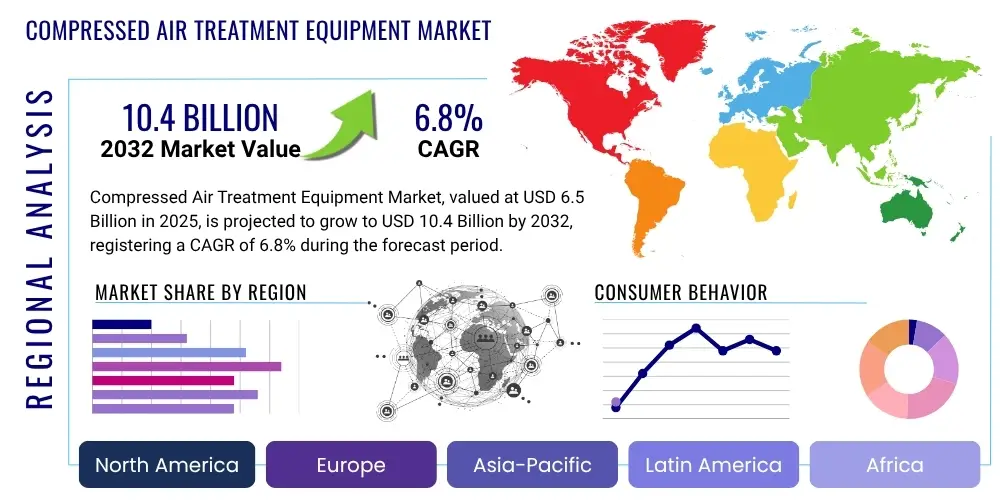

Compressed Air Treatment Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428712 | Date : Oct, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Compressed Air Treatment Equipment Market Size

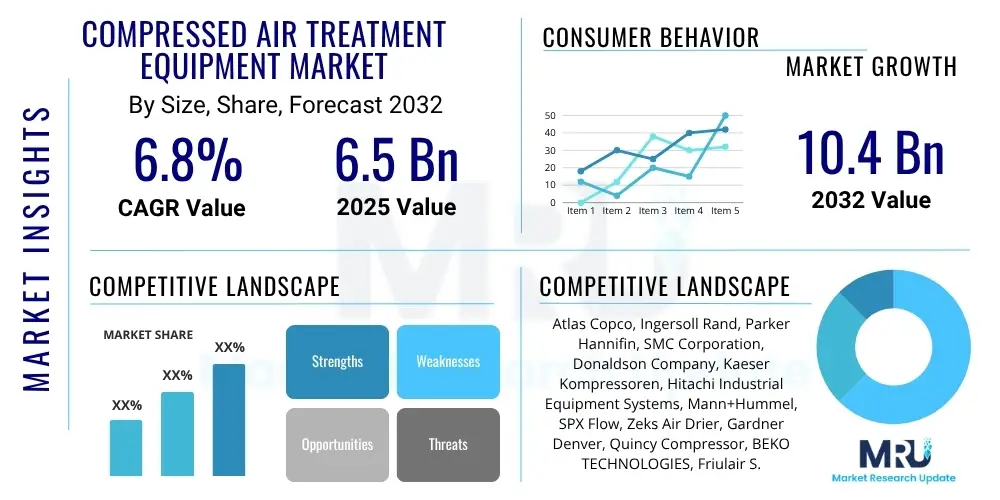

The Compressed Air Treatment Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 6.5 Billion in 2025 and is projected to reach USD 10.4 Billion by the end of the forecast period in 2032.

Compressed Air Treatment Equipment Market introduction

The Compressed Air Treatment Equipment Market encompasses a broad range of products and systems designed to purify and prepare compressed air for various industrial and commercial applications. Compressed air, while essential for powering numerous processes, naturally contains contaminants such as moisture, oil aerosols, solid particulates, and even microorganisms, which can severely compromise the efficiency, longevity, and safety of downstream equipment and end products. The treatment equipment addresses these issues by removing impurities, ensuring that the air delivered is clean, dry, and suitable for its intended use, whether in sensitive electronics manufacturing, critical pharmaceutical processes, or general industrial machinery operation. This market is fundamentally driven by the pervasive need for high-quality compressed air across nearly all sectors that utilize pneumatic tools or systems.

Key products within this market include various types of dryers, such as refrigerated dryers, desiccant dryers, and membrane dryers, which are crucial for removing water vapor and preventing condensation that can lead to corrosion and equipment damage. Filters constitute another vital component, available in multiple grades to remove particulates, oil aerosols, and odors, protecting sensitive machinery and ensuring product quality. Aftercoolers, air receivers, and auto-drains further complement the system by cooling compressed air, storing it, and efficiently expelling condensate. These components work synergistically to deliver air that meets specific ISO purity classes, essential for industries where air quality directly impacts operational integrity and product standards.

Major applications span across manufacturing, automotive, food and beverage, pharmaceuticals, chemicals, energy, and electronics industries, among others. The benefits derived from proper compressed air treatment are extensive, including enhanced operational efficiency, reduced maintenance costs for pneumatic equipment, extended lifespan of machinery, prevention of product contamination, and compliance with stringent industry standards and environmental regulations. The market is significantly driven by global industrialization, increasing automation in production processes, and the growing awareness among industries regarding the critical role of clean compressed air in maintaining competitive advantage and ensuring sustainable operations.

Compressed Air Treatment Equipment Market Executive Summary

The Compressed Air Treatment Equipment Market is experiencing robust growth driven by accelerating industrialization, particularly in emerging economies, and the escalating demand for high-quality, contaminant-free compressed air across diverse manufacturing sectors. Business trends indicate a strong shift towards energy-efficient solutions and smart, connected treatment systems that integrate Internet of Things (IoT) capabilities for real-time monitoring and predictive maintenance. Companies are increasingly investing in research and development to introduce innovative technologies that enhance filtration efficiency, reduce pressure drop, and minimize operational costs, thereby addressing the evolving needs of industrial end-users seeking optimized performance and sustainability. The competitive landscape is characterized by both global conglomerates and specialized regional players, focusing on product differentiation through advanced features and comprehensive service offerings.

Regional trends highlight the Asia Pacific as the fastest-growing market, propelled by rapid expansion in manufacturing, automotive, and electronics industries, alongside increasing governmental emphasis on industrial efficiency and environmental compliance. North America and Europe continue to represent mature markets, where demand is sustained by stringent regulatory standards for air purity in sensitive applications and a strong emphasis on upgrading existing infrastructure with more energy-efficient and technologically advanced equipment. Latin America and the Middle East & Africa regions are also showing promising growth, fueled by ongoing industrial development and diversification efforts, albeit from a smaller base. The varying regulatory frameworks and industrial maturity levels across these regions significantly influence market strategies and product adoption rates.

Segment trends reveal a sustained demand for advanced filtration solutions, particularly coalescing and activated carbon filters, essential for removing oil aerosols and odors to meet high-purity air standards. The dryer segment is also witnessing substantial innovation, with desiccant dryers and energy-saving refrigerated dryers gaining traction due to their effectiveness in achieving extremely low dew points critical for moisture-sensitive processes. There is a growing inclination towards integrated treatment packages that offer complete solutions, streamlining installation and maintenance for end-users. Furthermore, the increasing adoption of Industry 4.0 principles is fostering demand for intelligent treatment equipment capable of seamless integration into broader industrial automation systems, thereby contributing to overall operational excellence and resource optimization.

AI Impact Analysis on Compressed Air Treatment Equipment Market

The integration of Artificial Intelligence (AI) into the Compressed Air Treatment Equipment Market is poised to revolutionize operational efficiency, maintenance strategies, and energy management. Common user questions related to AI's impact often revolve around how it can minimize downtime, predict equipment failures, optimize energy consumption, and ensure consistent air quality. Users are keen to understand the practical benefits of AI in translating complex operational data into actionable insights, thereby moving beyond traditional reactive maintenance to a more proactive and preventative approach. This interest stems from the desire to reduce the total cost of ownership, enhance system reliability, and meet increasingly stringent production demands while adhering to sustainability goals. The expectation is that AI will make compressed air systems smarter, more autonomous, and significantly more cost-effective to operate.

Based on this analysis, AI's influence is primarily centered on enhancing the intelligence and self-optimization capabilities of compressed air treatment systems. Key themes include predictive maintenance facilitated by machine learning algorithms analyzing sensor data, dynamic energy management based on real-time demand and environmental conditions, and automated system adjustments to maintain optimal air quality. Concerns often relate to the initial investment in AI-enabled hardware and software, data security, and the technical expertise required for implementation and management. However, the overarching expectation is that AI will drive significant improvements in system uptime, reduce manual intervention, and unlock new levels of efficiency, making compressed air treatment more reliable and sustainable than ever before.

- AI-driven predictive maintenance: Algorithms analyze sensor data (pressure, temperature, flow, dew point) to forecast equipment failures, schedule maintenance proactively, and prevent costly downtime, extending the lifespan of components like filters and dryers.

- Optimized energy consumption: AI systems learn usage patterns and environmental conditions to dynamically adjust treatment parameters, such as dryer regeneration cycles or filter change indicators, minimizing energy waste and reducing electricity costs.

- Real-time performance monitoring: AI provides continuous, detailed insights into system health, air quality metrics, and energy efficiency, allowing operators to make informed decisions and respond instantly to deviations.

- Autonomous system adjustments: Advanced AI can enable treatment equipment to self-regulate, automatically adapting to changes in compressed air demand or incoming air quality to maintain optimal performance and purity levels without human intervention.

- Enhanced quality control: AI helps maintain consistent air purity by detecting subtle shifts in contamination levels, triggering alarms, or adjusting treatment processes to ensure compliance with critical ISO standards for specific applications.

DRO & Impact Forces Of Compressed Air Treatment Equipment Market

The Compressed Air Treatment Equipment Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, all shaped by various impact forces. A primary driver is the continuous expansion of industrial manufacturing activities across global economies, which inherently increases the demand for reliable and high-quality compressed air. As industries, particularly those in sectors like automotive, food and beverage, pharmaceuticals, and electronics, increasingly adopt automation and advanced production processes, the criticality of clean, dry air to protect sensitive machinery and ensure product integrity intensifies. Furthermore, stringent regulatory standards pertaining to air quality and environmental emissions, coupled with growing awareness regarding energy efficiency, compel industries to invest in advanced compressed air treatment solutions that minimize operational costs and enhance sustainability. The need to prevent equipment corrosion, reduce maintenance expenses, and extend the lifespan of pneumatic tools further underpins the market's growth.

Despite the robust growth drivers, the market faces several restraints that could impede its expansion. The most significant is the relatively high initial capital investment required for sophisticated compressed air treatment systems, which can be a barrier for small and medium-sized enterprises (SMEs) with limited budgets. Additionally, the ongoing operational costs associated with maintenance, replacement of consumables like filter elements, and the energy consumption of certain dryer types (though improving) can add to the total cost of ownership. A lack of comprehensive awareness regarding the long-term benefits of proper air treatment, especially in developing regions, also acts as a restraint, leading some industries to defer or underspend on essential treatment equipment. The complexity involved in integrating advanced treatment solutions with existing legacy systems can also pose technical challenges, necessitating specialized expertise.

Conversely, the market is ripe with opportunities for innovation and growth. The accelerating adoption of Industry 4.0 technologies, including the Internet of Things (IoT) and Artificial Intelligence (AI), presents significant avenues for developing smart, connected, and predictive compressed air treatment solutions. These technologies enable real-time monitoring, remote diagnostics, and optimized energy management, making systems more efficient and easier to maintain. The increasing global focus on sustainability and decarbonization offers opportunities for solutions that minimize energy footprints and facilitate waste heat recovery. Moreover, the vast potential in emerging economies, driven by rapid industrialization and infrastructure development, promises new market penetration. The demand for retrofitting older, inefficient systems with modern, energy-efficient treatment equipment also represents a substantial opportunity for market players to offer upgrade solutions and comprehensive service contracts.

Segmentation Analysis

The Compressed Air Treatment Equipment Market is broadly segmented based on product type, application, and end-use industry, allowing for a detailed analysis of market dynamics and tailored strategic approaches. This segmentation helps to understand specific demands arising from different operational requirements and industrial contexts, highlighting areas of high growth and technological innovation. The diverse range of equipment available, from various types of dryers and filters to aftercoolers and drains, caters to a wide spectrum of air purity levels and flow rates needed across different applications. Each segment possesses unique characteristics and growth trajectories, influenced by technological advancements, regulatory mandates, and industry-specific operational needs.

Understanding these segments is crucial for market participants to identify target customers, develop specialized products, and optimize distribution channels. For instance, the demand for highly sophisticated desiccant dryers would primarily originate from industries like pharmaceuticals or electronics, which require ultra-dry air, whereas refrigerated dryers might suffice for general manufacturing. Similarly, the requirements for filtration vary significantly, from basic particulate removal in workshops to extremely fine oil and odor removal in food-grade or breathable air applications. Analyzing these segments provides a granular view of market structure and competitive dynamics, enabling stakeholders to strategically position their offerings and capitalize on emerging trends within specific niches.

- By Product Type:

- Dryers:

- Refrigerated Dryers (Cycling, Non-Cycling)

- Desiccant Dryers (Heatless, Heated, Blower Purge, Heat of Compression)

- Membrane Dryers

- Chemical Dryers

- Filters:

- Particulate Filters

- Coalescing Filters (Oil Removal)

- Activated Carbon Filters (Odor Removal)

- Sterile Filters

- High-Efficiency Particulate Air (HEPA) Filters

- Aftercoolers (Air-Cooled, Water-Cooled)

- Air Receivers (Storage Tanks)

- Condensate Drains (Automatic, Manual, Electronic)

- Oil Water Separators

- Dryers:

- By Application:

- Industrial Manufacturing

- Food and Beverage Processing

- Pharmaceuticals and Biotechnology

- Automotive and Transportation

- Chemical and Petrochemical

- Energy (Oil and Gas, Power Generation)

- Electronics and Semiconductors

- Healthcare and Medical

- Textiles

- Pneumatic Tools and Equipment

- By End-Use Industry:

- Large Enterprises

- Small & Medium Enterprises (SMEs)

Value Chain Analysis For Compressed Air Treatment Equipment Market

The value chain for the Compressed Air Treatment Equipment Market begins with upstream activities involving the procurement and processing of raw materials and the manufacturing of essential components. This initial stage includes suppliers of metals such as steel and aluminum for housings and tanks, plastics for various internal components, and specialized materials like desiccants (e.g., activated alumina, silica gel) for dryers, and advanced media for filters. Key upstream players are also involved in the production of compressors, valves, sensors, and electronic controls that are integrated into sophisticated air treatment units. The quality and availability of these raw materials and components directly impact the overall cost, performance, and reliability of the final compressed air treatment solutions, making strong supplier relationships crucial for manufacturers. Innovation in material science and component technology at this stage can significantly enhance product efficiency and durability.

Further down the value chain, the manufactured equipment moves through various distribution channels to reach end-users. This involves a mix of direct and indirect sales approaches. Direct distribution often entails manufacturers selling directly to large industrial clients or through their own sales forces, offering customized solutions, installation, and after-sales support. Indirect channels primarily leverage a network of distributors, dealers, and system integrators who specialize in industrial equipment. These intermediaries play a vital role in market penetration, particularly for SMEs, by providing local sales support, inventory, technical assistance, and maintenance services. The effectiveness of these distribution networks is critical for market reach, customer relationship management, and ensuring timely delivery and service. After-sales support, including spare parts supply, maintenance contracts, and training, forms a crucial part of the downstream value chain, ensuring prolonged customer satisfaction and equipment longevity.

Compressed Air Treatment Equipment Market Potential Customers

Potential customers for compressed air treatment equipment represent a vast and diverse spectrum of industrial and commercial entities that rely on pneumatic systems for their operations. Fundamentally, any industry utilizing compressed air for power, process control, or as a direct contact medium for products or processes becomes a potential buyer. This includes the vast landscape of general manufacturing plants, where compressed air powers tools, machinery, and automation systems. From small workshops to large-scale production facilities, the need for dry, clean air to prevent equipment wear, reduce downtime, and improve product quality is universal. Industries that are sensitive to moisture and particulate contamination are particularly critical segments, as impure air can lead to severe product defects or even regulatory non-compliance.

Specific end-user/buyer categories include the automotive sector for paint shops and assembly lines, ensuring flawless finishes and reliable tool operation. The food and beverage industry requires sterile, oil-free, and dry air to prevent product spoilage and meet stringent hygiene standards. Pharmaceutical and biotechnology companies necessitate ultra-clean, dry, and often sterile air for processing, packaging, and laboratory environments to maintain product purity and efficacy. Other significant customer segments include chemical and petrochemical plants, where compressed air is used for instrumentation, process control, and conveying, demanding high reliability and safety. The electronics and semiconductor industries are highly sensitive to microscopic contaminants and moisture, making advanced air treatment indispensable for preventing product damage and ensuring cleanroom environments. Furthermore, power generation facilities, textile mills, and even dental clinics represent diverse applications with specific compressed air quality requirements, each constituting a significant pool of potential customers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 6.5 Billion |

| Market Forecast in 2032 | USD 10.4 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco, Ingersoll Rand, Parker Hannifin, SMC Corporation, Donaldson Company, Kaeser Kompressoren, Hitachi Industrial Equipment Systems, Mann+Hummel, SPX Flow, Zeks Air Drier, Gardner Denver, Quincy Compressor, BEKO TECHNOLOGIES, Friulair S.r.l., AIRTEC Corporation, FST filters, OMEGA AIR, CS Instruments, Hankison, Domnick Hunter |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Compressed Air Treatment Equipment Market Key Technology Landscape

The Compressed Air Treatment Equipment Market is consistently evolving with the integration of advanced technologies aimed at enhancing efficiency, reliability, and sustainability. A significant technological trend involves the development and adoption of smart and connected systems, leveraging IoT sensors and platforms. These intelligent systems enable real-time monitoring of critical parameters such as dew point, pressure drop, flow rate, and filter saturation levels. This data is then transmitted to centralized dashboards or cloud-based analytics platforms, allowing for remote diagnostics, predictive maintenance scheduling, and optimized operational adjustments. Such connectivity not only minimizes manual intervention but also significantly reduces potential downtime by identifying issues before they escalate, thereby extending the lifespan of the equipment and maintaining consistent air quality.

Further technological advancements are evident in energy recovery systems and improved filtration media. Innovations in heat recovery technologies, particularly for desiccant dryers, aim to utilize waste heat from compressors to regenerate desiccant material, drastically reducing energy consumption and operational costs. The development of advanced filter media offers higher efficiency in removing sub-micron particles, oil aerosols, and odors, even under challenging conditions, with lower pressure drops, which translates to energy savings for the entire compressed air system. There is also a growing focus on modular and compact designs, facilitating easier installation, maintenance, and scalability for various industrial footprints. Furthermore, the integration of AI and machine learning algorithms is emerging as a critical technological frontier, enabling self-optimizing systems that adapt to varying demand profiles and environmental conditions to achieve unparalleled levels of efficiency and performance.

Regional Highlights

- North America: This region represents a mature and technologically advanced market for compressed air treatment equipment. The demand is largely driven by stringent air quality regulations, a strong emphasis on energy efficiency and sustainability in manufacturing, and the continuous modernization of industrial infrastructure. Key industries such as automotive, aerospace, and food and beverage demand high-purity air, fostering the adoption of advanced filtration and drying technologies. The presence of major market players and a robust R&D ecosystem further contribute to market stability and growth in this region.

- Europe: Similar to North America, Europe is a well-established market characterized by high industrialization and strict environmental and occupational safety standards. Countries like Germany, the UK, and Italy are significant consumers, driven by their strong manufacturing bases and proactive initiatives towards industrial automation and energy optimization. The region shows a strong preference for innovative and energy-efficient solutions, with a growing trend towards integrated and smart compressed air treatment systems that align with Industry 4.0 principles and sustainable practices.

- Asia Pacific (APAC): The APAC region is the fastest-growing market globally, propelled by rapid industrialization, massive investments in manufacturing and infrastructure development, and increasing foreign direct investment. Countries like China, India, Japan, and South Korea are key contributors, experiencing significant growth in sectors such as electronics, automotive, textiles, and chemicals. The rising awareness regarding the benefits of clean compressed air for equipment longevity and product quality, coupled with less stringent but evolving regulations, fuels the demand for a wide range of compressed air treatment equipment.

- Latin America: This region is an emerging market for compressed air treatment equipment, characterized by ongoing industrial development and economic growth. Countries such as Brazil, Mexico, and Argentina are expanding their manufacturing capabilities, particularly in automotive, food and beverage, and mining sectors. While the adoption rate is increasing, awareness regarding the long-term benefits of advanced air treatment is still developing. This region offers significant opportunities for market players to introduce cost-effective and efficient solutions tailored to growing industrial needs.

- Middle East and Africa (MEA): The MEA market is witnessing steady growth, largely driven by investments in the oil and gas, petrochemical, construction, and manufacturing sectors. Infrastructure development projects and efforts towards economic diversification are creating new opportunities for compressed air treatment equipment. Although currently a smaller market compared to others, the region's increasing industrialization and the need for reliable operations in harsh environmental conditions are expected to drive future demand for robust and efficient air treatment solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Compressed Air Treatment Equipment Market.- Atlas Copco

- Ingersoll Rand

- Parker Hannifin

- SMC Corporation

- Donaldson Company

- Kaeser Kompressoren

- Hitachi Industrial Equipment Systems

- Mann+Hummel

- SPX Flow

- Zeks Air Drier

- Gardner Denver

- Quincy Compressor

- BEKO TECHNOLOGIES

- Friulair S.r.l.

- AIRTEC Corporation

- FST filters

- OMEGA AIR

- CS Instruments

- Hankison

- Domnick Hunter

Frequently Asked Questions

What is compressed air treatment equipment?

Compressed air treatment equipment refers to a range of devices designed to remove contaminants such as moisture, oil, and solid particulates from compressed air, ensuring it meets specific purity standards required for industrial applications and protects downstream pneumatic tools and machinery.

Why is air treatment important for compressed air systems?

Proper air treatment is crucial because untreated compressed air contains contaminants that can cause corrosion, wear down equipment, contaminate end products, increase maintenance costs, and reduce system efficiency. Treating air extends equipment life, ensures product quality, and prevents operational downtime.

What are the main types of compressed air dryers?

The main types of compressed air dryers include refrigerated dryers, which cool air to condense and remove moisture; desiccant dryers, which use absorbent materials to achieve very low dew points; and membrane dryers, which use selective permeability to separate water vapor.

How does AI improve compressed air treatment efficiency?

AI improves efficiency by enabling predictive maintenance through sensor data analysis, optimizing energy consumption by dynamically adjusting treatment processes based on real-time demand, and facilitating real-time monitoring and autonomous system adjustments, thereby reducing operational costs and downtime.

What are the benefits of proper compressed air treatment?

Benefits include enhanced operational efficiency, significant reduction in maintenance costs for pneumatic equipment, extended lifespan of machinery, pr

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager