CY Control Cable Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 427272 | Date : Oct, 2025 | Pages : 243 | Region : Global | Publisher : MRU

CY Control Cable Market Size

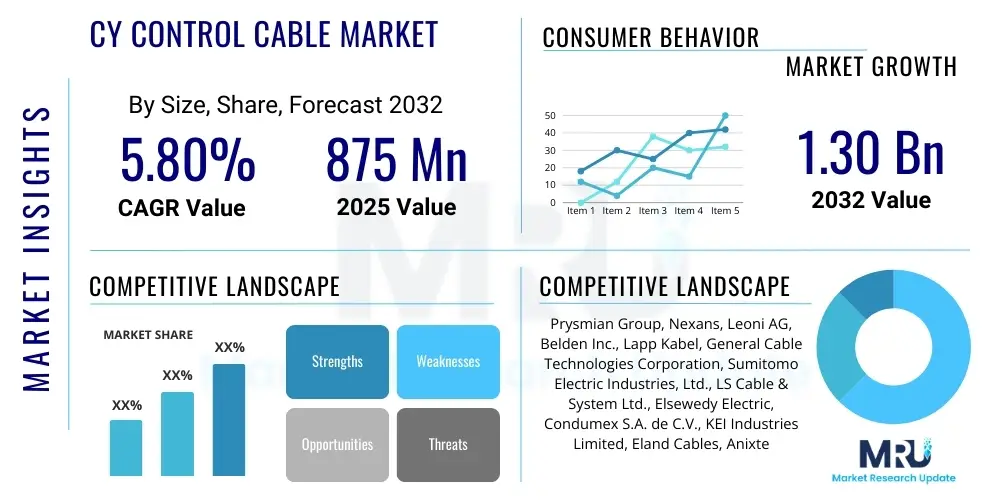

The CY Control Cable Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2025 and 2032. The market is estimated at USD 875 Million in 2025 and is projected to reach USD 1.30 Billion by the end of the forecast period in 2032.

CY Control Cable Market introduction

The CY control cable market encompasses a diverse range of multi-core, flexible electrical cables predominantly utilized for measurement, control, and regulation in various industrial and commercial applications. These cables are distinguished by their tinned copper braided screen, offering crucial electromagnetic interference (EMI) protection, making them ideal for environments where signal integrity is paramount. Their construction typically includes fine strands of plain or tinned copper conductors, PVC insulation, a galvanized steel wire braid (CY screen), and an outer PVC sheath, providing robust mechanical protection and chemical resistance. This design ensures reliable data transmission and power supply in demanding operational settings, safeguarding against external electrical noise and mechanical stress.

Major applications for CY control cables span across industrial automation, process control systems, machinery manufacturing, and building management systems. They are integral to connecting control panels, conveying signals to sensors, actuators, and other control equipment within factories, power plants, and infrastructure projects. The primary benefits include enhanced signal integrity due to superior EMI shielding, improved safety through robust construction and flame-retardant options, and excellent flexibility for easier installation in complex routing scenarios. Key driving factors for market expansion include the accelerating pace of industrial automation, the proliferation of smart manufacturing initiatives, significant investments in infrastructure development, and the increasing demand for reliable and safe electrical connectivity solutions in modern industrial setups globally.

CY Control Cable Market Executive Summary

The CY Control Cable Market is experiencing dynamic growth, propelled by the relentless march of industrial digitalization and the escalating demand for highly reliable and shielded cabling solutions. Key business trends indicate a strong focus on product innovation, particularly in developing cables with enhanced fire safety features, improved environmental resistance, and miniaturized designs to meet the evolving requirements of compact industrial machinery and smart infrastructure. Manufacturers are increasingly investing in research and development to integrate advanced materials and smart functionalities into their cable offerings, aligning with industry 4.0 paradigms. Furthermore, strategic collaborations and mergers among market players are becoming more prevalent, aimed at expanding geographical reach, diversifying product portfolios, and consolidating market share in a competitive landscape characterized by technological advancements and evolving regulatory standards.

Regionally, the Asia-Pacific continues to dominate the market, driven by rapid industrialization, burgeoning manufacturing sectors, and extensive infrastructure projects in countries like China and India. Europe and North America also exhibit steady demand, fueled by the modernization of existing industrial facilities, the adoption of advanced automation technologies, and stringent safety regulations that necessitate high-performance cabling. Segment-wise, the market sees robust growth in shielded cable types due to increasing electromagnetic compatibility (EMC) requirements in sensitive electronic applications. The demand for flame-retardant and halogen-free variants is also surging, driven by stricter safety codes in construction and public infrastructure. The industrial automation and machinery sectors remain the largest end-users, underscoring the critical role of CY control cables in ensuring precision, reliability, and safety across diverse operational environments.

AI Impact Analysis on CY Control Cable Market

Artificial intelligence is progressively reshaping the operational dynamics and demand patterns within the CY Control Cable Market by enhancing manufacturing efficiencies, driving the need for smarter infrastructure, and optimizing supply chain logistics. Users frequently inquire about how AI-driven analytics can improve the quality control processes for cable manufacturing, reduce production waste, and predict maintenance needs for industrial machinery connected by these cables. There is also significant interest in the role of AI in enabling smart factories and IoT ecosystems, which inherently require high-performance, robust, and often data-rich control cables for seamless communication between intelligent devices and centralized AI systems. Users seek to understand the implications of AI on cable specifications, particularly regarding data transmission capabilities, electromagnetic compatibility, and longevity in an increasingly interconnected and data-intensive industrial landscape.

The influence of AI extends to influencing the demand for specialized CY control cables that can support advanced sensor networks and real-time data processing, crucial for AI-powered predictive maintenance and operational optimization. As AI models become more sophisticated in managing complex industrial processes, the reliability and performance of the underlying cabling infrastructure, including CY control cables, become even more critical. AI also impacts market strategies by enabling more precise demand forecasting, inventory management, and personalized product development, allowing manufacturers to respond more agilely to market needs. The integration of AI in design and simulation tools is also leading to the development of more efficient and durable cable designs, pushing the boundaries of traditional cable engineering and manufacturing.

- Enhanced Manufacturing Efficiency: AI algorithms optimize cable production processes, reducing material waste and energy consumption.

- Predictive Maintenance Integration: AI-powered systems utilize data from sensors connected by control cables to predict equipment failures, extending operational lifespan.

- Smart Grid and IoT Demand: AI drives the proliferation of smart infrastructure and IoT devices, necessitating reliable CY control cables for data transmission.

- Supply Chain Optimization: AI improves logistics and inventory management for raw materials and finished cables, ensuring timely delivery and cost efficiency.

- New Product Development: AI assists in designing advanced control cables with improved data carrying capacity and enhanced shielding for AI-driven systems.

- Quality Control Automation: AI-vision systems detect defects in cable insulation and braiding with high precision, ensuring superior product quality.

DRO & Impact Forces Of CY Control Cable Market

The CY Control Cable Market is significantly influenced by a confluence of driving factors, restraints, opportunities, and external impact forces that collectively shape its growth trajectory and competitive landscape. Key drivers include the global surge in industrial automation and Industry 4.0 initiatives, which necessitate robust and shielded cabling for precise control and data transfer in automated manufacturing processes. Substantial investments in infrastructure development, particularly in smart cities, renewable energy projects, and intelligent transportation systems, also fuel demand for reliable control cables. Concurrently, the increasing emphasis on workplace safety and environmental protection mandates the use of high-quality, flame-retardant, and halogen-free cables, driving market adoption. The continuous evolution of manufacturing technologies further stimulates demand for specialized control cables capable of supporting advanced machinery and communication protocols.

However, the market faces several restraints, including the volatility of raw material prices, particularly for copper and PVC, which can impact manufacturing costs and profitability. Intense competition among established players and emerging entrants often leads to price pressures, challenging market participants to maintain margins. Stringent regulatory standards and certifications for cable performance and safety, while necessary, can also increase production complexities and costs. Opportunities abound in the burgeoning sectors of electric vehicles, where control cables are essential for battery management systems and charging infrastructure, and in smart factories that require high-performance, integrated cabling solutions for complex data networks. Emerging economies present significant untapped potential for market expansion. Impact forces such as rapid technological advancements in industrial electronics, evolving environmental regulations, and global trade policies profoundly affect supply chains, production strategies, and market access, requiring agile responses from market players to sustain growth and competitiveness.

Segmentation Analysis

The CY Control Cable Market is meticulously segmented based on several critical parameters to provide a comprehensive understanding of its dynamics and diverse application areas. These segmentations allow for a granular analysis of market trends, consumer preferences, and growth opportunities across various product types, material compositions, and end-user industries. Understanding these segments is crucial for manufacturers to tailor their product offerings, for distributors to optimize their supply chains, and for end-users to select the most appropriate cable solutions for their specific operational requirements. The primary segmentation criteria typically include cable type (e.g., shielded, unshielded), insulation and sheath materials, voltage ratings, number of cores, and the diverse range of end-use applications, each presenting unique demand characteristics and growth prospects within the broader market landscape.

- By Type:

- Shielded Control Cables: Offering enhanced EMI protection for sensitive applications.

- Unshielded Control Cables: Suitable for less demanding environments where EMI is not a critical concern.

- By Insulation Material:

- PVC (Polyvinyl Chloride): Widely used due to cost-effectiveness and good electrical properties.

- XLPE (Cross-Linked Polyethylene): Offers higher temperature resistance and improved mechanical strength.

- LSZH (Low Smoke Zero Halogen): Preferred in public areas for reduced smoke and toxic gas emission in case of fire.

- By Voltage Rating:

- Low Voltage (e.g., 300/500V, 450/750V): Most common for control and instrumentation circuits.

- By Number of Cores:

- Single-Core to Multi-Core (e.g., 2-core, 3-core, up to 61-core): Depending on the complexity of the control system.

- By Application:

- Industrial Automation: Connecting PLCs, sensors, actuators, and control panels.

- Machinery & Equipment: For internal wiring and external connections of various industrial machines.

- Building & Construction: For HVAC systems, security systems, and other building management controls.

- Energy & Utilities: Power generation, distribution, and renewable energy installations.

- Transportation: Automotive, railway signaling, and other transport infrastructure.

CY Control Cable Market Value Chain Analysis

The value chain for the CY Control Cable Market begins with upstream activities, primarily the sourcing and processing of raw materials essential for cable manufacturing. This stage involves suppliers of high-purity copper for conductors, various polymers like PVC, XLPE, and LSZH for insulation and sheathing, and materials for braiding shields such as tinned copper or galvanized steel wires. These raw material providers form the foundational layer, with their pricing, quality, and supply reliability significantly influencing the overall cost and performance of the final cable product. Effective upstream management involves long-term supplier relationships, stringent quality checks, and strategic procurement to mitigate supply chain risks and ensure a consistent flow of materials, which are critical for maintaining production schedules and product quality standards.

Moving downstream, the value chain encompasses the manufacturing processes, which involve conductor stranding, insulation extrusion, core twisting, screening, and outer sheathing. This stage adds significant value through precision engineering and adherence to international standards. Finished cables then move into distribution channels, which can be direct or indirect. Direct sales typically involve manufacturers supplying large quantities directly to major industrial clients, EPC contractors, or large-scale infrastructure projects. Indirect channels include a network of wholesalers, distributors, and retailers who make cables accessible to a broader range of smaller businesses, contractors, and specialized niche markets. These distributors often provide value-added services such as cutting cables to specific lengths, offering technical support, and managing inventory. The final stage involves installation and utilization by various end-users across industrial, commercial, and utility sectors, where the cables perform their intended function of control and signal transmission, completing the markets value cycle.

CY Control Cable Market Potential Customers

The potential customer base for the CY Control Cable Market is diverse and spans a wide array of industrial, commercial, and public sectors, each requiring reliable and shielded cabling solutions for their operational continuity and safety. Primary end-users include industrial automation firms that deploy these cables in complex manufacturing plants for connecting programmable logic controllers (PLCs), sensors, actuators, and human-machine interfaces. The automotive industry represents a significant segment, using these cables for vehicle assembly lines, robotics, and testing equipment. Construction companies, particularly those involved in large-scale infrastructure projects, utilize CY control cables for building management systems, HVAC controls, fire alarm systems, and security installations within commercial, residential, and public buildings, where signal integrity and safety are paramount.

Furthermore, the energy and utilities sector, encompassing power generation, transmission, and distribution companies, relies on CY control cables for control panel wiring, switchgear applications, and monitoring systems in conventional and renewable energy installations. Original Equipment Manufacturers (OEMs) of various machinery, from packaging equipment to textile machines, also represent a crucial customer segment, integrating these cables into their products. Emerging customer segments include companies specializing in smart city solutions, electric vehicle charging infrastructure, and advanced robotics, all of which demand high-performance, interference-resistant control cables for optimal functionality. The increasing digitalization across these sectors ensures a sustained and growing demand for versatile and robust CY control cable solutions, positioning them as an indispensable component in modern technological advancements.

CY Control Cable Market Key Technology Landscape

The technology landscape of the CY Control Cable Market is characterized by continuous innovation in materials, manufacturing processes, and integration of smart functionalities, aimed at enhancing cable performance, safety, and durability. Key advancements include the development of advanced insulation and sheathing materials such such as cross-linked polyethylene (XLPE) for higher temperature resistance and improved mechanical properties, and low smoke zero halogen (LSZH) compounds for enhanced fire safety in critical environments. Innovations in shielding technologies, including optimized braiding and foil arrangements, are crucial for achieving superior electromagnetic compatibility (EMC), minimizing signal interference in data-intensive industrial settings. Furthermore, ongoing research focuses on developing materials that offer better resistance to oils, chemicals, and UV radiation, extending cable lifespan in harsh operating conditions.

Manufacturing processes have also seen significant technological upgrades, with precision extrusion techniques ensuring uniform insulation thickness and enhanced conductor stranding methods improving flexibility and reducing conductor fatigue. The adoption of lean manufacturing principles and automation in cable production lines contributes to higher efficiency, reduced waste, and improved product consistency. Emerging technologies involve the integration of smart features into control cables, such as embedded sensors for monitoring temperature, current, or mechanical stress, enabling predictive maintenance and real-time fault detection. Furthermore, advancements in data transmission capabilities within control cables are essential for supporting the increasing bandwidth requirements of Industry 4.0 applications, propelling the market towards more intelligent and interconnected cabling solutions capable of seamless integration into digital industrial ecosystems.

Regional Highlights

- Asia-Pacific: Dominates the market share due to rapid industrialization, extensive manufacturing base in China and India, significant investments in infrastructure development, and growing adoption of automation technologies.

- Europe: Characterized by mature industrial sectors, stringent safety regulations, and a strong focus on Industry 4.0 adoption in countries like Germany, driving demand for high-performance and specialized control cables.

- North America: Exhibits steady growth fueled by modernization of industrial facilities, increasing demand for renewable energy projects, and technological advancements in automation and robotics in the United States and Canada.

- Latin America: Emerging market with increasing industrialization and infrastructure projects, particularly in Brazil and Mexico, contributing to a gradual rise in demand for control cables.

- Middle East & Africa: Experiencing growth due to investments in oil and gas infrastructure, urbanization, and diversification of economies, leading to increased demand for robust cabling solutions in new industrial and commercial projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the CY Control Cable Market.- Prysmian Group

- Nexans

- Leoni AG

- Belden Inc.

- Lapp Kabel

- General Cable Technologies Corporation (now part of Prysmian Group)

- Sumitomo Electric Industries, Ltd.

- LS Cable & System Ltd.

- Elsewedy Electric

- Condumex S.A. de C.V.

- KEI Industries Limited

- Eland Cables

- Anixter International Inc.

- Alpha Wire

- Helukabel GmbH

Frequently Asked Questions

What are CY Control Cables primarily used for?

CY Control Cables are primarily used for measurement, control, and regulation in industrial automation, machinery, and process control systems. Their tinned copper braided screen provides essential electromagnetic interference (EMI) protection, ensuring reliable signal transmission in electrically noisy environments.

How do CY Control Cables differ from other cable types?

CY Control Cables are distinguished by their specific construction, which includes a galvanized steel wire braid or tinned copper braid screen. This shielding is their defining feature, offering superior EMI protection compared to unshielded control cables, making them ideal for sensitive electronic applications where signal integrity is critical.

What key factors are driving the growth of the CY Control Cable Market?

Key drivers include the global increase in industrial automation and Industry 4.0 initiatives, significant investments in smart infrastructure, a growing focus on workplace safety, and the continuous demand for reliable and robust electrical connectivity solutions across diverse industrial and commercial applications.

What is the impact of AI on the CY Control Cable Market?

AI impacts the CY Control Cable Market by optimizing manufacturing processes, driving demand for advanced cables in smart infrastructure and IoT, improving supply chain efficiency, and influencing the development of new cable designs with enhanced data transmission capabilities for AI-driven systems and predictive maintenance applications.

What are the typical insulation materials used in CY Control Cables?

Common insulation materials include PVC (Polyvinyl Chloride) for its cost-effectiveness and good electrical properties, XLPE (Cross-Linked Polyethylene) for higher temperature resistance and improved mechanical strength, and LSZH (Low Smoke Zero Halogen) for enhanced fire safety in public and critical infrastructure environments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager