Equipment Manufacturers (OEMs) of commercial vehicles globally. This category includes prominent truck manufacturers producing heavy-duty, medium-duty, and light commercial trucks for freight, logistics, and specialized applications. Additionally, bus manufacturers, catering to public transportation and private charter services, represent a significant segment. Beyond road vehicles, manufacturers of off-highway equipment such as construction machinery (e.g., excavators, loaders, dumpers), agricultural vehicles (e.g., tractors, harvesters), and mining equipment also constitute vital potential customers, as these vehicles rely heavily on robust propeller shafts for power transmission in demanding environments.

Another substantial customer segment includes large fleet operators and logistics companies. These entities manage vast fleets of commercial vehicles for transportation, distribution, and delivery services. Their primary interest lies in the durability, reliability, and cost-effectiveness of propeller shafts, as these components directly impact vehicle uptime, operational efficiency, and overall fleet maintenance costs. These customers often purchase propeller shafts through the aftermarket for repairs and replacements, demanding high-quality parts that can withstand rigorous, continuous use and contribute to a lower total cost of ownership. Their purchasing decisions are often influenced by component lifespan, warranty, and ease of availability, making a strong aftermarket supply chain crucial for manufacturers.

Beyond the immediate manufacturers and operators, potential customers also extend to independent repair shops, authorized service centers, and government transport agencies. Independent garages and service centers serve as critical points for vehicle maintenance and repair, purchasing replacement propeller shafts from various suppliers and distributors. Government transport agencies, responsible for public works vehicles, municipal fleets, and sometimes defense vehicles, also procure propeller shafts, often under specific contractual terms that emphasize quality, compliance, and long-term support. In essence, any entity involved in the design, assembly, operation, or servicing of commercial vehicles requiring power transmission from the engine to the wheels represents a potential customer for commercial vehicle propeller shafts, reflecting the pervasive demand for these essential drivetrain components.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 3.2 Billion |

| Market Forecast in 2032 | USD 4.8 Billion |

| Growth Rate | 5.9% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Dana Incorporated, GKN Automotive (part of Melrose Industries PLC), ZF Friedrichshafen AG, American Axle & Manufacturing Holdings Inc., Neapco Holdings LLC, Meritor Inc. (now part of Cummins Inc.), JTEKT Corporation, Hyundai Wia Corporation, Nexteer Automotive, Bharat Forge Ltd., Hitachi Automotive Systems (now Hitachi Astemo), Shandong Futong Group, Wanxiang Qianchao Co. Ltd., IFA Rotorion - North America LLC, Sona Comstar, Leichtbauzentrum Sachsen GmbH (LZS), Mitsubishi Heavy Industries, NTN Corporation, Spicer Driveshaft Division, Metaldyne Performance Group (MPG) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Vehicle Propeller Shaft Market Key Technology Landscape

The Commercial Vehicle Propeller Shaft Market is continuously evolving, driven by significant technological advancements aimed at enhancing performance, efficiency, and durability. A pivotal area of innovation is in lightweighting, where manufacturers are increasingly utilizing advanced materials such as high-strength steel alloys, aluminum, and carbon fiber composites. These materials offer substantial weight reduction compared to traditional steel shafts, directly contributing to improved fuel efficiency, lower emissions, and increased payload capacity for commercial vehicles. The development of hybrid material shafts, combining the benefits of different materials, also represents a key technological trend, balancing cost-effectiveness with performance gains and providing solutions tailored to specific vehicle segment needs.

Another critical aspect of the technology landscape is the focus on noise, vibration, and harshness (NVH) reduction. Engineers are employing sophisticated design techniques, including optimized joint geometries, improved damping materials, and precision balancing methods, to minimize NVH levels. This leads to enhanced driver comfort, reduced fatigue, and a quieter cabin environment, which are crucial for long-haul commercial vehicle operations. Furthermore, the integration of advanced manufacturing processes, such as friction welding, laser welding, and automated assembly lines, ensures higher precision, consistency, and structural integrity of propeller shafts, contributing to their reliability and extended service life under demanding operating conditions. These manufacturing innovations also enable more efficient production volumes to meet growing global demand.

Looking ahead, the market is witnessing the integration of smart technologies and modular designs. Smart propeller shafts may incorporate embedded sensors for real-time monitoring of rotational speed, torque, temperature, and vibration. This data can be utilized for predictive maintenance, allowing operators to identify potential issues before critical failure, thereby minimizing downtime and maintenance costs. Modular design approaches facilitate greater customization and easier component replacement, simplifying logistics and servicing. Additionally, with the advent of electric and hybrid commercial vehicles, there is an ongoing technological push to develop propeller shafts compatible with new electric drivetrain configurations, including single-speed reductions and distributed motor architectures, ensuring seamless power transfer in the evolving landscape of vehicle propulsion systems. These technological strides are critical for addressing the future demands of the commercial vehicle sector.

Regional Highlights

- North America: A mature market characterized by a strong demand for heavy-duty trucks and a continuous focus on fleet modernization and technological upgrades. Stringent emission regulations drive the adoption of lightweight and high-efficiency propeller shafts.

- Europe: Driven by strict environmental policies and a robust automotive industry, Europe emphasizes advanced materials and NVH reduction for commercial vehicles. The region also shows increasing traction in electric commercial vehicle development, influencing propeller shaft design.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily fueled by rapid industrialization, extensive infrastructure projects, and the expansion of the logistics and e-commerce sectors in countries like China and India. High volume production and cost-effectiveness are key considerations.

- Latin America: An emerging market with growth driven by increasing urbanization, industrial development, and improving trade relations. Demand is rising for durable and affordable commercial vehicles, impacting the propeller shaft market with a focus on robustness.

- Middle East and Africa (MEA): Experiencing steady growth due to investments in infrastructure, oil and gas sectors, and a growing logistics industry. The region seeks reliable and resilient propeller shafts to withstand challenging operating conditions and diverse terrains.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Vehicle Propeller Shaft Market.- Dana Incorporated

- GKN Automotive (part of Melrose Industries PLC)

- ZF Friedrichshafen AG

- American Axle & Manufacturing Holdings Inc.

- Neapco Holdings LLC

- Meritor Inc. (now part of Cummins Inc.)

- JTEKT Corporation

- Hyundai Wia Corporation

- Nexteer Automotive

- Bharat Forge Ltd.

- Hitachi Automotive Systems (now Hitachi Astemo)

- Shandong Futong Group

- Wanxiang Qianchao Co. Ltd.

- IFA Rotorion - North America LLC

- Sona Comstar

- Leichtbauzentrum Sachsen GmbH (LZS)

- Mitsubishi Heavy Industries

- NTN Corporation

- Spicer Driveshaft Division

- Metaldyne Performance Group (MPG)

Frequently Asked Questions

Analyze common user questions about the Commercial Vehicle Propeller Shaft market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary drivers of growth for the Commercial Vehicle Propeller Shaft Market?

The market's growth is primarily driven by the expansion of the global logistics and transportation sector, increasing demand from e-commerce, significant infrastructure development projects worldwide, and ongoing modernization of commercial vehicle fleets.

How will the rise of Electric Vehicles (EVs) impact the Commercial Vehicle Propeller Shaft Market?

While EVs pose a long-term challenge by altering drivetrain designs and potentially reducing the need for traditional propeller shafts, they also create opportunities for new, specialized shaft configurations tailored to electric powertrains and their unique torque characteristics.

What key technological trends are shaping the future of propeller shafts in commercial vehicles?

Key trends include lightweighting through advanced materials (aluminum, carbon fiber composites), enhanced NVH (noise, vibration, and harshness) reduction techniques, integration of smart sensors for predictive maintenance, and modular designs for improved serviceability and customization.

What are the main challenges faced by manufacturers in this market?

Manufacturers face challenges such as high production costs for advanced materials, volatility in raw material prices, stringent regulatory requirements, and intense competition from both established players and emerging alternative power transmission technologies.

Which region is expected to dominate the Commercial Vehicle Propeller Shaft Market?

The Asia Pacific region is anticipated to dominate the market, primarily due to rapid industrialization, extensive infrastructure development, and significant growth in the logistics and e-commerce sectors, especially in economies like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager