Concrete Densification & Polishing Material Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430668 | Date : Nov, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Concrete Densification & Polishing Material Market Size

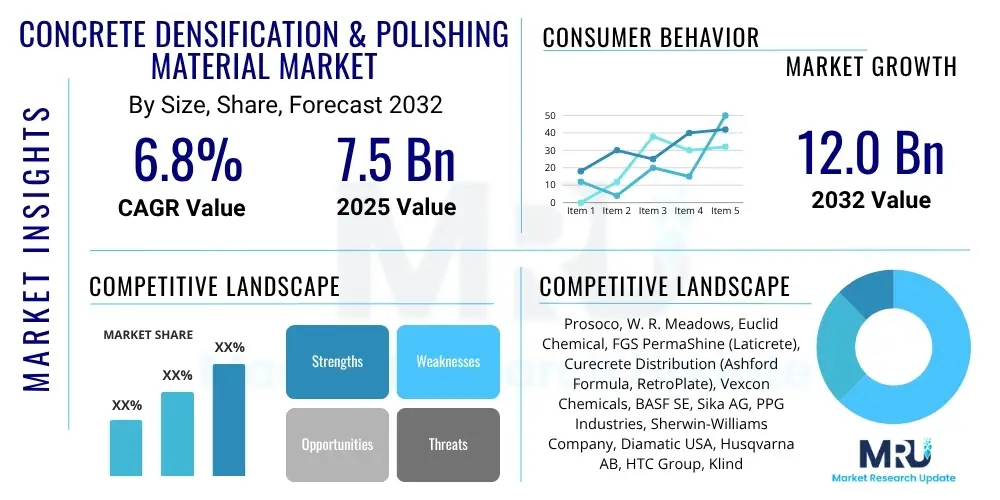

The Concrete Densification & Polishing Material Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at $7.5 Billion in 2025 and is projected to reach $12.0 Billion by the end of the forecast period in 2032.

Concrete Densification & Polishing Material Market introduction

The Concrete Densification & Polishing Material Market encompasses a range of chemical treatments and mechanical abrasive systems designed to enhance the durability, appearance, and performance of concrete surfaces. These materials primarily include chemical densifiers, sealers, and specialized abrasive tools used in conjunction with grinding and polishing equipment. Densifiers, typically silicate-based, chemically react with concrete to fill pores, increasing surface hardness and abrasion resistance, while polishing involves a multi-step mechanical process using progressively finer abrasives to achieve a desired level of sheen and smoothness.

Major applications for densified and polished concrete include industrial warehouses, retail establishments, commercial offices, educational institutions, healthcare facilities, and increasingly, residential spaces. The benefits of these flooring systems are substantial, offering extreme durability, low maintenance requirements, enhanced light reflectivity, improved hygiene, and a sustainable, aesthetically pleasing finish. Key driving factors for market growth include the rising global demand for long-lasting and aesthetically appealing flooring solutions, rapid urbanization leading to increased construction activities, a growing emphasis on green building practices, and the cost-effectiveness and versatility of polished concrete over its lifespan.

Concrete Densification & Polishing Material Market Executive Summary

The Concrete Densification & Polishing Material Market is experiencing robust growth driven by a convergence of business, regional, and segment trends. Businesses are increasingly focused on product innovation, offering advanced silicate formulations and eco-friendly sealers to meet evolving consumer demands for sustainable and high-performance flooring. Strategic partnerships and acquisitions are also prominent, as companies seek to expand their geographical reach and enhance their product portfolios, leading to a more consolidated and competitive market landscape. The emphasis on providing comprehensive solutions, from materials to equipment and training, is a key strategy among market leaders.

Regionally, the Asia Pacific continues to emerge as a powerhouse, propelled by rapid infrastructure development and urbanization, particularly in countries like China and India, where demand for durable and aesthetic commercial and industrial flooring is surging. North America and Europe, while more mature markets, demonstrate steady growth driven by renovation projects, stringent quality standards, and a strong preference for sustainable building materials. In terms of segments, lithium-based densifiers are gaining traction due to their superior performance and faster curing times, while the demand for advanced diamond tooling and sophisticated polishing machines reflects a broader trend towards higher quality finishes and greater operational efficiency in the application process. The industrial and commercial sectors remain the dominant application areas, although residential adoption is also steadily climbing.

AI Impact Analysis on Concrete Densification & Polishing Material Market

Common user questions regarding AI's impact on the Concrete Densification & Polishing Material Market often revolve around how artificial intelligence can optimize processes, improve material performance, and enhance the overall efficiency and quality of concrete flooring projects. Users are keen to understand if AI can predict material requirements more accurately, automate equipment operations, ensure consistent finish quality, or even contribute to the development of novel material formulations. The key themes that emerge are centered on automation, precision, predictive capabilities, and sustainable practices, reflecting an expectation that AI can address current challenges such as labor shortages, material waste, and variability in application outcomes, ultimately driving cost savings and higher standards across the industry.

- AI-driven optimization of material formulations for enhanced durability and performance.

- Predictive maintenance analytics for concrete polishing equipment, reducing downtime.

- Automated quality control systems using computer vision to assess surface finish and consistency.

- Robotic polishing systems integrated with AI for autonomous, precise, and consistent application.

- Smart scheduling and logistics optimization for concrete material supply chains.

- AI-powered design tools for simulating various concrete finishes and material interactions.

DRO & Impact Forces Of Concrete Densification & Polishing Material Market

The Concrete Densification & Polishing Material Market is shaped by a dynamic interplay of drivers, restraints, opportunities, and underlying impact forces. Key drivers include the escalating demand for high-performance, low-maintenance, and aesthetically pleasing flooring solutions across industrial, commercial, and institutional sectors. The rapid pace of global construction, particularly in emerging economies, coupled with a growing emphasis on green building practices and sustainable infrastructure, significantly bolsters market expansion. Furthermore, the inherent durability and long lifespan of polished concrete, offering superior resistance to abrasion, impact, and chemical spills, makes it a preferred choice for various end-users seeking long-term value.

However, the market also faces certain restraints, such as the relatively high initial capital investment required for specialized equipment and skilled labor, which can deter smaller contractors or projects with limited budgets. The presence of alternative flooring materials, including epoxy coatings, vinyl, and tile, presents a competitive challenge. Operational challenges like dust generation during the grinding process and the need for specialized application techniques also act as limiting factors. Despite these, opportunities abound in technological advancements, such as the development of advanced nano-silicate densifiers and more efficient polishing tools, alongside the untapped potential in renovation projects and the increasing adoption of polished concrete in the residential sector.

The market is further influenced by broader impact forces including rapid urbanization and industrialization, which fuel the construction of new facilities requiring durable flooring. Shifting consumer preferences towards sustainable and health-conscious building materials also play a crucial role. Regulatory frameworks promoting environmental safety and indoor air quality indirectly boost the demand for low-VOC (Volatile Organic Compound) concrete densifiers and sealers. Lastly, advancements in construction techniques and material science continually introduce innovative solutions, refining the market landscape and encouraging wider adoption of concrete densification and polishing as a premium flooring solution.

Segmentation Analysis

The Concrete Densification & Polishing Material Market is comprehensively segmented based on various critical parameters, including product type, chemical type, application area, end-use industry, and geographic region. This segmentation provides a granular view of market dynamics, allowing stakeholders to identify key growth pockets and strategic opportunities. The diverse range of products available caters to specific performance requirements and aesthetic preferences, reflecting the versatility of concrete as a flooring medium. Understanding these segments is crucial for manufacturers to tailor their offerings and for consumers to make informed decisions based on their project needs and budget.

- By Product Type:

- Densifiers (Liquid Silicate Hardeners)

- Polishing Abrasives (Diamond Pads, Grinding Discs)

- Sealants and Protectors (Acrylic, Urethane, Epoxy, Penetrating)

- Grouts and Patching Materials

- Cleaning and Maintenance Products

- By Chemical Type (for Densifiers):

- Sodium Silicate

- Potassium Silicate

- Lithium Silicate

- Colloidal Silica

- Magnesium Fluorosilicate

- By Application:

- Industrial (Warehouses, Manufacturing Plants, Distribution Centers)

- Commercial (Retail Stores, Shopping Malls, Offices, Restaurants)

- Institutional (Hospitals, Schools, Libraries, Museums)

- Residential (Garages, Basements, Living Spaces)

- Infrastructure (Airports, Bridges, Public Spaces)

- By End-Use Industry:

- Construction and Infrastructure

- Automotive

- Food and Beverage

- Healthcare

- Retail

- Logistics

- Education

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Value Chain Analysis For Concrete Densification & Polishing Material Market

The value chain for the Concrete Densification & Polishing Material Market encompasses a series of interconnected activities, beginning with the sourcing of raw materials and culminating in the application and maintenance of finished concrete floors. Upstream activities involve the extraction and processing of essential raw materials such as silica, alkali metals (sodium, potassium, lithium), polymers, and various abrasive components like industrial diamonds. These raw materials are then supplied to chemical manufacturers who formulate densifiers, sealers, and other liquid treatments, as well as to manufacturers of specialized grinding and polishing equipment and abrasive tools. The quality and availability of these raw materials significantly influence the cost and performance of the final products.

Midstream activities involve the manufacturing, blending, and packaging of densifiers, sealers, and other chemical solutions, alongside the production of various grits of diamond abrasives and sophisticated grinding machines. These products are then distributed through a network of wholesalers, specialized building material suppliers, and direct sales channels to reach the end-users. Downstream activities are dominated by flooring contractors and construction companies who perform the actual application of densifiers, grinding, and polishing of concrete surfaces. These contractors often rely on specialized training and expertise to ensure proper execution and achieve the desired finish. The effectiveness of the entire value chain is heavily dependent on efficient logistics and strong relationships between manufacturers, distributors, and applicators.

Distribution channels are critical in connecting manufacturers with a diverse customer base. Direct sales are often employed for large industrial projects or key accounts, allowing for customized solutions and direct technical support. Indirect channels, primarily through distributors and retailers, serve a broader market, including smaller contractors, architects, and designers. Online platforms are also gaining traction, offering a convenient way for professionals and DIY enthusiasts to procure materials. The choice of distribution channel can impact market reach, pricing strategies, and customer service efficiency, highlighting the importance of a well-optimized distribution network for sustainable market growth and penetration.

Concrete Densification & Polishing Material Market Potential Customers

The Concrete Densification & Polishing Material Market targets a broad spectrum of end-users and buyers, primarily those seeking durable, low-maintenance, and aesthetically pleasing flooring solutions for various types of facilities. Industrial facility owners represent a significant customer segment, including warehouses, logistics centers, manufacturing plants, and automotive facilities, all of whom require flooring capable of withstanding heavy traffic, chemical spills, and significant wear and tear. Commercial property developers and retail chains are also key customers, as polished concrete offers a modern, attractive, and long-lasting surface that enhances the customer experience while minimizing operational costs, making it ideal for shopping malls, grocery stores, and showrooms.

Institutional clients, such as hospitals, schools, universities, and government buildings, are increasingly adopting polished concrete due to its hygienic properties, ease of cleaning, and ability to improve indoor air quality by reducing dust and allergens. The absence of grout lines and the seamless nature of polished concrete floors contribute to superior sanitation standards, a critical factor in these environments. Furthermore, construction companies and independent flooring contractors are crucial intermediaries, acting as direct buyers of these materials and services for their various projects. They are responsible for specifying and applying these solutions, making their understanding and acceptance of products vital for market penetration.

Beyond these major segments, the residential sector is an emerging area of demand, particularly for high-end homes, basements, and garages where homeowners desire a unique, durable, and contemporary flooring option. Architects, interior designers, and facility managers also play an influential role as specifiers, guiding their clients towards concrete densification and polishing solutions based on performance, sustainability, and design aesthetics. The market's potential customers are thus diverse, spanning multiple sectors, each driven by specific functional, economic, and aesthetic requirements for their flooring infrastructure.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $7.5 Billion |

| Market Forecast in 2032 | $12.0 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Prosoco, W. R. Meadows, Euclid Chemical, FGS PermaShine (Laticrete), Curecrete Distribution (Ashford Formula, RetroPlate), Vexcon Chemicals, BASF SE, Sika AG, PPG Industries, Sherwin-Williams Company, Diamatic USA, Husqvarna AB, HTC Group, Klindex, WerkMaster Grinders & Sanders |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Concrete Densification & Polishing Material Market Key Technology Landscape

The Concrete Densification & Polishing Material Market is continually evolving, driven by advancements in material science and equipment engineering, aiming for improved performance, efficiency, and sustainability. A significant technological trend is the development of advanced chemical formulations for densifiers, particularly next-generation lithium and colloidal silicates. These newer formulations offer superior penetration, faster curing times, and enhanced hardness and abrasion resistance compared to traditional sodium or potassium silicates. Innovations in penetrating sealers, including those with nano-technology, provide better stain protection and longevity without altering the concrete's natural breathability or appearance, meeting demands for both protection and aesthetic preservation.

In terms of equipment, the market has seen considerable progress in grinding and polishing machinery. Modern planetary grinders feature more powerful motors, variable speed controls, and ergonomic designs, leading to more efficient material removal and finer finishes. The introduction of advanced diamond tooling, including hybrid pads and specialized resin-bonded diamonds, allows for more aggressive grinding and finer polishing steps, significantly reducing project completion times and enhancing finish quality. Dust extraction systems have also become more sophisticated, incorporating HEPA filters and improved suction capabilities to ensure cleaner, safer work environments, adhering to stricter health and safety regulations on job sites.

Emerging technologies include smart equipment with integrated sensors and automation capabilities, enabling more precise control over the polishing process and providing real-time data on surface conditions. Robotic polishing systems are in their nascent stages but hold immense potential for automating repetitive tasks, ensuring consistent quality, and addressing labor challenges. Furthermore, advancements in concrete mix designs themselves, incorporating supplementary cementitious materials and specialized admixtures, create a more receptive substrate for densification and polishing, contributing to the overall performance and lifespan of the finished floor. These technological innovations collectively enhance the value proposition of concrete densification and polishing, solidifying its position as a preferred flooring solution.

Regional Highlights

- North America: A mature market characterized by a high adoption rate in industrial and commercial sectors. Strong emphasis on sustainability, building renovations, and compliance with stringent indoor air quality standards. The United States and Canada are key contributors, driven by a stable construction industry and a preference for durable, low-maintenance flooring.

- Europe: Exhibits steady growth, propelled by robust commercial and institutional construction, particularly in Germany, the UK, and France. Stringent environmental regulations and a focus on aesthetically pleasing, long-lasting building materials drive innovation and adoption. Renovation of existing infrastructure is a significant market segment.

- Asia Pacific (APAC): The fastest-growing region, fueled by rapid urbanization, industrialization, and massive infrastructure development projects, especially in China, India, Japan, and Australia. Increasing foreign investments in manufacturing and retail sectors further boost demand for high-performance concrete flooring.

- Latin America: An emerging market with significant growth potential, primarily driven by increasing investments in commercial and industrial construction across Brazil, Mexico, and Argentina. Expanding retail infrastructure and growing awareness of the benefits of polished concrete contribute to market expansion.

- Middle East and Africa (MEA): Witnessing considerable growth due to large-scale construction projects in the UAE, Saudi Arabia, and Qatar, particularly in commercial, hospitality, and retail sectors. Government initiatives to diversify economies and enhance urban infrastructure are key drivers for the adoption of modern flooring solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Concrete Densification & Polishing Material Market.- Prosoco

- W. R. Meadows

- Euclid Chemical

- FGS PermaShine (Laticrete)

- Curecrete Distribution (Ashford Formula, RetroPlate)

- Vexcon Chemicals

- BASF SE

- Sika AG

- PPG Industries

- Sherwin-Williams Company

- Diamatic USA

- Husqvarna AB

- HTC Group

- Klindex

- WerkMaster Grinders & Sanders

- Bartell Global

- National Flooring Equipment

- Xinxiang North Micheng Co., Ltd.

- Runyon Surface Prep

- Surie Polex

Frequently Asked Questions

What are the primary benefits of concrete densification and polishing?

Concrete densification and polishing provide numerous benefits including significantly increased floor durability, abrasion resistance, and longevity. They also offer enhanced aesthetics, improved light reflectivity, reduced maintenance costs, and a hygienic surface that resists dust and allergens. Additionally, polished concrete is considered a sustainable and eco-friendly flooring option.

How do densifiers work to improve concrete durability?

Densifiers, typically silicate-based chemicals, penetrate the concrete surface and react with calcium hydroxide to form calcium silicate hydrate (CSH). This CSH compound fills the pores within the concrete, making the surface harder, denser, and less permeable, thereby increasing its resistance to abrasion, chemicals, and moisture penetration.

What types of facilities commonly utilize polished concrete floors?

Polished concrete floors are widely utilized across various facility types due to their durability and aesthetic appeal. Common applications include industrial warehouses, manufacturing plants, retail stores, shopping malls, commercial offices, schools, hospitals, restaurants, and increasingly, residential basements and living spaces.

Is polished concrete considered a sustainable flooring option?

Yes, polished concrete is highly regarded as a sustainable flooring option. It utilizes existing concrete slabs, reducing the need for new materials. Its long lifespan, low maintenance requirements, and improved light reflectivity (reducing energy consumption for lighting) contribute to its environmental benefits. Many densifiers and sealers are also low in VOCs.

What is the typical lifespan of a properly densified and polished concrete floor?

A properly densified and polished concrete floor can last for several decades, often exceeding 20 years, with minimal maintenance. Its exceptional durability and resistance to wear and tear contribute to its extended lifespan, making it a highly cost-effective and long-term flooring solution compared to many traditional alternatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager