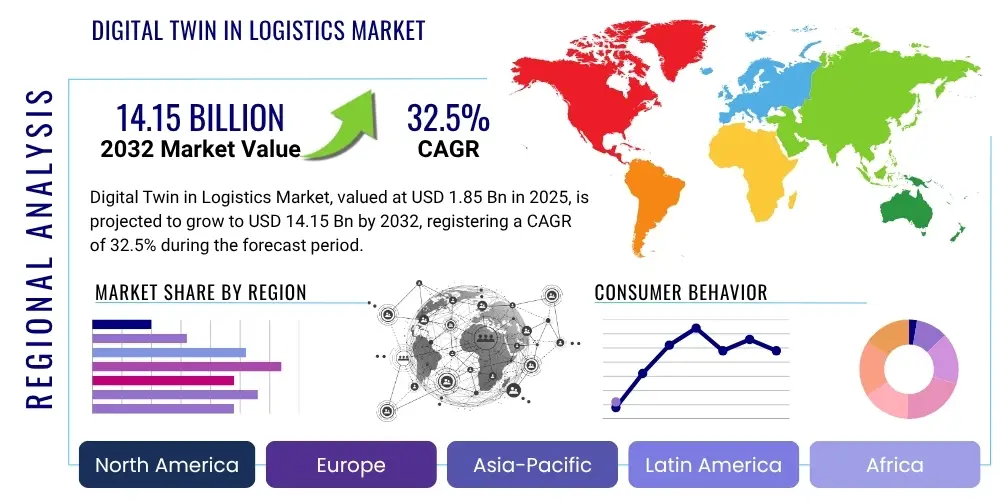

Digital Twin in Logistics Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2025 to 2032 (Financial Impact Analysis)

ID : MRU_ 429608 | Date : Nov, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Digital Twin in Logistics Market Size

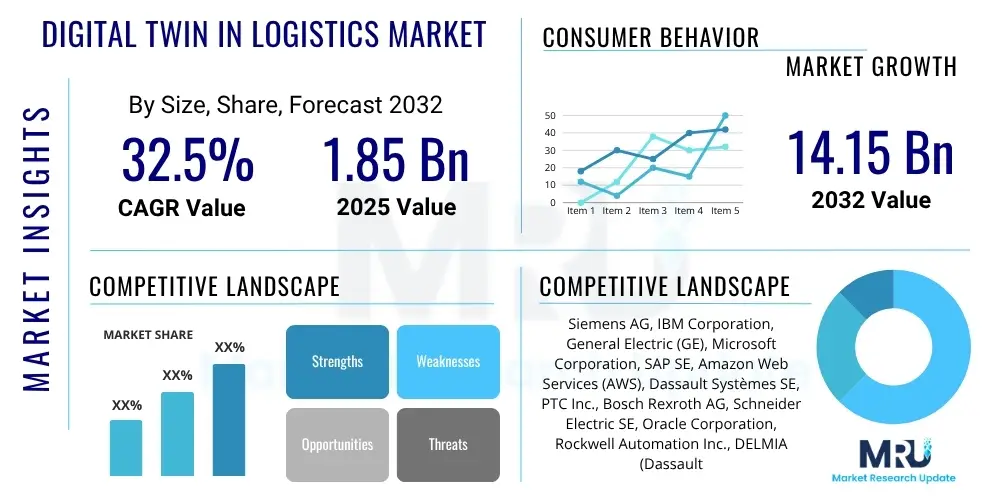

The Digital Twin in Logistics Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 32.5% between 2025 and 2032. The market is estimated at $1.85 Billion in 2025 and is projected to reach $14.15 Billion by the end of the forecast period in 2032.

Digital Twin in Logistics Market introduction

The Digital Twin in Logistics market encompasses the creation and utilization of virtual replicas of physical logistics assets, processes, and systems. These digital twins are powered by real-time data from sensors, IoT devices, and other sources, enabling comprehensive monitoring, analysis, and simulation of entire supply chain operations. The product description involves a dynamic virtual model that mirrors the characteristics, behavior, and state of a physical object or system within the logistics ecosystem, ranging from individual pallets and vehicles to entire warehouses and global supply networks.

Major applications of digital twin technology in logistics include optimizing warehouse layouts, enhancing freight management, enabling predictive maintenance for fleet vehicles, and streamlining inventory control. By providing an interactive, data-rich environment, digital twins allow logistics operators to visualize operations, identify bottlenecks, and test various scenarios without disrupting physical processes. This capability is crucial for proactive problem-solving and continuous improvement in an increasingly complex and dynamic global supply chain landscape.

The core benefits of adopting digital twins in logistics are profound, leading to increased operational efficiency, reduced costs, enhanced visibility across the supply chain, improved decision-making through predictive insights, and greater resilience to disruptions. Key driving factors propelling market growth include the accelerating adoption of Industry 4.0 technologies, the burgeoning demand for real-time visibility and predictive analytics, the increasing complexity of global supply chains, and the imperative for logistics companies to achieve higher levels of sustainability and operational agility. The synergy of IoT, AI, and cloud computing is making these sophisticated simulations more accessible and powerful for logistics providers seeking a competitive edge.

Digital Twin in Logistics Market Executive Summary

The Digital Twin in Logistics market is experiencing robust growth driven by the imperative for enhanced operational efficiency and real-time visibility across complex supply chains. Business trends indicate a strong focus on strategic partnerships between technology providers and logistics operators, aiming to integrate advanced analytics and AI capabilities into digital twin solutions. Companies are increasingly investing in end-to-end supply chain visibility platforms, with digital twins serving as the central nervous system for these interconnected systems, allowing for predictive insights and proactive management of potential disruptions. The emphasis is shifting from merely descriptive data to prescriptive and autonomous operational models.

Regional trends highlight North America and Europe as early adopters and significant contributors to market revenue, primarily due to advanced technological infrastructure, high industrial automation, and the presence of numerous key market players. The Asia Pacific region is anticipated to exhibit the fastest growth, fueled by rapid expansion of e-commerce, increasing manufacturing activities, and supportive government initiatives promoting digital transformation in logistics and manufacturing. Latin America, the Middle East, and Africa are also showing promising growth, albeit from a smaller base, as infrastructure development and investment in smart logistics solutions gain momentum.

Segment trends reveal that the software component continues to dominate the market, reflecting the intensive development and customization required for digital twin platforms. However, the services segment, encompassing implementation, maintenance, and consulting, is projected to grow significantly as businesses seek expert guidance for integrating these complex solutions. Application-wise, warehousing and inventory management, along with freight and transportation management, remain the largest segments, driven by the immediate and tangible benefits of optimization and cost reduction. The integration of AI/ML and IoT technologies within digital twin frameworks is a prevailing technological trend, enabling more intelligent and autonomous logistics operations.

AI Impact Analysis on Digital Twin in Logistics Market

User inquiries about AI's impact on the Digital Twin in Logistics market frequently revolve around its practical applications, return on investment, implementation challenges, and ethical considerations, particularly concerning data privacy and autonomous decision-making. Users are keen to understand how AI enhances predictive capabilities, automates processes, and provides actionable insights beyond traditional simulation. There is also significant interest in the role of AI in improving the accuracy of digital twin models and enabling them to adapt to dynamic market conditions in real time. The key themes include leveraging AI for advanced predictive analytics, fostering autonomous logistics operations, ensuring data security and integrity, and scaling AI-powered digital twin solutions across diverse logistical environments.

The integration of Artificial Intelligence (AI) profoundly amplifies the capabilities of digital twins in logistics, transforming them from mere virtual models into intelligent, self-optimizing systems. AI algorithms process vast amounts of real-time data collected by IoT sensors, enabling digital twins to perform highly accurate predictive analytics on equipment failures, potential delivery delays, and demand fluctuations. This predictive power allows logistics managers to anticipate issues before they escalate, facilitating proactive interventions such as rerouting shipments, optimizing maintenance schedules, and adjusting inventory levels with unprecedented precision. The ability of AI to identify subtle patterns and correlations in complex data sets significantly enhances the diagnostic and prognostic capabilities of digital twins, moving beyond simple data visualization to actionable foresight.

Furthermore, AI empowers digital twins to facilitate autonomous decision-making and optimization within logistics operations. Machine learning models, trained on historical and real-time operational data, can autonomously recommend optimal routes, intelligently allocate resources, and even manage warehouse automation systems without human intervention. This level of automation reduces human error, accelerates operational speeds, and drives substantial cost efficiencies. As AI continues to evolve, the digital twin in logistics will transition towards more prescriptive and self-healing systems, continuously learning from new data and adapting its virtual representation and recommendations to ensure the physical logistics network operates at peak performance and resilience.

- Enhanced Predictive Analytics: AI enables highly accurate forecasting of demand, equipment failures, and delivery timelines.

- Autonomous Operations: AI-driven insights facilitate self-optimizing routing, resource allocation, and warehouse automation.

- Real-time Anomaly Detection: Machine learning algorithms rapidly identify deviations from normal operations, preventing disruptions.

- Dynamic Optimization: AI allows digital twins to continuously adapt and optimize logistics processes in response to changing conditions.

- Improved Decision Support: AI-powered simulations provide actionable recommendations for strategic planning and operational adjustments.

- Supply Chain Resilience: AI helps digital twins model and mitigate risks, improving overall supply chain robustness.

DRO & Impact Forces Of Digital Twin in Logistics Market

The Digital Twin in Logistics market is shaped by a confluence of driving forces, restraining factors, and emerging opportunities. Key drivers include the escalating complexity of global supply chains, requiring advanced tools for management and optimization, and the pervasive adoption of Industry 4.0 technologies such as IoT, cloud computing, and advanced analytics, which provide the foundational infrastructure for digital twins. The intense pressure on logistics companies to reduce operational costs, enhance efficiency, and meet increasing customer expectations for faster and more transparent deliveries further fuels the demand for these sophisticated simulation and monitoring tools. The benefits of improved visibility, predictive maintenance, and optimized resource utilization are compelling businesses to invest in digital twin solutions.

However, several significant restraints challenge the market's growth trajectory. The substantial initial investment required for implementing digital twin technology, including sensor infrastructure, software licenses, and system integration, poses a barrier for many smaller and medium-sized enterprises. Concerns regarding data security and privacy, especially when handling sensitive supply chain information, are paramount. The shortage of skilled professionals capable of developing, deploying, and managing complex digital twin systems also impedes broader adoption. Furthermore, interoperability issues between disparate systems and data silos across different logistics partners can complicate the creation of a truly comprehensive digital twin, limiting its effectiveness.

Despite these challenges, abundant opportunities exist for market expansion. The continuous evolution of 5G technology promises enhanced connectivity and reduced latency, which will significantly improve the real-time data flow critical for digital twins. The explosive growth of e-commerce and the increasing sophistication of last-mile delivery services create new avenues for applying digital twin solutions to optimize delivery networks and customer experience. Expanding the application of digital twins into new logistics verticals, such as cold chain logistics, pharmaceutical distribution, and hazardous materials transport, offers significant untapped potential. Strategic partnerships, technological advancements, and a focus on modular, scalable solutions are crucial impact forces driving innovation and market penetration, addressing the need for greater supply chain resilience and efficiency in a volatile global economy.

Segmentation Analysis

The Digital Twin in Logistics market is comprehensively segmented to provide a granular understanding of its diverse components, applications, underlying technologies, and target end-users. This segmentation allows for a detailed analysis of market dynamics, growth drivers, and competitive landscapes within each specific category. The market’s intricate structure reflects the varied needs of the logistics sector, from raw material sourcing to final product delivery, encompassing multiple stages and stakeholders.

- By Component:

- Software: Includes simulation, visualization, analytics platforms, and AI/ML modules.

- Services: Comprises implementation, integration, consulting, maintenance, and support.

- Hardware: Encompasses sensors, IoT devices, gateways, and connectivity modules.

- By Application:

- Warehousing and Inventory Management: Optimization of warehouse layouts, stock levels, picking routes.

- Freight and Transportation Management: Route optimization, fleet management, real-time tracking, predictive maintenance for vehicles.

- Predictive Maintenance: Monitoring asset health (vehicles, machinery) to anticipate failures.

- Supply Chain Planning and Optimization: End-to-end visibility, demand forecasting, risk management.

- Last-Mile Delivery Optimization: Enhancing efficiency and speed of final delivery leg.

- By Technology:

- Internet of Things (IoT): For data collection from physical assets.

- Artificial Intelligence (AI) and Machine Learning (ML): For data analysis, predictive modeling, and autonomous decision-making.

- Cloud Computing: For scalable data storage, processing, and application hosting.

- Big Data Analytics: For processing and deriving insights from large datasets.

- Blockchain: For secure and transparent data sharing across the supply chain.

- Augmented Reality (AR) and Virtual Reality (VR): For immersive visualization and training.

- By End-User:

- Third-Party Logistics (3PLs) and Fourth-Party Logistics (4PLs): Providers offering integrated logistics services.

- Retail and E-commerce: Companies managing vast product movements and customer deliveries.

- Manufacturing and Automotive: Industries with complex inbound and outbound logistics.

- Pharmaceuticals and Healthcare: Requiring precise, temperature-controlled, and secure logistics.

- Aerospace and Defense: Managing high-value, critical component logistics.

- Food and Beverage: Dealing with perishable goods and cold chain requirements.

Value Chain Analysis For Digital Twin in Logistics Market

The value chain for the Digital Twin in Logistics market involves a series of interconnected activities spanning from raw component provision to end-user application and continuous support. Upstream analysis focuses on the foundational elements required to build and operate digital twin solutions. This includes manufacturers of advanced sensors and IoT devices that collect real-time data from physical logistics assets, providers of robust connectivity solutions (e.g., 5G, LPWAN), and developers of specialized data analytics and AI/ML tools. These entities supply the core technologies that enable the creation and intelligence of the virtual replicas, forming the initial layer of value creation within the ecosystem.

Moving downstream, the value chain encompasses system integrators and software platform providers who aggregate these foundational technologies to develop comprehensive digital twin solutions. These players are responsible for integrating various data sources, building sophisticated simulation models, and providing user-friendly visualization interfaces. Logistics service providers, including 3PLs and 4PLs, then adopt and customize these solutions to offer enhanced services to their clients. The direct distribution channel often involves direct sales and partnerships between technology vendors and large enterprises, where customized solutions are developed and deployed. Indirect channels primarily include value-added resellers (VARs), system integrators, and consulting firms that act as intermediaries, tailoring solutions for specific industry needs and providing implementation support.

The downstream activities extend to the end-user companies across various sectors, such as retail, manufacturing, and healthcare, who leverage digital twin solutions to optimize their supply chain operations, improve efficiency, and enhance resilience. Post-implementation, ongoing support, maintenance, and regular updates provided by the solution vendors or their partners ensure the continuous value generation from the digital twins. This includes data analysis services, performance monitoring, and iterative model improvements, highlighting the long-term engagement and service-oriented nature of the digital twin market. The entire value chain is characterized by collaboration and strategic alliances, as no single entity typically possesses all the necessary expertise and components to deliver a complete digital twin solution.

Digital Twin in Logistics Market Potential Customers

The potential customer base for Digital Twin in Logistics solutions is broad and diverse, primarily encompassing organizations that manage complex, dynamic, and large-scale supply chain operations where efficiency, visibility, and predictive capabilities are paramount. End-users and buyers of these advanced solutions include a wide array of enterprises, from global third-party logistics (3PL) providers and fourth-party logistics (4PL) providers who seek to offer cutting-edge services to their clients, to large-scale manufacturers and automotive original equipment manufacturers (OEMs) that need to optimize their intricate inbound and outbound material flows. These companies are driven by the imperative to reduce operational costs, mitigate risks, and achieve higher levels of operational agility in their production and distribution networks.

Furthermore, major players in the retail and e-commerce sectors represent a significant segment of potential customers. With the explosion of online shopping and the demand for rapid, accurate, and cost-effective last-mile delivery, these companies are continuously looking for ways to optimize their warehousing, inventory management, and transportation networks. Digital twins offer them the ability to simulate different demand scenarios, optimize stock placement, streamline order fulfillment, and enhance delivery route planning, directly impacting customer satisfaction and profitability. The ability to monitor and manage thousands of SKUs and delivery vehicles in real-time makes digital twins invaluable for these fast-paced environments.

Other crucial end-user segments include the pharmaceutical and healthcare industries, where precise temperature control, strict compliance, and secure transportation of sensitive goods are non-negotiable. Digital twins can provide detailed oversight of cold chain integrity and ensure the timely delivery of critical medical supplies. Similarly, companies in the aerospace and defense sectors, along with the food and beverage industry, which deals with perishable goods and complex distribution networks, are increasingly recognizing the value of digital twins for ensuring product quality, operational safety, and supply chain resilience. Any organization striving for a competitive edge through data-driven logistics optimization is a prime candidate for adopting digital twin technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2025 | $1.85 Billion |

| Market Forecast in 2032 | $14.15 Billion |

| Growth Rate | 32.5% CAGR |

| Historical Year | 2019 to 2023 |

| Base Year | 2024 |

| Forecast Year | 2025 - 2032 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, IBM Corporation, General Electric (GE), Microsoft Corporation, SAP SE, Amazon Web Services (AWS), Dassault Systèmes SE, PTC Inc., Bosch Rexroth AG, Schneider Electric SE, Oracle Corporation, Rockwell Automation Inc., DELMIA (Dassault Systèmes), Accenture plc, Capgemini SE, Wipro Limited, TCS (Tata Consultancy Services), Infosys Limited, Atos SE, Cognizant Technology Solutions |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Digital Twin in Logistics Market Key Technology Landscape

The Digital Twin in Logistics market is underpinned by a sophisticated array of interconnected technologies that collectively enable the creation, operation, and continuous improvement of virtual replicas of physical logistics systems. At the core are Internet of Things (IoT) sensors and devices, which form the primary data acquisition layer, collecting real-time information from assets such as vehicles, containers, warehouse equipment, and even individual packages. These sensors capture critical parameters like location, temperature, humidity, pressure, and operational status, feeding this raw data into the digital twin ecosystem. Robust connectivity solutions, including 5G, Wi-Fi, and various Low-Power Wide-Area Network (LPWAN) technologies, are essential to ensure the seamless and low-latency transmission of this vast amount of data from the physical world to the virtual environment.

Once data is collected, cloud computing platforms become indispensable for scalable storage, processing, and hosting of digital twin applications. Major cloud providers like Amazon Web Services (AWS), Microsoft Azure, and Google Cloud offer the infrastructure and services required to manage the immense data volumes and computational demands of complex simulations. Layered on top of this infrastructure are advanced analytics and Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These technologies are crucial for processing raw data into actionable insights, performing predictive maintenance, optimizing routes, forecasting demand, and enabling autonomous decision-making within the digital twin. AI capabilities allow the virtual model to learn, adapt, and intelligently respond to dynamic changes in the physical supply chain.

Furthermore, the technology landscape includes sophisticated visualization and simulation software that renders the digital twin in an interactive and comprehensible format, often leveraging Augmented Reality (AR) and Virtual Reality (VR) for immersive experiences in warehouse design or operational training. Big data analytics tools are employed to extract meaningful patterns and trends from aggregated historical and real-time data, while blockchain technology is increasingly being explored to enhance data security, transparency, and traceability across the multi-party logistics network. The integration of these diverse technological components, often facilitated by robust integration platforms, is what transforms raw data into a powerful, intelligent digital representation capable of revolutionizing logistics operations.

Regional Highlights

- North America: This region is a leading market for Digital Twin in Logistics, characterized by early adoption of advanced technologies, significant investments in supply chain digitalization, and the presence of numerous key technology providers and large logistics enterprises. The demand for operational efficiency, coupled with a highly developed IT infrastructure, drives innovation and market growth.

- Europe: Europe represents another mature market, propelled by strong industrial automation initiatives (Industry 4.0), a focus on sustainable logistics solutions, and stringent regulatory frameworks that encourage efficient resource management. Countries like Germany, the UK, and the Nordics are at the forefront of implementing digital twin solutions to optimize complex manufacturing and distribution networks.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by the rapid expansion of e-commerce, increasing manufacturing output, and significant government support for digital transformation and smart city initiatives. Countries such as China, India, Japan, and South Korea are witnessing substantial investments in logistics infrastructure and technology adoption to cater to burgeoning domestic and international trade volumes.

- Latin America: This emerging market shows promising growth potential, driven by increasing foreign investments, infrastructure development projects, and the growing awareness among local businesses about the benefits of supply chain optimization. While adoption is still in early stages, the need for improved efficiency in diverse geographical terrains is a strong motivator.

- Middle East and Africa (MEA): The MEA region is experiencing steady growth, primarily due to large-scale infrastructure projects, diversification efforts away from oil economies, and strategic geographical location for global trade. Countries in the GCC are investing heavily in smart logistics hubs and technological advancements to become key players in international supply chains, fostering digital twin adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Digital Twin in Logistics Market.- Siemens AG

- IBM Corporation

- General Electric (GE)

- Microsoft Corporation

- SAP SE

- Amazon Web Services (AWS)

- Dassault Systèmes SE

- PTC Inc.

- Bosch Rexroth AG

- Schneider Electric SE

- Oracle Corporation

- Rockwell Automation Inc.

- DELMIA (Dassault Systèmes)

- Accenture plc

- Capgemini SE

- Wipro Limited

- TCS (Tata Consultancy Services)

- Infosys Limited

- Atos SE

- Cognizant Technology Solutions

Frequently Asked Questions

What is a digital twin in logistics?

A digital twin in logistics is a virtual replica of a physical logistics asset, process, or system, such as a warehouse, vehicle, or entire supply chain, updated with real-time data to enable monitoring, analysis, and simulation for optimization.

How does digital twin technology benefit supply chains?

Digital twin technology benefits supply chains by offering real-time visibility, enhancing operational efficiency, enabling predictive maintenance, optimizing inventory and routes, and improving overall resilience against disruptions through data-driven insights.

What key technologies enable digital twins in logistics?

Key technologies enabling digital twins in logistics include Internet of Things (IoT) sensors for data collection, Artificial Intelligence (AI) and Machine Learning (ML) for analytics, cloud computing for scalable infrastructure, and advanced simulation software for virtual modeling.

What are the main challenges of implementing digital twins in logistics?

Challenges include high initial investment costs, ensuring data security and privacy across various stakeholders, addressing interoperability issues between diverse systems, and overcoming the shortage of skilled professionals required for deployment and management.

What is the future outlook for the Digital Twin in Logistics market?

The future outlook for the Digital Twin in Logistics market is highly positive, driven by continuous technological advancements, increasing adoption of Industry 4.0, the growth of e-commerce, and the growing imperative for highly efficient and resilient global supply chains.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager