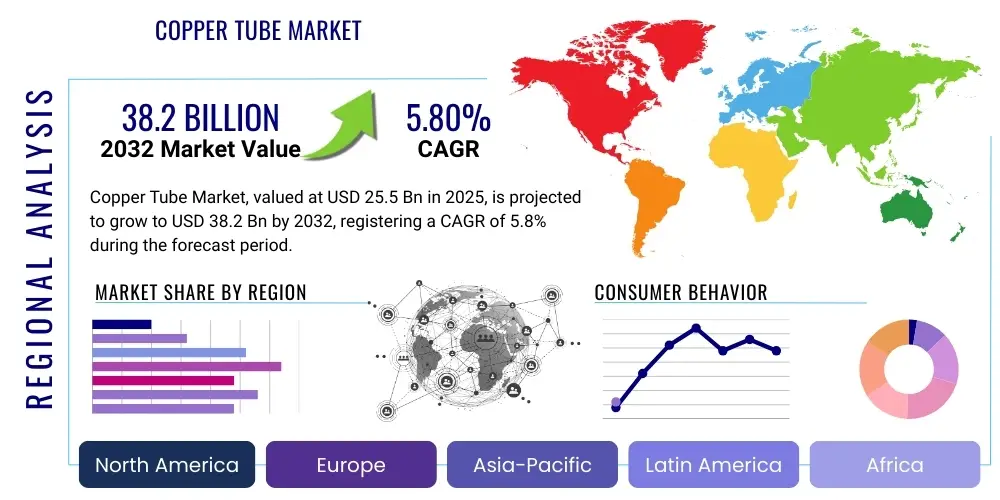

Copper Tube Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427803 | Date : Oct, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Copper Tube Market Size

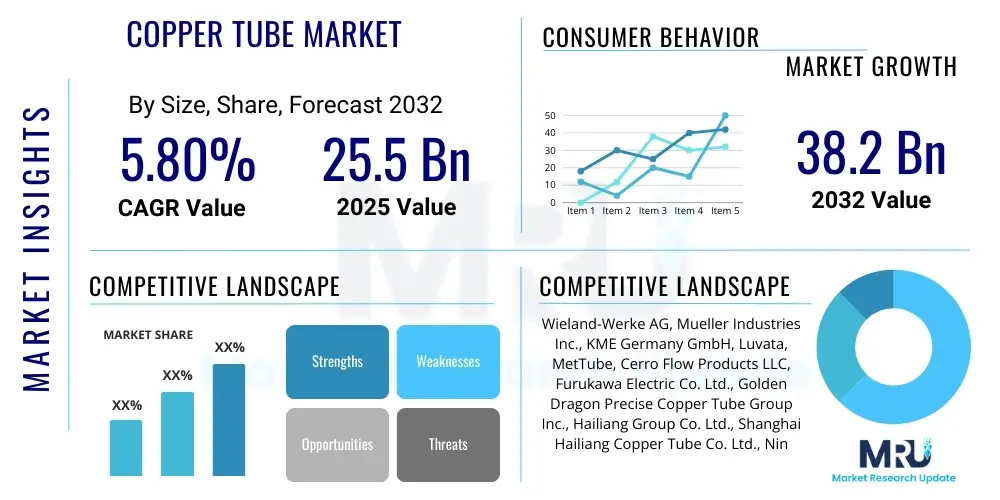

The Copper Tube Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 25.5 Billion in 2025 and is projected to reach USD 38.2 Billion by the end of the forecast period in 2032.

Copper Tube Market introduction

The copper tube market encompasses the production and distribution of tubes made from copper and its alloys, widely recognized for their excellent thermal and electrical conductivity, corrosion resistance, malleability, and durability. These tubes are manufactured through processes such as extrusion, drawing, and annealing, resulting in various forms including seamless and welded tubes. The inherent properties of copper make these tubes indispensable in a multitude of applications, ranging from domestic plumbing and refrigeration systems to complex industrial heat exchangers and advanced electrical wiring. Their long lifespan and recyclability also contribute significantly to their appeal in an increasingly sustainability-conscious global economy, positioning copper tubes as a preferred material in critical infrastructure.

Major applications for copper tubes span across several key industries. In Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC-R) systems, copper tubes are essential for refrigerant lines and heat exchangers due to their superior thermal transfer capabilities. The plumbing sector relies heavily on copper for water supply and drainage systems, benefiting from its resistance to corrosion and bacterial growth, which ensures water purity and system longevity. Furthermore, copper tubes are utilized in automotive applications, power generation, and various industrial settings where fluid conveyance, heat exchange, and electrical conductivity are paramount. The versatility and reliability of copper tubes cement their status as a foundational component in modern infrastructure and technological advancements.

The markets growth is primarily driven by several macroeconomic and industry-specific factors. Rapid urbanization and increasing global population necessitate extensive infrastructure development, particularly in residential and commercial construction, which directly fuels demand for plumbing and HVAC-R systems. Technological advancements in energy efficiency and building codes further promote the adoption of high-performance copper tubes. Moreover, the increasing demand for sustainable and recyclable materials, coupled with a rising awareness of health and safety standards in water delivery systems, reinforces the preference for copper. The expansion of industrial sectors and the growing need for efficient heat transfer solutions also contribute significantly to the markets positive trajectory, making copper tubes a vital element in global economic progress.

Copper Tube Market Executive Summary

The Copper Tube Market is experiencing robust growth, primarily propelled by burgeoning demand from the global construction industry, particularly within the HVAC-R and plumbing sectors. Business trends indicate a strong emphasis on product innovation, with manufacturers investing in advanced alloys and specialized coatings to enhance performance, durability, and energy efficiency. Sustainability initiatives are also shaping market dynamics, as the high recyclability of copper tubes aligns with green building standards and circular economy principles, driving preferential adoption over alternative materials. Furthermore, supply chain resilience and strategic partnerships are becoming critical competitive differentiators, influencing market share and operational efficiency across the value chain. Economic stability and industrial output fluctuations continue to exert influence, but the intrinsic demand for reliable fluid and heat transfer solutions underpins consistent market expansion.

Regional trends reveal distinct growth patterns and market maturity levels. Asia-Pacific stands out as the fastest-growing region, driven by rapid urbanization, massive infrastructure projects, and increasing disposable incomes boosting residential and commercial construction in countries like China, India, and Southeast Asian nations. North America and Europe, while more mature, demonstrate steady demand, fueled by renovation activities, stringent environmental regulations promoting energy-efficient systems, and the replacement of aging infrastructure. The Middle East and Africa present emerging opportunities, attributed to significant investments in new city developments and expanding industrial bases. Latin America also contributes to market growth through ongoing construction activities and the modernization of its industrial landscape, albeit at a more moderate pace compared to Asia-Pacific.

Segmentation analysis highlights key areas of market activity. By type, seamless copper tubes command a significant share due to their superior pressure bearing capacity and structural integrity, favored in critical applications. Welded tubes, while offering cost advantages, find niches in less demanding applications. Application-wise, the HVAC-R segment remains the largest consumer, reflecting the global need for climate control solutions. Plumbing and industrial heat exchangers also represent substantial and growing segments. End-use industries such as residential and commercial construction, manufacturing, and automotive are primary demand generators, with increasing focus on energy efficiency and system longevity influencing purchasing decisions. The interplay of these trends underscores a dynamic and evolving market, where quality, sustainability, and technological advancements are pivotal for sustained success.

AI Impact Analysis on Copper Tube Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the copper tube market, focusing on optimizing manufacturing processes, enhancing product quality, streamlining supply chains, and predicting market demand. Common questions revolve around AIs capability to reduce waste, improve operational efficiency, and accelerate innovation in material science and production techniques. There is keen interest in how AI can address the volatility of raw material prices and contribute to more sustainable manufacturing practices. The overarching theme is an expectation that AI will usher in a new era of precision, predictability, and competitive advantage for manufacturers and distributors in the copper tube sector.

- AI-driven predictive maintenance for manufacturing equipment, reducing downtime and optimizing operational efficiency.

- Enhanced quality control through computer vision and machine learning algorithms, identifying defects with higher accuracy and speed.

- Supply chain optimization using AI for demand forecasting, inventory management, and logistics planning, minimizing costs and improving delivery times.

- Accelerated research and development of new copper alloys and composite materials through AI-powered material design and simulation.

- Real-time monitoring and control of production parameters, leading to improved energy efficiency and reduced material waste.

- Automated anomaly detection in production data, enabling proactive problem-solving and consistent product quality.

- Personalized customer engagement and sales forecasting based on AI analysis of market trends and customer behavior.

DRO & Impact Forces Of Copper Tube Market

The Copper Tube Market is significantly influenced by a confluence of drivers, restraints, opportunities, and external impact forces. A primary driver is the accelerating pace of global urbanization and the resultant surge in infrastructure development, particularly within residential, commercial, and industrial construction sectors. This directly fuels demand for HVAC-R systems, plumbing, and various industrial applications where copper tubes are essential. The increasing focus on energy efficiency in building codes and appliance standards further propels the adoption of high-performance copper tubes due to their superior thermal conductivity. Additionally, the inherent properties of copper, such as its corrosion resistance and recyclability, align well with growing environmental consciousness and sustainability initiatives, reinforcing its market position.

However, several restraints challenge market expansion. The volatile pricing of copper, a primary raw material, significantly impacts manufacturing costs and profit margins, leading to pricing instability in the finished product market. Competition from alternative materials, such as PEX, PVC, and stainless steel, particularly in plumbing and certain industrial applications, poses a threat, especially in cost-sensitive segments. Environmental regulations related to mining and smelting operations, coupled with concerns over the social and environmental impact of copper extraction, can also constrain supply and increase production costs. Global economic downturns and fluctuations in construction activity directly affect demand, creating market uncertainties that manufacturers must navigate.

Opportunities for growth are abundant and diverse. The increasing adoption of renewable energy technologies, such as solar thermal systems and heat pumps, offers new avenues for copper tube applications due to their heat transfer capabilities. Expanding demand from emerging economies, where rapid industrialization and population growth are driving new construction and infrastructure projects, presents substantial market potential. Innovations in manufacturing processes, including advanced alloying and surface treatments, are creating opportunities for specialized, higher-value copper tube products with enhanced performance characteristics. Furthermore, the push towards smart cities and green buildings globally is expected to further integrate copper solutions due to their longevity, efficiency, and sustainability attributes.

Segmentation Analysis

The copper tube market is comprehensively segmented to provide a detailed understanding of its various facets, allowing for targeted analysis and strategic planning. These segmentations are typically based on the product type, the specific application areas, and the end-use industries, reflecting the diverse demand landscape for copper tubes globally. Understanding these divisions is crucial for identifying key growth drivers, competitive landscapes, and emerging opportunities across different market niches. Each segment exhibits unique characteristics, consumer preferences, and growth trajectories, contributing to the overall market dynamics and requiring tailored approaches for market penetration and expansion.

- By Type:

- Seamless Copper Tubes: Favored for high-pressure applications and where structural integrity is paramount, such as in HVAC-R systems and industrial heat exchangers, due to their uniform wall thickness and lack of welding seams.

- Welded Copper Tubes: Produced by welding copper strips, offering cost-effectiveness and flexibility for less critical applications or those requiring larger diameters, often used in less demanding plumbing or automotive systems.

- By Application:

- Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC-R): The largest application segment, driven by global demand for climate control, with copper tubes serving as essential refrigerant lines and heat exchange coils.

- Plumbing: Critical for residential and commercial water supply and drainage systems, valued for corrosion resistance, antimicrobial properties, and durability.

- Industrial Heat Exchangers: Utilized in various industrial processes for efficient heat transfer, including power generation, chemical processing, and marine applications.

- Electrical Applications: Found in electrical wiring, busbars, and components where high electrical conductivity is required, though less prominent for tubular forms.

- Others: Includes automotive (brake lines, fuel lines), medical gas lines, and general engineering applications.

- By End-Use Industry:

- Construction (Residential & Commercial): Directly linked to building activities, encompassing both new construction and renovation projects for plumbing and HVAC installations.

- Manufacturing: Includes industries producing appliances, automotive components, and industrial machinery that integrate copper tubes.

- Power Generation: Utilizes copper tubes in condensers and heat exchangers within power plants, including conventional and renewable energy facilities.

- Automotive: Employed in vehicle cooling systems, brake lines, and other fluid transfer applications.

- Others: Comprising sectors like marine, aerospace, and defense.

Copper Tube Market Value Chain Analysis

The value chain of the Copper Tube Market is a complex network that begins with the extraction of raw materials and extends through various processing stages to the final distribution and end-use. Upstream activities are centered around copper mining, smelting, and refining, where copper ore is transformed into pure copper cathodes or billets. This initial phase is capital-intensive and subject to global commodity price fluctuations and geopolitical factors, significantly influencing the cost structure of downstream products. Key players in this segment are large mining corporations and refining companies that ensure a consistent supply of high-quality raw copper to tube manufacturers. Efficiency and sustainability in these upstream processes are increasingly critical, driven by environmental regulations and market demand for ethically sourced materials.

Midstream activities involve the manufacturing of copper tubes from refined copper. This stage typically includes casting billets, extrusion processes to form basic tube shapes, and subsequent cold drawing and annealing operations to achieve precise dimensions, wall thicknesses, and desired mechanical properties. Advanced manufacturing techniques, such as continuous casting and specialized drawing machines, are employed to enhance efficiency and product quality. Quality control measures, including eddy current testing and ultrasonic inspection, are integral to ensure the tubes meet stringent industry standards for various applications. Manufacturers in this segment range from large multinational corporations to specialized regional producers, each contributing to the diverse product offerings available in the market.

Downstream activities encompass the fabrication, distribution, and installation of copper tubes. Fabrication may involve bending, cutting, flaring, and joining to meet specific project requirements, often performed by specialized fabricators or directly by end-users. Distribution channels are multifaceted, including direct sales from manufacturers to large industrial clients, and indirect channels through wholesalers, distributors, and retailers that serve smaller contractors and individual customers. The effectiveness of these distribution networks is crucial for market reach and timely delivery. Installation is typically performed by skilled tradespeople, such as plumbers and HVAC technicians, ensuring proper application and optimal system performance. The efficiency of the entire value chain, from raw material sourcing to final installation, directly impacts the competitiveness and overall health of the copper tube market.

Copper Tube Market Potential Customers

The potential customers for copper tubes are highly diverse, spanning across numerous industries that rely on the materials unique properties for fluid conveyance, heat exchange, and electrical applications. Primary end-users include manufacturers of HVAC-R systems, where copper tubes are indispensable for refrigerant lines and coils due to their excellent thermal conductivity and corrosion resistance. Residential and commercial construction companies are also significant buyers, utilizing copper tubes extensively in plumbing systems for water supply and drainage, valuing their durability, hygiene, and long service life. This broad base of customers underscores the foundational role copper tubes play in modern infrastructure and daily living.

Beyond construction and HVAC-R, the industrial sector represents a substantial customer segment. This includes companies involved in power generation, chemical processing, and other heavy industries that require efficient and reliable heat exchangers and fluid transfer systems. Copper tubes are preferred in these demanding environments for their ability to withstand high temperatures and pressures, as well as their resistance to various corrosive agents. The automotive industry also constitutes a niche market, using copper tubes for brake lines, fuel lines, and cooling systems in some vehicle models, appreciating their robustness and performance under challenging conditions. The diversity of these industrial applications highlights the materials adaptability and critical function across different manufacturing processes.

Moreover, the market extends to specialized applications and smaller-scale buyers. This includes medical facilities that use copper tubing for medical gas lines, benefiting from coppers antimicrobial properties. Retailers and wholesale distributors serve a multitude of small and medium-sized contractors, plumbers, and DIY enthusiasts, ensuring widespread availability for renovation, repair, and smaller-scale projects. The consistent demand from these various customer groups, driven by requirements for efficiency, reliability, and increasingly, sustainability, solidifies the enduring market for copper tubes. Understanding the distinct needs and purchasing behaviors of each customer segment is paramount for manufacturers and distributors aiming to maximize market penetration and customer satisfaction.

Copper Tube Market Key Technology Landscape

The copper tube market is characterized by a sophisticated technological landscape focused on optimizing production efficiency, enhancing product performance, and ensuring stringent quality standards. Core manufacturing technologies include continuous casting, which enables the production of high-quality copper billets directly from molten copper, minimizing material waste and energy consumption. This is followed by advanced extrusion presses that shape these billets into initial tube forms. Subsequent cold drawing processes, utilizing highly specialized dies and mandrels, reduce the tube diameter and wall thickness to precise specifications, while simultaneously increasing material strength and surface finish. Annealing, a heat treatment process, is crucial for restoring ductility and relieving internal stresses, ensuring the tubes are suitable for further processing or end-use applications. These integrated technologies are continuously refined to improve material yield, reduce cycle times, and lower overall production costs, while maintaining the superior properties inherent to copper.

Beyond primary manufacturing, the market extensively employs advanced quality control and inspection technologies to guarantee product reliability and compliance with international standards. Non-destructive testing methods such as eddy current testing are widely used to detect surface and subsurface flaws, ensuring the structural integrity of the tubes. Ultrasonic testing provides further detailed insights into wall thickness variations and internal defects, critical for high-pressure and critical applications. Automated visual inspection systems, often incorporating high-resolution cameras and image processing software, are employed for surface defect detection and dimensional accuracy verification. These technologies are instrumental in preventing defective products from reaching the market, enhancing consumer trust, and reducing warranty claims, thereby safeguarding manufacturers reputations and profitability.

Emerging technologies are also beginning to influence the copper tube market, promising further advancements in material science and production capabilities. Research into advanced copper alloys and composite materials aims to develop tubes with even greater strength, corrosion resistance, or specialized thermal properties for niche applications. Additive manufacturing (3D printing) holds potential for prototyping complex tube geometries or specialized components, though its application for mass production of standard tubes is still nascent. Furthermore, the integration of Industry 4.0 principles, including sensor technologies, IoT, and data analytics, is enabling smarter factories with real-time monitoring, predictive maintenance, and optimized process control. These technological advancements are not only improving current production paradigms but also paving the way for innovative copper tube solutions that meet future market demands for efficiency, sustainability, and performance.

Regional Highlights

- Asia-Pacific: Dominates the copper tube market due to rapid industrialization, extensive urbanization, and massive infrastructure development projects, particularly in China, India, and Southeast Asian countries. High demand from the burgeoning construction sector (both residential and commercial) and increasing adoption of HVAC-R systems are key drivers.

- North America: A mature market characterized by steady demand driven by renovation and replacement of aging infrastructure, stringent building codes promoting energy-efficient solutions, and a robust HVAC-R sector. The focus here is on high-quality, sustainable products and technological advancements.

- Europe: Exhibits stable growth, influenced by strict environmental regulations, a strong emphasis on energy efficiency in building and industrial sectors, and a move towards green construction practices. Germany, France, and the UK are significant contributors, with a focus on premium and specialized copper tube products.

- South America: An emerging market with growth potential spurred by increasing construction activities, especially in residential and commercial segments, and infrastructure investments in countries like Brazil and Argentina. Economic stability and industrial expansion will further boost demand.

- Middle East & Africa: Represents a region with significant growth opportunities, driven by large-scale infrastructure projects, new city developments, and a rising demand for air conditioning systems due to climatic conditions. Investments in industrial diversification also contribute to market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Copper Tube Market.- Wieland-Werke AG

- Mueller Industries Inc.

- KME Germany GmbH

- Luvata (Part of Mitsubishi Materials Corporation)

- MetTube (Malaysia)

- Cerro Flow Products LLC

- Furukawa Electric Co. Ltd.

- Golden Dragon Precise Copper Tube Group Inc.

- Hailiang Group Co. Ltd.

- Shanghai Hailiang Copper Tube Co. Ltd.

- Ningbo Jintian Copper (Group) Co., Ltd.

- CHALCO (Aluminum Corporation of China Limited)

- JMF Company

- Lawton Tubes

- Wednesbury Tube (A Division of Delta Group)

Frequently Asked Questions

What are the primary applications of copper tubes?

Copper tubes are predominantly used in Heating, Ventilation, Air Conditioning, and Refrigeration (HVAC-R) systems, plumbing for water supply and drainage, and various industrial heat exchangers due to their excellent thermal conductivity and corrosion resistance.

How does the price of copper impact the copper tube market?

Copper tube market prices are significantly affected by the volatility of raw copper prices, as copper is the primary material. Fluctuations can lead to increased manufacturing costs, impacting product pricing, profit margins, and overall market stability for producers and consumers.

What drives the growth of the copper tube market?

The markets growth is primarily driven by global urbanization, extensive infrastructure development, increasing demand for HVAC-R systems, stringent building codes promoting energy efficiency, and a growing emphasis on sustainable and recyclable construction materials.

What role does sustainability play in the copper tube industry?

Sustainability is crucial, as copper tubes are highly recyclable, contributing to a circular economy and reducing environmental impact. Their durability and long lifespan also minimize replacement needs, aligning with green building standards and consumer demand for eco-friendly products.

Which regions are major consumers of copper tubes?

Asia-Pacific is the largest and fastest-growing consumer due to rapid industrialization and construction. North America and Europe are mature markets with steady demand, driven by renovation and efficiency upgrades. The Middle East and Africa show significant emerging growth potential.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager