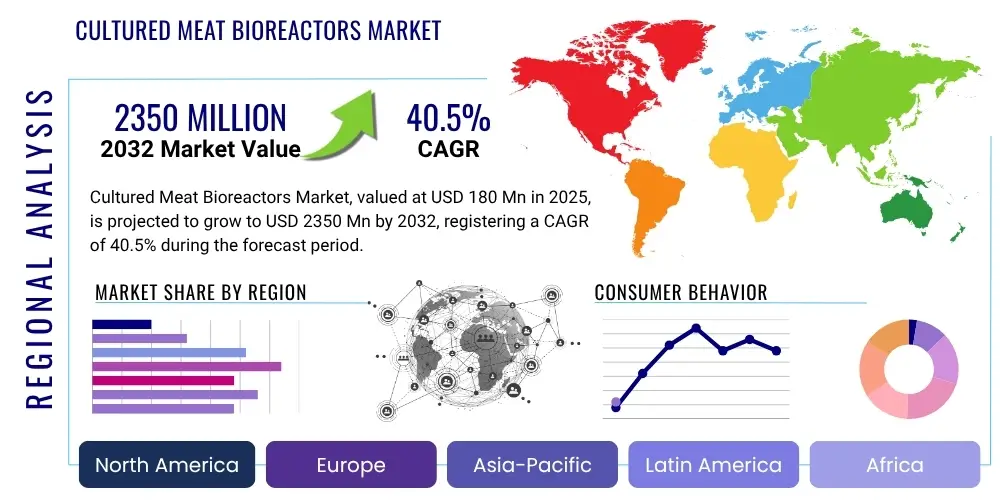

Cultured Meat Bioreactors Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430096 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Cultured Meat Bioreactors Market Size

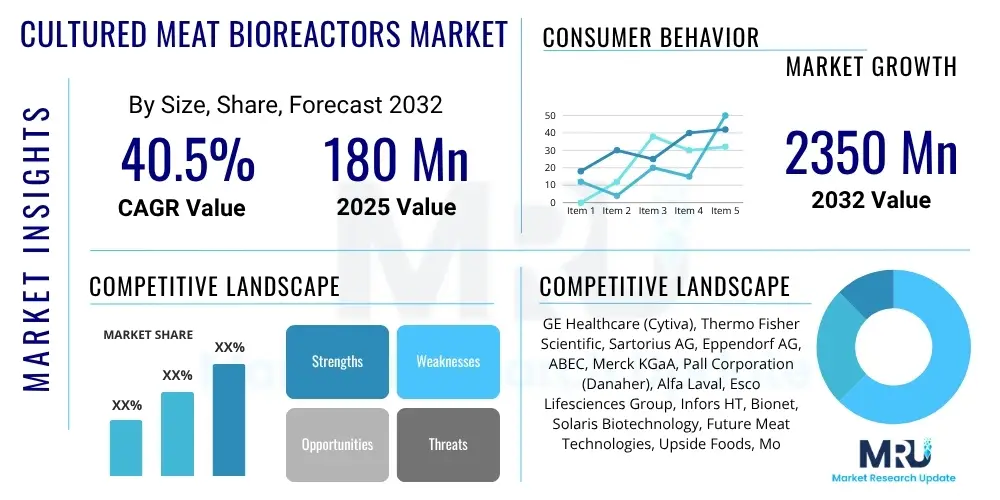

The Cultured Meat Bioreactors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 40.5% between 2025 and 2032. The market is estimated at USD 180 Million in 2025 and is projected to reach USD 2350 Million by the end of the forecast period in 2032.

Cultured Meat Bioreactors Market introduction

The Cultured Meat Bioreactors Market is at the forefront of the food technology revolution, addressing global demands for sustainable and ethical protein. Cultured meat, also known as cultivated or cell-based meat, involves growing animal cells directly to produce meat products without the need for traditional animal farming. Bioreactors are central to this process, providing the controlled environment necessary for cell proliferation and differentiation, mimicking the biological conditions found within an animal's body. These sophisticated systems facilitate the efficient growth of muscle, fat, and connective tissue cells, ensuring the safety and quality of the final product.

The primary product in this market consists of advanced bioreactor systems specifically designed for cellular agriculture. These systems range from laboratory-scale vessels used for research and development to large-scale industrial bioreactors capable of commercial production. Key features include precise control over temperature, pH, oxygen levels, nutrient supply, and waste removal, all critical for optimal cell growth. Different bioreactor types, such as stirred-tank, airlift, and perfusion systems, are employed depending on cell type, desired yield, and production scale, each offering distinct advantages in terms of mixing efficiency, shear stress management, and nutrient delivery.

Major applications of cultured meat bioreactors lie in the commercial production of a wide array of meat products, including beef, chicken, pork, and seafood, as well as hybrid products combining cultured cells with plant-based ingredients. The benefits are multifold: a significantly reduced environmental footprint compared to traditional livestock farming (lower land and water usage, reduced greenhouse gas emissions), ethical animal welfare considerations, and a more controlled, hygienic production environment free from antibiotics and common foodborne pathogens. These bioreactors are driving factors for the market's expansion, enabling the transition towards a more sustainable and resilient global food system.

Cultured Meat Bioreactors Market Executive Summary

The Cultured Meat Bioreactors Market is characterized by robust business trends centered around technological innovation, strategic collaborations, and a strong influx of venture capital. Startups and established biotech firms are heavily investing in research and development to optimize bioreactor designs, improve cell culture media efficiency, and overcome scaling challenges. Partnerships between cultured meat producers and bioreactor manufacturers are becoming increasingly common, aiming to accelerate the commercialization of cultivated meat. The focus is shifting from small-scale proof-of-concept to pilot and commercial-scale production, necessitating larger, more efficient, and cost-effective bioreactor solutions. Regulatory landscapes, particularly in pioneering regions, are also evolving, providing a clearer path for market entry and product commercialization.

Regional trends indicate North America and Europe as leading innovators and early adopters, driven by significant investment, a strong research infrastructure, and a growing consumer interest in alternative proteins. Countries like the United States, the Netherlands, and Israel are hubs for cultured meat innovation, pushing the boundaries of bioreactor technology. The Asia Pacific region, particularly Singapore, which was the first to approve cultured meat for sale, and emerging markets like South Korea and Japan, show immense potential for growth due to high population density, growing demand for protein, and increasing awareness of food sustainability. Latin America and the Middle East and Africa are also expected to see gradual adoption as technology matures and costs decline.

Segmentation trends highlight a diverse market, with bioreactor types evolving to suit different cell lines and production scales. Stirred-tank and perfusion bioreactors are gaining prominence for their efficiency in large-scale operations, while single-use bioreactors offer advantages in flexibility and contamination control for smaller batches or research. The market is also seeing specialization by cell type, with bioreactors optimized for myosatellite cells, fibroblasts, and adipose-derived stem cells, each requiring specific growth conditions. As the industry matures, there will be increasing demand for integrated bioreactor systems that combine cell cultivation with downstream processing, along with a strong emphasis on automation and digital control to achieve consistent and cost-effective production at commercial volumes.

AI Impact Analysis on Cultured Meat Bioreactors Market

Users frequently inquire about how Artificial Intelligence can enhance the efficiency, scalability, and cost-effectiveness of cultured meat production within bioreactors. Key concerns revolve around AI's ability to optimize complex cellular growth environments, predict and prevent contamination, and automate intricate processes to reduce human error and operational costs. Expectations often focus on AI's potential to accelerate research and development cycles, enable real-time monitoring, and facilitate the transition from laboratory experimentation to industrial-scale manufacturing, ultimately making cultured meat a viable and affordable alternative to traditional meat products.

- AI enables real-time monitoring and control of bioreactor parameters such as pH, dissolved oxygen, nutrient levels, and temperature, ensuring optimal cell growth conditions.

- Predictive analytics powered by AI can forecast cell growth kinetics and nutrient depletion, optimizing feeding strategies and reducing media waste.

- Machine learning algorithms analyze vast datasets from past cultivation runs to identify ideal conditions and improve yield and quality consistency.

- AI-driven automation systems can manage complex bioreactor operations, reducing manual labor and mitigating the risk of human error or contamination.

- Computer vision and image analysis, supported by AI, can detect early signs of contamination or abnormal cell morphology, preventing costly batch failures.

- AI assists in optimizing bioreactor design and scaling processes, simulating different configurations to find the most efficient and cost-effective solutions for commercial production.

- Deep learning can accelerate the discovery and optimization of novel, animal-free cell culture media and growth factors, significantly reducing production costs.

DRO & Impact Forces Of Cultured Meat Bioreactors Market

The Cultured Meat Bioreactors Market is propelled by a confluence of powerful drivers and opportunities while simultaneously navigating significant restraints and challenges. Key drivers include the escalating global demand for protein, coupled with increasing consumer awareness and concern for animal welfare, environmental sustainability, and food security. The immense investment pouring into the cellular agriculture sector from venture capitalists, governments, and food industry giants is further accelerating technological advancements in bioreactor design and cell culture techniques. These factors collectively create a fertile ground for market expansion, pushing for more efficient and scalable cultivation solutions to meet future demand.

However, the market faces considerable restraints. The high capital expenditure required for establishing large-scale bioreactor facilities presents a significant barrier to entry and expansion for many companies. Furthermore, the complex and often fragmented regulatory landscape across different regions poses challenges for product approval and market access. The current high cost of cell culture media and growth factors, essential for cell proliferation, contributes significantly to the overall production cost, making cultured meat less competitive on price compared to conventional meat. Consumer skepticism, fueled by misconceptions about the "naturalness" and safety of cultured meat, also represents a hurdle for widespread adoption, requiring extensive education and transparent communication.

Despite these challenges, numerous opportunities exist to drive future growth. The development of novel, cost-effective, and animal-free cell culture media is a prime area for innovation, promising to drastically reduce production expenses. Strategic partnerships between biotechnology firms, traditional food companies, and bioreactor manufacturers can pool resources and expertise to overcome technical and commercialization hurdles. Emerging markets, particularly in Asia Pacific, offer vast untapped potential for market penetration as local preferences for specific meat types can be addressed. Furthermore, continuous advancements in automation, sensor technology, and artificial intelligence for process optimization will enhance efficiency, reduce costs, and improve the consistency and quality of cultured meat products. These impact forces collectively define the market’s current state and its projected trajectory, emphasizing the critical role of innovation and collaboration in shaping its future.

Segmentation Analysis

The Cultured Meat Bioreactors Market is segmented across various dimensions to provide a detailed understanding of its dynamics and potential growth areas. This segmentation helps in identifying key trends, technological preferences, and demand patterns among different end-users. The market is primarily analyzed by bioreactor type, indicating the diverse technological approaches being adopted for cell cultivation. Further segmentation by scale provides insights into the progression from research and development to commercial production. Additionally, segmenting by cell type highlights the biological specificities influencing bioreactor design, while end-user segmentation clarifies the primary consumers and their respective needs within the broader cellular agriculture ecosystem.

- By Bioreactor Type

- Stirred-Tank Bioreactors: Widely adopted for their efficiency in mixing and mass transfer, suitable for larger volumes.

- Airlift Bioreactors: Preferred for shear-sensitive cells due to gentler mixing, often used in microbial fermentation but adapted for animal cells.

- Fixed-Bed Bioreactors: Utilize a scaffold or matrix for cell attachment and growth, allowing for high cell density.

- Perfusion Bioreactors: Characterized by continuous nutrient supply and waste removal, ideal for long-term, high-density cell cultures.

- Wave Bioreactors: Single-use, rocking-motion systems offering low shear stress and easy scalability.

- Hollow Fiber Bioreactors: Provide a large surface area for cell growth within a compact space, enabling high cell densities and continuous media exchange.

- Photobioreactors: Specifically designed for cultivating photosynthetic cells, though less common for traditional meat cells, they hold potential for certain cell lines or media component production.

- By Scale

- Laboratory Scale: Small volume bioreactors used for research, process development, and small-batch testing.

- Pilot Scale: Intermediate size bioreactors used for process optimization, scale-up studies, and producing larger quantities for sensory evaluation and regulatory trials.

- Commercial Scale: Large-volume bioreactors designed for industrial production to meet market demand, focusing on efficiency and cost-effectiveness.

- By Cell Type

- Myosatellite Cells: Precursor cells to skeletal muscle, crucial for muscle tissue development.

- Fibroblasts: Connective tissue cells often used as feeder cells or for scaffold development.

- Adipose-Derived Stem Cells: Multipotent stem cells isolated from fat tissue, capable of differentiating into various cell types, including fat and muscle.

- Induced Pluripotent Stem Cells (iPSCs): Reprogrammed somatic cells with pluripotent capabilities, offering ethical advantages and scalability potential.

- By End-User

- Cultured Meat Companies: Startups and established players focused on producing and commercializing cell-based meat products.

- Research Institutions: Universities, government labs, and private research organizations involved in cellular agriculture R&D.

- Biotechnology Firms: Companies specializing in cell culture technology, media development, and bioreactor manufacturing, supporting the cultured meat industry.

- Food and Beverage Companies (diversifying): Traditional food companies exploring or investing in cultured meat production as part of their innovation strategy.

Value Chain Analysis For Cultured Meat Bioreactors Market

The value chain for the Cultured Meat Bioreactors Market begins with a critical upstream segment, focusing on the sourcing and manufacturing of essential components. This involves suppliers of highly specialized raw materials such as cell culture media (growth factors, amino acids, vitamins, salts), scaffolds (plant-based or synthetic structures for cell attachment), and bioreactor raw materials like stainless steel, glass, or advanced polymers. Key players in this stage also include manufacturers of bioreactor hardware, sensors, pumps, filtration systems, and automation software. The quality and availability of these upstream inputs directly influence the efficiency and cost of cultured meat production, driving innovation in component design and media formulation to reduce dependence on animal-derived elements and achieve cost parity with traditional meat.

Moving through the midstream, the core activity is the design, manufacturing, and integration of the bioreactor systems themselves. This segment includes specialized engineering firms and biotechnology equipment manufacturers that develop bioreactors tailored for specific cell types and production scales, ranging from lab-scale prototypes to large commercial systems. These companies also provide installation, validation, and maintenance services, ensuring the optimal functioning of complex bioreactor setups. The continuous innovation in this segment focuses on improving scalability, reducing energy consumption, enhancing cell viability and proliferation rates, and integrating advanced monitoring and control technologies to maximize yield and minimize operational costs.

The downstream segment of the value chain involves the direct end-users of these bioreactors, primarily cultured meat production companies. These companies utilize the bioreactors to cultivate animal cells into edible meat products, followed by subsequent processing steps such as harvesting, structuring (e.g., extrusion or 3D printing to create desired textures), flavoring, and packaging. Distribution channels for the final cultured meat products vary, including direct-to-consumer models, partnerships with traditional food distributors, and sales to restaurants or retailers. Direct channels involve manufacturers selling bioreactors directly to large cultured meat companies, while indirect channels might involve distributors handling sales to smaller research institutions or startups, facilitating market penetration and technical support across a broader customer base. The efficiency and reach of these distribution networks are crucial for the widespread adoption and commercial success of cultured meat products globally.

Cultured Meat Bioreactors Market Potential Customers

The primary potential customers and end-users of cultured meat bioreactors are at the forefront of the cellular agriculture movement, spanning various sectors from innovative startups to established food giants. Cultured meat companies represent the most direct and significant customer segment. These pioneering firms are dedicated to developing and commercializing cell-based meat products, requiring state-of-the-art bioreactors for scalable and efficient cell cultivation. Their demand spans across all scales, from small research and development bioreactors for initial cell line optimization to large industrial systems for commercial production. These companies are driven by the need for cost-effective, high-yield, and ethically sound protein alternatives.

Beyond specialized cultured meat companies, a growing segment of potential customers includes traditional food and beverage corporations. Many of these established players are recognizing the paradigm shift towards sustainable protein sources and are actively exploring or investing in cellular agriculture technologies. For them, cultured meat bioreactors represent a strategic avenue for diversification, allowing them to expand their product portfolios and cater to an evolving consumer base demanding more ethical and environmentally friendly food options. Their interest often lies in robust, scalable, and reliable bioreactor solutions that can integrate seamlessly into their existing manufacturing and distribution infrastructures.

Furthermore, academic and research institutions, as well as biotechnology firms, constitute a significant customer base for cultured meat bioreactors, particularly at the laboratory and pilot scales. These entities utilize bioreactors for fundamental research into cell biology, optimizing cell culture media and growth factors, developing novel cell lines, and exploring advanced bioreactor designs and process parameters. Biotechnology firms, specializing in cell culture technology and bioprocessing equipment, not only provide the bioreactors but also serve as key partners in developing bespoke solutions and providing scientific expertise to the nascent cultured meat industry. These diverse customer segments underscore the broad applicability and critical role of bioreactor technology in advancing the entire cultured meat ecosystem.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 180 Million |

| Market Forecast in 2032 | USD 2350 Million |

| Growth Rate | 40.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GE Healthcare (Cytiva), Thermo Fisher Scientific, Sartorius AG, Eppendorf AG, ABEC, Merck KGaA, Pall Corporation (Danaher), Alfa Laval, Esco Lifesciences Group, Infors HT, Bionet, Solaris Biotechnology, Future Meat Technologies, Upside Foods, Mosa Meat, Good Meat (Eat Just), Culture Biosciences, Bioreactor Technologies, Nexcel Therapeutics, CellX |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cultured Meat Bioreactors Market Key Technology Landscape

The Cultured Meat Bioreactors Market is characterized by a dynamic and rapidly evolving technology landscape, essential for overcoming the complex challenges of cellular agriculture scalability and cost-efficiency. A primary technological focus is on advanced bioreactor designs that offer precise control over environmental parameters, such as temperature, pH, dissolved oxygen, and nutrient flow, while minimizing shear stress on delicate animal cells. This includes the development of sophisticated stirred-tank bioreactors with optimized impeller designs, as well as perfusion systems that enable continuous removal of waste products and replenishment of fresh media, crucial for maintaining high cell densities over extended periods. Single-use bioreactors are also gaining traction for their flexibility, reduced cleaning validation requirements, and mitigation of cross-contamination risks, particularly in smaller scale or developmental stages.

Another significant area of technological innovation lies in sensor and automation technologies. Integrated sensors provide real-time monitoring of critical process variables, allowing for immediate adjustments and data collection. This is complemented by advanced automation systems that streamline operational workflows, from media preparation and cell inoculation to harvesting and cleaning. Robotics and artificial intelligence are increasingly being employed to manage complex protocols, optimize feeding strategies, and predict potential issues, thereby enhancing process efficiency, reproducibility, and reducing labor costs. These smart systems are vital for transitioning from manual, labor-intensive lab processes to fully automated, industrial-scale production lines, ensuring consistent product quality and throughput.

Furthermore, the landscape includes innovations in cell culture media formulation and scaffolding technologies. The development of animal-free, serum-free, and cost-effective cell culture media is paramount to ethical and economic viability, with researchers exploring novel growth factors and nutrient mixes. Scaffolding technologies, including edible and biodegradable materials, are critical for providing structural support for cell attachment and growth, particularly for creating complex tissue structures that mimic the texture and mouthfeel of conventional meat. Integration of 3D bioprinting technologies with bioreactors is also emerging, enabling the precise layering of different cell types and scaffolds to construct intricate meat structures. These interconnected technological advancements are collectively driving the cultured meat industry towards achieving commercial feasibility and widespread consumer acceptance.

Regional Highlights

- North America: Leads the market with significant venture capital investment, a robust R&D infrastructure, and a growing number of cultured meat startups, particularly in the United States. Early regulatory frameworks and a strong consumer interest in sustainable food also contribute to its prominence.

- Europe: A key hub for scientific research and development in cellular agriculture, with countries like the Netherlands and Israel pioneering advancements in bioreactor technology and cell culture media. Increasing regulatory clarity and strong ethical considerations drive market adoption.

- Asia Pacific (APAC): Represents a high-growth region due to large populations, increasing protein demand, and a proactive regulatory approach in some countries, such as Singapore being the first to approve cultured meat for sale. Japan and South Korea are also emerging with substantial investments and research initiatives.

- Latin America: Shows nascent but growing interest, driven by concerns over environmental impact and food security. Early-stage startups and research collaborations are beginning to emerge, particularly in Brazil and Argentina, aiming to tap into local protein markets.

- Middle East and Africa (MEA): While still in early stages, there is increasing awareness and strategic investment in food technology to enhance food security and sustainability. Opportunities exist for technology transfer and local production as the market matures globally.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cultured Meat Bioreactors Market.- GE Healthcare (Cytiva)

- Thermo Fisher Scientific

- Sartorius AG

- Eppendorf AG

- ABEC

- Merck KGaA

- Pall Corporation (Danaher)

- Alfa Laval

- Esco Lifesciences Group

- Infors HT

- Bionet

- Solaris Biotechnology

- Future Meat Technologies

- Upside Foods

- Mosa Meat

- Good Meat (Eat Just)

- Culture Biosciences

- Bioreactor Technologies

- Nexcel Therapeutics

- CellX

Frequently Asked Questions

What are cultured meat bioreactors?

Cultured meat bioreactors are advanced biotechnological systems designed to cultivate animal cells into edible meat products in a controlled, sterile environment. They provide the optimal conditions, including nutrients, oxygen, pH, and temperature, necessary for cell proliferation and differentiation, mimicking the biological processes within an animal without slaughter.

Why are cultured meat bioreactors important?

Cultured meat bioreactors are crucial for scaling up the production of sustainable and ethical protein. They address environmental concerns associated with traditional livestock farming, enhance animal welfare, and offer a food production method less susceptible to contamination, ultimately contributing to global food security and public health.

What are the main types of bioreactors used for cultured meat?

Common types include stirred-tank bioreactors for efficient mixing, airlift bioreactors for shear-sensitive cells, fixed-bed bioreactors for high cell densities, and perfusion bioreactors for continuous, high-yield cultivation. Single-use and wave bioreactors also offer flexibility and ease of use for various scales.

What are the biggest challenges in the cultured meat bioreactors market?

Key challenges include the high capital cost of large-scale facilities, complex regulatory approval processes, the expensive nature of cell culture media, overcoming technical hurdles in scaling up production efficiently, and navigating consumer skepticism regarding acceptance and perception of cultured meat products.

What is the future outlook for the cultured meat bioreactors market?

The future outlook is highly promising, driven by continuous technological advancements, increasing investment, and growing consumer demand for sustainable protein. Expect significant growth in commercial-scale bioreactor development, cost reduction through innovation in media and processes, and broader regulatory approvals leading to wider market availability of cultured meat products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager