Concrete Accelerators and retarders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431080 | Date : Nov, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Concrete Accelerators and Retarders Market Size

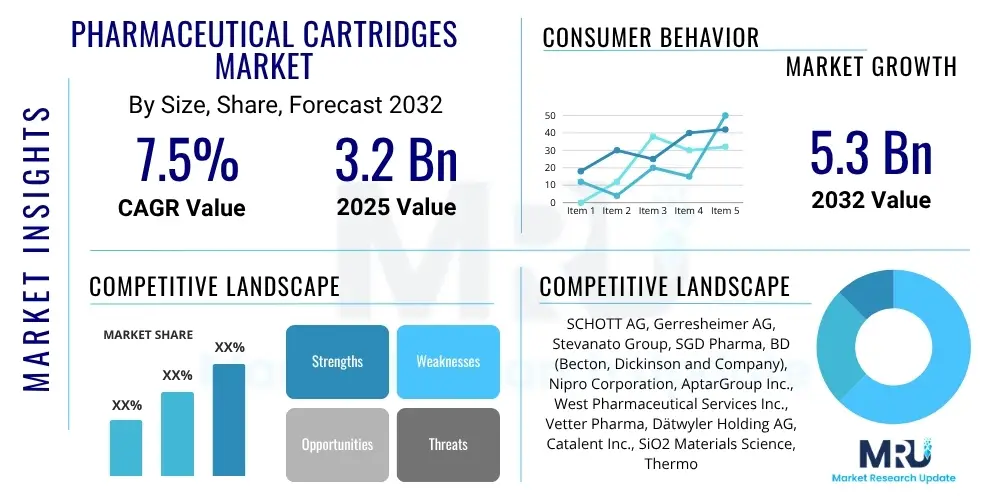

The Concrete Accelerators and Retarders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $15.8 Billion in 2025 and is projected to reach $25.1 Billion by the end of the forecast period in 2032.

Concrete Accelerators and Retarders Market Introduction

Concrete accelerators and retarders represent an indispensable category of chemical admixtures within the global construction industry, meticulously engineered to precisely manipulate the setting and hardening characteristics of fresh concrete. Accelerators are specifically formulated to significantly reduce both the initial and final setting times, a critical advantage in applications demanding rapid strength development such as precast concrete manufacturing, time-sensitive repair work, or during challenging cold weather conditions where conventional curing times would be excessively prolonged. Their judicious use ensures quicker demolding processes, enables faster turnaround for formwork reuse, and contributes to an overall acceleration of construction schedules, directly translating into enhanced project efficiency and substantial cost savings. These specialized chemical agents, frequently based on compounds like calcium chloride or more advanced non-chloride formulations, are instrumental in enhancing early compressive strength and facilitating earlier structural loading, thereby providing robust solutions for modern, fast-track building projects across diverse construction sectors, including residential, commercial, and industrial developments, ensuring foundational stability and rapid progression.

Conversely, concrete retarders are purposefully designed to extend the setting time of concrete, effectively preventing premature stiffening and maintaining the crucial workability of the mix for extended durations. This functionality is particularly vital in hot weather environments, which can cause rapid water evaporation and accelerate hydration reactions, leading to undesirable issues such as cold joints in large monolithic pours or compromised structural integrity if the concrete stiffens too quickly. Retarders are also invaluable when transporting ready-mix concrete over long distances, ensuring the mix remains perfectly workable upon arrival at the construction site, regardless of transit time. By strategically delaying the onset of hardening, these admixtures facilitate superior placement, more thorough compaction, and impeccable finishing of concrete, especially in complex structural elements, large slabs, or aesthetically demanding architectural applications where a flawless surface finish is paramount. The precise control offered by retarders allows for significantly greater flexibility in project planning and execution, mitigates the likelihood of costly construction defects, and ultimately enhances the long-term durability, structural integrity, and aesthetic appeal of concrete structures, making them indispensable for complex and large-scale projects.

The burgeoning market for concrete accelerators and retarders is propelled by several powerful and interconnected driving forces, fundamentally rooted in global demographic and economic shifts. These include the relentless pace of global urbanization, which necessitates continuous investment in new residential complexes, expansive commercial hubs, and extensive public infrastructure to accommodate rapidly growing populations. This unprecedented urban expansion fuels an insatiable demand for concrete and, by extension, for high-performance admixtures that can optimize its properties and significantly speed up construction timelines. The increasing demand for high-performance and specialized concrete, capable of withstanding extreme environmental conditions, achieving superior durability, or delivering unique aesthetic qualities, further intensifies the need for these sophisticated chemical modifiers. Additionally, a growing global emphasis on sustainable construction practices and a concerted desire to reduce material waste, minimize energy consumption, and lower carbon footprints throughout the construction lifecycle actively drives innovation in admixture formulation. These multifaceted factors collectively underscore the critical and evolving role accelerators and retarders play in enhancing construction efficiency, improving concrete quality, fostering resilience in infrastructure development worldwide, and positioning them as essential, innovative components in the transforming landscape of modern building materials and engineering solutions.

Concrete Accelerators and Retarders Market Executive Summary

The Concrete Accelerators and Retarders market is currently experiencing a period of robust and sustained expansion, propelled by significant global business trends primarily centered around an unprecedented wave of urbanization and substantial governmental and private sector investments in critical infrastructure development across continents. There is an industry-wide discernible shift towards specialized and high-performance concrete solutions that demand precise control over setting times, workability, and long-term durability, thereby rapidly escalating the adoption of advanced chemical admixtures. The increasing complexity of modern architectural designs, coupled with ambitious engineering feats, further necessitates the fine-tuning of concrete properties to meet stringent performance specifications and aesthetic demands, positioning accelerators and retarders as critical enablers for the successful execution of challenging construction projects. This comprehensive market evolution is deeply underpinned by a growing awareness of the need for efficient resource utilization and the imperative to significantly reduce construction timelines, where these sophisticated admixtures play a pivotal role in optimizing both on-site operations and advanced prefabrication processes, contributing directly to project viability and economic returns.

From a precise regional perspective, the Asia Pacific region continues to exert its dominance in both market share and impressive growth trajectory, largely attributed to rapid economic development, extensive industrialization, and massive infrastructure expansion programs underway in populous nations such as China, India, and various Southeast Asian countries. These dynamic regions are witnessing an unparalleled boom across residential, commercial, and extensive transportation infrastructure sectors, creating an immense and continuous demand for concrete modifiers. In stark contrast, mature markets like North America and Europe exhibit stable, albeit more moderate, growth rates, primarily driven by stringent building codes, a strong and enduring focus on sustainable construction practices, the imperative maintenance of existing aging infrastructure, and the widespread adoption of technologically advanced building techniques, including prefabrication and modular construction methods that rely on consistent concrete properties. Emerging markets in Latin America, the Middle East, and Africa are demonstrating high-potential growth, spurred by significant investments in new urban centers, vital energy projects, and fundamental basic infrastructure development, often operating in challenging climatic conditions that specifically benefit from the precise control offered by setting-time modifying admixtures, thus highlighting global diversity in market drivers.

Detailed segment trends within the market conspicuously highlight a rising preference for non-chloride-based accelerators, primarily driven by escalating concerns over rebar corrosion and the long-term structural integrity of concrete, alongside the increasing sophistication of lignosulfonate and hydrocarboxylic acid-based retarders engineered for enhanced and more predictable performance. The ready-mix concrete sector steadfastly remains the single largest consumer of these admixtures, while the precast concrete manufacturing segment is demonstrating accelerated growth due to its inherent efficiency benefits, including faster production cycles and improved quality control in factory settings. There is also an increasingly pronounced demand for multi-functional admixtures that provide combined benefits extending beyond just setting time modification, such as significant water reduction, improved workability, or enhanced durability. Furthermore, the market is witnessing continuous and rapid innovation in bio-based and environmentally friendly admixture formulations, directly responding to global sustainability mandates, stringent environmental regulations, and the construction industry's collective commitment to significantly reducing its ecological footprint and promoting green building practices. These overarching and interconnected trends collectively indicate a highly dynamic and resilient market poised for sustained growth and profound technological evolution, driven by both traditional construction demands and a forward-looking approach to advanced material science and sustainable engineering solutions.

AI Impact Analysis on Concrete Accelerators and Retarders Market

Common user questions related to the profound impact of Artificial Intelligence (AI) on the Concrete Accelerators and Retarders market frequently revolve around how this advanced technology can fundamentally optimize admixture dosage, accurately predict material performance under varying conditions, and significantly streamline complex supply chain logistics. Users are increasingly keen to understand if AI can lead to dramatically more precise application of admixtures, substantially reduce material waste through intelligent systems, and improve the overall efficiency and predictability of concrete production and placement processes, delivering consistent results. There are also significant expectations regarding AI's transformative role in developing novel admixture formulations through sophisticated predictive modeling and simulation, and its profound potential to enhance automated quality control systems and revolutionize project management methodologies in real-time. Concerns often include the substantial initial investment costs required for comprehensive AI integration, the critical need for vast quantities of specialized, high-quality data and expert human interpretation, and the potential for job displacement in traditional labor-intensive roles. However, the overarching theme among stakeholders is one of considerable optimism regarding AI's inherent capacity to revolutionize the entire industry by fostering unprecedented levels of efficiency, enhancing predictability, driving superior quality, and ultimately promoting greater sustainability across the concrete value chain.

- AI-driven optimization algorithms for precise admixture dosages, considering real-time environmental conditions, concrete mix designs, and desired performance characteristics.

- Predictive analytics frameworks for accurately forecasting concrete setting times, strength development, and long-term durability based on various input parameters, improving project planning and scheduling.

- Enhanced automated quality control systems leveraging computer vision and machine learning for real-time monitoring of concrete properties and immediate detection of anomalies during production.

- Streamlined and intelligent supply chain management for raw materials and finished admixtures, optimizing inventory levels, predicting demand fluctuations, and reducing logistics costs and lead times.

- Accelerated research and development processes for discovering and formulating new, high-performance, and environmentally sustainable admixture chemistries through AI-powered molecular modeling and simulation.

- Automation and intelligent control of concrete mixing plants, leading to higher consistency in batching, reduced human error, and optimized energy consumption during production cycles.

- Provision of data-driven insights and actionable recommendations for project managers to make informed decisions on concrete pouring, curing strategies, and overall construction site operations.

- Facilitation of sophisticated remote monitoring and control systems for construction sites, enabling off-site management and immediate response to any concrete-related issues.

- Development of digital twins for concrete structures, allowing for simulations of material behavior over time and proactive maintenance planning, further optimizing admixture selection.

DRO & Impact Forces Of Concrete Accelerators and Retarders Market

The Concrete Accelerators and Retarders market is significantly shaped by a powerful interplay of dynamic drivers, inherent restraints, and compelling opportunities, all profoundly influenced by various pervasive impact forces. A primary and dominant driver is the accelerating pace of global urbanization, which necessitates the continuous development of vast residential complexes, expansive commercial hubs, and extensive public infrastructure to accommodate rapidly growing populations. This unprecedented urban expansion fuels an insatiable demand for concrete and, by extension, for sophisticated admixtures that can precisely optimize its performance and significantly speed up construction timelines. Furthermore, substantial governmental and private sector investments in critical infrastructure projects, encompassing roads, bridges, dams, airports, and vital energy facilities, particularly in rapidly developing economies, serve as a monumental impetus for sustained market growth. The increasing adoption of advanced construction techniques, such as modular construction, prefabrication, and the widespread use of ready-mix concrete, which inherently require precise control over concrete setting and hardening, further cements the market's expansive trajectory. The growing global preference for high-performance concrete, capable of withstanding extreme environmental conditions and delivering enhanced durability for longer service life, also contributes significantly to this upward trend, as admixtures are absolutely crucial for achieving such exacting properties in modern construction.

However, the market faces notable and persistent restraints that invariably temper its full growth potential and introduce complexities. Foremost among these is the inherent volatility in the prices of key raw materials, including calcium chloride, various nitrates, lignosulfonates, and hydrocarboxylic acids, alongside other specialized organic and inorganic chemical components. These unpredictable price fluctuations can lead to significant variations in manufacturing costs, consequently impacting pricing strategies, profit margins for admixture producers, and the overall affordability of products for end-users. Additionally, increasingly stringent environmental regulations, particularly prevalent in developed economies, concerning the chemical composition, responsible usage, and safe disposal of certain admixtures, pose significant challenges. Manufacturers are compelled to invest heavily in extensive research and development to formulate eco-friendly, compliant, and sustainable products, which can inadvertently increase production costs and potentially limit the widespread use of certain conventional, albeit often more cost-effective, chemical formulations. The complex logistics involved in the secure storage, efficient transportation, and on-site handling of bulk chemical admixtures, alongside the critical need for specialized handling expertise at diverse construction sites, also present operational hurdles that can restrict broader market penetration, especially in regions with less developed infrastructure and logistical capabilities.

Amidst these prevalent challenges, significant and transformative opportunities are continuously emerging, promising to redefine the market's future trajectory and drive innovation. A key and highly impactful opportunity lies in the extensive research, development, and subsequent commercialization of sustainable and bio-based accelerators and retarders, actively driven by global green building initiatives, escalating environmental consciousness within the construction industry, and a collective push towards circular economy principles. These innovative products offer the profound potential to significantly reduce the carbon footprint of concrete production and align seamlessly with stringent global sustainability goals. Furthermore, the burgeoning construction markets in rapidly developing economies across Africa, Latin America, and parts of Asia, currently underserved and undergoing rapid urbanization, represent vast untapped potential for significant market expansion. These regions are experiencing unprecedented infrastructure transformation, creating a conducive environment for new market entrants and accelerated product adoption. Technological advancements, particularly in smart admixtures that can dynamically respond to environmental cues or be digitally monitored for real-time performance, and the development of multi-functional formulations offering combined benefits beyond just setting time modification (e.g., water reduction, corrosion inhibition), also present lucrative avenues for sustained innovation and market differentiation. The continuous evolution of construction practices, coupled with breakthroughs in material science, will undoubtedly uncover further opportunities for highly specialized and high-performance concrete admixtures, ensuring a dynamic and forward-looking market landscape.

Segmentation Analysis

The Concrete Accelerators and Retarders market is meticulously segmented to provide a comprehensive and granular understanding of its diverse applications, product types, and end-user demands, enabling precise market targeting, strategic resource allocation, and informed business planning. This detailed segmentation is crucial for accurately analyzing market trends, identifying nascent growth opportunities, and understanding the specific performance requirements of various end-users across distinct geographical regions and climatic zones. The market is primarily categorized by the specific type of admixture, its underlying chemical composition, the diverse application area where it is utilized, and the ultimate end-use industry it serves, with each segment playing a critical and interconnected role in shaping overall market dynamics, influencing product development, and guiding consumer preferences. A thorough understanding of these distinct market segments is absolutely crucial for all stakeholders, including manufacturers, distributors, and construction firms, to effectively tailor their product portfolios, optimize their technical support services, and refine their marketing and sales strategies to capture maximum market share and ensure customer satisfaction.

- By Type:

- Accelerators: Chemical admixtures that expedite the rate of hydration of hydraulic cement, leading to an earlier setting time and faster development of initial concrete strength. Essential for cold weather concreting, urgent repair work, or precast concrete manufacturing requiring rapid mold turnover.

- Retarders: Chemical admixtures that slow down the rate of hydration of hydraulic cement, thereby extending the setting time of concrete. Crucial for hot weather conditions, large concrete pours to prevent cold joints, or situations demanding prolonged workability during transportation and placement.

- By Chemical Type:

- Calcium Chloride Based: A widely used and cost-effective accelerator that significantly increases the rate of hydration and early strength gain, though its use is often restricted in reinforced concrete due to corrosion risks.

- Non-Chloride Based Accelerators: Includes compounds such as calcium nitrite, calcium formate, and triethanolamine. These alternatives offer acceleration without the corrosive effects on steel reinforcement, making them suitable for high-performance and critical infrastructure projects.

- Lignosulfonate Based Retarders: Derived from wood pulp processing, these are common and effective retarders that also often provide some water-reducing properties, improving workability and strength.

- Hydrocarboxylic Acid Based Retarders: Organic acid salts used for their robust retarding action, often more potent than lignosulfonates, and particularly effective in high-temperature environments or for very long setting times.

- Others: Includes a range of other organic compounds such as sugars, starches, and inorganic salts that can exhibit accelerating or retarding properties, often used in specialized applications or niche formulations.

- By Application:

- Ready-Mix Concrete: The largest application segment, where admixtures are crucial for controlling setting times based on transportation distance, ambient temperature, and specific project requirements, ensuring concrete arrives at the site in optimal condition.

- Precast Concrete: Accelerators are vital for achieving rapid demolding, allowing for faster production cycles and increased efficiency in controlled factory environments, enhancing manufacturing throughput.

- Shotcrete: Both accelerators and retarders can be used to control setting for spray application, with accelerators reducing rebound and improving early strength for structural stability.

- Pumping Concrete: Admixtures improve pumpability by enhancing workability and cohesion, preventing blockages and ensuring smooth flow through pumps and pipelines.

- High-Performance Concrete: Admixtures are essential for achieving superior strength, durability, and specialized properties required for demanding structural applications and extreme environments.

- Repair Concrete: Accelerators are often used in repair mortars and concretes to achieve rapid setting and strength development, minimizing downtime for existing structures.

- By End-Use Industry:

- Residential Construction: Used in housing projects, apartments, and condominiums to optimize slab setting, foundation work, and structural elements for efficiency and durability.

- Commercial Construction: Applied in office buildings, retail centers, and hotels to meet complex structural demands, achieve aesthetic finishes, and adhere to tight construction schedules.

- Infrastructure (Roads, Bridges, Tunnels, Dams, Railways): Critical for large-scale public works where precise control over concrete setting, extended workability for massive pours, and enhanced durability against environmental stressors are paramount.

- Industrial Construction: Utilized in factories, warehouses, and power plants for durable flooring, heavy-duty structures, and specialized foundations, ensuring structural integrity and operational resilience.

- Architectural & Decorative Concrete: Admixtures help achieve specific aesthetic effects, improve workability for intricate designs, and ensure consistent color and finish in visible concrete elements.

Value Chain Analysis For Concrete Accelerators and Retarders Market

The value chain for the Concrete Accelerators and Retarders market is a complex and highly integrated ecosystem involving a meticulously sequenced series of interconnected activities, each designed to incrementally add value to the final product from its initial raw material genesis to its ultimate application by the end-user. Upstream activities constitute the foundational phase, commencing with the critical procurement and meticulous processing of a diverse array of essential raw materials. These foundational components include primary chemicals such as calcium chloride, various forms of nitrates, lignosulfonates derived from wood pulp, hydrocarboxylic acids, and a spectrum of other specialized organic and inorganic chemical compounds. A robust network of highly specialized chemical manufacturers and commodity suppliers plays a pivotal role in providing these basic ingredients to the admixture producers. The unwavering quality, consistent purity, and reliable availability of these raw materials are absolutely paramount, as they directly and profoundly influence the efficacy, performance characteristics, and overall economic viability of the final concrete admixtures. This upstream segment is distinctively characterized by sophisticated chemical synthesis processes, stringent quality control measures implemented at every stage, and often long-term strategic supply agreements forged to ensure a stable, predictable, and reliable input stream for the subsequent intricate manufacturing stages, thereby establishing a resilient and robust foundation for the entire concrete admixture value chain.

The core of the value chain firmly resides within the manufacturing and sophisticated formulation segment, where the procured raw materials are expertly transformed into highly engineered concrete accelerators and retarders. This pivotal stage necessitates extensive and continuous investment in research and development (R&D) to create innovative chemical blends that precisely meet stringent performance specifications, carefully considering dynamic factors such as ambient temperature, desired setting time profiles, and critical compatibility with other essential concrete constituents like cement types and aggregates. Admixture manufacturers employ advanced blending, compounding, and reaction techniques to achieve optimal product consistency, superior chemical stability, and maximum effectiveness in diverse concrete mixes. Comprehensive quality assurance protocols and stringent performance testing are absolutely integral to this stage, rigorously ensuring that all manufactured products consistently comply with established international standards (e.e., ASTM C494, EN 934-2) and evolving national regulatory requirements. Sophisticated packaging solutions and strategic branding also occur here, meticulously preparing the high-performance products for their subsequent journey through market distribution channels. Manufacturers often develop and protect proprietary formulations, fostering a highly competitive landscape largely driven by technological superiority, demonstrated product differentiation, and continuous innovation, which necessitates substantial ongoing investment in both scientific expertise, state-of-the-art production infrastructure, and intellectual property protection.

Downstream activities encompass the intricate processes of distribution, targeted sales, and ultimate end-user application. Manufacturers typically leverage a highly strategic hybrid distribution model to effectively reach their extensive and diverse customer base. Direct sales channels are frequently employed for large-volume, key accounts, such as major ready-mix concrete producers, significant precast concrete manufacturers, and large-scale infrastructure developers, facilitating direct technical support, customized product solutions, and long-term partnerships. Concurrently, an extensive network of indirect channels, comprising specialized distributors, knowledgeable agents, and regional retailers, is absolutely crucial for efficiently reaching smaller contractors, localized construction projects, and geographically dispersed markets requiring tailored local support, expedited delivery services, and localized technical expertise. These critical intermediaries play a vital role in efficient warehousing, precise local distribution, and providing invaluable on-site technical assistance, effectively bridging the geographical and informational gap between sophisticated manufacturers and a fragmented, diverse end-user market. The final and crucial stage involves the precise incorporation of accelerators and retarders into concrete mixes, either at centralized batching plants or directly on various construction sites, where highly trained personnel ensure correct dosages, optimal mixing procedures, and adherence to specific project specifications. This meticulous application enables engineers and contractors to achieve desired concrete properties, optimize workability windows, and deliver exceptional project outcomes, ensuring superior performance, enhanced durability, and ultimately, significant value creation for all stakeholders across the entire construction ecosystem.

Concrete Accelerators and Retarders Market Potential Customers

The primary potential customers and essential end-users of concrete accelerators and retarders are diverse entities deeply embedded within the production, delivery, and application of concrete across a wide spectrum of construction sectors. These highly specialized chemical admixtures are indispensable for precisely optimizing concrete performance, accurately controlling its setting characteristics, and reliably accelerating or extending construction timelines, thereby making them absolutely crucial for a vast array of industry participants, from large multinational corporations to local contractors. Understanding the diverse operational scales, specific technical requirements, and unique project demands of these multifaceted customer segments is vitally important for manufacturers and suppliers to effectively tailor their extensive product portfolios, provide unparalleled technical support, and refine their sophisticated distribution strategies to ensure maximum market penetration and sustained customer loyalty. The increasing complexity of modern construction projects, coupled with the escalating global demand for specialized, high-performance concrete capable of meeting stringent standards, continuously expands the customer base for these essential chemical solutions, highlighting their foundational role in contemporary building practices.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $15.8 Billion |

| Market Forecast in 2032 | $25.1 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| Segments Covered |

|

| Key Companies Covered | Sika AG, BASF SE, Fosroc International Ltd., GCP Applied Technologies Inc., Master Builders Solutions (MBCC Group), The Dow Chemical Company, CEMEX S.A.B. de C.V., Holcim Ltd. (formerly LafargeHolcim), Chryso SAS (a Saint-Gobain Company), Mapei S.p.A., W.R. Grace & Co., Evonik Industries AG, Arkema S.A., RPM International Inc., Denka Company Limited, Kao Corporation, Flowcrete Group Ltd. (part of The Euclid Group), Euclid Chemical Company, Contech Chemicals Pvt. Ltd., CICO Technologies Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Regional Highlights

The global Concrete Accelerators and Retarders market exhibits distinct and intricate regional dynamics, each profoundly influenced by varying levels of ongoing infrastructure development, prevailing stringent regulatory frameworks, diverse and often challenging climatic conditions, and deeply entrenched local construction practices. Every geographical segment presents unique growth opportunities and specific challenges for market participants, thereby necessitating highly localized and nuanced strategic approaches for successful market penetration, sustainable expansion, and long-term viability. Understanding these inherent regional nuances is absolutely paramount for all stakeholders, including manufacturers, distributors, and construction firms, to precisely optimize their comprehensive product offerings, efficiently configure their extensive distribution networks, and meticulously refine their targeted marketing and sales efforts to effectively address specific local demands, comply with complex regional regulatory landscapes, and maximize their overall market share and profitability in a competitive global environment.

- Asia Pacific (APAC): This region unequivocally dominates the global market for concrete accelerators and retarders, driven by an unparalleled pace of rapid urbanization, substantial governmental and private sector investments in mega-infrastructure projects, and robust, continuous growth across residential, commercial, and vast industrial construction sectors. Countries like China and India are at the forefront of this expansion, with their extensive development agendas including high-speed rail networks, smart city initiatives, and immense housing projects. The extremely diverse climatic conditions, ranging from tropical heat to severe cold winters, necessitate a broad and varied application of both accelerating and retarding admixtures to ensure optimal concrete quality, workability, and structural integrity. Furthermore, the increasing adoption of advanced construction techniques and a growing emphasis on high-performance concrete to meet increasingly stringent durability requirements actively fuel continuous demand, making APAC the primary engine of global market growth and a significant hub for innovation, particularly in sustainable concrete solutions and advanced admixture technologies.

- North America: As a mature and highly developed market, North America is characterized by a stable yet consistent demand primarily driven by extensive repair, renovation, and critical maintenance of aging infrastructure, coupled with new commercial building developments and a strong, unwavering focus on sustainable construction practices and energy efficiency. The region benefits from highly stringent building codes and uncompromising quality standards that actively encourage the widespread use of specialized admixtures for enhanced concrete performance, extended service life, and superior durability. Innovation in environmentally friendly and high-efficiency admixtures is a key strategic focus, particularly for addressing the unique challenges posed by cold weather concreting, where accelerators are essential for faster setting and accelerated early strength development. The market is also propelled by significant advancements in prefabrication and modular construction techniques, which rely heavily on precise and predictable control over concrete setting times, ensuring consistent quality and significantly accelerated project timelines, thereby reducing overall construction costs and durations.

- Europe: The European market is distinctly defined by its highly regulated environment, with an unwavering and strong commitment to environmental sustainability, exceptional energy efficiency, and the development of durable, long-lasting structures that adhere to strict quality benchmarks. Growth in this region is primarily fueled by ongoing critical infrastructure upgrades, extensive residential and commercial building renovation projects, and the increasing prevalence of sophisticated precast concrete solutions in modern construction. Western European countries, with their established economies and highly advanced construction industries, lead in the adoption of sophisticated and environmentally compliant admixtures, setting global standards for sustainable building materials. Meanwhile, Eastern Europe presents significant emerging growth opportunities as construction activities intensify, driven by robust economic development and the modernization of existing infrastructure, progressively adopting more advanced concrete technologies and performance-enhancing admixtures in their evolving construction practices, moving towards higher quality and efficiency.

- Latin America: This dynamic region is experiencing steady and promising growth in the concrete accelerators and retarders market, buoyed by ongoing rapid urbanization trends, substantial government investments in crucial public infrastructure projects, and an expanding residential construction sector in key economies such as Brazil, Mexico, and Argentina. While the market can sometimes be sensitive to economic fluctuations and political instabilities, the long-term potential remains profoundly significant due to a large and continuously growing population, coupled with persistent development projects aimed at improving living standards, enhancing connectivity, and fostering economic growth. The increasing adoption of modern construction techniques and the escalating demand for durable, high-performance concrete solutions capable of enduring diverse and often challenging climatic conditions contribute significantly to the sustained and rising demand for these essential admixtures across the entire continent, driving both innovation and market expansion.

- Middle East and Africa (MEA): The MEA region is uniquely characterized by substantial and often ambitious investments in mega-projects, especially within the Gulf Cooperation Council (GCC) countries (e.g., UAE, Saudi Arabia, Qatar), focusing on the development of entirely new cities, luxurious hospitality infrastructure, and vast commercial complexes, often under challenging desert climates. The extreme hot climatic conditions prevalent throughout the Middle East necessitate the widespread and absolutely critical use of concrete retarders to effectively manage setting times, prevent premature stiffening, and ensure optimal workability during placement and finishing operations, which are crucial for large pours. Concurrently, Africa's burgeoning population, coupled with ongoing robust economic development and increasing foreign direct investment, is driving significant construction activity, particularly in basic infrastructure (roads, ports, utilities) and residential housing, presenting considerable long-term opportunities for market expansion in both accelerators and retarders as construction standards and demands for performance steadily rise across the continent, promising substantial future growth.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Concrete Accelerators and Retarders Market.- Sika AG

- BASF SE

- Fosroc International Ltd.

- GCP Applied Technologies Inc.

- Master Builders Solutions (MBCC Group)

- The Dow Chemical Company

- CEMEX S.A.B. de C.V.

- Holcim Ltd. (formerly LafargeHolcim)

- Chryso SAS (part of Saint-Gobain Construction Chemicals)

- Mapei S.p.A.

- W.R. Grace & Co.

- Evonik Industries AG

- Arkema S.A.

- RPM International Inc.

- Denka Company Limited

- Kao Corporation

- Flowcrete Group Ltd. (part of The Euclid Group)

- Euclid Chemical Company

- Contech Chemicals Pvt. Ltd.

- CICO Technologies Ltd.

Frequently Asked Questions

What is the primary purpose of concrete accelerators and retarders in construction?

Concrete accelerators are specifically utilized to expedite the setting time and accelerate the early strength development of concrete, which is often vital for efficient cold weather concreting, urgent structural repair work, or faster project turnaround requirements. Conversely, retarders are engineered to extend the setting time, which is critically important for hot weather applications, massive concrete pours to prevent undesirable cold joints, or situations where concrete transportation requires longer working times, thereby meticulously optimizing concrete workability, placement, and long-term performance under various environmental and operational conditions.

What are the main types of chemical compositions for these admixtures?

The predominant chemical compositions for accelerators include highly effective calcium chloride and various advanced non-chloride alternatives like calcium nitrite, calcium formate, and triethanolamine, which mitigate corrosion risks. For retarders, the primary chemical bases typically involve lignosulfonates, derived from wood processing, and various hydrocarboxylic acids. These diverse chemical chemistries allow for the formulation of precisely tailored performance characteristics, enabling optimal concrete behavior based on specific project requirements, environmental factors, and desired structural outcomes, ensuring adaptability and high performance in varied applications.

Which end-use industries are the biggest consumers of concrete accelerators and retarders?

The largest and most significant consumers of concrete accelerators and retarders are typically the extensive ready-mix concrete industry, high-volume precast concrete manufacturers, and major construction contractors extensively involved in large-scale infrastructure projects (such as expansive roads, critical bridges, intricate tunnels), as well as significant residential and commercial building developments. These industries fundamentally rely on these essential admixtures to precisely control concrete setting, enhance its workability, and significantly improve its overall performance and durability for a wide array of specialized applications, thereby ensuring structural integrity and project efficiency.

How do environmental regulations impact the market for concrete admixtures?

Environmental regulations exert a substantial influence on the market by actively driving the increasing demand for eco-friendly and sustainable admixture formulations, including bio-based products and those with significantly lower volatile organic compound (VOC) emissions, aligning with global green building standards. Manufacturers are consequently compelled to invest heavily in extensive research and development to comply with these evolving regulations, actively pushing innovation towards greener, more sustainable chemical solutions and ensuring safe, responsible usage and disposal practices throughout the entire concrete lifecycle, promoting long-term environmental stewardship.

What role does technology, including AI, play in the future of this market?

Technology, particularly Artificial Intelligence (AI), is poised to profoundly revolutionize the market through sophisticated optimized dosage control, advanced predictive analytics for concrete performance under various conditions, and significantly streamlined supply chain management, ensuring efficiency and cost savings. AI can fundamentally accelerate the development of novel, high-performance, and sustainable admixtures through predictive modeling, dramatically enhance automated quality control systems, and contribute to more efficient, data-driven, and precise construction processes, ultimately leading to greater accuracy, reduced waste, and enhanced overall sustainability across the entire concrete construction industry, heralding a new era of intelligent building.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager