Diamond Wire Saw Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 431065 | Date : Nov, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Diamond Wire Saw Market Size

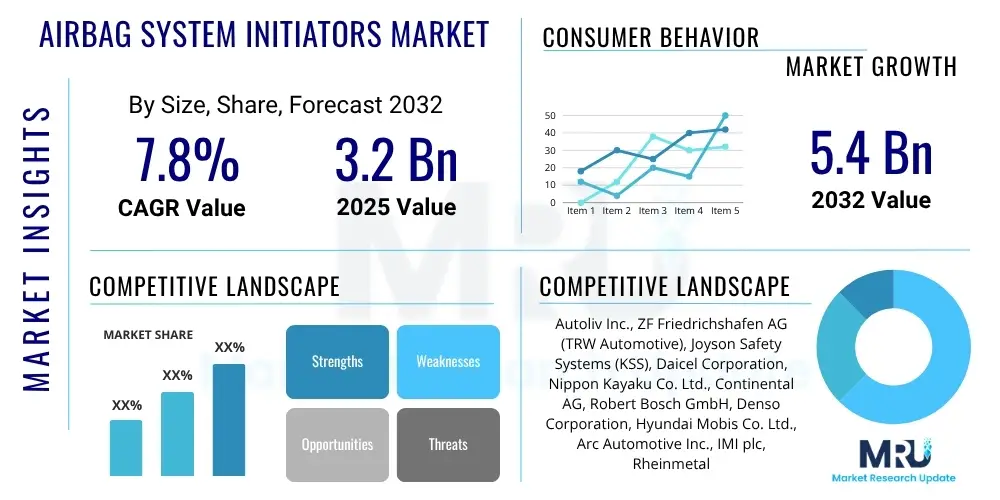

The Diamond Wire Saw Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2025 and 2032. The market is estimated at USD 420 million in 2025 and is projected to reach USD 700 million by the end of the forecast period in 2032.

Diamond Wire Saw Market introduction

The Diamond Wire Saw Market encompasses a sophisticated category of cutting tools fundamentally designed for the precise and highly efficient severance of exceptionally hard, abrasive, and often reinforced materials. At its core, this technology employs a continuous loop of high-tensile wire, meticulously embedded with industrial-grade diamond abrasives, which acts as the cutting medium. These diamonds, renowned for their unparalleled hardness, are typically affixed to the wire through advanced bonding processes such as electroplating, sintering, or vacuum brazing, ensuring maximum abrasive power and durability during operation. The diamond wire, driven by powerful hydraulic or electric motors, is guided through the target material, progressively eroding it with minimal friction and heat generation, thereby preventing material damage and ensuring a clean cut.

The operational versatility of diamond wire saws positions them as indispensable tools across a multitude of critical industrial sectors. In the construction industry, they are extensively utilized for demanding tasks like concrete demolition, precise cutting of reinforced concrete structures, bridge dismantling, and creating openings in thick walls and foundations, often where traditional methods are too noisy, slow, or structurally compromising. The natural stone industry relies heavily on this technology for the efficient quarrying of large blocks of granite, marble, sandstone, and other valuable ornamental stones, as well as for subsequent processing into slabs and architectural elements with superior surface finishes. Additionally, in advanced manufacturing, particularly in the semiconductor and electronics sectors, ultra-fine diamond wires are employed for slicing delicate silicon wafers and sapphire substrates with micron-level precision, which is critical for producing high-performance electronic components.

The myriad benefits offered by diamond wire saws are key drivers of their expanding market adoption. These benefits include unparalleled cutting precision, which significantly reduces material waste and allows for intricate and complex cutting geometries that are challenging with other methods. The technology contributes to enhanced operational safety by often enabling remote or semi-automated operation, minimizing direct human exposure to hazardous cutting environments. Furthermore, diamond wire saws typically operate with reduced noise and vibration levels compared to conventional methods, which is advantageous in urban areas or sensitive industrial settings. The ability to cut through extremely thick and varied materials, including steel-reinforced concrete and exotic alloys, with high efficiency and environmental consciousness, underscores their value. Global infrastructure development projects, the sustained demand for high-quality natural stone products, the burgeoning requirements for precision cutting in advanced materials, and the increasing scope of decommissioning activities in various industrial facilities collectively serve as the primary driving forces behind the robust growth observed within the Diamond Wire Saw Market, pushing continuous innovation and expanded application fields.

Diamond Wire Saw Market Executive Summary

The global Diamond Wire Saw Market is currently experiencing a period of significant expansion and technological evolution, driven by increasing industrial demands for precision, efficiency, and safety in material cutting. Key business trends indicate a pronounced shift towards automation and the integration of smart technologies, such as advanced sensor systems for real-time operational monitoring and predictive maintenance. This strategic focus by manufacturers aims to optimize cutting processes, extend wire lifespan, and reduce overall operational costs for end-users. There is also a growing emphasis on developing more robust and environmentally friendly diamond wire compositions, along with portable and robotic wire saw solutions that offer greater flexibility for specialized, hazardous, or hard-to-reach applications, consequently broadening the market's addressable scope and enhancing competitive dynamics within the sector.

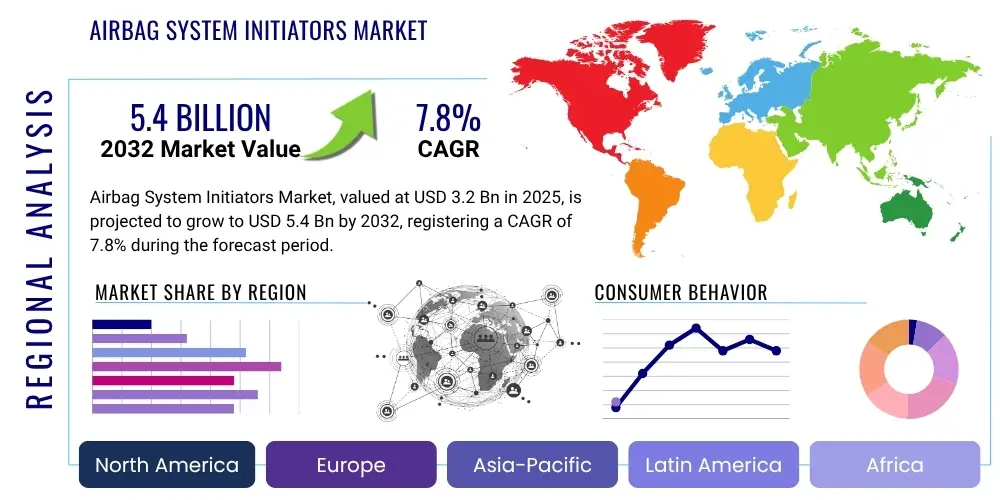

From a regional perspective, the market's growth trajectory is distinctly influenced by varied economic development patterns and industrial priorities. The Asia Pacific (APAC) region stands out as a dominant and rapidly expanding market, fueled by aggressive urbanization initiatives, extensive government investments in infrastructure projects, and the rapid growth of construction and manufacturing sectors, particularly in populous economies like China and India. Conversely, established markets such as North America and Europe continue to demonstrate steady growth, primarily driven by ongoing infrastructure modernization, the increasing scope of nuclear facility decommissioning, and the persistent demand for high-precision cutting in advanced industrial applications like aerospace and electronics. These regions also lead in technological innovation, fostering the development and adoption of high-performance, automated cutting solutions. Emerging markets in Latin America and the Middle East & Africa are showing promising potential, stimulated by expanding mining operations, new construction booms, and the establishment of nascent industrial facilities, which collectively create a growing demand for reliable and efficient diamond wire cutting technologies.

Segmentation analysis reveals nuanced trends across product types and applications. The construction sector consistently remains the largest and most influential application segment, with an unceasing demand for precise and efficient cutting tools crucial for urban redevelopment, demolition, and large-scale public works. Concurrently, the stone quarrying and processing segment maintains a stable and substantial market share, underpinned by the global architectural and aesthetic demand for natural stones. A noteworthy trend is the high-growth trajectory observed in niche segments such as semiconductor and electronics manufacturing, where the requirement for ultra-thin, highly precise wafer slicing continues to drive innovation in finer wire diameters and advanced material separation techniques. Furthermore, the market for vacuum brazed and electroplated diamond wire saws is witnessing increased adoption due to their specific performance advantages in diverse material types and demanding cutting environments, underscoring the ongoing technological diversification and specialization within the diamond wire saw product landscape to meet varied industrial specifications and operational challenges effectively.

AI Impact Analysis on Diamond Wire Saw Market

Common inquiries from users regarding the integration of Artificial Intelligence (AI) into the Diamond Wire Saw Market frequently highlight its transformative potential in areas such as operational optimization, precision enhancement, and safety protocol advancements. Users are keen to understand how AI algorithms can deliver real-time adjustments to cutting parameters across a spectrum of materials, thereby moving beyond static settings to dynamic, adaptive control. Significant interest is also focused on the application of AI in predictive maintenance, aiming to minimize costly unplanned downtime by foreseeing equipment failures and scheduling interventions proactively. Furthermore, there are questions about AI's role in reducing the dependency on highly skilled human operators by automating complex decision-making processes, as well as its contribution to environmental sustainability through optimized material yield and reduced waste. The overarching expectation is for AI to usher in a new era of 'smart cutting' solutions, characterized by greater autonomy, data-driven insights, and superior overall performance in challenging industrial environments.

The influence of AI on the diamond wire saw market is poised to be multifaceted and profound, fundamentally reshaping how these tools operate and are managed. One of the most significant impacts will be in the realm of real-time process optimization. AI-driven algorithms, drawing upon data from integrated sensors monitoring wire tension, cutting speed, material hardness, and temperature, can dynamically adjust operational settings to maintain peak efficiency and prevent excessive wear. This adaptive control not only enhances cutting speed and precision but also significantly extends the lifespan of the diamond wire and the associated machinery. Furthermore, AI will revolutionize maintenance practices by enabling highly accurate predictive maintenance. By analyzing vibration patterns, motor performance, and historical failure data, AI systems can forecast potential equipment malfunctions, allowing for scheduled maintenance before critical failures occur, thereby drastically reducing downtime and maintenance costs. This proactive approach ensures continuous operation and maximizes asset utilization.

Beyond operational adjustments, AI integration will also lead to substantial improvements in quality control and safety. AI-powered vision systems can conduct real-time inspections of the cut surface, identifying any imperfections or deviations from specified tolerances instantly, thus ensuring consistent output quality without human intervention. These systems can also monitor the integrity of the diamond wire itself, detecting micro-cracks or wear patterns that could lead to breakage. In terms of safety, AI algorithms can analyze operational data to identify potential hazards, such as unusual vibrations or overheating, and trigger immediate alerts or automatic shutdowns, significantly mitigating risks for operators. Moreover, AI can contribute to more sustainable operations by optimizing cutting paths to reduce material loss and minimize energy consumption. The ability of AI to process vast amounts of data and learn from experience will drive continuous improvement in cutting strategies, making diamond wire saws more intelligent, efficient, and safer tools for a wide array of industrial applications, solidifying their role in the smart manufacturing ecosystem.

- Predictive maintenance schedules for extended equipment lifespan and significantly reduced unplanned downtime.

- Optimized cutting parameters (speed, tension, coolant flow) in real-time based on material properties and wear for maximum efficiency and precision.

- Enhanced quality control through AI-powered visual inspection of cut surfaces, detecting anomalies and ensuring consistent output.

- Automated diagnostics and proactive troubleshooting of operational issues, minimizing the need for constant human supervision.

- Improved operational safety by continuously monitoring equipment performance and environmental conditions to predict and prevent potential hazards.

- Data-driven insights for superior resource management, including optimizing diamond wire consumption, energy usage, and coolant efficiency.

DRO & Impact Forces Of Diamond Wire Saw Market

The Diamond Wire Saw Market is dynamically shaped by a compelling interplay of driving forces, inherent restraints, and burgeoning opportunities that collectively dictate its growth trajectory and competitive landscape. Among the primary drivers is the relentless expansion of the global construction industry, particularly pronounced in developing economies and urban centers where extensive infrastructure projects, large-scale demolitions, and precise concrete cutting for renovations are consistently in demand. This is coupled with the sustained global appetite for natural stone, driving the need for highly efficient and precise quarrying and processing techniques for granite, marble, and other architectural stones. Furthermore, the increasing complexity of specialized cutting tasks, such as those in nuclear facility decommissioning, underwater cutting, and aerospace component manufacturing, where conventional methods are inadequate or unsafe, significantly propels the adoption of advanced diamond wire saw technology. The overarching industrial trend towards automation and higher productivity, aiming to reduce labor costs and improve operational consistency, further solidifies the market's growth impetus, making these saws integral to modern industrial processes.

Despite these robust drivers, the market navigates several notable restraining factors that present challenges to widespread adoption and market expansion. A significant hurdle is the substantial initial capital investment required for acquiring high-performance diamond wire saw machinery, which can be prohibitive for smaller enterprises or those with limited access to financing. This high entry cost is compounded by the ongoing operational expenses associated with consumable components, particularly the diamond wires themselves, which are subject to wear and require periodic replacement, along with specialized coolants and slurry management. Moreover, the operation and maintenance of these sophisticated systems demand a highly skilled workforce, and the scarcity of such specialized technical expertise in certain regions can act as a significant bottleneck. Stringent environmental regulations related to noise pollution, dust emissions, and wastewater discharge in densely populated areas or protected sites also impose additional operational complexities and costs, requiring compliance measures that can add to the overall project expenditure, influencing purchasing decisions.

However, the market is rife with substantial opportunities that promise to unlock new growth avenues and foster innovation. Emerging economies, especially in Southeast Asia, Africa, and Latin America, present vast untapped potential as they embark on ambitious infrastructure development and urbanization programs, creating significant demand for efficient cutting solutions. The global shift towards renewable energy sources, such as the construction and decommissioning of large-scale wind farms (onshore and offshore) and solar energy facilities, necessitates specialized cutting tools capable of handling robust and sometimes novel materials. Technological advancements in material science are also paving the way for diamond wire saws to be increasingly utilized in cutting advanced composites, high-performance ceramics, and superalloys in high-tech industries, expanding their application beyond traditional sectors. The pervasive influence of Industry 4.0, including the integration of the Internet of Things (IoT), Artificial Intelligence (AI), and advanced robotics, offers transformative opportunities for developing smarter, more autonomous, and interconnected wire sawing systems, leading to unprecedented levels of optimized performance, predictive maintenance capabilities, and enhanced operational safety. These converging factors, coupled with continuous research and development aimed at improving wire durability, cutting precision, and energy efficiency, are set to broaden the market's scope and accelerate its penetration into new and evolving industrial applications globally.

Segmentation Analysis

The Diamond Wire Saw Market is meticulously segmented to offer a comprehensive and granular understanding of its diverse components, encompassing various product types, operational mechanisms, and critical end-use applications. This detailed categorization facilitates a precise analysis of market dynamics, enabling stakeholders to identify specific growth drivers, competitive landscapes, and technological advancements pertinent to each segment. Such segmentation is vital for crafting targeted business strategies, informing product development, and understanding the nuanced demands of different industrial verticals. The market's structure reflects the continuous innovation geared towards specialization and enhanced efficiency, addressing the unique challenges presented by a wide array of materials and cutting environments.

The primary segmentation includes distinctions by the manufacturing process of the diamond wire, which directly impacts its performance characteristics and suitability for different materials; by the various industrial applications where these saws are deployed, highlighting their versatility; and by the physical attributes of the wire, such as its diameter, which dictates the precision and scale of the cut. Further sub-segmentation often considers factors like the power source (electric, hydraulic), the level of automation (manual, semi-automatic, fully automatic/robotic), and the mobility of the equipment (fixed, portable). These distinctions collectively illustrate the evolving technological landscape of the diamond wire saw industry, showcasing its adaptability to increasingly complex and demanding cutting requirements across global markets and solidifying its position as a cornerstone technology in precision material processing.

- By Type: This segment classifies diamond wires based on how the diamond particles are bonded to the wire core, influencing their durability, cutting aggressiveness, and suitability for specific materials.

- Electroplated Diamond Wire Saw: Diamonds are electrochemically bonded to the wire, often used for general-purpose cutting of medium-hard materials due to its free-cutting nature.

- Sintered Diamond Wire Saw: Diamonds are mixed with a metallic powder and heated to form a strong bond, ideal for demanding applications involving hard and abrasive materials like granite, offering extended life.

- Vacuum Brazed Diamond Wire Saw: Diamonds are brazed onto the wire in a vacuum furnace, providing extremely strong adhesion and exposure of diamond crystals, making them highly effective for very hard materials and tough cutting conditions.

- By Application: This segmentation highlights the diverse industries and specific tasks where diamond wire saws are employed, demonstrating their wide range of utility.

- Construction (Concrete Cutting, Bridge Demolition, Building Dismantling, Reinforced Concrete Structures, Road Sawing, Urban Renewal Projects)

- Stone Quarrying and Processing (Extraction of Granite, Marble, Sandstone, Limestone blocks; Slab Cutting, Monument Making, Dimension Stone Processing)

- Semiconductor and Electronics (Silicon Wafer Slicing, Sapphire Processing, Precision Cutting of Brittle Materials for Microchips and Optoelectronics)

- Aerospace and Defense (Cutting Advanced Composites, High-Performance Alloys, Specialized Ceramics for Aircraft Components and Military Hardware)

- Nuclear Decommissioning (Controlled Cutting of Radioactive Concrete, Metal Structures, Reactor Components, and Waste Segregation in Nuclear Facilities)

- Recycling and Scrapping (Demolition of Large Metal Structures, Ship Breaking, Reinforced Concrete Recycling for Material Recovery)

- Others (Metallurgical Applications, Ceramic Processing, Glass Cutting, Mining beyond natural stone, Scientific Research & Development)

- By Wire Diameter: Categorizes wires based on their thickness, which dictates cutting precision, speed, and material handling capabilities.

- Small Diameter (typically below 0.5 mm): Primarily for ultra-precision cutting in semiconductor, electronics, and delicate material applications, allowing for minimal kerf loss.

- Medium Diameter (0.5 mm to 2.0 mm): Used for a broad range of general industrial cutting tasks, including smaller construction projects, laboratory cutting, and some stone processing.

- Large Diameter (above 2.0 mm): Employed for heavy-duty applications in large-scale construction, demolition, and bulk stone quarrying, where robustness and fast material removal are paramount.

- By Operation Type: Distinguishes between the level of human intervention and automation in the sawing process.

- Manual/Semi-Automatic: Requires significant operator involvement for setup, control, and monitoring, common in smaller operations or custom jobs.

- Fully Automatic/Robotic: Integrated with advanced control systems and robotics, allowing for programmed, autonomous operation, often used in large industrial settings for consistency and safety.

Value Chain Analysis For Diamond Wire Saw Market

The value chain within the Diamond Wire Saw Market is a multi-tiered system that begins with the highly specialized sourcing and processing of raw materials, which form the fundamental components of the diamond wire itself. The upstream segment is dominated by a relatively concentrated group of expert suppliers responsible for producing industrial-grade diamonds, which are either natural or synthetic, and high-tensile steel wires. These suppliers also provide various sophisticated bonding agents, such as nickel, cobalt, copper, and bronze alloys, crucial for effectively affixing the diamond particles to the wire core through processes like electroplating, sintering, or vacuum brazing. Significant research and development efforts at this initial stage are continuously focused on enhancing diamond quality, improving diamond-to-wire bonding strength, and increasing wire flexibility and fatigue resistance. These advancements are paramount for boosting cutting performance, extending wire longevity, and ultimately reducing the cost per cut for end-users, underscoring the critical role of material science in the market's innovation.

Moving downstream, the value chain progresses into the manufacturing, assembly, and integration of the diamond wire saws, followed by their intricate distribution to diverse end-user segments. Manufacturers in this phase meticulously combine the diamond-impregnated wires with complex mechanical drives, hydraulic systems, precise electronic control units, and essential safety mechanisms. This stage encompasses rigorous quality assurance, comprehensive testing protocols, and often includes customization services to tailor the equipment to specific application requirements, such as unique material types or operational environments. The distribution channels for diamond wire saws are multifaceted, strategically designed to reach a global customer base. These channels typically include direct sales from the manufacturers, particularly for large industrial clients or for highly bespoke systems where direct technical consultation and support are critical. Additionally, a robust network of regional distributors, specialized equipment dealers, and rental companies plays a vital role, especially in accessing broader markets, including smaller contractors and international territories. These indirect channels provide localized sales support, comprehensive technical assistance, and accessible after-sales services, which are crucial for customer satisfaction and market penetration.

The final crucial stage of the value chain involves the deployment of diamond wire saws by end-users across various industries, complemented by essential post-sales services that add significant value. End-users span sectors such as heavy construction, large-scale stone quarrying and processing, and advanced electronics manufacturing. Post-sales support, including professional installation, comprehensive operator training, routine maintenance services, and the readily available supply of replacement wires and spare parts, is indispensable for ensuring the uninterrupted and efficient operation of these high-value tools. The effectiveness and responsiveness of these distribution and service channels directly impact market penetration, customer loyalty, and operational uptime. A robust feedback loop between manufacturers, distributors, and end-users is fundamental for continuous product improvement and innovation, ensuring that diamond wire saws evolve to meet the dynamic and increasingly stringent demands of industrial applications, thereby strengthening the entire value chain and driving market growth through sustained technological advancement and customer-centric solutions.

Diamond Wire Saw Market Potential Customers

The Diamond Wire Saw Market serves a highly diversified clientele, consisting of end-users and institutional buyers whose operational needs demand unparalleled precision, efficiency, and safety in material cutting. Foremost among these are large-scale construction companies and civil engineering firms, particularly those engaged in critical infrastructure projects such as the construction and demolition of bridges, highways, dams, and multi-story buildings. These customers require robust and reliable diamond wire saws for controlled demolition, making precise cuts in heavily reinforced concrete, pre-stressed concrete, and masonry, often in sensitive urban environments where noise, vibration, and dust must be meticulously controlled. The ability of wire saws to perform complex cuts without compromising structural integrity or generating excessive collateral damage makes them indispensable for modern, efficient, and safe construction and demolition practices.

Another substantial customer segment is the natural stone industry, encompassing quarry operators, stone processors, and fabricators of architectural elements and monuments. These businesses leverage diamond wire saws for the primary extraction of massive blocks of valuable natural stones like granite, marble, travertine, and onyx from quarries, maximizing yield and minimizing waste. Subsequent processing involves slicing these blocks into precise slabs and intricate shapes, where the high accuracy and smooth finish provided by wire saws are crucial for meeting aesthetic and structural quality standards for commercial and residential applications. The efficiency of these saws directly impacts production capacity and profitability for stone industry players. Additionally, the semiconductor and advanced electronics manufacturing sectors represent a high-value, albeit niche, customer base. These industries require ultra-fine diamond wires for the extraordinarily precise slicing of brittle and hard materials such as silicon, sapphire, and various ceramics into wafers and substrates, where micron-level accuracy is paramount for device performance and yield, driving continuous innovation in wire technology.

Beyond these core industries, the scope of potential customers extends into specialized and emerging fields. Nuclear facility decommissioning companies represent a critical segment, utilizing diamond wire saws for the safe and precise cutting of highly radioactive concrete structures, metal components, and reactor vessels, often requiring remote-controlled or submersible operations to minimize human exposure. The aerospace and defense industries are also significant buyers, employing these saws for cutting advanced composite materials, superalloys, and specialized ceramics used in the fabrication of high-performance aircraft components, propulsion systems, and ballistic protection. Furthermore, recycling and scrap processing plants, particularly those handling large industrial machinery, ship breaking, and highly reinforced concrete from urban demolition, increasingly adopt diamond wire saws for efficient material separation and resource recovery. This broad and growing spectrum of demanding applications underscores the versatility, technological sophistication, and critical utility of diamond wire saw technology across a diverse global industrial landscape, creating varied and expanding market opportunities.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 420 million |

| Market Forecast in 2032 | USD 700 million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Husqvarna Group, Tyrolit Schleifmittelwerke Swarovski K.G., Hilti Corporation, WEKA Elektrowerkzeuge GmbH, Saint-Gobain (Norton Clipper), Diteq (A Division of Husqvarna), Cedima GmbH, Lissmac Maschinenbau GmbH, Braun Maschinenfabrik GmbH, Dr. Fritsch GmbH & Co. KG, Diamantwerkzeug GmbH (Diamantwerk), Wuxi Geotec Geological Equipment Co., Ltd., Well-Link Industrial Ltd., Sino-Crystal Diamond Co., Ltd., EHWA Diamond Industrial Co., Ltd., DD-Group, Beijing Grish Hitech Co., Ltd., Shenzhen Jingshan Science & Technology Co., Ltd., Fujian Quanzhou Wanlong Diamond Tools Co., Ltd., Gangsaw Wire Saw Machine Co., Ltd., DIAMOND TOOLS Abrasives Technology, Gemini Saw Company, Diaquip Ltd, Advanced Diamond Technologies (ADT), Winterstone Tools |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Diamond Wire Saw Market Key Technology Landscape

The technological landscape of the Diamond Wire Saw Market is characterized by relentless innovation aimed at significantly improving cutting performance, enhancing wire durability, and ensuring paramount operational safety and efficiency. A pivotal area of development lies in advanced diamond bonding technologies, where manufacturers are constantly refining methods for embedding industrial diamonds onto the wire matrix. This includes sophisticated electrochemical plating techniques that ensure a denser, more uniform distribution and exceptionally strong adhesion of diamond particles, as well as highly specialized sintering and vacuum brazing processes designed to yield superior wear resistance, optimized diamond exposure, and significantly extended wire lifespan under the most challenging cutting conditions. The overarching objective is to maximize the active cutting edges while preserving the wire's structural integrity, leading directly to faster cutting speeds, reduced operational friction, and ultimately, a lower cost per linear meter for end-users, which is a critical performance metric in industrial applications.

Furthermore, significant advancements are being made in the core materials used for the wire itself. Modern diamond wires frequently incorporate high-strength steel alloys, often designed as multi-stranded configurations, to achieve superior flexibility, exceptional tensile strength, and enhanced fatigue resistance. These material innovations are crucial for minimizing wire breakage and deformation, particularly in demanding applications involving heavily reinforced concrete, abrasive natural stones, or exotic alloys. The integration of advanced sensor technologies has also become a standard feature, providing real-time, granular data on critical operational parameters such as wire tension, linear cutting speed, material temperature, and coolant flow rates. This continuous stream of data is invaluable for implementing highly effective predictive maintenance strategies, enabling operators to precisely monitor wire wear, anticipate potential component failures, and dynamically optimize cutting parameters on the fly, thereby preventing costly unexpected downtime and significantly enhancing overall system reliability and throughput.

The evolution of the Diamond Wire Saw Market also extends profoundly into the design and intelligence of the sawing machines. There is a discernible trend towards developing more modular, compact, and highly portable machine designs, which vastly improves their versatility and ease of deployment across diverse job sites—from densely populated urban construction zones to remote quarries and specialized industrial facilities. A major technological leap involves the growing integration of advanced robotics and artificial intelligence (AI) for fully automated wire saw operation. These intelligent systems enable pre-programmed, autonomous cutting sequences, real-time adaptive control, and remote monitoring, which are particularly advantageous in hazardous environments such as nuclear decommissioning or deep-sea cutting operations, significantly enhancing safety and precision. Moreover, ongoing innovations in eco-friendly coolants, efficient slurry management systems, and sophisticated wastewater treatment solutions are gaining substantial traction, addressing critical environmental concerns and contributing to more sustainable and compliant operational practices. These holistic technological advancements collectively drive the market's growth, positioning diamond wire saws as increasingly intelligent, resilient, and indispensable tools capable of tackling an ever-wider array of complex and demanding cutting applications worldwide.

Regional Highlights

- North America: This region stands as a significant and mature market for diamond wire saws, primarily propelled by extensive governmental and private sector investments in infrastructure refurbishment projects, controlled urban demolition, and the complex decommissioning of aging nuclear power plants. The market here is characterized by a high demand for technologically advanced, often automated, cutting solutions, reflecting a strong regional emphasis on stringent worker safety standards, environmental compliance, and operational efficiency. North America is also a hub for innovation in robotics and smart cutting technologies, which facilitates the widespread adoption of high-performance wire saw equipment across urban development, aerospace component manufacturing, and specialized industrial maintenance. The presence of major construction giants and a robust manufacturing sector further solidifies and fuels the market's sustained growth.

- Europe: Europe represents another key, albeit mature, market segment, distinguished by its stringent environmental regulations, a pervasive focus on precision engineering, and high efficiency requirements across construction, advanced stone processing, and sophisticated recycling industries. Countries such as Germany, Italy, France, and Spain are leading contributors, particularly renowned for their advancements in efficient stone quarrying techniques, the controlled demolition of obsolete infrastructure, and specialized cutting for historical preservation. The region also experiences substantial demand from the high-value automotive, aerospace, and renewable energy sectors for cutting advanced composite materials and specialized alloys. Escalating efforts towards sustainable building practices, circular economy initiatives, and enhanced resource recovery significantly contribute to the steady and growing uptake of advanced diamond wire saw technology throughout the continent.

- Asia Pacific (APAC): The APAC region is unequivocally projected to be the fastest-growing market globally for diamond wire saws. This accelerated expansion is overwhelmingly driven by rapid urbanization trends, monumental government-led infrastructure development projects (e.g., high-speed rail networks, smart cities), and flourishing construction activities across key economies such as China, India, and various Southeast Asian nations. The burgeoning demand for natural stone in both new construction and architectural designs, coupled with the rapid expansion of manufacturing capabilities, particularly in the electronics and semiconductor industries (requiring ultra-precise material slicing), is driving considerable adoption. The region is witnessing a robust growth of local manufacturers who, alongside established international players, are catering to the diverse and ever-increasing industrial needs for efficient and precise cutting solutions.

- Latin America: This region presents considerable emerging market opportunities, primarily spurred by increasing mining activities, particularly for precious metals and industrial minerals, and ongoing large-scale infrastructure development projects. Key markets like Brazil, Mexico, and Chile are experiencing significant demand, fueled by expansive stone quarrying operations and the consistent growth of residential and commercial construction sectors. While the initial capital outlay for advanced diamond wire saw equipment can sometimes pose a barrier, the undeniable long-term benefits of enhanced efficiency, superior precision, and increased operational safety are progressively being recognized and adopted. Substantial investments in extensive public works and private development initiatives continue to contribute significantly to the burgeoning demand for reliable wire cutting technologies across the continent.

- Middle East and Africa (MEA): The MEA market is undergoing substantial growth, predominantly driven by highly ambitious infrastructure projects, especially in the Gulf Cooperation Council (GCC) countries, coupled with significant investments in expanding and maintaining oil and gas facilities. The rapid construction of new cities, mega-projects, airports, and extensive commercial complexes fuels a strong demand for efficient concrete and stone cutting solutions. Furthermore, the region’s abundant natural stone reserves support a vibrant and expanding quarrying and processing industry. While still considered a developing market in terms of advanced industrial adoption, the increasing embrace of modern construction techniques, stricter safety standards, and a focus on high-quality outputs bodes exceptionally well for the future expansion and maturation of the diamond wire saw market throughout the Middle East and Africa, attracting further international investment and technological transfer.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Diamond Wire Saw Market.- Husqvarna Group

- Tyrolit Schleifmittelwerke Swarovski K.G.

- Hilti Corporation

- WEKA Elektrowerkzeuge GmbH

- Saint-Gobain (Norton Clipper)

- Diteq (A Division of Husqvarna)

- Cedima GmbH

- Lissmac Maschinenbau GmbH

- Braun Maschinenfabrik GmbH

- Dr. Fritsch GmbH & Co. KG

- Diamantwerkzeug GmbH (Diamantwerk)

- Wuxi Geotec Geological Equipment Co., Ltd.

- Well-Link Industrial Ltd.

- Sino-Crystal Diamond Co., Ltd.

- EHWA Diamond Industrial Co., Ltd.

- DD-Group

- Beijing Grish Hitech Co., Ltd.

- Shenzhen Jingshan Science & Technology Co., Ltd.

- Fujian Quanzhou Wanlong Diamond Tools Co., Ltd.

- Gangsaw Wire Saw Machine Co., Ltd.

- DIAMOND TOOLS Abrasives Technology

- Gemini Saw Company

- Diaquip Ltd

- Advanced Diamond Technologies (ADT)

- Winterstone Tools

Frequently Asked Questions

What are the primary advantages of diamond wire saws over traditional cutting methods?

Diamond wire saws offer significant advantages over traditional cutting methods such as demolition hammers, thermal lances, or abrasive discs. They provide unparalleled cutting precision, enabling clean, straight, and highly accurate cuts even through heavily reinforced concrete, thick stone, or intricate structures. This precision dramatically reduces material waste, allows for complex geometric cuts, and minimizes the need for extensive post-cutting finishing. Furthermore, diamond wire saws operate with significantly lower noise and vibration levels, making them ideal for urban environments or sensitive areas. Their capability to cut extremely large or irregularly shaped objects, often remotely, enhances operational safety and efficiency across diverse industrial applications, including controlled demolition, stone quarrying, and precision manufacturing.

How does the choice of diamond wire type and diameter impact its application?

The selection of diamond wire type and diameter is critical for optimizing performance in a given application. Diamond wires are primarily categorized by their bonding method (electroplated, sintered, vacuum brazed), which determines their durability, cutting aggressiveness, and suitability for specific material hardness. Electroplated wires are often favored for general-purpose cutting of medium-hard materials due to their sharper initial cut, while sintered and vacuum brazed wires offer superior wear resistance and extended lifespan for highly demanding applications involving granite, reinforced concrete, or abrasive materials. Wire diameter also plays a crucial role: smaller diameters (e.g., below 0.5 mm) are essential for ultra-precision slicing in semiconductor manufacturing to minimize kerf loss, whereas larger diameters (e.g., above 2.0 mm) are designed for heavy-duty, high-volume material removal in large-scale construction or stone quarrying, balancing speed and robustness.

What are the key maintenance requirements for ensuring the longevity of diamond wire saws?

Ensuring the longevity and optimal performance of diamond wire saws necessitates diligent and regular maintenance. Key requirements include consistent inspection of the diamond wire for signs of wear, tension, and damage, as wire integrity is paramount for effective cutting. Proper tensioning of the wire must be maintained according to manufacturer specifications to prevent breakage or erratic cutting. Regular checks and lubrication of all moving components, such as pulleys, guide rollers, and drive systems, are essential to minimize friction and wear. It is also crucial to ensure an adequate and clean supply of coolant, as this prevents overheating of both the wire and the material, flushing away cutting debris effectively. Adherence to manufacturer-recommended service schedules, including replacement of worn-out parts like bearings or hydraulic fluids, combined with timely preventative measures, significantly extends the operational lifespan of both the wire and the sawing machine, minimizing costly downtimes and ensuring consistent output quality.

What environmental considerations are associated with the use of diamond wire saws?

The use of diamond wire saws involves several important environmental considerations, primarily related to noise, dust, and water management. While generally quieter than impact tools, operating noise must still be managed, especially in urban or residential areas. Cutting processes can generate fine dust particles, necessitating robust dust suppression systems, often achieved through wet cutting methods using water. The resultant water-based slurry, containing fine particles of cut material and diamond wire debris, requires responsible collection, treatment, and disposal to prevent environmental contamination. Modern diamond wire saw systems increasingly incorporate water recycling units and advanced filtration systems to minimize water consumption and ensure environmentally compliant discharge. Additionally, the inherent precision of wire saws contributes positively to resource efficiency by reducing material loss and optimizing yield, aligning with broader sustainability goals by minimizing waste generation from the outset.

How are recent technological advancements impacting the performance of diamond wire saws?

Recent technological advancements are profoundly impacting the performance of diamond wire saws, making them significantly more efficient, precise, and user-friendly. Innovations in diamond bonding techniques, such as advanced electroplating and vacuum brazing, have led to diamond wires with superior cutting aggressiveness and extended operational lifespans. Concurrently, the development of high-strength, fatigue-resistant wire core materials minimizes breakage and allows for faster cutting speeds. The integration of smart sensor technology provides real-time data on critical parameters like wire tension, cutting speed, and temperature, enabling dynamic process optimization and highly accurate predictive maintenance. Furthermore, the incorporation of artificial intelligence (AI) and robotics is paving the way for fully autonomous operations, enhancing safety in hazardous environments, improving cutting path optimization, and ensuring consistent quality. These advancements collectively boost productivity, reduce operational costs, and expand the application scope of diamond wire saws into increasingly complex and demanding industrial sectors worldwide.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager