Digital Shipyard Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 430278 | Date : Nov, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Digital Shipyard Market Size

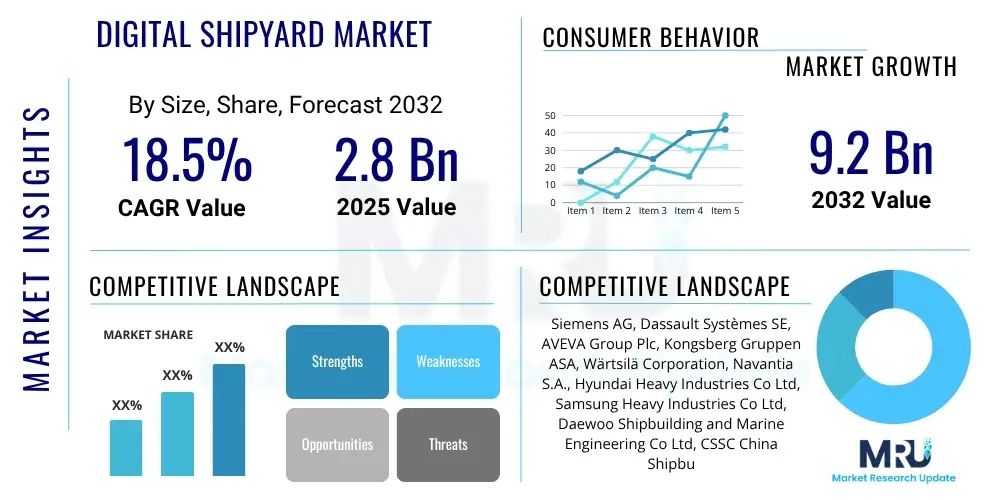

The Digital Shipyard Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2025 and 2032. The market is estimated at USD 2.8 Billion in 2025 and is projected to reach USD 9.2 Billion by the end of the forecast period in 2032.

Digital Shipyard Market introduction

The Digital Shipyard Market signifies a transformative shift in global shipbuilding, integrating advanced digital technologies across the entire maritime value chain. This encompasses a comprehensive approach to modernizing traditional shipbuilding processes by leveraging innovative solutions from initial vessel design and engineering through to production, operational management, maintenance, and end-of-life considerations. The core objective is to create highly efficient, precise, and data-driven ecosystems that replace conventional labor-intensive methods with smart, automated, and interconnected workflows.

Product offerings within this market are diverse, including sophisticated software platforms for Product Lifecycle Management PLM, Computer-Aided Design CAD, Computer-Aided Manufacturing CAM, and Enterprise Resource Planning ERP. These are complemented by advanced hardware components such as Internet of Things IoT sensors for real-time data acquisition, robotics for automated fabrication and assembly, and virtual reality VR or augmented reality AR devices for immersive design reviews and training. Major applications span critical areas such as optimizing hull design, streamlining production planning, enabling virtual prototyping for accelerated development cycles, facilitating real-time monitoring of construction progress, and implementing predictive maintenance strategies for operational vessels to minimize downtime and extend asset life.

The benefits derived from adopting digital shipyard solutions are extensive, translating into significantly improved operational efficiency, substantial reductions in overall production costs, enhanced safety protocols for shipyard workers through automation and remote monitoring, and a faster time-to-market for new vessels. Furthermore, these technologies lead to consistently higher quality builds with fewer errors, adhering to stringent international standards. Key driving factors fueling the expansion of this market include the global imperative for more sustainable and environmentally compliant shipping practices, the widespread adoption of Industry 4.0 principles across industrial sectors, the increasing complexity and customization demands of modern vessel designs, and significant governmental investments aimed at modernizing naval fleets and strengthening domestic shipbuilding capabilities. These integrated drivers position the digital shipyard as a pivotal element in the future of maritime industry innovation.

Digital Shipyard Market Executive Summary

The Digital Shipyard Market is experiencing dynamic growth, propelled by technological advancements and strategic industry shifts. Current business trends indicate a strong emphasis on automation, the adoption of digital twin technology for comprehensive lifecycle management, and a heightened focus on cybersecurity to protect intellectual property and operational integrity. Companies are increasingly investing in integrating artificial intelligence and machine learning to optimize design, production, and maintenance processes, seeking to achieve greater predictive capabilities and operational agility across their value chains. This digital transformation is not merely about efficiency but also about creating resilient, adaptable, and technologically superior shipbuilding capabilities.

Regionally, the market exhibits diverse growth patterns. The Asia Pacific region stands out as a dominant force, driven by the immense shipbuilding capacities of countries like South Korea, China, and Japan, which are aggressively adopting digital solutions to maintain global competitiveness and meet escalating demand for both commercial and naval vessels. Europe continues to lead in advanced research and development, particularly focusing on sustainable shipbuilding, specialized vessels, and high-value maritime innovation. North America, while having a smaller commercial shipbuilding footprint, is characterized by substantial investments in naval applications and defense-related digital shipyard technologies, emphasizing security and advanced capabilities. These regional trends underscore a global commitment to modernizing maritime manufacturing.

Segmentation trends reveal that the software component holds the largest market share due to its foundational role in enabling digital processes, encompassing design, planning, and management platforms. The services segment is projected to demonstrate the fastest growth, as shipyards increasingly require expert consultation, integration, and ongoing support to effectively implement and manage complex digital solutions. Hardware components, including robotics and IoT devices, serve as critical enablers, supporting the physical automation and data collection necessary for digital operations. This holistic market evolution reflects an industry-wide recognition that digital transformation is not an option but a strategic imperative for future success and competitiveness.

AI Impact Analysis on Digital Shipyard Market

User inquiries about AI's influence in the Digital Shipyard Market frequently center on its practical application in automating highly intricate processes and enhancing decision-making. Individuals are keen to understand how AI can streamline ship design through generative algorithms, improve the precision of predictive maintenance for critical marine assets, and automate repetitive tasks within shipyard environments. Furthermore, there is considerable interest in AI's role in optimizing supply chains, managing inventory, and ensuring robust quality control during various construction phases. Underlying these inquiries are concerns about the necessary data infrastructure, the availability of a skilled workforce capable of leveraging AI tools, potential implications for employment, and the paramount importance of cybersecurity for AI-driven systems in safeguarding sensitive information and operational integrity.

Based on these themes, Artificial Intelligence is expected to profoundly transform the Digital Shipyard Market by introducing unprecedented levels of automation, precision, and intelligence across the entire shipbuilding lifecycle. AI facilitates advanced data analytics, moving beyond reactive measures to proactive, predictive strategies in design, production, and operational maintenance. This shift promises to enhance operational efficiency, significantly reduce costs associated with errors and downtime, and improve the overall quality and safety of maritime vessels. The successful adoption of AI will hinge on effective data integration strategies, continuous workforce upskilling, and a robust cybersecurity framework to mitigate emerging risks and maximize the strategic advantages offered by these intelligent systems.

- Enhanced predictive maintenance by analyzing real-time sensor data from vessels and equipment, accurately forecasting potential failures, and scheduling proactive interventions to minimize costly downtime.

- Automated and generative design capabilities, allowing for rapid iteration, optimization of hull forms, structural integrity analysis, and material selection with reduced human input and improved performance.

- Optimized production planning and scheduling through intelligent algorithms that efficiently manage resources, synchronize complex tasks, and identify and resolve potential bottlenecks in real-time.

- Improved quality control and inspection processes using computer vision and machine learning for automated defect detection, ensuring adherence to stringent specifications and regulatory compliance.

- Intelligent supply chain management, enabling better forecasting of material needs, optimizing logistics for parts delivery, and reducing lead times for critical components, enhancing resilience.

- Advanced robotics and automation, leveraging AI for autonomous welding, precise assembly, efficient material handling, and painting operations, increasing consistency, speed, and worker safety.

- Real-time data analytics and sophisticated decision support systems, providing deep insights into operational performance across the shipyard and empowering informed strategic choices for management.

- Virtual and augmented reality integration for immersive training, remote technical assistance, and interactive assembly instructions, powered by AI to adapt to user needs and provide contextual information.

- Simulation and digital twin applications for comprehensive lifecycle management, where AI models predict vessel performance under various conditions and suggest improvements for design and operation.

- Enhanced safety protocols through AI-driven monitoring of hazardous environments and worker behavior, preventing accidents, detecting anomalies, and ensuring a safer working environment.

- Optimized energy consumption and waste reduction through AI algorithms that manage power systems, material usage, and process flows, contributing to more sustainable shipbuilding.

DRO & Impact Forces Of Digital Shipyard Market

The Digital Shipyard Market's trajectory is profoundly shaped by a dynamic interplay of driving forces, critical restraints, emerging opportunities, and broader impact forces that collectively dictate its growth, investment landscape, and strategic priorities. These elements interact to influence the pace of technological adoption and the evolution of shipbuilding practices worldwide. The fundamental imperative to achieve superior operational efficiency, significantly reduce costs, and enhance the overall quality and environmental sustainability of shipbuilding processes serves as the primary catalyst for the widespread embrace of digital transformation within the maritime industry. However, this transformative journey is not without its significant challenges, as substantial barriers such as high upfront capital expenditure, a pronounced shortage of specialized digital skills, and inherent cybersecurity risks continue to temper rapid adoption rates.

Driving the market forward are several powerful forces, prominently featuring the pervasive global trend of Industry 4.0, which advocates for intelligent automation, data exchange, and advanced connectivity within manufacturing ecosystems, directly aligning with the core principles of digital shipyards. The increasing global demand for technologically sophisticated, energy-efficient, and environmentally compliant vessels further fuels this growth, as shipbuilders seek advanced tools to meet these complex requirements. Moreover, significant governmental investments in naval modernization programs across various nations, coupled with a strategic focus on bolstering defense capabilities, are accelerating the adoption of cutting-edge digital solutions. As modern vessel designs become inherently more complex, incorporating advanced materials and integrated systems, digital tools become indispensable for managing these intricacies with unparalleled precision and efficiency.

Conversely, the market faces considerable restraints that challenge its unbridled expansion. The substantial initial investment required for implementing comprehensive digital infrastructure, including sophisticated software licenses, integrated hardware systems, and network upgrades, can be a deterrent for many shipyards, especially smaller and medium-sized enterprises. Furthermore, a critical scarcity of a workforce proficient in advanced digital technologies, such as AI, IoT, and cybersecurity, poses a significant hurdle to effective deployment and operation. The inherent cybersecurity risks associated with increasingly interconnected digital systems, making them vulnerable to sophisticated attacks, represent a constant threat. Additionally, a degree of resistance to change within traditionally conservative shipbuilding practices can impede the rapid uptake of new solutions, requiring substantial organizational and cultural shifts. Despite these challenges, numerous opportunities abound, particularly in the integration of nascent technologies like quantum computing and advanced material science, the accelerating global focus on green shipbuilding initiatives, and the expansion of marine logistics demanding smarter vessel management, all pointing towards a future of sustained innovation.

Segmentation Analysis

The Digital Shipyard Market is intricately segmented across various critical parameters, reflecting the diverse components, underlying technologies, practical applications, and distinct end-user requirements that characterize this rapidly evolving industry. This granular market segmentation provides a comprehensive framework for understanding the complex dynamics at play, identifying specific pockets of growth, and enabling stakeholders to precisely tailor their product development and market entry strategies. Analyzing these segments is instrumental in discerning the key drivers, inhibitors, and emerging trends within each category, offering invaluable insights into where innovation and investment are most concentrated and how different parts of the ecosystem interact to propel overall market expansion.

Understanding the market through these detailed segments is crucial for a broad spectrum of stakeholders, including technology providers, shipbuilders, marine operators, and financial investors. It facilitates the development of highly targeted solutions that address the specific needs of, for example, commercial vessel operators versus naval forces, or distinguishes between the demand for specialized software platforms versus robust hardware components. The interplay between these segments also vividly highlights the integrated and synergistic nature of modern digital shipyard solutions, where various technologies and services converge to deliver comprehensive digital transformation. This holistic view enables companies to optimize their value propositions and achieve sustainable competitive advantages in a globally competitive maritime landscape.

- By Component: This segment categorizes the market based on the fundamental building blocks of digital shipyard solutions, reflecting where investments are primarily directed and the core offerings of technology providers.

- Software: Includes sophisticated CAD/CAM/CAE software for design and engineering, comprehensive PLM Product Lifecycle Management systems, integrated ERP Enterprise Resource Planning solutions, advanced MES Manufacturing Execution Systems, cutting-edge data analytics platforms, robust cybersecurity software, and powerful simulation and modeling tools. This often forms the largest and fastest-growing component due to its foundational role in driving digital transformation and intellectual property.

- Hardware: Encompasses advanced sensor technologies for extensive IoT deployments, state-of-the-art robotics and automation equipment for manufacturing, high-performance computing systems, specialized AR/VR devices for visualization and training, industrial drones for inspection, and resilient network infrastructure for seamless connectivity.

- Services: Covers essential implementation and integration services for new systems, expert consulting for strategic planning, comprehensive maintenance and support, specialized training programs for workforce development, and managed services for ongoing operational efficiency and optimization of digital platforms. This segment is critical for successful deployment and sustained operational excellence.

- By Technology: This segment focuses on the specific digital technologies that underpin and enable the diverse functionalities of a digital shipyard, illustrating the profound technological depth and innovative capacity of the market.

- Internet of Things IoT: For pervasive real-time data collection from various shipyard assets, machinery, and vessels, providing invaluable operational insights.

- Artificial Intelligence AI and Machine Learning ML: For advanced predictive analytics, sophisticated process optimization, automated design generation, and intelligent quality control.

- Big Data Analytics: For processing, analyzing, and deriving actionable insights from the vast amounts of operational and performance data generated across the shipyard.

- Cloud Computing: For providing scalable and secure infrastructure for data storage, processing, collaborative design, and access to applications from anywhere.

- Augmented Reality AR and Virtual Reality VR: For immersive visualization, advanced training simulations, remote technical assistance, and interactive virtual prototyping and assembly.

- Digital Twin: For creating highly accurate virtual replicas of physical vessels and shipyard processes, enabling comprehensive simulation, testing, and lifecycle management.

- Robotics and Automation: For automated welding, precise material handling, efficient assembly, painting, and critical inspection tasks, significantly increasing precision and speed.

- Cybersecurity: Essential for protecting sensitive intellectual property, operational data, and critical control systems from an evolving landscape of cyber threats.

- By Ship Type: This segmentation differentiates solutions based on the specific requirements, operational contexts, and regulatory environments of various types of vessels, recognizing distinct market demands and specialized needs.

- Commercial Vessels: Includes a broad range of vessels such as cargo ships, oil and chemical tankers, container ships, bulk carriers, passenger ships, ferries, and offshore support vessels. Solutions focus on optimizing efficiency, cost-effectiveness, and compliance with commercial shipping regulations.

- Naval Vessels: Encompasses highly specialized vessels such as frigates, submarines, aircraft carriers, destroyers, patrol vessels, and various auxiliary ships. Emphasizes advanced combat systems integration, survivability, stealth capabilities, and secure operational readiness.

- By Application: This segment outlines the specific operational areas within shipbuilding and broader maritime operations where digital shipyard solutions are deployed, highlighting their practical utility and impact across the value chain.

- Ship Design and Engineering: For conceptual design, detailed engineering, advanced structural analysis, hydrodynamic simulations, and material flow optimization during the initial stages.

- Production Planning and Management: For meticulous scheduling, efficient resource allocation, workflow optimization, real-time progress tracking, and bottleneck identification across production lines.

- Ship Assembly and Fabrication: For automated welding, precise module integration, advanced robotics in fabrication, and other manufacturing processes requiring high accuracy and speed.

- Quality Control and Inspection: For automated defect detection using computer vision, ensuring rigorous adherence to design standards, and facilitating regulatory compliance checks throughout construction.

- Maintenance and Repair: For enabling predictive maintenance schedules, remote diagnostics, optimized repair scheduling, and efficient dry-docking and overhaul services.

- Supply Chain and Logistics: For intelligent inventory management, optimized procurement processes, streamlined material flow, and real-time tracking of components and equipment.

- Post-delivery Operations: For continuous performance monitoring, comprehensive lifecycle management, in-service support, and optimization of vessel operations after delivery.

- By End User: This segment identifies the primary clients and beneficiaries of digital shipyard technologies, underscoring the market's extensive reach across various maritime stakeholders and their unique requirements.

- Shipbuilders: The primary adopters, actively seeking to modernize their facilities, enhance production efficiency, reduce costs, and improve competitive positioning.

- Ship Operators: Utilizing digital tools for advanced fleet management, performance optimization, fuel efficiency monitoring, and proactive maintenance planning across their entire fleet.

- Marine Designers and Engineering Firms: Leveraging advanced software and digital platforms for innovation, precision, and collaborative work in vessel design and engineering services.

- Naval Forces and Defense Organizations: Investing in digital shipyards for the construction, modernization, and maintenance of advanced naval vessels, ensuring strategic readiness and operational superiority.

- Repair and Maintenance Yards: Implementing digital solutions for efficient dry-docking, overhauls, general vessel servicing, and optimized project management for maintenance tasks.

Value Chain Analysis For Digital Shipyard Market

The value chain within the Digital Shipyard Market is a complex and highly integrated ecosystem, encompassing a multitude of specialized players from the foundational technology developers to the ultimate end-users in maritime operations. This chain is characterized by a sequential flow of activities that create and deliver sophisticated digital solutions, beginning with upstream providers who lay the critical technological groundwork, extending through various solution integrators and distribution channels, and culminating with the diverse downstream entities that leverage these digital tools for shipbuilding, vessel operation, and maintenance. A thorough understanding of this intricate value flow is paramount for identifying key interdependencies, pinpointing potential areas for strategic value addition, and optimizing competitive positioning for all stakeholders within the evolving maritime industry.

In the upstream segment of this value chain, the market is defined by a diverse group of foundational technology providers. These include specialized software developers crafting cutting-edge CAD/CAM, PLM, and ERP systems tailored for maritime applications, alongside hardware manufacturers producing a wide array of components such as advanced IoT sensors, precision robotics, high-performance computing infrastructure, and immersive AR/VR devices. Core technology firms offering innovative AI/ML frameworks, robust cloud computing platforms, and secure cybersecurity solutions also play a critical role. These upstream entities are fundamental to the entire ecosystem, providing the essential digital components, intellectual property, and technological advancements that enable the sophisticated functionalities of modern digital shipyard solutions. Their continuous innovation cycles and significant R&D investments directly influence the capabilities, scalability, and overall sophistication of the entire digital shipyard value chain.

Moving downstream, the primary beneficiaries and integrators of these advanced digital solutions are shipbuilders, who utilize them extensively to modernize and optimize their design, production, and assembly lines. This integration leads to significantly enhanced efficiency and reduced lead times in vessel construction. Further along the chain, ship operators and owners adopt these technologies for advanced fleet management, comprehensive predictive maintenance, and real-time operational optimization, thereby extending the digital influence far beyond initial construction into the entire operational lifecycle of a vessel. Naval forces and marine repair facilities also constitute significant downstream consumers, leveraging digital tools for mission-critical applications, ensuring precise and secure vessel construction, and delivering highly efficient service and maintenance operations.

The distribution channels for digital shipyard solutions typically involve a combination of direct and indirect approaches designed to maximize market reach and cater to varying customer scales and needs. Direct sales are common for larger, highly customized projects, where solution providers engage directly with major shipyards, defense contractors, and large fleet owners, offering bespoke integration services, extensive support, and tailored solutions. Indirect channels, conversely, involve strategic partnerships with system integrators, value-added resellers VARs, and channel partners who combine various technologies and services to offer comprehensive, turnkey solutions. These partners often target a broader range of smaller to medium-sized shipyards and maritime firms, providing localized support and specialized expertise. This dual approach ensures broad market penetration and addresses the diverse requirements of a global customer base, from large multinational shipbuilders to specialized regional repair facilities.

Digital Shipyard Market Potential Customers

The Digital Shipyard Market serves an extensive array of potential customers, all of whom share the overarching goal of enhancing efficiency, substantially reducing operational costs, improving the overall quality of construction, and advancing the sustainability of their maritime operations through cutting-edge digital transformation. These crucial end-users span the entire maritime ecosystem, ranging from the core entities directly involved in vessel conceptualization and construction to those responsible for the ongoing operation, maintenance, and eventual decommissioning of marine assets. This broad applicability of digital shipyard solutions underscores its pivotal role across the entire maritime value chain. Therefore, accurately identifying, segmenting, and thoroughly understanding these diverse customer profiles is paramount for technology providers to develop highly tailored solutions and execute targeted marketing strategies that precisely address specific industry needs and prevailing challenges.

Primary buyers within this market segment include large-scale commercial shipyards globally, which are increasingly making significant investments in digital tools to streamline their inherently complex construction processes, efficiently manage vast and intricate supply chains, and meticulously comply with stringent international regulations concerning operational efficiency and environmental emissions. These shipyards are typically involved in building a wide variety of commercial vessels, ranging from container ships, oil and chemical tankers, and bulk carriers to sophisticated cruise liners and offshore support vessels. They require comprehensive digital solutions that offer seamless integration across design, production, and extensive lifecycle management functions to maintain their competitive edge and operational excellence.

Naval defense organizations and various governmental maritime agencies represent another immensely significant customer segment. These entities actively seek and deploy advanced digital shipyard technologies for the construction, modernization, and meticulous maintenance of military vessels, where precision, absolute security, and the integration of highly advanced capabilities are paramount. The focus within this segment is often concentrated on developing highly resilient, technologically superior, and mission-ready ships equipped with integrated digital systems for critical operational functions, ensuring long-term fleet readiness, and maintaining national security objectives in a rapidly evolving geopolitical landscape.

Beyond the initial construction phase, ship operators and owners, as well as specialized marine repair and maintenance yards, constitute crucial end-users within the digital shipyard ecosystem. Ship operators extensively leverage digital twin technology, sophisticated IoT sensors, and advanced AI-driven analytics for proactive predictive maintenance, optimized route planning, efficient fuel consumption, and real-time performance monitoring across their entire fleets, thereby extending the lifespan of their assets and minimizing operational disruptions. Similarly, repair yards adopt cutting-edge digital solutions to significantly enhance efficiency in crucial operations such as dry-docking, major overhauls, and general vessel servicing, utilizing technologies like augmented reality AR for precise inspections and comprehensive digital platforms for streamlined project management and resource allocation, ensuring rapid turnaround times and high-quality repairs.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | USD 2.8 Billion |

| Market Forecast in 2032 | USD 9.2 Billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Dassault Systèmes SE, AVEVA Group Plc, Kongsberg Gruppen ASA, Wärtsilä Corporation, Navantia S.A., Hyundai Heavy Industries Co Ltd, Samsung Heavy Industries Co Ltd, Daewoo Shipbuilding and Marine Engineering Co Ltd, CSSC China Shipbuilding Corporation, General Dynamics Corporation, BAE Systems plc, Saab AB, Rolls-Royce plc, Caterpillar Inc., Rockwell Automation Inc., ABB Ltd, PTC Inc., Hexagon AB, Inmarsat Global Limited |

| Regions Covered | North America, Europe, Asia Pacific APAC, Latin America, Middle East, and Africa MEA |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Digital Shipyard Market Key Technology Landscape

The Digital Shipyard Market is fundamentally defined and continuously shaped by a sophisticated and rapidly evolving technology landscape, where the seamless integration of cutting-edge digital tools and platforms is absolutely paramount to transforming traditional shipbuilding into an extraordinarily efficient, deeply data-driven, and highly automated industry. This comprehensive landscape encompasses a wide array of advanced technologies that are designed to work synergistically, covering every conceivable aspect of a vessel's intricate lifecycle, from its initial conceptual design and meticulous engineering phases through to precise production, optimized operational management, and proactive maintenance strategies. The relentless advancement and strategic convergence of these diverse technologies are the primary enablers for continuous innovation and the attainment of a significant competitive advantage within the highly demanding global maritime sector.

At the very core of this technological ecosystem are foundational innovations such as the Internet of Things IoT. This technology deploys an extensive network of intelligent sensors across virtually all shipyard equipment, critical materials, and even the vessels themselves, enabling the collection of vast amounts of real-time operational data. This invaluable data is then fed into sophisticated Big Data Analytics platforms, where it is rigorously processed, meticulously analyzed, and transformed into actionable insights that can be used to identify potential bottlenecks, optimize workflows, and inform highly accurate predictive maintenance schedules. Artificial Intelligence AI and Machine Learning ML algorithms further leverage this deluge of data for performing exceedingly complex tasks, including generative design optimization, automated quality control with unparalleled precision, and intelligent resource allocation, all of which dramatically improve overall efficiency and accuracy in shipbuilding processes.

Cloud Computing provides the essential, scalable, and secure infrastructure necessary to store, process, and distribute the enormous quantities of data generated across a digital shipyard, while simultaneously enabling seamless collaborative design environments and remote access to critical information for geographically dispersed teams. Augmented Reality AR and Virtual Reality VR technologies are becoming increasingly crucial for conducting immersive design reviews, facilitating realistic virtual prototyping, and providing hands-on training for complex assembly procedures, thereby significantly reducing errors and enhancing comprehension among the workforce. The transformative concept of the Digital Twin, which creates a precise virtual replica of a physical vessel or an entire shipyard process, allows for comprehensive simulation, rigorous testing, and proactive lifecycle management in a risk-free, virtual environment, leading to optimized performance and reduced physical prototypes.

Advanced Robotics and sophisticated automation systems are strategically deployed for high-precision tasks such as automated welding, efficient material handling, intricate component assembly, and uniform painting, dramatically enhancing production speed and consistency while concurrently improving worker safety in hazardous environments. Finally, the implementation of robust Cybersecurity measures is absolutely non-negotiable and critically essential for protecting invaluable proprietary designs, sensitive operational data, and mission-critical control systems from the ever-evolving landscape of sophisticated cyber threats in an increasingly interconnected and digitally dependent maritime industry. These powerful technological pillars collectively define the modern digital shipyard, driving its formidable capabilities and shaping its promising future growth trajectory.

Regional Highlights

The global Digital Shipyard Market exhibits distinct and multifaceted regional dynamics, largely influenced by varying levels of industrial development, the extent of governmental support for maritime industries, strategic investments in critical maritime infrastructure, and the differing rates of technological adoption across diverse geographical areas. Each major region presents a unique confluence of drivers, opportunities, and challenges, contributing uniquely to the overall market growth while frequently specializing in particular aspects of digital shipbuilding innovation and application. A profound understanding of these intricate regional nuances is absolutely essential for market players to formulate effective strategies, optimize resource allocation, and capitalize on localized growth potentials and emerging trends within the highly competitive maritime sector.

For instance, North America is notably characterized by substantial and strategic investments in naval defense programs, coupled with a strong emphasis on integrating advanced technologies for secure, resilient, and high-performance shipbuilding for military applications. European countries, particularly those with long-established and highly sophisticated maritime industries such as Germany, Norway, and the Netherlands, stand as leaders in sustainable shipping technologies, green maritime solutions, and extensive research and development for highly automated and environmentally friendly vessels. Their strategic focus often extends to niche markets, high-value specialized ship types, and pioneering innovations in marine engineering and design. The Asia Pacific APAC region, conversely, presents a different dynamic.

The Asia Pacific APAC region unequivocally stands out as the largest and most rapidly growing market, primarily driven by the colossal shipbuilding capacities and aggressive modernization efforts of key nations like South Korea, China, and Japan. These nations are proactively and rapidly adopting advanced digital shipyard solutions to not only maintain but also enhance their global competitive edge, significantly improve operational efficiency, and expand their capabilities in constructing an incredibly diverse range of commercial and highly specialized vessels. Latin America is emerging as a market with increasing strategic investments in critical port infrastructure development and marine logistics, which, in turn, fuels the demand for modern shipyard capabilities and highly efficient vessel management solutions. Meanwhile, the Middle East and Africa MEA region is experiencing notable growth primarily due to expanding oil and gas maritime operations and significant strategic investments in regional port development, which are collectively driving an escalating demand for efficient vessel management, advanced repair, and maintenance solutions.

- North America: This region is characterized by robust investments in naval defense modernization programs and a strong strategic focus on advanced, secure shipbuilding technologies for military applications. It extensively leverages its expertise in aerospace and information technology for pioneering maritime innovation.

- Europe: A prominent hub for high-value shipbuilding, Europe emphasizes sustainable practices, pioneering green maritime technologies, and extensive research and development in automation, advanced materials, and comprehensive digitalization for the construction of complex and specialized vessels.

- Asia Pacific APAC: Representing the largest global shipbuilding market, dominated by industrial powerhouses such as China, South Korea, and Japan. This region experiences rapid adoption of advanced digital solutions to substantially enhance efficiency, significantly reduce costs, and maintain a crucial competitive advantage in both commercial and specialized vessel construction.

- Latin America: An emerging market demonstrating increasing strategic investments in critical port infrastructure development and maritime logistics capabilities, which is consequently driving a growing need for modernized shipyard capabilities and efficient vessel management solutions across the region.

- Middle East and Africa MEA: Characterized by significant and expanding investments in oil and gas maritime operations, substantial strategic port development projects, and a rising demand for advanced repair and maintenance capabilities, all of which are leading to increased adoption of digital shipyard technologies throughout the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Digital Shipyard Market.These companies represent a comprehensive spectrum of innovators, ranging from global technology conglomerates with extensive portfolios to highly specialized maritime software and hardware providers, all of whom are contributing significantly to the digital transformation of the shipbuilding industry. Their strategic investments in cutting-edge research and development, continuous portfolio expansion through acquisitions and organic growth, and collaborative regional partnerships are absolutely pivotal in shaping the competitive landscape and driving the widespread adoption of advanced digital shipyard solutions across the globe. These key players are consistently at the forefront of delivering integrated platforms that meticulously enhance design precision, optimize production efficiency, and improve operational effectiveness, continually pushing the boundaries of what is technologically possible in modern maritime engineering and manufacturing. Their diverse offerings encompass everything from comprehensive software suites for advanced product lifecycle management and robust enterprise resource planning to sophisticated hardware for automation, pervasive IoT connectivity, and immersive augmented reality applications, alongside specialized consulting and critical integration services that ensure seamless deployment and functionality for shipyards worldwide.

- Siemens AG

- Dassault Systèmes SE

- AVEVA Group Plc

- Kongsberg Gruppen ASA

- Wärtsilä Corporation

- Navantia S.A.

- Hyundai Heavy Industries Co Ltd

- Samsung Heavy Industries Co Ltd

- Daewoo Shipbuilding and Marine Engineering Co Ltd

- CSSC China Shipbuilding Corporation

- General Dynamics Corporation

- BAE Systems plc

- Saab AB

- Rolls-Royce plc

- Caterpillar Inc.

- Rockwell Automation Inc.

- ABB Ltd

- PTC Inc.

- Hexagon AB

- Inmarsat Global Limited

Frequently Asked Questions

Frequently Asked Questions often shed light on critical aspects of the Digital Shipyard Market, addressing common queries from industry professionals, investors, and prospective adopters. These questions typically focus on the core definition, the tangible operational benefits derived, the key technologies involved in implementation, the significant challenges encountered during adoption, and the prevailing regional adoption patterns, providing concise and informative answers that reflect current market understanding and future outlooks. These FAQs are designed to offer quick, authoritative insights into the most pertinent topics surrounding the digital transformation of the shipbuilding industry, serving as a valuable resource for anyone seeking clarity on this evolving sector.

What precisely defines a Digital Shipyard and its core purpose?

A Digital Shipyard is a modern, technologically advanced shipbuilding facility that integrates a comprehensive suite of digital technologies, including IoT, AI, VR/AR, automation, and advanced data analytics, across every stage of a vessel's lifecycle. Its core purpose is to optimize ship design, construction, operation, and maintenance through data-driven processes and interconnected systems, significantly enhancing efficiency, quality, and sustainability beyond traditional manual methods.

How do Digital Shipyards significantly enhance operational efficiency and contribute to cost reduction?

Digital Shipyards substantially enhance efficiency and reduce costs by enabling extensive automation of processes, facilitating rapid virtual prototyping, and implementing real-time monitoring of construction and operational phases. This leads to a dramatic reduction in errors, optimized resource utilization, considerably shorter construction times, and advanced predictive maintenance capabilities that prevent costly failures and extend asset operational life, ultimately leading to significant cost savings.

What are the primary technologies that are fundamentally driving the Digital Shipyard Market?

Key technologies fundamentally driving the Digital Shipyard Market include the Internet of Things IoT for pervasive data collection, Artificial Intelligence AI and Machine Learning ML for advanced analytics and automation, Cloud Computing for scalable infrastructure and collaboration, Digital Twin for creating comprehensive virtual replicas, and Augmented Reality AR and Virtual Reality VR for immersive visualization, specialized training, and remote assistance across the entire value chain.

What are the main challenges that are associated with adopting Digital Shipyard solutions?

Major challenges in adopting Digital Shipyard solutions include the substantial initial capital investment required for comprehensive technology infrastructure, the critical shortage of a skilled workforce proficient in advanced digital tools and methodologies, ensuring robust cybersecurity measures against increasingly sophisticated threats, and overcoming inherent resistance to change within traditionally conservative shipbuilding industries, which often rely on long-established manual practices.

Which geographical regions are currently leading in the adoption and pioneering innovation of Digital Shipyards?

The Asia Pacific APAC region, particularly industrial leaders like China, South Korea, and Japan, currently leads in Digital Shipyard adoption due to their vast shipbuilding capacities and rapid integration of advanced technologies to maintain global competitiveness. Europe also stands as a significant leader in sustainable and high-value shipbuilding innovation, while North America particularly excels in advanced naval defense applications, prioritizing security and sophisticated capabilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager