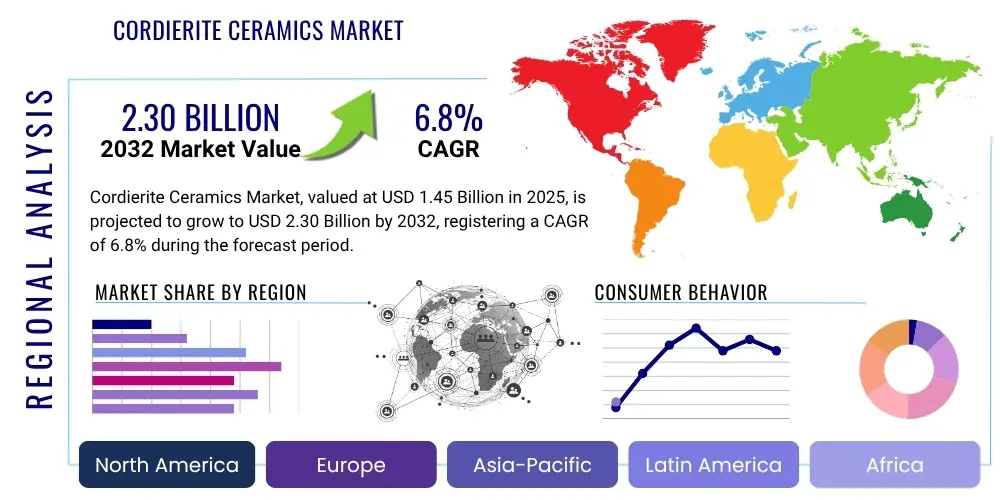

Cordierite Ceramics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 428439 | Date : Oct, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Cordierite Ceramics Market Size

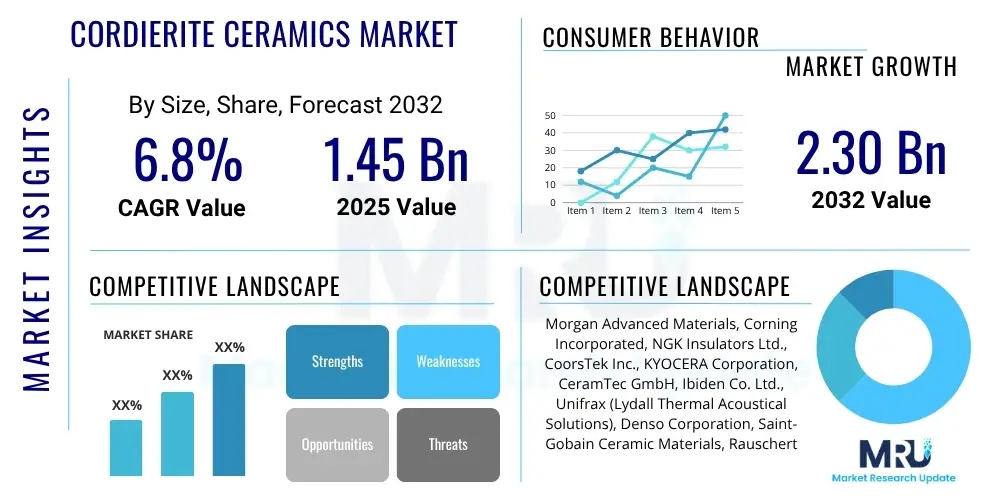

The Cordierite Ceramics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2025 and 2032. The market is estimated at USD 1.45 billion in 2025 and is projected to reach USD 2.30 billion by the end of the forecast period in 2032.

Cordierite Ceramics Market introduction

The Cordierite Ceramics Market encompasses the production and distribution of materials primarily composed of magnesium aluminum silicate, known for their exceptional thermomechanical properties. These advanced ceramic materials are characterized by their remarkably low thermal expansion coefficient, high resistance to thermal shock, and excellent dielectric characteristics, making them indispensable in applications requiring stability under extreme temperature fluctuations.

Cordierite ceramics are utilized across a diverse range of industries due to their unique combination of properties. Key applications include catalytic converters and diesel particulate filters in the automotive sector, heat exchangers, kiln furniture in industrial high-temperature processing, and electrical insulators in electronics. Their ability to withstand rapid heating and cooling cycles without degradation, coupled with chemical inertness, positions them as a critical material solution.

The market's growth is predominantly driven by the surging demand from the automotive industry, particularly with the increasing adoption of more stringent emission standards globally. Furthermore, the push towards energy-efficient industrial processes and the continuous innovation in the electronics sector for miniaturized and high-performance components are significant contributing factors. The inherent benefits of cordierite, such as its lightweight nature and robust performance in harsh environments, continue to fuel its market expansion.

Cordierite Ceramics Market Executive Summary

The global Cordierite Ceramics Market is experiencing robust expansion, largely propelled by escalating demand within the automotive industry, particularly for emission control systems like catalytic converters and diesel particulate filters. Business trends indicate a strong emphasis on research and development, focusing on enhancing material properties such as improved porosity control and mechanical strength, alongside the exploration of advanced manufacturing techniques like additive manufacturing. Strategic collaborations and mergers and acquisitions are also prevalent, aimed at consolidating market share and fostering technological advancements, leading to a more competitive landscape and diversified product offerings.

Regionally, the Asia Pacific continues to dominate the market, primarily due to the rapid growth of its automotive manufacturing base, coupled with extensive industrialization and infrastructure development in countries such as China and India. Europe and North America exhibit mature markets characterized by stringent environmental regulations driving innovation in automotive emissions control and a consistent demand from specialized industrial and electronics applications. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, fueled by industrial expansion and increasing vehicle parc.

Segment-wise, the automotive application segment remains the largest and fastest-growing, reflecting the global imperative for reduced vehicular emissions. The electronics and industrial sectors also contribute significantly, driven by demand for high-performance insulators, kiln furniture, and components for thermal management. Future trends suggest a shift towards more customized solutions and the development of advanced cordierite composites to meet evolving industrial requirements, further diversifying revenue streams and application areas for market players.

AI Impact Analysis on Cordierite Ceramics Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Cordierite Ceramics Market predominantly revolve around optimizing manufacturing processes, accelerating material innovation, and enhancing quality control. Users are keen to understand how AI can improve efficiency, reduce production costs, predict material performance, and aid in the design of novel cordierite formulations. There is a clear expectation that AI will streamline complex operations, from raw material selection to final product inspection, ultimately leading to higher yields and superior product characteristics, while also providing predictive insights into market trends and supply chain dynamics.

- AI driven process optimization: Machine learning algorithms can analyze vast datasets from manufacturing operations to identify optimal parameters for mixing, extrusion, sintering, and firing, leading to reduced energy consumption, waste, and improved yield.

- Predictive maintenance: AI models can monitor equipment performance in real-time, forecasting potential failures and enabling proactive maintenance, thus minimizing downtime and extending the lifespan of machinery used in cordierite production.

- Enhanced quality control: Computer vision and AI analytics can detect microscopic defects or inconsistencies in ceramic products faster and more accurately than manual inspection, ensuring adherence to stringent quality standards.

- Accelerated material design and discovery: AI can simulate and predict the properties of new cordierite compositions, significantly reducing the time and cost associated with traditional trial-and-error R&D cycles for developing advanced ceramics with tailored properties.

- Supply chain optimization: AI algorithms can improve inventory management, forecast demand fluctuations, and optimize logistics for raw materials and finished goods, leading to greater supply chain resilience and cost efficiency.

DRO & Impact Forces Of Cordierite Ceramics Market

The Cordierite Ceramics Market is significantly shaped by a confluence of driving forces, inherent restraints, and emerging opportunities, all interacting to create dynamic impact forces. The primary drivers include the burgeoning global automotive industry, particularly the escalating demand for emission control systems such as catalytic converters and diesel particulate filters, which heavily rely on cordierite for their thermal stability. Additionally, the increasing focus on energy efficiency in industrial applications and the continuous advancement in electronic devices demanding lightweight, thermally stable, and electrically insulating materials further propel market growth. These factors underscore the essential role of cordierite in modern manufacturing and environmental protection.

However, the market also faces notable restraints that temper its expansion. High manufacturing costs associated with the complex production processes of cordierite ceramics, including precision molding and high-temperature sintering, pose a challenge. Furthermore, the availability of alternative materials, though often lacking the unique combination of properties offered by cordierite, presents competitive pressure in certain applications. Fluctuations in the prices of key raw materials like magnesia, alumina, and silica can also impact production costs and overall market stability, necessitating robust supply chain management strategies for manufacturers.

Despite these restraints, significant opportunities are emerging for market participants. The growth of new application areas, such as components for electric vehicles (EVs) requiring advanced thermal management and lightweighting, and components for renewable energy systems like fuel cells and concentrated solar power, offers substantial growth avenues. Technological advancements in processing methods, including additive manufacturing of ceramics, promise to enhance production efficiency, enable intricate designs, and potentially lower costs. The ongoing trend towards miniaturization in electronics and the demand for high-performance materials in aerospace and defense sectors also present lucrative opportunities for specialized cordierite products, driving innovation and market diversification.

Segmentation Analysis

The Cordierite Ceramics Market is comprehensively segmented to provide granular insights into its diverse applications, material types, and end-use industries. This segmentation helps in understanding the specific drivers and challenges pertinent to each category, enabling stakeholders to formulate targeted strategies and capitalize on distinct market opportunities. The robust properties of cordierite ceramics lend themselves to a wide array of uses, necessitating a detailed breakdown of the market landscape to accurately assess its current state and future potential across various verticals and product forms.

- By Type

- Dense Cordierite

- Porous Cordierite

- By Application

- Catalytic Converters

- Diesel Particulate Filters (DPF)

- Heat Exchangers

- Kiln Furniture

- Electrical Insulators

- Ceramic Substrates

- Burner Nozzles

- Refractory Components

- Others (e.g., consumer goods, laboratory ware)

- By End-Use Industry

- Automotive

- Electronics and Electrical

- Industrial (e.g., Metallurgy, Chemical, Glass)

- Consumer Goods

- Aerospace and Defense

- Energy and Environment

- Healthcare

- By Form

- Extruded Parts

- Pressed Parts

- Cast Parts

- Injection Molded Parts

- Machined Parts

Value Chain Analysis For Cordierite Ceramics Market

The value chain for the Cordierite Ceramics Market begins with the upstream activities involving the sourcing and processing of raw materials. This stage is crucial as the purity and consistency of materials such as magnesia, alumina, and silica directly impact the final ceramic properties. Key suppliers in this segment focus on mining, refining, and preparing these raw materials to meet stringent industrial specifications. Strategic partnerships with raw material providers are essential for manufacturers to ensure a stable supply chain and cost efficiency, especially given potential geopolitical influences on material availability.

Midstream activities encompass the manufacturing process of cordierite ceramics, which involves several complex steps including mixing, forming (e.g., extrusion, dry pressing, slip casting, injection molding), drying, and high-temperature sintering. This stage is highly capital-intensive and requires specialized expertise and technology to produce high-quality, defect-free ceramic components. Manufacturers often invest heavily in research and development to optimize these processes, improve material properties, and develop new forming techniques like additive manufacturing for intricate designs. Quality control and assurance are paramount at every stage to meet the demanding performance requirements of various end-user applications.

Downstream activities involve the distribution, sales, and end-use application of cordierite ceramic products. Distribution channels are varied, including direct sales to large automotive OEMs or electronics manufacturers, and indirect channels through specialized distributors or agents for smaller industrial clients or custom orders. The choice of channel depends on the market segment, geographical reach, and the complexity of the product. The strong technical support and application engineering services provided by manufacturers or their distributors are often critical in assisting end-users with product selection, integration, and performance optimization, thereby enhancing customer satisfaction and loyalty in a highly specialized market.

Cordierite Ceramics Market Potential Customers

The Cordierite Ceramics Market caters to a diverse range of end-users and buyers, spanning multiple industrial sectors that require materials with exceptional thermal stability, low thermal expansion, and good dielectric properties. Foremost among these are the automotive original equipment manufacturers (OEMs) and their Tier 1 suppliers, who utilize cordierite for critical components in emission control systems, such as catalytic converter substrates and diesel particulate filters. The stringent global regulations on vehicular emissions continue to drive the demand from this sector, making it a cornerstone of the cordierite market.

Beyond the automotive industry, manufacturers in the electronics and electrical sectors represent a significant customer base. These companies employ cordierite ceramics for insulating substrates, coil formers, heating element supports, and other components where electrical insulation combined with thermal shock resistance is essential. The ongoing miniaturization of electronic devices and the demand for high-performance components in telecommunications, computing, and consumer electronics further solidify this segment as a key area for cordierite ceramic adoption.

Furthermore, various industrial sectors serve as crucial end-users. Manufacturers of industrial furnaces, kilns, and thermal processing equipment frequently purchase cordierite ceramics for kiln furniture, saggers, and other refractory components due to their ability to withstand extreme temperatures and repeated thermal cycling. The chemical processing, metallurgy, and glass industries also rely on cordierite for specialized parts requiring chemical inertness and high-temperature performance. Emerging applications in renewable energy and aerospace further expand the potential customer landscape, highlighting the material's versatility and critical role in advanced technological applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 1.45 Billion |

| Market Forecast in 2032 | USD 2.30 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Morgan Advanced Materials, Corning Incorporated, NGK Insulators Ltd., CoorsTek Inc., KYOCERA Corporation, CeramTec GmbH, Ibiden Co. Ltd., Unifrax (Lydall Thermal Acoustical Solutions), Denso Corporation, Saint-Gobain Ceramic Materials, Rauschert GmbH, Vesuvius plc, Wacker Chemie AG, Zircar Ceramics Inc., Insulcon Group, Du-Co Ceramics Company, Mantec Technical Ceramics, Dyson Technical Ceramics, Advanced Ceramics Manufacturing, CUMI Murugappa |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cordierite Ceramics Market Key Technology Landscape

The technological landscape of the Cordierite Ceramics Market is characterized by continuous advancements aimed at improving material properties, manufacturing efficiency, and expanding application possibilities. Traditional ceramic processing techniques such as extrusion, dry pressing, and slip casting remain fundamental for producing a wide range of cordierite components. These methods are constantly being refined to achieve higher precision, better surface finish, and more consistent material density, especially for complex geometries required in automotive and industrial applications. Innovations in binder systems and additives are also crucial for enhancing green strength and reducing defects during the forming stage.

Significant progress is being made in sintering technologies, moving towards more controlled and energy-efficient firing cycles. Advanced sintering techniques, including spark plasma sintering (SPS) and microwave sintering, are being explored to achieve finer microstructures, improved mechanical properties, and reduced processing times compared to conventional methods. These technologies allow for better control over grain growth and porosity, which are critical factors influencing the performance of cordierite ceramics, particularly in demanding environments where thermal shock resistance and strength are paramount.

Furthermore, the emergence of advanced manufacturing techniques like additive manufacturing (3D printing) is revolutionizing the production of cordierite ceramics. Technologies such as stereolithography (SLA), binder jetting, and material extrusion are enabling the creation of highly intricate and customized cordierite components with complex internal geometries that are impossible to achieve with traditional methods. This offers unprecedented opportunities for designing lighter, more efficient, and specialized parts for aerospace, biomedical, and advanced thermal management applications, significantly expanding the market potential and driving future innovation in the cordierite ceramics industry.

Regional Highlights

- Asia Pacific: This region is projected to be the largest and fastest-growing market for cordierite ceramics, driven by robust growth in the automotive industry, particularly in countries like China, India, Japan, and South Korea. Rapid industrialization, increasing demand for energy-efficient materials, and expanding electronics manufacturing also contribute significantly to market expansion.

- Europe: The European market holds a substantial share, primarily due to stringent environmental regulations enforcing lower vehicular emissions, leading to high demand for catalytic converters and DPFs. Advanced R&D capabilities and a strong focus on high-performance industrial and aerospace applications further bolster the market in countries such as Germany, France, and the UK.

- North America: This region demonstrates a mature market with a consistent demand from the automotive, electronics, and industrial sectors. Innovation in material science and increasing investments in electric vehicle (EV) technologies and advanced manufacturing are key drivers, particularly in the United States and Canada.

- Latin America: An emerging market for cordierite ceramics, characterized by developing automotive industries and growing industrial infrastructure. Countries like Brazil and Mexico are witnessing increasing demand, albeit from a lower base, as their manufacturing capabilities expand.

- Middle East and Africa (MEA): This region is experiencing nascent growth, driven by infrastructure development projects, investments in diversified industrial sectors, and a gradual increase in vehicle production and import. The market is expected to witness steady growth as industrialization progresses.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cordierite Ceramics Market.- Morgan Advanced Materials

- Corning Incorporated

- NGK Insulators Ltd.

- CoorsTek Inc.

- KYOCERA Corporation

- CeramTec GmbH

- Ibiden Co. Ltd.

- Unifrax (Lydall Thermal Acoustical Solutions)

- Denso Corporation

- Saint-Gobain Ceramic Materials

- Rauschert GmbH

- Vesuvius plc

- Wacker Chemie AG

- Zircar Ceramics Inc.

- Insulcon Group

- Du-Co Ceramics Company

- Mantec Technical Ceramics

- Dyson Technical Ceramics

- Advanced Ceramics Manufacturing

- CUMI Murugappa

Frequently Asked Questions

What are Cordierite Ceramics primarily used for?

Cordierite ceramics are extensively used in applications requiring high thermal shock resistance and low thermal expansion, predominantly in automotive catalytic converters and diesel particulate filters, kiln furniture, heat exchangers, and electrical insulators.

Why is Cordierite considered an ideal material for high-temperature applications?

Cordierite is ideal for high-temperature applications due to its exceptionally low coefficient of thermal expansion, which minimizes material stress during rapid temperature changes, and its excellent thermal shock resistance, allowing it to withstand extreme thermal cycles without fracturing.

What are the key properties that define Cordierite Ceramics?

The defining properties of cordierite ceramics include very low thermal expansion, superior thermal shock resistance, good mechanical strength at elevated temperatures, chemical inertness, and effective dielectric insulation capabilities, making them highly versatile.

How does the automotive industry specifically benefit from Cordierite Ceramics?

The automotive industry heavily relies on cordierite ceramics for emission control systems like catalytic converters and diesel particulate filters, where its ability to withstand rapid temperature fluctuations and harsh exhaust gases is critical for efficient pollutant reduction and vehicle performance.

What are the future growth prospects for the Cordierite Ceramics Market?

The Cordierite Ceramics Market is expected to grow steadily, driven by increasing environmental regulations, expanding electric vehicle market needs for thermal management, and advancements in industrial and electronics sectors requiring high-performance, lightweight, and durable ceramic components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager