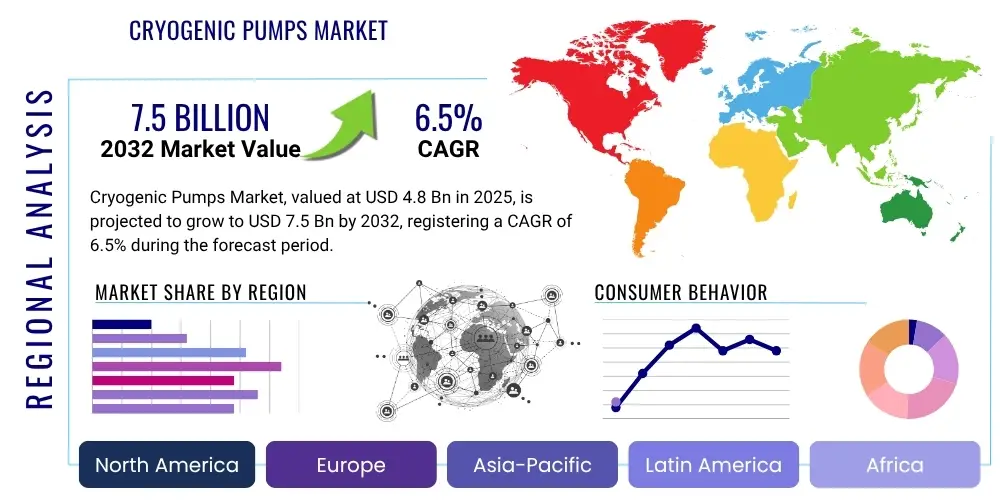

Cryogenic Pumps Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429791 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Cryogenic Pumps Market Size

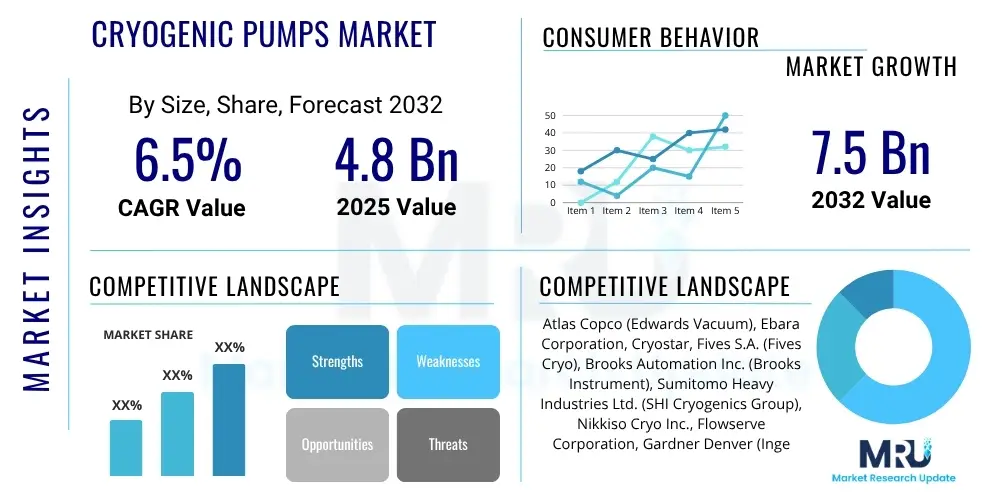

The Cryogenic Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2025 and 2032. The market is estimated at USD 4.8 Billion in 2025 and is projected to reach USD 7.5 Billion by the end of the forecast period in 2032.

Cryogenic Pumps Market introduction

Cryogenic pumps are specialized mechanical devices designed to operate at extremely low temperatures, typically below 120 Kelvin (-153 degrees Celsius or -243 degrees Fahrenheit), to handle liquefied gases such as liquid nitrogen, liquid oxygen, liquid hydrogen, and liquefied natural gas (LNG). These pumps are crucial for maintaining ultra-high vacuum environments and for the efficient transfer and storage of cryogens, which are essential across a multitude of high-tech industries. The inherent challenges of handling fluids at such low temperatures necessitate robust engineering and advanced materials to prevent issues like material embrittlement, thermal contraction, and heat leaks, making these pumps highly sophisticated pieces of equipment.

The product description for cryogenic pumps encompasses a variety of designs, including centrifugal, reciprocating, and regenerative pumps, each optimized for specific flow rates, pressures, and cryogen types. Major applications span critical sectors such as industrial gas production and distribution, liquefied natural gas (LNG) infrastructure, aerospace and defense for rocket propulsion and space simulation, advanced healthcare equipment like MRI systems and biobanking, as well as scientific research in particle physics and superconductivity. Key benefits of these pumps include their ability to achieve very low base pressures, maintain high purity of gases, provide high pumping speeds, and offer contamination-free environments, which are paramount in sensitive applications. The market is currently driven by the expanding demand for industrial gases, the global energy transition towards cleaner fuels like LNG and hydrogen, and continuous advancements in medical and research fields.

Cryogenic Pumps Market Executive Summary

The Cryogenic Pumps Market is experiencing robust growth, primarily fueled by significant business trends such as the increasing global demand for industrial gases, the expansion of liquefied natural gas (LNG) infrastructure, and the surging investment in advanced research and development in quantum computing, space exploration, and medical imaging. These trends underscore a critical need for efficient and reliable cryogenic fluid management. Technological advancements, including the integration of smart sensors for predictive maintenance and the development of more energy-efficient pump designs, are further enhancing market prospects and driving product innovation.

Regionally, the market exhibits diverse growth patterns. Asia Pacific stands out as a rapidly expanding market due to its burgeoning industrial sector, growing energy demands, and increasing investment in cryogenics for manufacturing and healthcare. North America and Europe, while mature, continue to be significant contributors, driven by stringent quality standards in industrial gas applications, advanced aerospace programs, and a strong presence of R&D institutions. These regions also lead in the adoption of advanced pumping technologies and digitalization within cryogenic systems. Segment-wise, centrifugal pumps are seeing increased adoption for high-flow applications, while positive displacement pumps remain crucial for high-pressure, low-flow scenarios. The LNG and industrial gas segments are projected to maintain their dominant market shares, with healthcare and semiconductor manufacturing emerging as high-growth application areas.

AI Impact Analysis on Cryogenic Pumps Market

Users frequently inquire about how artificial intelligence can transform the operational efficiency and reliability of cryogenic pump systems, highlighting expectations for predictive maintenance capabilities, enhanced process control, and optimized energy consumption. There is keen interest in AI's role in diagnosing potential faults before they lead to downtime, thereby reducing maintenance costs and improving safety. Users are also exploring how AI can integrate complex data streams from various sensors to provide real-time insights, enabling more precise control over cryogenic processes and ensuring optimal performance under varying load conditions. Concerns often revolve around the initial investment in AI infrastructure, data security for sensitive operational data, and the availability of a skilled workforce capable of implementing and managing AI-driven systems within a specialized field like cryogenics. Overall, the sentiment is one of cautious optimism, with a strong emphasis on practical, tangible benefits that AI can deliver to address long-standing operational challenges.

- AI-driven predictive maintenance for early fault detection and reduced downtime.

- Optimized pump operation and energy efficiency through real-time data analysis.

- Enhanced process control and automation in cryogenic fluid transfer and storage.

- Improved safety protocols by identifying potential operational risks via AI algorithms.

- Development of smart diagnostics and remote monitoring capabilities for pumps.

- Facilitation of autonomous decision-making in complex cryogenic systems.

- Better resource allocation and inventory management for spare parts based on AI forecasts.

- Advanced data analytics for identifying patterns and improving overall system reliability.

DRO & Impact Forces Of Cryogenic Pumps Market

The Cryogenic Pumps Market is primarily driven by the escalating demand for industrial gases such as nitrogen, oxygen, and argon across various manufacturing sectors, coupled with the rapid expansion of the global liquefied natural gas (LNG) infrastructure to meet growing energy needs. Additionally, significant investments in space exploration programs, advancements in medical technologies like MRI and cryosurgery, and intensive scientific research in low-temperature physics further propel market growth. However, the market faces notable restraints, including the high initial capital expenditure associated with cryogenic pump systems, the complexity of installation and maintenance requiring specialized expertise, and stringent safety regulations governing the handling of volatile cryogenic fluids. The volatility in raw material prices and the need for continuous technological upgrades to meet evolving industrial demands also pose challenges, potentially impacting the profitability and market accessibility for smaller players. These factors collectively shape the market landscape, influencing investment decisions and strategic planning within the industry.

Opportunities within the market are abundant, particularly in emerging economies where industrialization and energy consumption are rapidly increasing, creating new demand centers for cryogenic applications. The growing focus on hydrogen as a clean energy source presents a substantial long-term opportunity for cryogenic hydrogen pumps in storage and transportation. Furthermore, ongoing innovations in superconductivity, quantum computing, and advanced materials research necessitate increasingly sophisticated cryogenic environments, driving demand for specialized pumping solutions. The impact forces on the market include the accelerating pace of technological advancements, leading to more efficient and reliable pump designs, and the evolving regulatory landscape which mandates higher safety and environmental standards. Economic fluctuations can influence investment cycles in large-scale projects, while geopolitical factors can affect energy supply chains and demand for LNG. The continuous pursuit of energy efficiency and sustainability also exerts pressure on manufacturers to develop greener cryogenic solutions, shaping the future trajectory of the market.

Segmentation Analysis

The Cryogenic Pumps Market is extensively segmented to reflect the diverse applications and technological variations inherent in this specialized industry. These segmentations allow for a granular understanding of market dynamics, growth drivers, and competitive landscapes across different product types, operational characteristics, and end-use sectors. Analyzing these segments helps stakeholders identify key growth pockets and tailor their strategies to specific market needs, from high-pressure industrial applications to ultra-sensitive scientific research environments.

- By Type:

- Centrifugal Pumps

- Reciprocating Pumps

- Positive Displacement Pumps (excluding reciprocating)

- Regenerative Pumps

- Cryocooler-based Pumps

- Other Pump Types

- By Cryogen Type:

- Liquid Nitrogen Pumps

- Liquid Oxygen Pumps

- Liquid Argon Pumps

- Liquid Hydrogen Pumps

- Liquid Helium Pumps

- Liquefied Natural Gas (LNG) Pumps

- Other Cryogen Pumps

- By Application:

- Industrial Gas Production and Distribution

- Liquefied Natural Gas (LNG) Operations (Storage, Transfer, Regasification)

- Aerospace and Defense (Rocketry, Space Simulation, Satellite Cooling)

- Healthcare (MRI, Cryosurgery, Biobanking, Pharmaceuticals)

- Scientific Research and Development (Particle Physics, Superconductivity, Quantum Computing)

- Semiconductor Manufacturing

- Food and Beverage Processing

- Metal Treatment

- Other Industrial Applications

- By Operating Temperature:

- Below 77K (Liquid Helium, Liquid Hydrogen)

- 77K to 120K (Liquid Nitrogen, Liquid Oxygen, Liquid Argon)

- Above 120K (LNG)

- By End-User:

- Industrial Gas Companies

- Energy & Power Sector

- Aerospace & Defense Industry

- Healthcare & Pharmaceutical Industry

- Research Institutions & Universities

- Electronics & Semiconductor Industry

- Chemical & Petrochemical Industry

- Food & Beverage Industry

- By Pressure Range:

- Low Pressure

- Medium Pressure

- High Pressure

- By Region:

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Value Chain Analysis For Cryogenic Pumps Market

The value chain for the Cryogenic Pumps Market begins with a robust upstream segment, encompassing raw material suppliers and component manufacturers. Key raw materials include specialized alloys like stainless steel and aluminum, composites, and advanced ceramics capable of withstanding extreme cryogenic temperatures and pressures without embrittlement or degradation. Component suppliers provide critical parts such as motors, seals, bearings, sensors, valves, and vacuum insulation materials. Precision machining and fabrication services are also integral upstream activities, ensuring the high tolerances required for cryogenic pump assembly. These upstream activities are vital for the quality, reliability, and cost-effectiveness of the final product, directly impacting the performance characteristics and durability of the pumps.

Further along the value chain, the manufacturing process involves complex assembly, extensive testing, and quality control procedures, given the critical nature of cryogenic applications. After manufacturing, the pumps move through distribution channels, which can be both direct and indirect. Direct distribution often involves sales teams working closely with major industrial gas companies, LNG terminals, aerospace contractors, and large research institutions, providing bespoke solutions and extensive after-sales support. Indirect channels include a network of authorized distributors, system integrators, and value-added resellers who provide regional coverage, technical expertise, and localized support, particularly for smaller clients or more standardized products. This multi-channel approach ensures broad market reach and caters to diverse customer requirements, from highly customized large-scale projects to off-the-shelf solutions for specialized applications.

The downstream segment primarily consists of the end-users who integrate cryogenic pumps into their larger systems and processes. This includes industrial gas producers utilizing pumps for liquefaction and distribution, energy companies operating LNG plants, aerospace entities for spacecraft propulsion and ground support, healthcare providers for MRI cooling and biobanking, and various research institutions for scientific experiments. Post-purchase activities involve installation, commissioning, maintenance, and repair services, which are often provided by the pump manufacturers themselves or by certified third-party service providers. The continuous requirement for specialized technical support and spare parts throughout the operational life of these pumps forms a significant part of the downstream value, reinforcing long-term relationships between manufacturers and end-users and contributing to recurring revenue streams within the market.

Cryogenic Pumps Market Potential Customers

The Cryogenic Pumps Market serves a diverse range of end-users and buyers, each with specific requirements driven by their operational needs and industrial applications. Among the primary potential customers are large industrial gas production and distribution companies, which rely heavily on cryogenic pumps for the liquefaction, storage, and transfer of gases like liquid nitrogen, oxygen, argon, and carbon dioxide. These companies require high-capacity, reliable pumps to maintain the purity and temperature of vast quantities of industrial gases essential for manufacturing, healthcare, and electronics industries. The performance and efficiency of these pumps directly impact their operational costs and service delivery capabilities, making them critical investments for sustained business operations.

Another significant customer base comprises energy and power sector entities, particularly those involved in the liquefied natural gas (LNG) value chain. This includes LNG import and export terminals, regasification plants, and LNG transportation facilities, which require specialized cryogenic pumps for the loading, unloading, and transfer of LNG at extremely low temperatures. As the global energy landscape shifts towards cleaner fuels, the demand for natural gas and subsequently LNG is increasing, making these customers a pivotal segment for cryogenic pump manufacturers. Furthermore, aerospace and defense organizations represent key buyers, using cryogenic pumps for rocket fuel transfer (e.g., liquid hydrogen and oxygen) in launch vehicles, space simulation chambers, and satellite cooling systems. Their demand is characterized by stringent performance specifications, extreme reliability, and often custom-engineered solutions tailored for mission-critical applications.

The healthcare and pharmaceutical industries are also substantial purchasers, utilizing cryogenic pumps for various applications such as cooling in Magnetic Resonance Imaging (MRI) machines, cryosurgery, and the preservation of biological samples in biobanking. Research institutions and universities globally invest in cryogenic pumps for fundamental and applied scientific research, including particle physics, superconductivity experiments, and materials science at ultra-low temperatures. Additionally, the electronics and semiconductor manufacturing sector employs cryogenic pumps to achieve and maintain ultra-high vacuum environments essential for processes like thin-film deposition and ion implantation, ensuring the integrity and performance of advanced microelectronic components. These varied applications underscore the broad and critical role of cryogenic pumps across multiple high-tech industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 4.8 Billion |

| Market Forecast in 2032 | USD 7.5 Billion |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Atlas Copco (Edwards Vacuum), Ebara Corporation, Cryostar, Fives S.A. (Fives Cryo), Brooks Automation Inc. (Brooks Instrument), Sumitomo Heavy Industries Ltd. (SHI Cryogenics Group), Nikkiso Cryo Inc., Flowserve Corporation, Gardner Denver (Ingersoll Rand), Leybold GmbH, Pfeiffer Vacuum Technology AG, Vanzetti Engineering S.p.A., ACD LLC, Phcbi (Panasonic Healthcare Co. Ltd.), Air Liquide (Airgas), Linde plc, Chart Industries Inc., Barber-Nichols Inc., Cryomech Inc., Janis Research Company LLC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cryogenic Pumps Market Key Technology Landscape

The technological landscape of the Cryogenic Pumps Market is characterized by continuous innovation aimed at enhancing efficiency, reliability, and operational lifespan under extreme conditions. A significant trend involves the integration of advanced materials, such as specialized stainless steels, high-strength aluminum alloys, and composites, which offer superior mechanical properties and thermal insulation capabilities at cryogenic temperatures, preventing material embrittlement and reducing heat ingress. Magnetic bearings are becoming increasingly prevalent, offering contact-free operation that eliminates friction, wear, and the need for lubrication, thereby extending pump life and reducing maintenance requirements. These advancements contribute to higher rotational speeds and improved pump performance, especially in high-flow, low-temperature applications.

Another pivotal area of technological development is the incorporation of smart sensing and Internet of Things (IoT) capabilities. Modern cryogenic pumps are equipped with an array of sensors to monitor critical parameters such as temperature, pressure, flow rate, vibration, and bearing health in real-time. This data is then transmitted to central control systems, often leveraging cloud platforms, enabling remote monitoring, predictive maintenance, and operational optimization. AI and machine learning algorithms are increasingly being applied to analyze this vast data, predicting potential failures before they occur, scheduling maintenance proactively, and fine-tuning pump operations for maximum energy efficiency and output. This smart technology integration is transforming the operational paradigm of cryogenic systems, moving towards more autonomous and resilient solutions.

Furthermore, advancements in vacuum insulation technology, including multi-layer insulation (MLI) and high-performance vacuum jackets, are crucial for minimizing heat leakage into the cryogen, thereby reducing boil-off losses and improving system efficiency. The development of more compact and energy-efficient cryocoolers, which are sometimes integrated into cryogenic pump systems, also represents a key technological frontier, enabling smaller footprints and lower power consumption. Additive manufacturing, or 3D printing, is also beginning to play a role in the rapid prototyping and production of complex pump components with optimized geometries, leading to improved fluid dynamics and reduced manufacturing costs. These diverse technological thrusts collectively drive the evolution of cryogenic pumps, making them more sophisticated, robust, and adaptable to a wider array of demanding applications.

Regional Highlights

- North America: This region is a mature market for cryogenic pumps, characterized by significant investment in aerospace and defense, a robust healthcare sector, and advanced research & development activities. The United States, in particular, drives demand for high-performance pumps in industrial gas production, LNG infrastructure, and semiconductor manufacturing. Innovation in energy-efficient designs and smart technologies is a key focus, supported by a strong base of technology companies and research institutions.

- Europe: Europe represents a stable market, propelled by stringent industrial gas quality standards, ongoing projects in space exploration, and a growing emphasis on hydrogen energy. Countries like Germany, France, and the UK are major contributors, with strong manufacturing capabilities and a focus on sustainable cryogenic solutions. The region also benefits from a well-established industrial base and significant R&D spending in cryogenics and superconductivity.

- Asia Pacific (APAC): APAC is the fastest-growing market for cryogenic pumps, primarily due to rapid industrialization, burgeoning energy demands, and increasing investments in LNG terminals and industrial gas facilities, especially in China, India, and Southeast Asian countries. The expanding healthcare sector, coupled with government initiatives for scientific research and infrastructure development, further fuels market expansion. The region is also becoming a hub for semiconductor manufacturing, which heavily relies on cryogenic environments.

- Latin America: This region shows promising growth, driven by expanding oil and gas exploration activities, growing industrial production, and increasing investments in healthcare infrastructure. Countries like Brazil and Mexico are leading the adoption of cryogenic pumps, particularly in industrial gas applications and nascent LNG projects. The market here is also influenced by foreign investments and technological transfers from more developed regions.

- Middle East and Africa (MEA): The MEA region is witnessing growth spurred by large-scale oil and gas projects, the expansion of petrochemical industries, and significant investments in LNG export capabilities. Saudi Arabia, Qatar, and the UAE are key players, with substantial demand for cryogenic pumps in liquefaction, storage, and transportation of natural gas. While relatively smaller in R&D, the region's energy sector continues to drive substantial demand for specialized cryogenic equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cryogenic Pumps Market.- Atlas Copco (Edwards Vacuum)

- Ebara Corporation

- Cryostar

- Fives S.A. (Fives Cryo)

- Brooks Automation Inc. (Brooks Instrument)

- Sumitomo Heavy Industries Ltd. (SHI Cryogenics Group)

- Nikkiso Cryo Inc.

- Flowserve Corporation

- Gardner Denver (Ingersoll Rand)

- Leybold GmbH

- Pfeiffer Vacuum Technology AG

- Vanzetti Engineering S.p.A.

- ACD LLC

- Phcbi (Panasonic Healthcare Co. Ltd.)

- Air Liquide (Airgas)

- Linde plc

- Chart Industries Inc.

- Barber-Nichols Inc.

- Cryomech Inc.

- Janis Research Company LLC

Frequently Asked Questions

What are the primary applications of cryogenic pumps?

Cryogenic pumps are primarily used in industrial gas production and distribution, liquefied natural gas (LNG) operations, aerospace and defense, healthcare (e.g., MRI cooling, biobanking), scientific research, and semiconductor manufacturing for creating ultra-high vacuum environments.

What types of cryogenic pumps are available in the market?

The market offers various types including centrifugal pumps for high flow rates, reciprocating pumps for high pressure, positive displacement pumps, regenerative pumps, and cryocooler-based pumps, each designed for specific operational requirements and cryogen types.

What are the main factors driving the growth of the cryogenic pumps market?

Key drivers include the increasing global demand for industrial gases, the expansion of LNG infrastructure, growing investment in space exploration, and advancements in healthcare technologies requiring cryogenic temperatures.

How does AI impact the cryogenic pumps market?

AI significantly impacts the market by enabling predictive maintenance, optimizing pump operational efficiency, enhancing process control, improving safety protocols, and facilitating smart diagnostics and remote monitoring for cryogenic pump systems.

What are the major challenges faced by the cryogenic pumps market?

Significant challenges include the high initial capital investment for these specialized systems, the complexity of their installation and maintenance, stringent safety regulations for handling cryogens, and volatility in raw material prices.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager