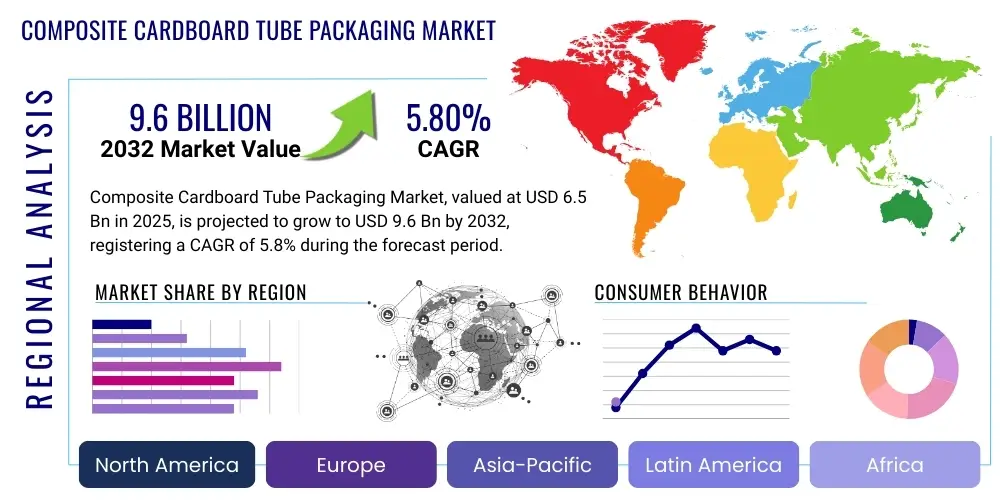

Composite Cardboard Tube Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427743 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Composite Cardboard Tube Packaging Market Size

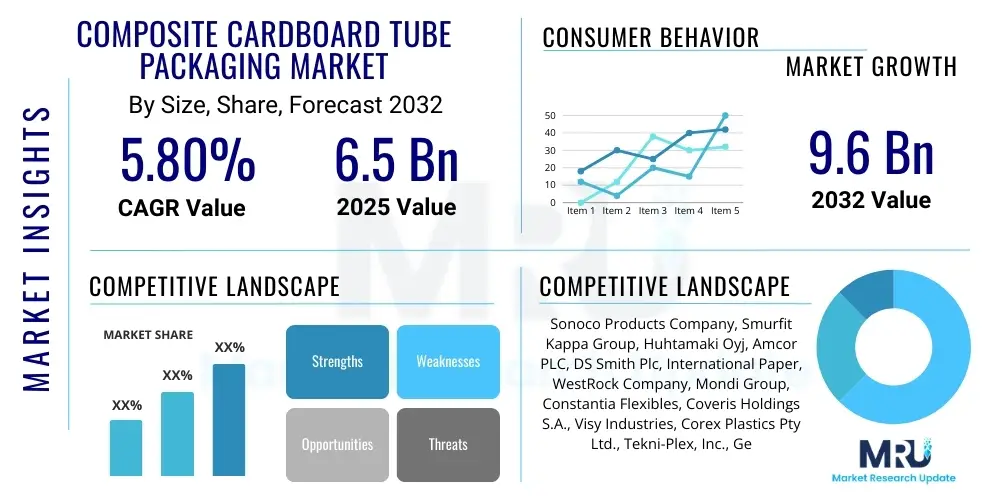

The Composite Cardboard Tube Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 6.5 Billion in 2025 and is projected to reach USD 9.6 Billion by the end of the forecast period in 2032.

Composite Cardboard Tube Packaging Market introduction

The Composite Cardboard Tube Packaging Market encompasses the production and distribution of cylindrical packaging solutions crafted from multiple layers of paperboard, often combined with other materials like foils, films, or plastics, to enhance barrier properties, strength, and overall functionality. These versatile tubes are distinguished by their robust construction, offering superior protection for a wide array of products compared to conventional flexible packaging. Products encased in composite tubes benefit from improved structural integrity, resistance to crushing, and enhanced shelf appeal, making them ideal for premium and sensitive items. Major applications span across diverse industries, including food and beverages for snacks and spices, cosmetics and personal care for lotions and deodorants, pharmaceuticals for effervescent tablets and medical devices, and industrial goods for adhesives, sealants, and components. The primary benefits of composite cardboard tube packaging include their significant sustainability profile, as they are predominantly made from renewable and recyclable paperboard, their customization potential in terms of size, shape, and printing, and their ability to provide excellent product preservation through effective barrier layers. Driving factors for market expansion include the increasing consumer demand for eco-friendly packaging alternatives, the growing e-commerce sector requiring robust and protective shipping solutions, and the continuous innovation in material science that enables enhanced barrier properties and functional attributes for a broader range of product applications, solidifying their role in modern packaging strategies.

Composite Cardboard Tube Packaging Market Executive Summary

The Composite Cardboard Tube Packaging Market is experiencing robust growth driven by a confluence of evolving business trends, significant regional expansion, and dynamic shifts within key segments. Businesses are increasingly prioritizing sustainable packaging solutions, with composite tubes emerging as a preferred choice due to their high recyclability and use of renewable resources, aligning with corporate environmental responsibility initiatives and consumer preferences for green products. This emphasis on sustainability is reshaping supply chains and fostering innovation in material development, leading to tubes with improved barrier properties and reduced environmental footprints. From a regional perspective, North America and Europe continue to be dominant markets, characterized by established manufacturing infrastructure and stringent environmental regulations that favor paper-based packaging. However, the Asia Pacific region, particularly emerging economies like China and India, is poised for accelerated growth, fueled by rapid industrialization, expanding consumer bases, and rising disposable incomes, alongside a growing awareness for sustainable practices. Segment-wise, the food and beverage industry remains a cornerstone of demand, driven by the need for secure, hygienic, and attractive packaging for dry goods, snacks, and confectionery. The cosmetics and personal care sector is also a significant contributor, leveraging composite tubes for their premium aesthetics and functional appeal, while the pharmaceutical and industrial sectors are adopting these solutions for their protective qualities and material compatibility. The ongoing digitalization of trade, particularly the surge in e-commerce, further amplifies demand for durable and shippable packaging formats, positioning composite cardboard tubes as an increasingly vital component in the global packaging landscape.

AI Impact Analysis on Composite Cardboard Tube Packaging Market

Common user questions regarding the impact of Artificial Intelligence (AI) on the Composite Cardboard Tube Packaging Market often revolve around how AI can enhance efficiency, sustainability, and product innovation, while also addressing concerns about job displacement and the complexity of integration. Users frequently inquire about AIs role in optimizing production lines, predicting market demand, personalizing packaging designs, and improving supply chain resilience. There is a keen interest in how AI can contribute to more precise material usage, waste reduction, and the development of intelligent packaging features. Concerns typically include the initial investment costs for AI implementation, the need for specialized skills, data privacy implications, and the potential for AI to automate tasks traditionally performed by human labor. Expectations are high for AI to revolutionize manufacturing processes, enable hyper-customization, and facilitate advanced quality control, ultimately leading to more cost-effective, environmentally friendly, and consumer-centric packaging solutions across the industry.

- AI-powered predictive analytics can optimize inventory management and demand forecasting, reducing material waste and overproduction in composite tube manufacturing.

- Integration of AI in quality control systems can identify defects with greater precision and speed, enhancing product consistency and reducing recalls.

- AI algorithms can optimize cutting patterns and material usage during the production process, leading to significant reductions in raw material consumption and waste generation.

- Generative AI tools are capable of assisting in the design phase, rapidly producing innovative and customizable packaging aesthetics and structural forms, catering to specific brand requirements.

- Robotics and automation, often enhanced by AI, can streamline assembly, filling, and sealing processes, increasing production throughput and operational efficiency.

- AI-driven supply chain management platforms can provide real-time tracking, optimize logistics, and predict potential disruptions, ensuring timely delivery of materials and finished products.

- Machine learning can analyze consumer preferences and market trends to inform new product development and packaging features, leading to more targeted and successful product launches.

- AI in intelligent packaging can enable features like enhanced traceability, anti-counterfeiting measures, and consumer engagement through QR codes or NFC tags.

- Energy consumption in manufacturing can be optimized by AI-powered systems, adjusting machinery settings for peak efficiency, thus contributing to sustainability goals.

- Maintenance schedules for production machinery can be predicted by AI, transitioning from reactive to predictive maintenance, minimizing downtime and extending equipment lifespan.

DRO & Impact Forces Of Composite Cardboard Tube Packaging Market

The Composite Cardboard Tube Packaging Market is significantly shaped by a dynamic interplay of Drivers, Restraints, and Opportunities, collectively forming powerful impact forces. A primary driver is the accelerating global demand for sustainable and eco-friendly packaging solutions, propelled by increasing consumer environmental awareness, stringent regulatory mandates, and corporate sustainability initiatives aiming to reduce plastic reliance. The rapid expansion of e-commerce also acts as a powerful catalyst, as composite tubes offer superior product protection during transit, reducing damage and enhancing the unboxing experience. Furthermore, the aesthetic appeal and customization capabilities of these tubes attract brands seeking premium, distinctive packaging for products across various sectors. However, the market faces notable restraints, including the fluctuating prices and availability of raw materials, predominantly paper pulp, which can impact manufacturing costs and supply chain stability. The complex multi-material composition of some composite tubes can also pose challenges for end-of-life recycling processes, despite ongoing innovations in monomaterial or easily separable designs. Opportunities abound in technological advancements, particularly in developing high-barrier coatings and sustainable adhesives that enhance tube functionality without compromising recyclability. The penetration into new end-use applications, such as specialized industrial components or emerging health and wellness products, presents significant growth avenues. Furthermore, strategic collaborations between manufacturers and waste management companies can improve collection and recycling infrastructure, addressing current limitations and strengthening the markets environmental credentials. The cumulative effect of these drivers, restraints, and opportunities creates a competitive and innovative environment, compelling market players to continuously adapt and evolve their product offerings and operational strategies to remain resilient and capitalize on future growth prospects.

Segmentation Analysis

The Composite Cardboard Tube Packaging Market is comprehensively segmented to provide a granular understanding of its diverse applications, material compositions, and end-user demands. These segmentations allow for a detailed analysis of market dynamics, identifying specific growth areas, competitive landscapes, and evolving preferences within the industry. Understanding these distinctions is crucial for manufacturers to tailor their product offerings, for suppliers to optimize material sourcing, and for end-use industries to select the most appropriate and effective packaging solutions. The market can be dissected based on factors such as the primary material components, the diameter and wall thickness of the tubes, the intended end-use industry, and the type of closures utilized, each influencing the functional performance, aesthetic appeal, and cost-effectiveness of the final packaging product. This layered approach to segmentation helps to highlight the varying requirements across different applications, from the moisture-sensitive needs of food products to the robust protection required for industrial goods, thereby illustrating the versatility and adaptability inherent in composite cardboard tube packaging solutions.

- By Material Type:

- Virgin Pulp: Offers superior strength, brightness, and consistency, often preferred for premium products or specific barrier requirements.

- Recycled Pulp: Environmentally friendly and cost-effective, driving sustainability initiatives across various industries.

- Specialty Coatings: Includes wax, polyethylene (PE), polypropylene (PP), or EVOH barriers to enhance moisture, oxygen, or grease resistance.

- Adhesives: Plant-based, water-based, or synthetic adhesives used to bond multiple layers, crucial for structural integrity and barrier performance.

- By Diameter:

- Up to 50mm: Typically used for small personal care items, single-serve snacks, or pharmaceutical samples.

- 51mm-100mm: Common for cosmetics, effervescent tablets, spices, and small industrial components.

- 101mm-150mm: Utilized for larger food items, stationery, textiles, and some industrial goods.

- Above 150mm: Primarily for heavy-duty industrial applications, large posters, or bulk consumer goods.

- By End-Use Industry:

- Food & Beverages: Packaging for snacks, spices, coffee, tea, confectioneries, and other dry goods, requiring strong barrier properties.

- Cosmetics & Personal Care: Used for deodorants, lotions, bath salts, and luxury cosmetic items, emphasizing aesthetics and product protection.

- Pharmaceuticals: Packaging for effervescent tablets, medical devices, and over-the-counter medicines, demanding hygiene and child-resistant features.

- Industrial Goods: Applications for adhesives, sealants, lubricants, automotive parts, and electronic components, requiring robust and protective packaging.

- Consumer Goods: Encompassing stationery, arts and crafts, textiles, and other household items, where visual appeal and protection are key.

- Others: Includes construction materials, promotional items, and specialized agricultural products.

- By Closure Type:

- Plastic Caps: Common for reusability, tamper-evidence, and barrier protection, often made from PE or PP.

- Metal Caps: Provides a premium feel, enhanced barrier, and secure sealing, often used in high-end or industrial applications.

- Paperboard Lids: Sustainable and fully recyclable option, often used for dry goods where a strong barrier is not paramount.

- Custom Closures: Specialized designs for unique product dispensing, child safety, or brand differentiation, including sifter tops, shaker caps, or flip-top designs.

- By Wall Thickness:

- Single-ply: Lighter tubes, suitable for less demanding applications where minimal protection is needed.

- Multi-ply: Offers enhanced strength, barrier properties, and insulation, crucial for sensitive or heavy products.

- By Functionality:

- Moisture Resistant: Incorporates layers or coatings to protect hygroscopic products from moisture ingress.

- Grease Resistant: Designed with specialized internal coatings to prevent oil and grease from staining the exterior.

- Child-Resistant: Features specific closure mechanisms to prevent accidental opening by children, mandated for certain products.

- Tamper-Evident: Includes seals or designs that visibly indicate if the package has been opened or altered, ensuring product integrity.

Composite Cardboard Tube Packaging Market Value Chain Analysis

The value chain of the Composite Cardboard Tube Packaging Market is a complex and interconnected network, beginning with the sourcing of raw materials and extending through various stages of manufacturing, distribution, and final consumption. The upstream analysis focuses on the procurement of essential raw materials, primarily paperboard, which can be virgin pulp or recycled paper, along with specialized foils, films, adhesives, and inks. Key suppliers in this segment include forestry companies, paper mills, chemical manufacturers, and plastic extruders, whose pricing, quality, and sustainability practices directly impact the cost and environmental footprint of the final packaging product. Manufacturers of composite tubes then convert these raw materials into finished packaging, employing sophisticated machinery for winding, laminating, printing, and finishing processes. This stage involves significant capital investment in technology and skilled labor to ensure precision and efficiency. The downstream analysis involves the distribution and end-use of these tubes. Distribution channels are varied, including direct sales from manufacturers to large-scale end-users in industries such as food and beverage, cosmetics, pharmaceuticals, and industrial goods, which often involve large volume contracts and customized solutions. Indirect channels include packaging distributors, wholesalers, and third-party logistics (3PL) providers who cater to a broader range of smaller and medium-sized enterprises, offering a wider selection and more flexible purchasing options. Both direct and indirect channels play crucial roles in market penetration and reaching diverse customer segments, with the effectiveness of these channels greatly influencing market reach, speed-to-market, and overall customer satisfaction. The efficiency and sustainability embedded at each stage of this value chain are critical for optimizing costs, enhancing product quality, and meeting evolving consumer and regulatory demands for environmentally responsible packaging.

Composite Cardboard Tube Packaging Market Potential Customers

The Composite Cardboard Tube Packaging Market serves a broad and diverse range of potential customers, primarily comprising end-users and buyers who seek robust, aesthetically pleasing, and increasingly sustainable packaging solutions for their products. These customers span across multiple industries, each with unique requirements for protection, presentation, and functionality. In the food and beverage sector, manufacturers of snacks, confectioneries, dry goods like coffee, tea, and spices, as well as protein powders, represent a significant customer base, valuing the tubes ability to provide barrier protection against moisture, oxygen, and light, along with their premium shelf appeal. The cosmetics and personal care industry is another major consumer, utilizing composite tubes for deodorants, creams, lotions, bath salts, and high-end makeup, where brand image, tactile experience, and product integrity are paramount. Pharmaceutical companies are increasingly adopting these tubes for effervescent tablets, vitamins, and certain medical devices, driven by the need for child-resistant features, tamper-evidence, and strict hygiene standards. Furthermore, industrial goods manufacturers, encompassing adhesives, lubricants, sealants, automotive parts, and specialized electronic components, seek the superior structural protection and durability offered by composite tubes for their often heavy or sensitive products. Beyond these core sectors, the market extends to consumer goods such as stationery, arts and crafts supplies, textiles, and even promotional items, where customizability, strength, and visual attractiveness are key purchasing criteria. The growing emphasis on sustainability also makes composite cardboard tube packaging highly attractive to brands committed to reducing their environmental footprint, thus expanding the customer base to any entity prioritizing eco-friendly packaging alternatives and seeking to appeal to environmentally conscious consumers.

Composite Cardboard Tube Packaging Market Key Technology Landscape

The Composite Cardboard Tube Packaging Market is characterized by a dynamic and evolving technology landscape, continuously driven by innovations aimed at enhancing functionality, sustainability, and production efficiency. Core technologies revolve around the precise and high-speed manufacturing processes of tube winding, where multiple layers of paperboard and other barrier materials are spirally wound and bonded together using advanced adhesives. Laminating technologies are crucial for integrating various films, foils, or specialty coatings, such as polyethylene (PE), polypropylene (PP), or ethylene vinyl alcohol (EVOH), to achieve specific barrier properties against moisture, oxygen, grease, or UV light, critical for product preservation. Advancements in printing technologies, including flexographic, gravure, and digital printing, enable high-resolution graphics, vibrant colors, and intricate designs directly onto the tube surface or label, allowing for superior brand messaging and aesthetic appeal. Furthermore, the development of sustainable material science is a significant area of focus, with ongoing research into bio-based plastics, compostable barrier films, and water-soluble adhesives to improve the recyclability and overall environmental profile of composite tubes. Automated assembly and finishing technologies, including robotic cap application, tamper-evident sealing, and precision cutting, ensure consistent product quality and increase manufacturing throughput. Intelligent packaging technologies, such as integrated QR codes, NFC tags, and time-temperature indicators, are also emerging, offering enhanced product traceability, anti-counterfeiting measures, and consumer engagement capabilities. These technological advancements collectively contribute to a versatile and efficient manufacturing ecosystem, allowing for the production of highly customized, functional, and environmentally responsible composite cardboard tube packaging solutions that meet the diverse and evolving demands of various end-use industries.

Regional Highlights

- North America: This region represents a mature and significant market, driven by high consumer awareness regarding sustainable packaging and stringent regulations encouraging eco-friendly alternatives. The robust presence of major consumer goods, food and beverage, and pharmaceutical companies contributes significantly to demand. Innovation in barrier technologies and custom design for premium products also fuels growth here.

- Europe: Europe stands as a leading market, characterized by strong sustainability mandates and a circular economy focus. Countries like Germany, France, and the UK are at the forefront of adopting recyclable packaging. The region benefits from established manufacturing capabilities and a high preference for premium, aesthetically pleasing packaging in cosmetics and food sectors.

- Asia Pacific: Expected to be the fastest-growing region, propelled by rapid industrialization, burgeoning populations, increasing disposable incomes, and the expansion of the e-commerce sector in countries like China, India, and Japan. The rising awareness of environmental issues is also gradually shifting preferences towards sustainable packaging solutions.

- Latin America: This region exhibits steady growth, influenced by improving economic conditions and increasing foreign investments in manufacturing and consumer goods sectors. Brazil and Mexico are key markets, with rising demand for convenience food and personal care products driving the adoption of composite tubes.

- Middle East & Africa: The market here is emerging, primarily driven by urbanization, expanding retail infrastructure, and increasing demand for packaged food and personal care items. Investment in local manufacturing capabilities and a gradual shift towards sustainable practices are expected to accelerate growth in the long term.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Composite Cardboard Tube Packaging Market.- Sonoco Products Company

- Smurfit Kappa Group

- Huhtamaki Oyj

- Amcor PLC

- DS Smith Plc

- International Paper

- WestRock Company

- Mondi Group

- Constantia Flexibles

- Coveris Holdings S.A.

- Visy Industries

- Corex Plastics Pty Ltd.

- Tekni-Plex, Inc.

- Gerard Packaging

- Universal Packaging

- Alliance Paperboard

- Cone Drive Operations Inc.

- Paper Tubes, Inc.

- Nagase & Co., Ltd.

- Indevco Group

Frequently Asked Questions

What are composite cardboard tubes and their primary composition?

Composite cardboard tubes are robust cylindrical packaging solutions primarily made from multiple layers of paperboard, often combined with barrier materials like foils or plastic films. This multi-layered structure enhances strength, barrier properties, and product protection, making them ideal for diverse applications requiring durability and integrity.

Which industries are the largest consumers of composite cardboard tube packaging?

The largest consumers include the food and beverage industry for snacks and dry goods, cosmetics and personal care for premium packaging, pharmaceuticals for medical tablets and devices, and industrial goods for adhesives and components. These sectors value the tubes protection, aesthetic appeal, and customization options.

How do composite cardboard tubes contribute to sustainability?

Composite cardboard tubes are largely made from renewable and recyclable paperboard, significantly reducing reliance on virgin plastics. Ongoing innovations focus on incorporating recycled content, developing bio-based barrier layers, and designing for easier recyclability, aligning with global sustainability goals and circular economy principles.

What technological advancements are driving innovation in this market?

Innovations include advanced barrier coatings for enhanced product preservation, high-speed automated winding and laminating processes for efficiency, sophisticated digital printing for superior aesthetics, and the integration of smart packaging features like QR codes for traceability. Material science also plays a key role in developing more sustainable and functional compositions.

What are the key benefits of choosing composite cardboard tube packaging over other alternatives?

Key benefits include superior structural rigidity and protection against crushing, excellent barrier properties when integrated with films or foils, high customization potential for branding, a premium aesthetic appeal, and a favorable environmental profile due to the use of renewable paperboard. They offer a versatile and robust solution for various product needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager