Corrugated Equipment Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430830 | Date : Nov, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Corrugated Equipment Market Size

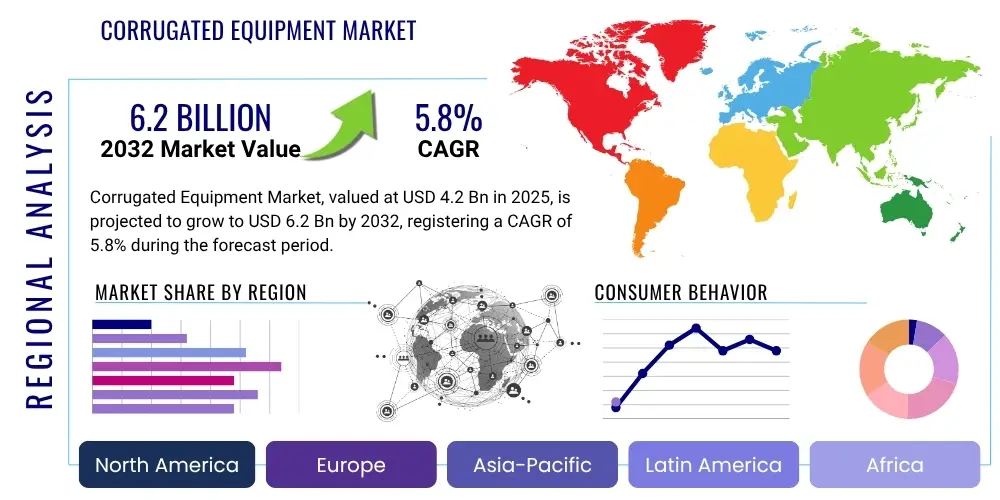

The Corrugated Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 4.2 Billion in 2025 and is projected to reach USD 6.2 Billion by the end of the forecast period in 2032.

Corrugated Equipment Market introduction

The Corrugated Equipment Market encompasses the entire spectrum of machinery and systems utilized in the production, processing, and finishing of corrugated board and packaging. This includes a wide array of sophisticated machines ranging from complete corrugators that transform paper rolls into corrugated sheets, to printing and converting equipment that shapes, folds, glues, and decorates these sheets into final corrugated boxes and displays. These highly specialized machines are critical for manufacturers within the packaging industry to meet the ever-growing global demand for sustainable and versatile packaging solutions. Major applications for corrugated equipment span across diverse sectors such as food and beverage, e-commerce, electronics, automotive, pharmaceuticals, and consumer goods, where robust, cost-effective, and customizable packaging is essential for product protection, logistics, and brand presentation.

The primary benefits derived from advanced corrugated equipment include enhanced production efficiency, superior product quality, reduced waste through optimized material usage, and increased operational flexibility to handle a variety of board types, sizes, and print specifications. Modern machinery integrates automation and precision engineering, leading to faster throughputs and lower labor costs, directly contributing to competitive advantages for manufacturers. The market is significantly driven by several macroeconomic and industry-specific factors. The relentless expansion of the e-commerce sector globally fuels demand for reliable shipping solutions, often leveraging corrugated packaging. Additionally, a growing consumer preference for sustainable and recyclable packaging materials positions corrugated board as an environmentally friendly alternative, propelling investments in advanced production capabilities. Technological advancements in automation, digital printing, and smart factory integration further serve as pivotal driving forces, enabling producers to offer high-quality, customized, and short-run packaging economically, thereby expanding the market's overall potential and reach.

Corrugated Equipment Market Executive Summary

The Corrugated Equipment Market is experiencing robust growth, primarily driven by the burgeoning e-commerce sector and increasing consumer preference for sustainable packaging solutions. Business trends indicate a strong focus on automation, digital integration, and efficiency improvements across the production value chain. Manufacturers are investing in high-speed corrugators, advanced printing technologies, and sophisticated converting machines to meet diverse customer demands, including customized packaging and shorter lead times. The competitive landscape is characterized by innovation in machine design, with a particular emphasis on reducing energy consumption and optimizing material usage. Strategic alliances, mergers, and acquisitions are also common as companies seek to expand their product portfolios and geographical reach, catering to the evolving needs of packaging producers globally. There is a clear shift towards smart manufacturing practices, where data analytics and interconnected systems enhance operational performance and predictive maintenance capabilities.

Regional trends reveal Asia Pacific as the dominant market, propelled by rapid industrialization, expanding manufacturing bases, and a significant rise in disposable incomes driving consumption across various industries. Countries like China and India are at the forefront of this growth, with substantial investments in new corrugated plants and equipment upgrades. North America and Europe also maintain significant market shares, characterized by a demand for high-quality, specialized packaging, and a strong emphasis on automation to combat rising labor costs. These regions are early adopters of advanced digital printing and smart factory solutions. Latin America, the Middle East, and Africa are emerging markets, showing considerable potential due to economic development, increasing urbanization, and growing industrial output, leading to greater demand for packaging infrastructure and equipment. Government initiatives supporting manufacturing and trade further bolster market expansion in these developing regions, making them attractive for equipment suppliers looking to broaden their global footprint.

Segmentation trends highlight the increasing demand for advanced corrugators and converting equipment that offer greater flexibility and precision. The segment for digital printing solutions is experiencing accelerated growth, driven by the need for variable data printing, personalization, and shorter production runs without the need for traditional printing plates. Automation equipment, including robotics for material handling and stacking, is also gaining significant traction as manufacturers aim to minimize human intervention, reduce errors, and improve workplace safety. Furthermore, the market is seeing a push towards modular equipment designs that allow for easier upgrades and adaptability to future technological changes. Packaging for the food and beverage industry remains a leading application segment due to its non-negotiable requirement for safe, hygienic, and visually appealing packaging, while the e-commerce segment continues its exponential growth, demanding durable and efficient shipping solutions that corrugated equipment effectively provides, influencing continuous innovation in machine capabilities.

AI Impact Analysis on Corrugated Equipment Market

Users frequently inquire about how Artificial Intelligence (AI) will revolutionize the operational efficiency, quality control, and predictive maintenance within the Corrugated Equipment Market. Common themes revolve around AI's capacity to optimize production lines, minimize material waste, enhance machine diagnostics, and facilitate customized packaging solutions. There is considerable interest in AI-driven automation for tasks like precise cutting, scoring, and folding, as well as its role in integrating complex supply chain logistics. Concerns often focus on the initial investment costs, the availability of skilled labor to manage AI systems, and the data security implications of highly interconnected manufacturing environments. Expectations are high regarding AI's potential to unlock new levels of productivity, reduce downtime, and enable corrugated packaging manufacturers to respond with unprecedented agility to fluctuating market demands and increasingly complex customer specifications, fundamentally transforming traditional manufacturing paradigms.

- AI-powered predictive maintenance reduces downtime by anticipating equipment failures.

- AI optimizes machine settings for speed, quality, and material efficiency, minimizing waste.

- Automated quality inspection systems using AI detect defects with high precision and speed.

- AI enhances production scheduling and inventory management through real-time data analysis.

- Machine learning algorithms improve energy consumption by optimizing equipment operation.

- AI facilitates customized and short-run packaging production with intelligent workflow management.

- Robotics integrated with AI streamlines material handling and stacking processes.

- Computer vision systems enable advanced sorting and quality verification.

- AI-driven analytics provide actionable insights for process improvement and operational excellence.

- Enhanced security features for connected equipment and data integrity through AI.

DRO & Impact Forces Of Corrugated Equipment Market

The Corrugated Equipment Market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, shaping its growth trajectory and future outlook. Key drivers include the exponential expansion of the e-commerce sector globally, which necessitates robust and sustainable packaging solutions, with corrugated board being a primary choice. The increasing consumer awareness and regulatory pressures for environmentally friendly packaging are also propelling demand for efficient corrugated equipment that can produce recyclable and biodegradable materials. Furthermore, rapid industrialization and urbanization, especially in emerging economies, are leading to higher consumption of packaged goods across various sectors such as food and beverage, electronics, and automotive, thereby escalating the need for advanced corrugated production capabilities. Technological advancements, including automation, digital printing, and Industry 4.0 integration, offer substantial benefits in terms of efficiency, quality, and customization, driving investments in new machinery and equipment upgrades across the industry landscape.

Conversely, several restraints impede the market's growth. The high initial capital investment required for acquiring sophisticated corrugated equipment can be a significant barrier for smaller manufacturers or those in developing regions. Fluctuations in raw material prices, particularly for paper pulp, directly impact the cost of corrugated board production, potentially dampening equipment demand. Additionally, the availability of alternative packaging materials like plastics, though less sustainable, poses a competitive challenge, especially where cost-effectiveness and specific functional properties are prioritized. The need for a skilled workforce to operate and maintain advanced, automated corrugated machinery also presents a challenge, requiring ongoing training and development. Global economic uncertainties and geopolitical tensions can also lead to reduced industrial output and investment, indirectly affecting equipment sales. The market must also contend with increasing operational costs, including energy and labor, which pressure manufacturers to seek more efficient yet costly advanced solutions.

Despite these challenges, numerous opportunities exist for market participants. The growing demand for lightweight and high-strength corrugated board offers avenues for innovation in material science and equipment design, enabling the production of more efficient packaging. The trend towards personalized and on-demand packaging, fueled by digital printing technologies, presents a lucrative niche for equipment manufacturers capable of delivering flexible and versatile solutions. Expanding into untapped geographical markets, particularly in Africa and parts of Latin America, where industrial growth is accelerating, represents significant growth potential. The continuous focus on sustainability drives opportunities for developing energy-efficient machines and processes that minimize environmental footprint, appealing to eco-conscious brands and consumers. Furthermore, the integration of advanced analytics, artificial intelligence, and Internet of Things (IoT) in corrugated equipment offers avenues for enhancing predictive maintenance, optimizing production, and improving overall operational intelligence, creating a competitive edge for innovators in the sector and attracting further investment into smart factory solutions.

Segmentation Analysis

The Corrugated Equipment Market is broadly segmented based on crucial parameters such as the type of equipment, level of automation, application in end-use industries, and geographic regions. This segmentation provides a granular view of market dynamics, enabling manufacturers and investors to identify key growth areas and tailor strategies effectively. The various equipment types, including corrugators, printing machines, and converting equipment, each cater to distinct stages of the corrugated board production process, from basic sheet formation to intricate finishing and decoration. Automation levels differentiate between manual, semi-automatic, and fully automatic systems, reflecting varying degrees of capital investment and operational efficiency requirements. The diverse applications across industries highlight the ubiquitous need for corrugated packaging, demonstrating the market's resilience and broad utility.

- By Equipment Type:

- Corrugators

- Single Facer

- Double Facer

- Cut-off Knives

- Stackers

- Printing Machines

- Flexographic Printers

- Digital Printers

- Lithographic Laminators

- Converting Equipment

- Die-Cutters (Flatbed, Rotary)

- Folder Gluers

- Stitchers

- Bundling and Strapping Machines

- Pre-feeders and Palletizers

- Ancillary Equipment

- Sheet Handling Systems

- Waste Management Systems

- Ink and Coating Systems

- Roll Stands

- Corrugators

- By Automation Level:

- Manual Equipment

- Semi-Automatic Equipment

- Fully Automatic Equipment

- By End-Use Industry:

- Food and Beverage

- E-commerce and Retail

- Electronics

- Consumer Goods

- Automotive

- Pharmaceuticals

- Industrial Packaging

- Other Manufacturing

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Value Chain Analysis For Corrugated Equipment Market

The value chain for the Corrugated Equipment Market is a complex ecosystem involving various stages, from raw material sourcing to the final delivery of equipment and after-sales services. Upstream activities primarily involve the procurement of critical components and raw materials such as steel, electronics, precision engineering parts, and specialized control systems from various suppliers. These components are essential for the manufacturing of robust, high-performance machinery. Suppliers often specialize in advanced robotics, electrical components, and software solutions that are integrated into modern corrugated equipment. The quality and availability of these upstream inputs directly influence the cost, reliability, and technological capabilities of the final machinery. Strong relationships with reliable component suppliers are crucial for maintaining production efficiency and ensuring the technological edge of equipment manufacturers.

Midstream activities encompass the design, engineering, manufacturing, and assembly of the corrugated equipment itself. This stage involves significant research and development investments to innovate machine functionalities, improve efficiency, and integrate advanced technologies like automation, digital printing, and IoT. Manufacturers of corrugators, printing machines, and converting equipment employ specialized expertise in mechanical engineering, electrical engineering, and software development to produce sophisticated systems. Production processes often involve precision machining, assembly, testing, and quality control to ensure that the equipment meets stringent performance and safety standards. Economies of scale and advanced manufacturing techniques play a vital role in optimizing production costs and improving competitive positioning within the market. Furthermore, sustainability considerations are increasingly integrated into the manufacturing process, focusing on energy-efficient designs and reduced material waste.

Downstream activities involve the distribution, sales, installation, and after-sales support for the corrugated equipment. Distribution channels can be both direct and indirect. Direct sales involve equipment manufacturers selling directly to corrugated board producers and packaging companies through their own sales teams, offering tailored solutions and direct technical support. Indirect channels include a network of distributors, agents, and value-added resellers who facilitate sales, provide local support, and sometimes offer financing solutions to end-users. After-sales services are a critical component of the value chain, encompassing installation, training, maintenance, spare parts supply, and technical assistance. These services not only ensure optimal equipment performance and longevity but also build long-term customer relationships and generate recurring revenue for equipment providers. Effective distribution and robust service networks are paramount for market penetration and customer satisfaction, especially in a globalized market where quick response times and specialized support are highly valued by clients.

Corrugated Equipment Market Potential Customers

The primary potential customers and end-users of corrugated equipment are diverse entities within the packaging and manufacturing sectors, all of whom rely on efficient and high-quality corrugated board production to support their operations. These include large-scale corrugated board manufacturers who operate integrated plants, producing corrugated sheets from raw paper and converting them into final packaging products. Independent box makers and packaging converters form another significant segment, purchasing corrugated sheets from larger producers and then utilizing specialized converting equipment to create custom boxes and displays for various industries. Furthermore, large multinational corporations with their own in-house packaging departments may also invest in corrugated equipment to achieve greater control over their supply chain, ensure specific quality standards, and respond quickly to internal packaging needs. These customers are driven by the need for cost-efficiency, production speed, product protection, and increasingly, sustainable packaging solutions.

Beyond traditional packaging producers, a growing segment of potential customers includes businesses heavily reliant on corrugated packaging for their products, such as major e-commerce retailers and food and beverage companies. While they might not directly manufacture corrugated sheets, they invest in advanced converting and finishing equipment, including digital printing solutions, to customize their packaging for branding, marketing, and operational efficiency. The demand for personalized and on-demand packaging from brands seeking to differentiate themselves in competitive markets further expands the customer base for flexible and technologically advanced corrugated equipment. Ultimately, any industry that requires robust, recyclable, and customizable packaging for shipping, storage, or retail display of their goods represents a potential customer for either new corrugated equipment or upgrades to existing machinery to enhance their packaging capabilities and meet evolving market demands.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.2 Billion |

| Market Forecast in 2032 | USD 6.2 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BHS Corrugated, BOBST, Fosber, MarquipWardUnited, Mitsubishi Heavy Industries, Dongfang Precision Group, EFI, HP, Koenig & Bauer, EMBA, G&M Corrugated, Ming Wei, Taiwan United, Shinko Machine, TCY Machine, ISOWA Corporation, Lamina System, Eterna, Vega S.p.A., Curioni Sun Teramo |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Corrugated Equipment Market Key Technology Landscape

The Corrugated Equipment Market is characterized by a rapidly evolving technological landscape, driven by the relentless pursuit of higher efficiency, greater flexibility, and superior product quality. A cornerstone of this evolution is the integration of advanced automation systems, including robotics for material handling, stacking, and palletizing, which significantly reduce labor costs and improve operational safety. Precision engineering in components like cut-off knives, single facers, and die-cutters ensures minimal waste and high accuracy in board production and converting processes. Digitalization plays a critical role, with digital printing technology gaining immense traction for its ability to enable short runs, variable data printing, and high-quality graphics directly onto corrugated board, eliminating the need for traditional printing plates and reducing setup times. This shift is particularly important for customized and on-demand packaging solutions, catering to specific brand requirements and marketing campaigns.

Furthermore, Industry 4.0 principles, encompassing the Internet of Things (IoT), Artificial Intelligence (AI), and machine learning, are becoming integral to modern corrugated equipment. IoT sensors are embedded in machinery to collect real-time data on performance, temperature, vibration, and other critical parameters, enabling predictive maintenance that minimizes unplanned downtime and extends equipment lifespan. AI algorithms analyze this vast dataset to optimize machine settings, predict potential failures, and suggest improvements for energy efficiency and material utilization. This intelligent integration allows for proactive adjustments, reduces waste, and enhances overall operational intelligence. Cloud computing facilitates data storage, analysis, and remote monitoring, providing manufacturers with unprecedented control and insight into their production lines, even across multiple facilities, thus fostering a highly interconnected and optimized manufacturing environment.

Sustainability-focused technologies are also paramount within the key technology landscape. Innovations include energy-efficient motors, regenerative drives, and optimized heating and cooling systems for corrugators, all aimed at reducing energy consumption and operational costs. Material efficiency technologies, such as advanced warp control systems and precise glue application, minimize waste during the manufacturing process. Moreover, the development of equipment capable of handling a wider range of recycled content and lighter-weight boards without compromising strength addresses the growing demand for eco-friendly packaging solutions. The adoption of modular machine designs further enhances flexibility, allowing manufacturers to easily upgrade specific components or add new functionalities without replacing the entire production line, ensuring future-proofing and adaptability to evolving market needs and technological advancements.

Regional Highlights

- Asia Pacific: This region is the largest and fastest-growing market for corrugated equipment, driven by rapid industrialization, expanding manufacturing sectors, and increasing disposable incomes in countries like China, India, Japan, and Southeast Asian nations. The booming e-commerce market and rising demand for packaged goods significantly contribute to investment in new production facilities and equipment upgrades. Government support for manufacturing and export-oriented industries further fuels market expansion.

- North America: Characterized by a mature industrial base and high adoption of advanced technologies, North America is a significant market. Demand is driven by the robust e-commerce sector, strict quality standards for packaging, and a strong emphasis on automation to optimize labor costs and enhance efficiency. The region also sees a strong trend towards sustainable and digitally printed packaging, leading to investments in sophisticated equipment.

- Europe: Europe is another key market, marked by a focus on sustainable packaging solutions, high automation levels, and a demand for high-quality, customized packaging. Countries like Germany, Italy, and the UK are prominent for their technological advancements and investment in modern, energy-efficient corrugated equipment. Environmental regulations and consumer preferences for recyclable materials are key drivers.

- Latin America: This region presents emerging opportunities due to economic growth, increasing urbanization, and expanding retail and food processing sectors. Brazil and Mexico are leading markets, with growing demand for both basic and advanced corrugated equipment to meet local and export packaging needs. Investments in infrastructure and manufacturing capabilities are expected to drive steady growth.

- Middle East and Africa (MEA): While currently a smaller market, the MEA region is projected to witness significant growth. Factors such as diversification of economies, industrial development, and growing consumer markets, particularly in countries like Saudi Arabia, UAE, and South Africa, are stimulating demand for corrugated packaging and, consequently, corrugated equipment. Infrastructure development and foreign investments are contributing to market expansion.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Corrugated Equipment Market.- BHS Corrugated

- BOBST

- Fosber

- MarquipWardUnited (BW Papersystems)

- Mitsubishi Heavy Industries Printing & Packaging Machinery, Ltd.

- Dongfang Precision Group (including FOSBER ASIA)

- EFI (Electronics For Imaging)

- HP Inc.

- Koenig & Bauer AG

- EMBA Machinery AB

- G&M Corrugated (Hangzhou Gangmei Packaging Co., Ltd.)

- Ming Wei (Shanghai Ming Wei Machinery Manufacturing Co., Ltd.)

- Taiwan United (T.U. Corrugated Supplies Co., Ltd.)

- Shinko Machine Co., Ltd.

- TCY Machine Co., Ltd.

- ISOWA Corporation

- Lamina System AB

- Eterna (Wenzhou Eterna Machinery Co., Ltd.)

- Vega S.p.A.

- Curioni Sun Teramo S.p.A.

Frequently Asked Questions

What is the projected growth rate of the Corrugated Equipment Market?

The Corrugated Equipment Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032, driven by e-commerce expansion and demand for sustainable packaging.

Which factors are driving the demand for corrugated equipment?

Key drivers include the rapid growth of the e-commerce sector, increasing preference for sustainable and recyclable packaging, global industrialization, and continuous technological advancements in automation and digital printing.

How is AI impacting the Corrugated Equipment Market?

AI is transforming the market through predictive maintenance, optimized production settings, automated quality control, enhanced production scheduling, and efficient energy consumption, leading to increased productivity and reduced downtime.

What are the main types of corrugated equipment?

The main types include Corrugators (for board production), Printing Machines (flexographic, digital), Converting Equipment (die-cutters, folder gluers), and various Ancillary Equipment for sheet handling and waste management.

Which region holds the largest share in the Corrugated Equipment Market?

Asia Pacific is currently the largest and fastest-growing market, primarily due to rapid industrialization, expanding manufacturing bases, and significant e-commerce growth in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager